Contents

Manufacturing Insight: 20 Gauge Automotive Sheet Metal

Precision 20 Gauge Automotive Sheet Metal Fabrication at Honyo Prototype

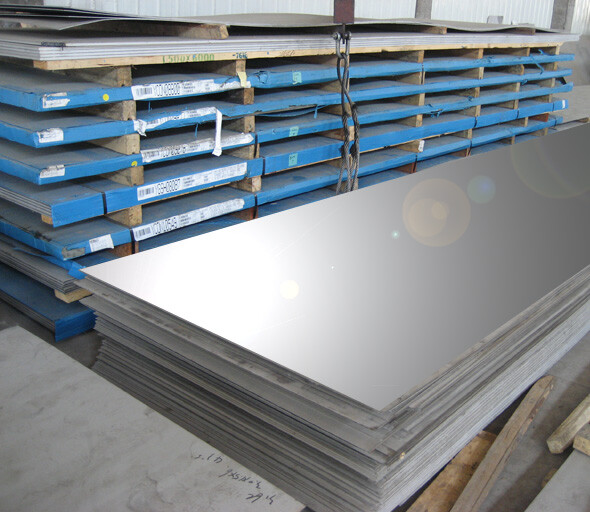

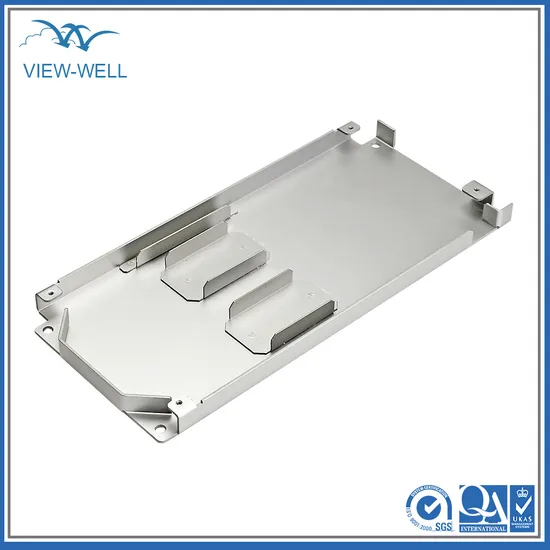

For automotive applications demanding an optimal balance of structural integrity, weight efficiency, and formability, 20 gauge sheet metal (0.0359 inches / 0.912 mm thickness) remains a critical material choice. This gauge is widely specified for components such as brackets, housings, chassis reinforcements, and interior structural elements where consistent flatness, weldability, and compliance with stringent automotive tolerances are non-negotiable. At Honyo Prototype, we specialize in transforming 20 gauge cold-rolled steel, aluminum, and high-strength low-alloy (HSLA) automotive-grade materials into precision-engineered parts through our end-to-end fabrication capabilities.

Our ISO 9001 and AS9100-certified processes leverage advanced fiber laser cutting, CNC press braking with ±0.1mm accuracy, and robotic MIG/TIG welding tailored specifically to the nuances of thin-gauge automotive metals. This ensures minimal distortion, repeatable dimensional stability, and seamless integration into complex assemblies—critical for prototyping and low-volume production in the automotive supply chain. We rigorously control material traceability, surface finish, and edge quality to meet OEM specifications, reducing rework and accelerating time-to-test.

Engineers and procurement teams can immediately assess project feasibility and cost through our Online Instant Quote platform. Simply upload CAD files (STEP, DWG, DXF), specify material grade and finish requirements, and receive a detailed fabrication quote within minutes—not days—enabling faster iteration and supply chain responsiveness.

| Key 20 Gauge Automotive Fabrication Capabilities |

|---|

| Material Compatibility |

| Tolerance Control |

| Secondary Operations |

| Volume Range |

Leverage Honyo’s expertise to convert your 20 gauge automotive designs into functionally validated components with engineering-grade precision. Initiate your project today using our instant quoting system for transparent, data-driven procurement.

Technical Capabilities

Technical Specifications for 20 Gauge Automotive Sheet Metal – Focus on Laser Cutting, Bending, and Welding

20 gauge sheet metal is commonly used in automotive applications for brackets, housings, trim, and structural supports. The thickness and material type significantly influence manufacturability in laser cutting, bending, and welding operations. Below is a comparative overview of 20 gauge sheet metal formed from aluminum, steel, ABS, and nylon, focusing on processing characteristics.

| Material | Thickness (20 Gauge) | Tensile Strength | Laser Cutting Suitability | Bending Characteristics | Welding Process & Notes |

|---|---|---|---|---|---|

| Steel (Mild/Carbon) | 0.953 mm (0.0375 in) | 370–440 MPa | Excellent – clean cuts with CO₂ or fiber lasers; minimal dross with proper assist gas (O₂ or N₂) | Good formability; minimum bend radius ~0.8 mm (1t); springback ~2–3° | Readily weldable using MIG, TIG, or spot welding; pre-cleaning required; zinc-coated variants may require fume extraction |

| Aluminum (e.g., 5052, 6061) | 0.953 mm (0.0375 in) | 190–310 MPa | Good – reflective nature requires high-power fiber lasers with N₂ assist; higher energy input needed | Excellent ductility; minimum bend radius ~1.5 mm (1.5t); minimal springback | TIG or MIG welding preferred; requires shielding gas (Ar/He); surface oxide layer must be removed; prone to hot cracking if not properly controlled |

| ABS (Thermoplastic) | 0.953 mm (0.0375 in) | 40–50 MPa | Moderate – laser cutting possible but with risk of melting, charring, or edge curling; CO₂ lasers at low power with air assist recommended | Limited – high ductility but low stiffness; prone to creep and stress relaxation; not ideal for structural bends | Not weldable in traditional sense; joining via adhesive bonding, ultrasonic welding, or solvent welding; poor heat resistance limits fusion processes |

| Nylon (e.g., PA6, PA66) | 0.953 mm (0.0375 in) | 70–85 MPa | Poor – highly absorptive but melts easily; CO₂ lasers can cut with precise control and compressed air; high risk of warping | Poor – low modulus and high moisture absorption lead to dimensional instability; not recommended for precision bends | Not suitable for arc welding; limited to hot gas welding, ultrasonic, or adhesive bonding; moisture must be removed prior to processing |

Notes:

20 gauge is standardized under the U.S. Standard Gauge (USG) for sheet metal.

Steel and aluminum are the only materials from this list suitable for full integration into structural automotive components requiring welding and bending.

ABS and nylon are typically not classified as “sheet metal” but may be processed in sheet form; they are more common in non-structural, interior, or protective applications.

Laser cutting parameters must be optimized per material thickness and composition to ensure edge quality and dimensional accuracy.

Bending operations require tooling selection (V-die width, punch radius) matched to material properties to avoid cracking or deformation.

From CAD to Part: The Process

Honyo Prototype Process for 20 Gauge Automotive Sheet Metal Components

Our streamlined workflow for 20 gauge (0.914 mm / 0.0359 inch) automotive sheet metal parts ensures precision, compliance, and rapid turnaround. This process integrates advanced digital tools with rigorous engineering validation to meet automotive industry standards including ISO/TS 16949 and material-specific requirements for steel or aluminum alloys commonly used at this thickness.

Upload CAD

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid) via our secure customer portal. For 20 gauge automotive applications, we specifically validate critical parameters including flange widths, hole-to-edge distances, and bend radii against material ductility limits. Automotive CAD models must reference AMS, SAE, or OEM-specific material specifications; incomplete metadata triggers immediate client consultation to prevent downstream delays.

AI Quote Generation

Our proprietary AI engine processes the CAD geometry, material selection, and finish requirements to generate an initial cost and lead time estimate within 2 hours. For 20 gauge sheet metal, the AI cross-references automotive-specific databases for material costs (e.g., CR1008 steel, 5052-H32 aluminum), standard gauge tolerances (±0.08 mm per ASTM A480), and secondary operation pricing. The quote explicitly flags potential cost drivers such as zinc-nickel plating requirements or sub-1.5T minimum hole diameters. Human oversight by our quoting team ensures automotive compliance factors are weighted correctly before client delivery.

DFM Analysis

Engineers conduct a formal Design for Manufacturability review within 72 hours, focusing on automotive-grade producibility for thin-gauge metal. Key evaluations include:

Bend allowance validation for springback compensation in high-strength steels

Flange stability assessment to prevent distortion during welding or coating

Tolerance stack-up analysis for sub-assembly interfaces per GD&T standards

Tooling feasibility for features like louvers or countersinks within 20ga thickness constraints

The DFM report provides actionable alternatives with cost/time impact metrics, such as recommending laser cutting over stamping for low-volume prototyping to avoid tooling expenses.

Production Execution

Approved designs move to our climate-controlled production floor with dedicated automotive work cells. For 20 gauge parts:

Material is verified via handheld XRF for alloy composition and lot-tracked to mill certificates

Cutting employs 4kW fiber lasers with nitrogen assist for burr-free edges critical to sealing surfaces

Press brakes use coining techniques with real-time angle feedback to hold ±0.5° bend tolerances

Secondary operations like PEM insertion or robotic welding follow AIAG-recommended parameters

In-process inspections at critical stages (e.g., post-bending, pre-coating) utilize CMM and optical comparators, with full FAI reports available per PPAP Level 3 requirements.

Delivery and Documentation

Finished components undergo final automotive-grade validation including:

Dimensional verification against primary datums

Coating thickness testing per ASTM B487

Visual inspection for surface defects under 100 lux lighting

Shipments include material certs, process flow diagrams, and non-conformance reports if applicable. Parts are packaged in ESD-safe, barcoded containers with FCA terms clearly defined. Standard delivery is 10–15 business days for prototyping quantities, with expedited options for urgent automotive validation cycles.

This integrated approach minimizes iteration risks for thin-gauge automotive components while maintaining traceability from digital model to physical part. All processes are auditable through our QMS portal, providing clients real-time visibility into production status and quality metrics.

Start Your Project

Looking for high-precision 20 gauge automotive sheet metal components? Honyo Prototype delivers consistent quality with fast turnaround times for prototyping and low-volume production. Our manufacturing facility in Shenzhen is equipped to handle demanding automotive specifications with tight tolerances and robust material controls.

For project inquiries or to request a quote, contact Susan Leo at [email protected]. We provide comprehensive DFM feedback, rapid prototyping, and scalable production solutions tailored to your automotive engineering requirements.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.