Contents

Manufacturing Insight: 3 2 Axis Cnc Machine

Precision Manufacturing Through Advanced 3+2 Axis CNC Capabilities

At Honyo Prototype, we engineer complex components with uncompromising accuracy using our state-of-the-art 3+2 axis CNC machining technology. This strategic approach positions workpieces at optimal fixed angles using two rotational axes, enabling multi-faceted machining in a single setup. By eliminating repositioning errors and reducing cycle times, we deliver geometrically intricate parts with tight tolerances down to ±0.005mm—critical for aerospace, medical, and defense applications where precision directly impacts performance and safety.

Our comprehensive CNC machining services extend beyond 3+2 axis solutions to include 3-axis, 4-axis, and full 5-axis simultaneous milling, supported by rigorous in-process inspection and material expertise spanning aluminum alloys, titanium, stainless steel, and engineering plastics. Every project leverages Honyo’s ISO 9001-certified processes, ensuring repeatable quality from prototype to low-volume production.

Accelerate your development timeline with our Online Instant Quote platform. Upload CAD files in under 60 seconds to receive a detailed, no-obligation manufacturing assessment—including lead time, cost breakdown, and DFM feedback—within minutes. This seamless integration of advanced capability and digital efficiency provides a streamlined path from design to certified production, reducing time-to-market without sacrificing precision. Partner with Honyo Prototype to transform complex geometries into mission-critical realities.

Technical Capabilities

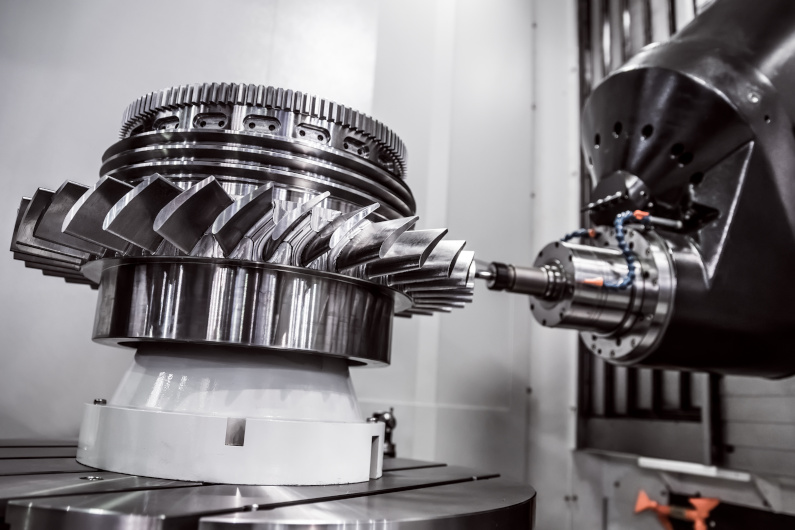

The term “3 2 axis CNC machine” typically refers to a 3+2 axis machining setup, which is a method used on 5-axis CNC machines. In this configuration, the machine uses all five axes, but the two rotational axes (A, B, or C) are positioned (locked) to orient the cutting tool at a fixed angle relative to the workpiece, while the three linear axes (X, Y, Z) perform the actual cutting. This is also known as “positional 5-axis machining” or “3+2 axis machining,” as opposed to full continuous 5-axis milling.

Below is a technical specification overview for a high-precision CNC machine capable of 3+2 and full 5-axis milling, precision turning, and tight-tolerance machining across common engineering materials.

| Specification | Detail |

|---|---|

| Machine Type | 5-Axis CNC Milling & Turning Center (capable of 3+2 axis operation) |

| Axes Configuration | X, Y, Z linear axes; A and C rotary axes (or B and C, depending on setup) |

| Control System | Fanuc 31i, Siemens 840D, or Heidenhain TNC7 – supporting 5-axis interpolation and tool center point control (RTCP) |

| Spindle Speed | Up to 24,000 RPM (high-speed option), standard 12,000–18,000 RPM |

| Spindle Power | 22–40 kW, depending on model and application |

| Positioning Accuracy | ±0.005 mm (0.0002 in) |

| Repeatability | ±0.002 mm (0.0001 in) |

| Tool Changer | Automatic Tool Changer (ATC) with 24–120 tool capacity, HSK-A63 or CAT 40/50 interface |

| Work Envelope (X×Y×Z) | Typical: 700 × 500 × 400 mm (27.6 × 19.7 × 15.7 in); varies by model |

| Rotary Table | Integrated or trunnion-type 2-axis rotary table with ±180° rotation on A/B axes |

| Coolant System | High-pressure through-spindle coolant (up to 70 bar), optional mist cooling |

| Tight Tolerance Capability | Achieves tolerances down to ±0.01 mm (±0.0004 in), with micro-finishing options to ±0.005 mm |

| Surface Finish | As low as Ra 0.4 µm (16 µin), depending on material and tooling |

| Compatible Materials | Aluminum (6061, 7075), Steel (4140, 1018, Stainless 304/316), ABS, Nylon (PA6, PA66), PEEK, and other engineering plastics |

| Machining Processes | 5-axis simultaneous milling, 3+2 axis positional milling, precision turning (with live tooling), contouring, pocketing, drilling, tapping |

| Applications | Aerospace components, medical implants, mold & die, automotive prototypes, complex brackets, and high-precision housings |

This machine setup is ideal for producing complex geometries with high accuracy across a wide range of materials. For aluminum and steel, carbide end mills with optimized coatings (e.g., TiAlN) are used to achieve tight tolerances and superior surface finishes. For plastics like ABS and Nylon, sharp high-speed steel or carbide tools with high rake angles prevent melting and burring, with lower feed rates and specialized clamping to avoid deformation.

The 3+2 axis technique reduces the need for multiple setups, improves part accuracy, and enables access to undercuts and deep cavities. When combined with high-resolution encoders and thermal compensation systems, these machines deliver repeatable precision in production and prototype environments.

From CAD to Part: The Process

Honyo Prototype employs a rigorously defined workflow for 3+2 axis CNC machining projects, ensuring precision, efficiency, and alignment with client specifications. This process specifically addresses the capabilities of 3+2 axis machining, where the workpiece is fixtured at fixed angular positions (using two rotational axes) while the three linear axes perform the cutting, distinct from continuous 5-axis simultaneous motion. Our standardized sequence is as follows:

CAD File Upload and Initial Processing

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid, or native formats like SLDPRT, IPT, PRT) via our secure customer portal. Our system performs an immediate automated validation check for file integrity, unit consistency, and basic geometry completeness. Simultaneously, the file enters parallel processing streams: one for AI-driven preliminary analysis and another for manual review by our engineering team. This dual-path approach ensures no critical detail is overlooked during initial intake.

AI-Powered Preliminary Quoting

Our proprietary AI engine analyzes the validated CAD geometry to generate a rapid preliminary quote within minutes. The algorithm assesses key factors including raw material volume, estimated machine runtime based on feature complexity and toolpath length, required tooling types, and fixture considerations specific to 3+2 axis constraints. Crucially, the AI identifies potential geometric challenges inherent to positional 5-axis machining, such as undercuts requiring multiple setups or extreme tilt angles impacting tool reach. This output provides clients with an instant cost and lead time estimate, clearly labeled as preliminary and subject to engineering validation during DFM.

Engineering-Led DFM Analysis and Quote Finalization

All projects undergo mandatory Design for Manufacturability (DFM) review by Honyo’s senior CNC engineering team before quote finalization. This phase is critical for 3+2 axis work, where setup strategy directly impacts cost and quality. Engineers meticulously evaluate:

| DFM Focus Area | Specific Checks for 3+2 Axis Machining |

|————————-|———————————————————–|

| Feature Accessibility | Tool reach for all features at each required tilt position; collision risks with fixture or machine envelope |

| Setup Strategy | Minimum number of fixture repositions; feasibility of tombstone or custom fixture design |

| Tolerance Feasibility | GD&T capability within positional constraints; thermal stability impact on critical dimensions |

| Material Utilization | Optimal stock size relative to part envelope; avoidance of thin walls prone to deflection during repositioning |

The engineering team collaborates directly with the client to resolve issues, suggesting cost-saving modifications (e.g., adjusting draft angles, consolidating features) while preserving functional intent. The final quote, incorporating all DFM insights and validated machine time calculations, is issued with a detailed manufacturing plan including setup diagrams and critical process notes.

Precision Production Execution

Approved orders move to production in our climate-controlled facility. For 3+2 axis jobs, we utilize Haas UMC-750 and DMG MORI CTX beta 1250 machines equipped with Renishaw probing systems. Key production steps include:

Workholding is engineered using modular tombstone systems or custom fixtures designed during DFM, with probe routines verifying work coordinate systems for each position. Toolpaths are generated in Mastercam with specialized 3+2 axis strategies, rigorously simulated offline to prevent collisions. In-process inspections at each setup transition validate critical dimensions before proceeding. Full first-article inspection reports with CMM data are provided for client review prior to batch production.

Quality-Controlled Delivery

Completed parts undergo final cleaning, deburring per client specifications, and comprehensive metrology against the original CAD model. All 3+2 axis machined components receive a detailed inspection report including positional tolerance verification across multiple setups. Parts are packaged using anti-corrosion VCI paper and rigid custom crating to prevent transit damage, with real-time shipment tracking provided. Delivery includes all quality documentation digitally via our portal and physical copies with the shipment, meeting AS9100 and ISO 9001 traceability requirements. Our standard lead time for 3+2 axis projects is 10-15 business days from DFM approval, with expedited options available.

Start Your Project

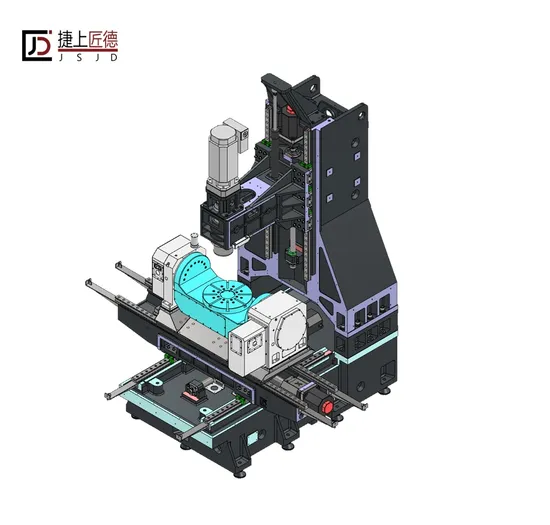

Explore our advanced 3-axis and 2-axis CNC machining solutions designed for precision prototyping and low-volume production. Built for performance and reliability, these machines support a wide range of materials and complex geometries, making them ideal for R&D teams, engineers, and manufacturers.

Manufactured in our Shenzhen facility, our CNC systems reflect strict quality control and engineering excellence. Whether you’re setting up a new production line or enhancing in-house capabilities, we offer scalable solutions tailored to your needs.

For detailed specifications, pricing, and technical support, contact Susan Leo at [email protected]. Let’s build what’s next—together.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.