Introduction: Navigating the Global Market for 22 ga metal

Navigating the complexities of sourcing 22 ga metal can be a daunting task for international B2B buyers, particularly in rapidly evolving markets across Africa, South America, the Middle East, and Europe. The challenge lies not only in identifying high-quality suppliers but also in understanding the various applications, specifications, and costs associated with this versatile material. This guide aims to streamline your purchasing journey by providing a comprehensive overview of 22 ga metal, including its types, applications across different industries, and insights into supplier vetting processes.

By delving into the intricacies of 22 ga metal, this resource empowers buyers to make informed decisions that align with their specific operational needs. From construction and automotive to HVAC systems, the applications of 22 ga metal are vast and diverse, making it essential for businesses to understand how this material can best serve their projects. Additionally, we will explore essential factors such as pricing trends, shipping considerations, and quality assurance practices that are vital for successful procurement.

With a focus on actionable insights and best practices, this guide is tailored to help international B2B buyers navigate the global market with confidence, ensuring that they can secure the right materials at the right prices while fostering strong supplier relationships. Whether you are a seasoned professional or new to sourcing metal, this guide serves as your essential toolkit for making strategic purchasing decisions in the dynamic world of 22 ga metal.

Understanding 22 ga metal Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Mild Steel | Cost-effective, good weldability, moderate strength | Construction, automotive parts | Pros: Affordable, versatile. Cons: Prone to rust without coating. |

| Stainless Steel | Corrosion-resistant, durable, aesthetic appeal | Food processing, chemical industries | Pros: Long lifespan, low maintenance. Cons: Higher cost compared to mild steel. |

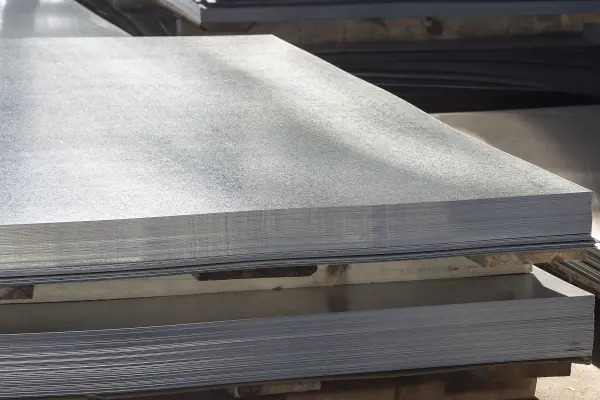

| Galvanized Steel | Coated with zinc for corrosion resistance | Outdoor structures, HVAC systems | Pros: Excellent weather resistance. Cons: Coating can be damaged, leading to rust. |

| Aluminum | Lightweight, non-corrosive, good thermal conductivity | Aerospace, electronics, automotive | Pros: Lightweight, easy to work with. Cons: Lower strength compared to steel. |

| Copper | Excellent electrical conductivity, corrosion-resistant | Electrical applications, plumbing | Pros: High conductivity, antimicrobial properties. Cons: Expensive, softer material. |

What Are the Characteristics and Suitability of Mild Steel 22 ga Metal?

Mild steel, commonly used in various industries, is characterized by its balance of strength, ductility, and affordability. It is particularly suitable for applications that require welding, such as automotive parts and structural supports in construction. When considering mild steel, buyers should note its susceptibility to corrosion; therefore, protective coatings or treatments are often necessary for outdoor or humid environments.

How Does Stainless Steel 22 ga Metal Stand Out in B2B Applications?

Stainless steel is renowned for its corrosion resistance and durability, making it ideal for industries such as food processing and pharmaceuticals. Its aesthetic appeal also allows for use in architectural elements. Buyers should consider the higher upfront costs, but the long-term benefits of lower maintenance and extended lifespan often justify the investment.

What Makes Galvanized Steel 22 ga Metal a Preferred Choice for Outdoor Use?

Galvanized steel is coated with zinc to enhance its resistance to corrosion, making it a preferred material for outdoor applications like HVAC systems and construction frameworks. The zinc layer protects the underlying steel from rust, although it can be compromised if scratched. Buyers should weigh the cost-effectiveness against potential maintenance needs if the coating is damaged.

Why Is Aluminum 22 ga Metal Gaining Popularity in Diverse Industries?

Aluminum’s lightweight nature and resistance to corrosion make it highly suitable for applications in aerospace, electronics, and automotive sectors. Its good thermal and electrical conductivity adds to its versatility. However, buyers should be aware that while aluminum is easier to work with, it is not as strong as steel, which may limit its use in heavy-duty applications.

What Are the Key Considerations for Using Copper 22 ga Metal in B2B Settings?

Copper is valued for its exceptional electrical conductivity and resistance to corrosion, making it ideal for electrical applications and plumbing. Its antimicrobial properties also make it suitable for healthcare environments. However, the high cost and softness of copper can be drawbacks, necessitating careful consideration of its application to ensure it meets the required durability and budget constraints.

Key Industrial Applications of 22 ga metal

| Industry/Sector | Specific Application of 22 ga metal | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | HVAC ductwork and ventilation systems | Enhances energy efficiency and air quality | Ensure compliance with local regulations and standards |

| Automotive | Body panels and structural components | Provides strength with reduced weight | Look for corrosion resistance and fabrication capabilities |

| Manufacturing | Custom enclosures for machinery and equipment | Protects sensitive components from environmental damage | Confirm availability of various finishes and sizes |

| Agriculture | Equipment housings and protective covers | Increases durability and lifespan of equipment | Assess material compatibility with agricultural chemicals |

| Electrical & Electronics | Electrical panels and junction boxes | Ensures safety and reliability in electrical systems | Verify certifications and standards for electrical applications |

How is 22 ga Metal Used in Construction for HVAC Applications?

In the construction industry, 22 ga metal is commonly utilized for HVAC ductwork and ventilation systems. Its strength and lightweight properties make it ideal for creating ducts that require minimal support while maintaining structural integrity. This application helps solve issues related to energy efficiency and air quality, as properly designed ducts can reduce energy loss and improve airflow. International buyers should consider sourcing options that comply with local building codes and standards to ensure a safe and efficient installation.

What Role Does 22 ga Metal Play in the Automotive Sector?

In the automotive industry, 22 ga metal is frequently used for body panels and structural components. Its balance of strength and weight reduction is crucial for improving fuel efficiency and overall vehicle performance. Manufacturers benefit from using this gauge as it allows for easier shaping and fabrication into complex designs. Buyers should prioritize suppliers that offer corrosion-resistant coatings, especially in regions with harsh weather conditions, to enhance the longevity of automotive components.

How is 22 ga Metal Essential for Manufacturing Equipment?

Manufacturers often rely on 22 ga metal for constructing custom enclosures for machinery and equipment. This application protects sensitive components from environmental factors such as dust, moisture, and mechanical impact. The use of 22 ga metal not only enhances the durability of these enclosures but also contributes to a safer working environment. Buyers should evaluate suppliers based on their ability to provide various finishes and cut-to-size options that meet specific machinery requirements.

In What Ways is 22 ga Metal Used in Agriculture?

In the agricultural sector, 22 ga metal is used for equipment housings and protective covers. This application is vital for ensuring that farming equipment withstands the rigors of outdoor environments while minimizing maintenance costs. The durability of 22 ga metal helps extend the lifespan of agricultural machinery, ultimately leading to increased productivity. Buyers should consider sourcing materials that are compatible with common agricultural chemicals to prevent corrosion and degradation.

How is 22 ga Metal Applied in Electrical and Electronics?

For electrical and electronics applications, 22 ga metal is often used in the fabrication of electrical panels and junction boxes. This metal provides the necessary strength and safety features required for housing electrical components, ensuring reliability and compliance with safety standards. Businesses benefit from using 22 ga metal as it can also help in heat dissipation and protection against external factors. Buyers should verify that their suppliers adhere to relevant electrical certifications and standards to guarantee the safety and efficacy of their products.

3 Common User Pain Points for ’22 ga metal’ & Their Solutions

Scenario 1: Sourcing Quality 22 ga Metal for Specific Applications

The Problem: B2B buyers often face challenges in sourcing 22 ga metal that meets specific quality and dimensional standards. This issue is particularly pronounced in regions where local suppliers may not offer a wide variety of metals or where the quality of available materials is inconsistent. Buyers may encounter discrepancies in thickness, coating, or finish, which can lead to delays in production or increased costs if the metal needs to be reworked or replaced.

The Solution: To ensure you source high-quality 22 ga metal, start by creating a detailed specification sheet that outlines your exact requirements, including thickness, material type (e.g., galvanized, stainless steel), and surface finish. Engage with multiple suppliers, preferably those with established reputations in the industry, and request samples to verify their claims. Additionally, leverage local metal distribution networks and online platforms that specialize in B2B transactions to compare offerings. Using a standardized gauge chart can help you confirm that the materials meet the required dimensions, reducing the risk of discrepancies. Forming long-term relationships with reliable suppliers can also facilitate more consistent sourcing.

Scenario 2: Understanding the Gauge System for Accurate Metal Selection

The Problem: Many B2B buyers, especially those new to the metal industry, struggle to understand the gauge system used to specify the thickness of metals like 22 ga. This confusion can lead to selecting the wrong gauge, resulting in unsuitable materials for their projects. Misunderstanding the gauge can have significant implications, including structural failures or increased costs due to incorrect purchases.

The Solution: Educate yourself and your team on the gauge system by utilizing resources such as gauge conversion charts. Familiarize yourself with how different materials (like aluminum versus steel) have different thicknesses for the same gauge number. When making a purchase, always refer to the specific material’s gauge chart to confirm that you are ordering the correct thickness. Training sessions or workshops on material selection can empower your purchasing team and improve their understanding of how gauge affects performance. Additionally, don’t hesitate to consult with your suppliers’ technical experts who can provide guidance on the best gauge for your specific application.

Scenario 3: Managing Cost Fluctuations in 22 ga Metal Purchases

The Problem: Fluctuating prices for 22 ga metal can significantly impact budgeting and project planning for B2B buyers. Factors such as global market trends, tariffs, and local demand can lead to unpredictable costs, making it difficult for companies to maintain profitability on projects that rely on consistent pricing for materials.

The Solution: To mitigate the impact of price fluctuations, consider implementing a strategic purchasing plan. This plan can involve bulk purchasing agreements with suppliers to lock in prices for a specified period. Additionally, establish relationships with multiple suppliers across different regions to diversify your sourcing options and secure competitive pricing. Stay informed about market trends and potential changes in supply chains that could affect pricing by subscribing to industry reports and newsletters. Finally, consider using financial instruments such as futures contracts if your purchasing volume justifies it, allowing you to hedge against rising costs. These proactive measures can help stabilize your material costs and improve overall financial planning.

Strategic Material Selection Guide for 22 ga metal

What Are the Key Properties of Common Materials Used for 22 Gauge Metal?

When selecting materials for 22 gauge metal applications, several common options stand out, each with unique properties that affect their performance in various environments. This guide will analyze mild steel, stainless steel, aluminum, and galvanized steel, focusing on their key properties, advantages, disadvantages, and implications for international buyers.

How Does Mild Steel Perform as a 22 Gauge Material?

Mild steel is a popular choice for 22 gauge applications due to its excellent weldability and formability. It typically has a yield strength of around 250 MPa and can withstand moderate temperatures and pressures, making it suitable for a variety of structural applications. However, mild steel is prone to corrosion, which can limit its use in environments with high humidity or exposure to chemicals.

Pros: Mild steel is cost-effective and readily available, making it a go-to option for many manufacturers. Its ease of machining and welding allows for complex shapes and designs.

Cons: The main drawback is its lack of corrosion resistance, necessitating protective coatings in certain applications. Additionally, it may not perform well in high-temperature environments.

Impact on Application: Mild steel is compatible with various media but may require additional treatments for corrosive substances.

Considerations for International Buyers: Buyers should ensure compliance with ASTM standards and consider local availability, as mild steel is widely used globally.

What Are the Benefits of Using Stainless Steel for 22 Gauge Metal?

Stainless steel is known for its superior corrosion resistance and durability, making it ideal for applications exposed to moisture or chemicals. With a yield strength typically around 520 MPa, it can handle higher stresses than mild steel. Stainless steel also performs well at elevated temperatures, maintaining its strength and integrity.

Pros: The primary advantage of stainless steel is its longevity and resistance to rust, which reduces maintenance costs over time. It is also aesthetically appealing, making it suitable for visible applications.

Cons: The main limitation is its higher cost compared to mild steel. Additionally, stainless steel can be more challenging to work with due to its hardness.

Impact on Application: Stainless steel is highly compatible with a range of media, including food and pharmaceuticals, due to its non-reactive nature.

Considerations for International Buyers: Buyers should verify compliance with ASTM and ISO standards, as well as local regulations regarding food safety and hygiene.

How Does Aluminum Compare as a Material for 22 Gauge Metal?

Aluminum is lightweight and has excellent corrosion resistance, making it suitable for applications where weight is a concern. Its yield strength is lower than that of steel, typically around 200 MPa, but it can be alloyed to enhance strength. Aluminum also has good thermal and electrical conductivity.

Pros: The lightweight nature of aluminum allows for easier handling and transportation, reducing overall project costs. Its natural resistance to corrosion makes it ideal for outdoor applications.

Cons: Aluminum is generally more expensive than mild steel and may not be suitable for high-stress applications without alloying.

Impact on Application: Aluminum is compatible with various media but may not be suitable for high-temperature environments.

Considerations for International Buyers: Buyers should consider local preferences for aluminum alloys and ensure compliance with JIS or DIN standards, particularly in Europe and Asia.

What Role Does Galvanized Steel Play in 22 Gauge Applications?

Galvanized steel is mild steel coated with zinc to enhance its corrosion resistance. It retains the workability of mild steel while providing a protective layer that extends its lifespan in outdoor or humid environments. The yield strength is similar to that of mild steel, around 250 MPa.

Pros: The galvanization process significantly improves the durability of mild steel, making it suitable for outdoor applications without extensive maintenance.

Cons: The coating can be damaged during fabrication, exposing the underlying steel to corrosion. Additionally, galvanized steel can be more expensive than untreated mild steel.

Impact on Application: Galvanized steel is ideal for applications where moisture is a concern, such as roofing and siding.

Considerations for International Buyers: Buyers should check for compliance with ASTM and local standards for galvanized products, especially in regions with high humidity.

Summary Table of Material Selection for 22 Gauge Metal

| Material | Typical Use Case for 22 ga metal | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Mild Steel | Structural components, automotive parts | Cost-effective and widely available | Prone to corrosion | Low |

| Stainless Steel | Food processing, medical equipment | Excellent corrosion resistance | Higher cost and harder to work with | High |

| Aluminum | Aerospace, automotive, outdoor furniture | Lightweight and corrosion-resistant | Lower strength compared to steel | Medium |

| Galvanized Steel | Roofing, siding, outdoor structures | Enhanced corrosion resistance | Coating can be damaged | Medium |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling informed decisions based on performance, cost, and compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for 22 ga metal

What Are the Main Manufacturing Processes for 22 ga Metal?

The manufacturing of 22 gauge metal involves several critical stages that ensure the final product meets the required specifications and performance standards. The main processes include material preparation, forming, assembly, and finishing.

How Is Material Prepared for 22 ga Metal Production?

Material preparation begins with sourcing high-quality raw materials, often in the form of coils or sheets of metal. For 22 gauge steel, this typically means using mild steel or stainless steel, depending on the intended application. The metal is cut into manageable sizes, and any impurities are removed through processes like degreasing or cleaning. This stage is crucial as it sets the foundation for the subsequent manufacturing steps.

What Forming Techniques Are Commonly Used in 22 ga Metal Fabrication?

Forming techniques for 22 ga metal include processes like shearing, bending, and punching. Shearing involves cutting the metal to specific dimensions using powerful blades, while bending is performed using press brakes to achieve desired angles and shapes. Punching creates holes for fastening or assembly purposes. Advanced technologies such as CNC (Computer Numerical Control) machines are often employed for precision and consistency, allowing for complex shapes and intricate designs.

How Is Assembly Conducted in 22 ga Metal Manufacturing?

Once the metal is formed, assembly may take place, especially if the product is part of a larger system or structure. This can involve welding, riveting, or using adhesives to join different components. The choice of assembly technique often depends on the specific requirements of the final product, such as strength, durability, and resistance to environmental factors. For instance, welded joints are common for structural applications where strength is paramount.

What Finishing Processes Are Applied to 22 ga Metal?

Finishing processes are essential for enhancing the appearance and performance of 22 ga metal. Common techniques include painting, galvanizing, and powder coating. Painting provides aesthetic benefits and can also offer a level of corrosion resistance. Galvanizing involves coating the metal with a layer of zinc to prevent rust, which is particularly beneficial in humid or coastal environments. Powder coating provides a durable finish and can be customized in various colors, making it suitable for consumer-facing products.

What Quality Assurance Standards Are Relevant for 22 ga Metal?

Quality assurance (QA) is a critical aspect of manufacturing 22 ga metal to ensure that products meet international and industry-specific standards. Relevant standards include ISO 9001, which focuses on quality management systems, and CE marking, indicating compliance with EU safety, health, and environmental protection standards. For specific industries, such as oil and gas, compliance with API (American Petroleum Institute) standards may be necessary.

How Are QC Checkpoints Established in the Manufacturing Process?

Quality control (QC) checkpoints are strategically integrated throughout the manufacturing process. These include:

- Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specifications before production begins.

- In-Process Quality Control (IPQC): During manufacturing, samples are taken at various stages to ensure the processes are functioning correctly and producing within tolerances.

- Final Quality Control (FQC): After the product is completed, a final inspection ensures that the finished product meets all specifications and quality standards before shipment.

What Testing Methods Are Commonly Used for 22 ga Metal?

To verify the quality of 22 ga metal, several testing methods are employed. Common techniques include:

- Visual Inspection: A straightforward method to detect surface defects, such as scratches or dents.

- Dimensional Measurement: Using calipers or laser measurement tools to ensure that the dimensions match specifications.

- Mechanical Testing: This includes tensile tests to assess strength and ductility, and hardness tests to evaluate material resistance.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing or magnetic particle testing are used to identify internal flaws without damaging the product.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several proactive measures to verify the quality control practices of their suppliers:

- Conduct Audits: Regular audits of the supplier’s manufacturing facility can provide insights into their processes and adherence to quality standards.

- Request Quality Reports: Suppliers should provide documentation of their quality management systems, including results from IQC, IPQC, and FQC.

- Third-Party Inspections: Engaging third-party inspection agencies can add an additional layer of assurance, providing unbiased verification of quality claims.

What Are the QC and Certification Nuances for International B2B Buyers?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, must navigate various certification requirements and quality standards. Understanding local regulations and compliance standards is critical. For instance, products shipped to the EU must have CE marking, while those intended for specific industries may require additional certifications.

Moreover, cultural differences in business practices can affect how quality assurance is perceived. Buyers should establish clear communication channels and expectations regarding quality standards and certifications from the outset. Being proactive in these discussions can lead to better partnerships and ensure that the products meet the necessary specifications and regulations.

Conclusion: Ensuring Quality in 22 ga Metal Manufacturing

The manufacturing and quality assurance processes for 22 ga metal are intricate and vital for ensuring that the final products meet the demands of various industries. By understanding the manufacturing stages, quality standards, and verification methods, international B2B buyers can make informed decisions when selecting suppliers, ultimately leading to successful partnerships and high-quality outcomes.

Practical Sourcing Guide: A Step-by-Step Checklist for ’22 ga metal’

Introduction

Sourcing 22-gauge metal can be a pivotal decision for businesses across various industries, from construction to manufacturing. This guide provides a practical checklist to help B2B buyers efficiently navigate the procurement process, ensuring they find the right materials at the best prices while maintaining quality and compliance with industry standards.

Step 1: Define Your Technical Specifications

Clearly outlining your technical requirements is the first step in sourcing 22-gauge metal. Consider factors such as thickness, material type (e.g., galvanized steel, stainless steel), and any specific industry standards that must be met. This precision helps avoid costly errors and ensures compatibility with your project needs.

- Material Type: Identify whether you need galvanized, stainless, or another metal variant.

- Thickness Tolerance: Specify acceptable tolerances to avoid issues during fabrication or assembly.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers who specialize in 22-gauge metal. Look for companies with a strong reputation in your region, as local suppliers may offer advantages like reduced shipping costs and faster delivery times. Online reviews and industry forums can provide insights into supplier reliability.

- Industry Experience: Prioritize suppliers with a proven track record in your specific sector.

- Product Range: Ensure they offer various types of 22-gauge metal to meet your needs.

Step 3: Evaluate Supplier Certifications

Before finalizing a supplier, verify their certifications and compliance with relevant industry standards. Certifications such as ISO 9001 can indicate a commitment to quality management, while specific material certifications ensure the metal meets safety and performance requirements.

- Quality Assurance: Check for certifications that align with your industry needs.

- Environmental Compliance: Consider suppliers who adhere to environmental regulations, which may be crucial for sustainability-focused projects.

Step 4: Request Samples

Obtaining samples of the 22-gauge metal can help you assess quality before making a bulk purchase. Examine the physical properties, such as finish, thickness, and weight, to ensure they meet your specifications. This step can prevent future issues related to material quality.

- Testing: Conduct tests on samples to check for durability and suitability for your application.

- Visual Inspection: Inspect the finish and any coatings for consistency and defects.

Step 5: Compare Pricing and Terms

Once you have shortlisted suppliers, compare their pricing structures and terms of sale. Look beyond the initial cost; consider factors such as bulk discounts, payment terms, and shipping costs. Understanding the total cost of ownership will help you make an informed decision.

- Bulk Discounts: Inquire about pricing structures for larger orders.

- Lead Times: Assess delivery timelines to ensure they align with your project schedules.

Step 6: Negotiate Contracts Carefully

When you’re ready to proceed, negotiate the terms of your contract meticulously. Ensure that all aspects, including delivery schedules, payment terms, and warranty conditions, are clearly defined. A well-structured contract protects your interests and fosters a transparent relationship with the supplier.

- Clear Terms: Specify all expectations to avoid misunderstandings.

- Dispute Resolution: Include clauses for resolving potential disputes to safeguard your investment.

Step 7: Establish a Long-Term Relationship

After the initial purchase, consider establishing a long-term relationship with your supplier. Consistent orders can lead to better pricing and service. Regular communication will ensure that your evolving needs are met and that you remain informed about new products or changes in availability.

- Feedback Loop: Provide feedback on quality and service to help improve future transactions.

- Continuous Assessment: Regularly evaluate supplier performance to ensure they continue to meet your expectations.

Comprehensive Cost and Pricing Analysis for 22 ga metal Sourcing

What Are the Key Cost Components in Sourcing 22 Gauge Metal?

When sourcing 22 gauge metal, understanding the cost structure is essential for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The cost of raw materials is often the largest component. Prices fluctuate based on market demand, availability, and the type of metal (e.g., galvanized steel, stainless steel). It’s crucial to consider the quality and specifications required for your project, as this can significantly impact material costs.

-

Labor: Labor costs encompass wages for workers involved in manufacturing and processing the metal. This includes skilled labor for cutting, welding, and finishing processes. Labor rates can vary widely by region, impacting overall cost.

-

Manufacturing Overhead: This includes expenses related to the operation of manufacturing facilities, such as utilities, rent, and equipment maintenance. Efficient production processes can help lower these costs.

-

Tooling: If specific shapes or forms are required, tooling costs for dies, molds, and specialized machinery may be significant. Custom tooling can drive up costs but may be necessary for unique specifications.

-

Quality Control: Ensuring the metal meets industry standards and certifications often requires additional investment in testing and inspection. Buyers should account for these costs when evaluating total expenses.

-

Logistics: Shipping costs can vary based on distance, weight, and mode of transport. International buyers should also consider customs duties and tariffs that may apply.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks. This can vary based on competition, market conditions, and the supplier’s positioning.

How Do Pricing Influencers Affect the Cost of 22 Gauge Metal?

Several factors can influence the pricing of 22 gauge metal:

-

Volume/MOQ: Bulk purchases often lead to lower per-unit costs. Understanding the minimum order quantity (MOQ) set by suppliers can help in negotiating better prices.

-

Specifications and Customization: Custom specifications can increase costs. Standard sizes and grades are usually more cost-effective, while bespoke solutions may require additional tooling and processing.

-

Materials and Quality Certifications: Higher-quality materials or those with specific certifications (e.g., ISO, ASTM) typically come with a higher price tag. Buyers must assess the required quality versus cost-effectiveness.

-

Supplier Factors: Reputation, reliability, and service levels of suppliers can influence pricing. Established suppliers with a track record of quality may charge a premium.

-

Incoterms: The chosen Incoterms can significantly impact total costs. For example, FOB (Free on Board) versus CIF (Cost, Insurance, and Freight) can lead to differing shipping responsibilities and expenses.

What Are Essential Buyer Tips for Cost-Efficiency in 22 Gauge Metal Sourcing?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, implementing effective sourcing strategies is vital.

-

Negotiation: Always negotiate terms with suppliers. Factors like payment terms, delivery schedules, and bulk discounts can yield significant savings.

-

Total Cost of Ownership (TCO): Assess the total cost of ownership, which includes purchase price, shipping, handling, and any potential costs related to quality issues. TCO provides a more comprehensive view of expenses than just the upfront cost.

-

Pricing Nuances: Be aware of regional pricing dynamics. For instance, sourcing from suppliers in Europe may have different pricing due to labor costs and material availability compared to suppliers in Asia.

-

Market Research: Stay updated on market trends and material price fluctuations. This knowledge can empower buyers to make informed purchasing decisions and negotiate better.

-

Supplier Relationships: Cultivating strong relationships with suppliers can lead to better pricing and more favorable terms in the long run.

Disclaimer on Indicative Prices

Prices for 22 gauge metal can vary widely based on the factors outlined above, and the information provided herein should be considered indicative. Always seek multiple quotes and conduct thorough due diligence before finalizing any procurement decisions.

Alternatives Analysis: Comparing 22 ga metal With Other Solutions

Exploring Alternatives to 22 Ga Metal: What Are the Options?

When evaluating material solutions in industrial applications, it’s essential to consider alternatives to 22 gauge metal. This analysis will compare 22 ga metal with two viable alternatives: aluminum sheets and fiberglass composites. Each option has its strengths and weaknesses, which can significantly influence a buyer’s decision based on their specific requirements.

| Comparison Aspect | 22 Ga Metal | Aluminum Sheets | Fiberglass Composites |

|---|---|---|---|

| Performance | Good tensile strength and durability; resistant to corrosion when galvanized. | Lightweight; excellent corrosion resistance; good thermal conductivity. | Very strong for its weight; excellent chemical resistance; non-conductive. |

| Cost | Generally lower cost per sheet; prices can vary by region and supplier. | Typically higher upfront cost; offers long-term savings due to durability. | Higher initial investment; cost-effective over time due to low maintenance. |

| Ease of Implementation | Easy to work with; commonly available; requires standard metalworking tools. | Requires specialized tools for cutting and welding; can be more challenging to work with. | Easier to mold and shape; can be fabricated using simpler techniques. |

| Maintenance | Requires periodic maintenance to prevent rust; galvanized options reduce this need. | Low maintenance; does not rust; may require cleaning to maintain appearance. | Minimal maintenance; resistant to many chemicals and environmental factors. |

| Best Use Case | Ideal for structural applications and where strength is paramount. | Excellent for applications requiring lightweight materials, such as aerospace or automotive. | Best suited for environments with high chemical exposure or where weight savings are critical. |

What Are the Advantages and Disadvantages of Aluminum Sheets?

Aluminum sheets are a popular alternative to 22 ga metal due to their lightweight nature and excellent corrosion resistance. They are ideal for applications in the aerospace and automotive industries where weight savings are crucial. However, the cost of aluminum can be significantly higher than that of 22 ga metal, making it less appealing for budget-sensitive projects. Additionally, working with aluminum may require specialized tools, which can increase initial investment costs.

How Do Fiberglass Composites Compare to 22 Ga Metal?

Fiberglass composites present a unique alternative, particularly in environments that are chemically aggressive or where electrical insulation is necessary. They offer significant strength relative to their weight and are resistant to a variety of chemicals. Despite their advantages, fiberglass composites often come with a higher initial cost and may not provide the same structural rigidity as 22 ga metal in heavy-duty applications. Fabrication can also be simpler, as they can be molded into complex shapes without the need for heavy machinery.

How Should B2B Buyers Choose the Right Material for Their Needs?

When selecting the appropriate material, B2B buyers should carefully assess their specific application requirements, including strength, weight, cost, and environmental factors. Understanding the performance characteristics and long-term implications of each material is crucial. For instance, if cost is the primary concern, 22 ga metal may be the best choice. Conversely, for applications where weight and corrosion resistance are critical, aluminum or fiberglass composites may be more suitable despite their higher costs. By aligning material properties with project requirements, businesses can make informed decisions that enhance operational efficiency and reduce long-term costs.

Essential Technical Properties and Trade Terminology for 22 ga metal

What Are the Essential Technical Properties of 22 ga Metal?

When purchasing 22 gauge (ga) metal, understanding its technical properties is crucial for B2B buyers. Here are some key specifications that impact its application and suitability for various industries:

1. Material Grade

The material grade of 22 ga metal, often categorized as mild steel, stainless steel, or galvanized steel, plays a significant role in determining its strength, corrosion resistance, and overall durability. For instance, stainless steel is ideal for environments exposed to moisture, while galvanized steel is preferred for outdoor applications due to its protective zinc coating. Knowing the right grade helps buyers select the appropriate metal for their specific applications.

2. Thickness

The thickness of 22 ga metal is approximately 0.0299 inches (0.759 mm). This measurement is critical as it directly affects the metal’s structural integrity and weight-bearing capacity. For B2B buyers, understanding thickness ensures that the metal can withstand the intended loads in construction, manufacturing, or automotive applications.

3. Tolerance

Tolerance refers to the allowable variation in the thickness of the metal. For 22 ga metal, standard tolerances can range from ±0.002 to ±0.005 inches. This specification is vital for manufacturers who require precise dimensions for fit and assembly in their products. Ensuring tight tolerances can minimize waste and improve the efficiency of production processes.

4. Yield Strength

Yield strength indicates the maximum stress that the metal can withstand without permanent deformation. For 22 ga mild steel, the yield strength typically ranges from 30,000 to 40,000 psi. This property is crucial for B2B buyers as it helps in assessing the metal’s performance under mechanical loads, ensuring it meets safety and durability requirements.

5. Coating and Finish

The surface finish of 22 ga metal, including coatings like galvanization or paint, affects its corrosion resistance and aesthetic appeal. A galvanized finish enhances durability in harsh environments, while painted surfaces offer additional protection and design options. Buyers should consider the environment in which the metal will be used to choose the right finish.

What Are Common Trade Terms Related to 22 ga Metal?

Understanding industry terminology is equally important for B2B transactions. Here are some common terms associated with purchasing 22 ga metal:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of 22 ga metal, OEMs often require specific grades and tolerances to meet their product standards. Understanding OEM specifications is essential for ensuring compatibility and quality in manufacturing.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest amount of product that a supplier is willing to sell. For 22 ga metal, MOQs can vary based on the supplier and material grade. Knowing the MOQ helps buyers plan their purchases effectively, especially when budgeting for large projects.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price quotes from suppliers for specific products, like 22 ga metal. This process helps businesses compare prices, terms, and conditions, ensuring they make informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. They dictate who is responsible for shipping, insurance, and tariffs. Understanding Incoterms is crucial for B2B buyers, particularly when importing 22 ga metal from different countries, as it clarifies logistics and cost responsibilities.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order until it is delivered. For 22 ga metal, lead times can vary based on the supplier and the complexity of the order. Understanding lead times is vital for project planning and ensuring materials are available when needed.

By grasping these essential properties and trade terms, international B2B buyers can make informed decisions, ensuring they select the right 22 ga metal products for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the 22 ga metal Sector

What are the Key Market Dynamics and Trends Influencing the 22 Gauge Metal Sector?

The 22 gauge metal sector is currently witnessing significant growth driven by several global factors. The increasing demand for lightweight and durable materials in construction, automotive, and manufacturing industries is a primary driver. As economies in Africa, South America, the Middle East, and Europe recover and expand, the need for versatile materials like 22 gauge metal is surging. Emerging technologies such as automation in manufacturing and advancements in metal processing are enhancing production efficiency, leading to cost reductions that benefit B2B buyers.

Furthermore, the trend towards digital sourcing platforms is reshaping how international buyers procure 22 gauge metal. Platforms that facilitate bulk purchasing and provide real-time inventory data are gaining traction, allowing buyers to streamline their procurement processes. As sustainability becomes a central concern, buyers are increasingly inclined to partner with suppliers who prioritize green practices, ensuring that their sourcing aligns with global sustainability goals.

The market dynamics are also influenced by geopolitical factors and trade regulations, particularly in regions like Europe and the Middle East. Tariffs, import restrictions, and fluctuating currency values can impact pricing and availability, making it essential for international buyers to stay informed and agile in their sourcing strategies.

How is Sustainability and Ethical Sourcing Shaping the 22 Gauge Metal Industry?

Sustainability has emerged as a crucial consideration in the sourcing of 22 gauge metal. The environmental impact of metal production is significant, with traditional manufacturing processes contributing to carbon emissions and waste. Consequently, ethical sourcing practices are gaining momentum among B2B buyers who recognize the importance of sustainability in their supply chains.

Buyers are increasingly seeking suppliers that adopt sustainable practices, such as using recycled materials and minimizing energy consumption in production. Certifications such as ISO 14001 for environmental management and LEED for green building materials are becoming essential criteria for procurement decisions. Suppliers that can demonstrate their commitment to sustainability not only meet regulatory requirements but also enhance their market appeal.

Moreover, the demand for ‘green’ materials is on the rise. Buyers are looking for 22 gauge metal products that comply with environmental standards, which often translates to lower lifecycle costs and better long-term value. As a result, B2B companies that prioritize sustainability in their sourcing strategies are likely to gain a competitive edge in the global marketplace.

What is the Historical Context of the 22 Gauge Metal Sector for B2B Buyers?

The gauge system for metals, including 22 gauge, has a rich history that dates back to the British wire industry, where it was initially developed to describe wire diameter. As the industrial revolution progressed, the gauge system evolved to standardize measurements for sheet metals. The 22 gauge measurement, which corresponds to a thickness of approximately 0.0299 inches or 0.759 mm, became widely adopted for various applications due to its balance of strength and weight.

Over the decades, the 22 gauge metal sector has adapted to technological advancements and changing market needs. The introduction of galvanized coatings and other protective finishes has improved the durability and corrosion resistance of 22 gauge products, making them suitable for a broader range of applications, from construction to automotive manufacturing. This evolution not only reflects advancements in material science but also the increasing importance of quality and performance in the B2B sector.

In conclusion, understanding the market dynamics, sustainability imperatives, and historical context surrounding 22 gauge metal is essential for international buyers looking to navigate this complex landscape effectively. By aligning sourcing strategies with these insights, businesses can enhance their competitiveness and contribute to a more sustainable future.

Frequently Asked Questions (FAQs) for B2B Buyers of 22 ga metal

-

1. How do I determine the thickness of 22 ga metal?

The thickness of 22 gauge (ga) metal is approximately 0.0299 inches or 0.759 millimeters. It’s important to note that the gauge system varies by material type, so a gauge conversion chart can be helpful. For instance, 22 ga aluminum will have different thickness measurements compared to 22 ga steel. Always confirm the specific material’s gauge chart to ensure the right specifications for your project. -

2. What applications are best suited for 22 ga metal?

22 ga metal is commonly used in various applications, including HVAC ductwork, automotive components, roofing, and decorative metalwork. Its balance of strength and weight makes it ideal for both structural and aesthetic purposes. B2B buyers should assess their specific needs, considering factors like corrosion resistance and fabrication requirements when selecting 22 ga metal for their projects. -

3. What are the typical minimum order quantities (MOQs) for 22 ga metal?

MOQs for 22 ga metal can vary widely depending on the supplier and the specific product. Generally, suppliers may have MOQs ranging from 100 to 500 kg for bulk orders. However, some suppliers may accommodate smaller orders, especially for customized sheets or specific dimensions. It is advisable to discuss your needs with potential suppliers to find a suitable arrangement. -

4. How can I ensure the quality of 22 ga metal before purchase?

To ensure quality, request certifications such as ISO or ASTM compliance from your supplier. Additionally, consider ordering samples to evaluate the material’s physical properties and finish. Engaging in a detailed discussion about the supplier’s quality assurance processes and their handling of defects or returns can also provide insight into their commitment to product quality. -

5. What payment terms should I expect when sourcing 22 ga metal internationally?

Payment terms can vary significantly among suppliers. Common practices include partial upfront payments (30-50%), with the balance due upon delivery or after quality inspection. Some suppliers may offer letter of credit (LC) options, especially for larger transactions. Always clarify payment terms upfront to avoid misunderstandings and ensure a smooth transaction. -

6. How do I vet suppliers for 22 ga metal?

When vetting suppliers, consider their industry reputation, years of experience, and customer reviews. Request references from previous clients and check their compliance with international trade standards. It’s also beneficial to evaluate their manufacturing capabilities, delivery timelines, and customer service responsiveness to ensure they align with your business needs. -

7. What logistics considerations are there for importing 22 ga metal?

Logistics for importing 22 ga metal involve several key factors, including shipping methods, customs clearance, and delivery timelines. It’s important to work with freight forwarders experienced in handling metal shipments to navigate regulatory requirements. Additionally, consider the cost implications of shipping methods, as air freight is faster but more expensive than sea freight. -

8. Can I customize 22 ga metal products?

Yes, many suppliers offer customization options for 22 ga metal, including specific dimensions, finishes, and coatings. Discuss your requirements with potential suppliers to determine their capabilities for customization. Be sure to request detailed specifications and lead times for any custom orders to ensure they meet your project needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 22 Ga Metal Manufacturers & Suppliers List

1. Metal Supermarkets – Sheet Metal Gauge Chart

Domain: metalsupermarkets.com

Registered: 1996 (29 years)

Introduction: Sheet Metal Gauge Chart – Metal Supermarkets offers various metal types including Mild Steel, Aluminum, Stainless Steel, Alloy Steel, Brass, Bronze, and Copper. Each metal type has specific gauge charts detailing thickness in inches and millimeters. For example, 18 gauge steel is 0.0478 inches thick (1.214 mm), while 18 gauge aluminum is 0.0403 inches thick (1.024 mm). The chart includes gauges ra…

2. Metals Depot – Hot Rolled Steel Sheet

Domain: metalsdepot.com

Registered: 1999 (26 years)

Introduction: {“products”:[{“type”:”Hot Rolled Steel Sheet”,”specification”:”ASTM A1011 CS Type B”,”description”:”Economical steel sheets with a slightly grainy surface, ideal for painting.”,”uses”:[“general fabrication”,”equipment panels”,”tool boxes”,”hoppers”,”drip pans”],”thicknesses”:[{“gauge”:16,”thickness”:”.060″},{“gauge”:14,”thickness”:”.075″},{“gauge”:12,”thickness”:”.105″},{“gauge”:11,”thickness”:”.1…

3. American Metals Supply – 22 Gauge Galvanized Steel Sheets

Domain: americanmetalssupply.com

Registered: 2000 (25 years)

Introduction: {“category”:”Galvanized Steel Sheets”,”sub_category”:”Flat Sheets by Gauge”,”gauge”:”22 Gauge”,”sizes”:[{“size”:”36 x 96″},{“size”:”36 x 120″},{“size”:”48 x 96″},{“size”:”48 x 120″},{“size”:”60 x 120″}],”G90_options”:[{“size”:”36 x 120″},{“size”:”48 x 96″},{“size”:”48 x 120″},{“size”:”60 x 120″}]}

4. Ferguson – 22+ga Sheet Metal

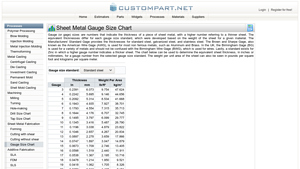

5. Custom Part Net – Sheet Metal Gauge Size Chart

Domain: custompartnet.com

Registered: 2006 (19 years)

Introduction: Sheet Metal Gauge Size Chart: Gauge sizes indicate the thickness of sheet metal, with higher numbers referring to thinner sheets. Different gauge size standards exist, including the Manufacturers’ Standard Gage for steel types, the Brown and Sharpe Gage for non-ferrous metals, and the Birmingham Gage in the UK. The chart provides equivalent thicknesses in inches and millimeters, along with weight …

6. MK Metal – GALV SHEET 22 GA X 48 X 120

Domain: mkmetal.net

Registered: 1999 (26 years)

Introduction: {“Product Name”: “GALV SHEET 22 GA X 48 X 120”, “Alloy”: “galvanized”, “Thickness”: “22 ga”, “Width”: “48 inches”, “Length”: “120 inches”, “Weight per Square Foot”: “1.4953 lbs”, “Price per Piece”: “$49.3”, “Price Each”: “$141.13”}

7. Sheffield Metals – 24-Gauge Steel

Domain: sheffieldmetals.com

Registered: 1998 (27 years)

Introduction: 24-Gauge Steel: Advantages: Widely available, available engineering, great defense against oil canning, great defense against extreme weather, color selection variety, easier to work with than 22-gauge, less expensive than 22-gauge. Disadvantages: More prone to hail damage vs. 22-gauge. Best Uses: Residential, Commercial. Overview: Popular in the metal roofing industry, commonly used for standing …

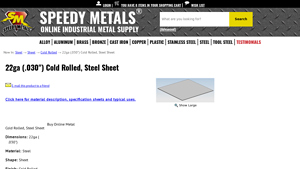

8. Speedy Metals – 22ga Cold Rolled Steel Sheet

Domain: speedymetals.com

Registered: 2001 (24 years)

Introduction: {“Product Name”: “22ga (.030″) Cold Rolled Steel Sheet”, “Material”: “Steel”, “Shape”: “Sheet”, “Finish”: “Cold Rolled”, “Dimensions”: [{“Size”: “12×12”, “Weight”: “1.2096 lbs”, “Price”: “$6.71”}, {“Size”: “12×18”, “Weight”: “1.8144 lbs”, “Price”: “$8.81”}, {“Size”: “12×24”, “Weight”: “2.4192 lbs”, “Price”: “$10.74”}], “Cutting Tolerance”: “Plus or Minus 1/4″”}

Strategic Sourcing Conclusion and Outlook for 22 ga metal

What Are the Key Takeaways for Sourcing 22 Gauge Metal?

Strategic sourcing of 22 gauge metal is crucial for international buyers looking to enhance their supply chain efficiency and product quality. As a versatile material, 22 gauge metal finds applications across various industries, from construction to automotive. By understanding the thickness specifications and properties associated with this gauge, buyers can ensure they select the right materials that meet their project requirements.

How Can Strategic Sourcing Benefit Your Business?

Engaging in strategic sourcing allows businesses to mitigate risks associated with supply chain disruptions, particularly in regions like Africa, South America, and the Middle East. By building strong relationships with reputable suppliers and diversifying sourcing options, companies can secure competitive pricing and reliable delivery timelines.

What’s Next for International Buyers?

Looking ahead, the demand for 22 gauge metal is expected to grow, driven by infrastructure projects and industrial expansion. International buyers, particularly from Europe and emerging markets such as Vietnam, should remain proactive in their sourcing strategies. Consider leveraging digital platforms to connect with suppliers, assess market trends, and negotiate favorable terms.

By prioritizing strategic sourcing, businesses can not only enhance their operational efficiency but also position themselves for sustainable growth in an evolving global market.