Introduction: Navigating the Global Market for 19 gauge metal

The global market for 19 gauge metal presents a unique set of challenges for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. Sourcing high-quality 19 gauge metal, which offers a balance between durability and weight, is crucial for various applications including construction, automotive, and manufacturing. However, understanding the nuances of gauge measurements and the implications of different materials can be daunting. This guide aims to demystify the complexities surrounding 19 gauge metal, providing a comprehensive overview of its types, applications, and the critical factors to consider when vetting suppliers.

In this guide, you will discover essential insights into the diverse applications of 19 gauge metal, from structural components to decorative elements. We will delve into the various standards of gauge measurements, ensuring you can accurately assess thickness and weight across different materials. Additionally, we will cover supplier vetting processes, cost considerations, and tips for negotiating favorable terms. By equipping you with this knowledge, this guide empowers informed purchasing decisions that can enhance your operational efficiency and project outcomes. Whether you’re based in Brazil or Nigeria, navigating the 19 gauge metal market with confidence has never been more achievable.

Understanding 19 gauge metal Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cold Rolled Steel | Smooth surface finish, higher strength, precision dimensions | Automotive parts, appliance casings | Pros: Excellent surface finish, good dimensional accuracy. Cons: More expensive than hot rolled variants. |

| Galvanized Steel | Coated with zinc for corrosion resistance | Construction, HVAC systems | Pros: Enhanced durability, rust resistance. Cons: Coating may chip, requiring careful handling. |

| Stainless Steel | Corrosion-resistant alloy with a polished finish | Food processing, medical equipment | Pros: High corrosion resistance, aesthetic appeal. Cons: Higher cost, more complex fabrication processes. |

| Aluminum | Lightweight, non-corrosive metal with good strength-to-weight ratio | Aerospace, automotive, packaging | Pros: Lightweight, good thermal conductivity. Cons: Lower strength compared to steel, can be more expensive. |

| Brass | Copper-zinc alloy known for its machinability | Plumbing fittings, decorative items | Pros: Excellent machinability, antimicrobial properties. Cons: Prone to tarnishing, higher cost than some other metals. |

What Are the Characteristics of Cold Rolled Steel in 19 Gauge?

Cold rolled steel is produced through a process that involves rolling the metal at room temperature, which imparts a smooth surface finish and precise dimensions. This type of 19 gauge metal is commonly used in applications requiring high strength and durability, such as automotive parts and appliance casings. When purchasing cold rolled steel, buyers should consider its cost relative to performance, as it tends to be more expensive than hot rolled alternatives but offers superior surface quality and mechanical properties.

How Does Galvanized Steel Enhance Durability?

Galvanized steel is a 19 gauge metal coated with zinc to protect against corrosion, making it an ideal choice for construction and HVAC systems. This coating provides an additional layer of protection, significantly extending the lifespan of the material in harsh environments. Buyers should be aware that while galvanized steel is durable, the zinc coating can chip if mishandled, which may expose the underlying metal to corrosion. Understanding the environment in which the metal will be used is crucial for making informed purchasing decisions.

Why Choose Stainless Steel for Specific Applications?

Stainless steel in 19 gauge offers high corrosion resistance and a polished aesthetic, making it suitable for industries such as food processing and medical equipment. Its ability to withstand harsh conditions without degrading makes it a preferred choice for applications where hygiene and durability are critical. However, the higher cost and complex fabrication requirements can be a consideration for buyers. Evaluating the long-term benefits against initial costs is essential for businesses looking to invest in stainless steel.

What Advantages Does Aluminum Provide as 19 Gauge Metal?

Aluminum is a lightweight, non-corrosive metal that boasts a favorable strength-to-weight ratio, making it highly sought after in the aerospace and automotive sectors. Its excellent thermal conductivity also makes it suitable for various packaging applications. However, while aluminum is advantageous for its weight and resistance to corrosion, it may not offer the same strength as steel and can be more expensive. Buyers should assess their specific application needs to determine if aluminum is the right choice.

What Makes Brass a Unique Option in 19 Gauge Metal?

Brass, an alloy of copper and zinc, is known for its excellent machinability and antimicrobial properties, making it ideal for plumbing fittings and decorative items. Its attractive appearance and ease of machining make it a popular choice for custom parts. However, brass can tarnish over time and is generally more expensive than other metals. Buyers should weigh the aesthetic and functional benefits of brass against its potential maintenance needs and cost implications.

Key Industrial Applications of 19 gauge metal

| Industry/Sector | Specific Application of 19 gauge metal | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Manufacturing of vehicle body panels | Lightweight yet durable, improving fuel efficiency | Ensure compliance with automotive standards and specifications. |

| Construction | Structural framing and support systems | Provides strength and stability in building projects | Consider local regulations and availability of corrosion-resistant options. |

| HVAC Systems | Ductwork fabrication | Enhances energy efficiency and airflow management | Focus on precision cutting and custom sizing for specific installations. |

| Appliances | Components for household appliances | Offers durability and aesthetic appeal in consumer products | Verify compatibility with various appliance designs and energy standards. |

| Agricultural Equipment | Fabrication of farm machinery components | Increases longevity and performance under harsh conditions | Assess the need for rust resistance and weight specifications. |

How is 19 Gauge Metal Used in the Automotive Industry?

In the automotive sector, 19 gauge metal is primarily utilized for manufacturing vehicle body panels. Its thickness strikes a balance between weight and strength, which is crucial for enhancing fuel efficiency without compromising safety. For international buyers, especially from regions like Africa and South America, sourcing must include adherence to specific automotive standards, such as ISO certifications, to ensure product integrity and safety.

What Role Does 19 Gauge Metal Play in Construction?

Within the construction industry, 19 gauge metal is essential for structural framing and support systems. It provides the necessary strength to withstand loads while being lightweight, which is advantageous for modern building techniques. Buyers should consider local building codes and the availability of corrosion-resistant finishes, particularly in regions with harsh climates, to ensure the longevity of their projects.

Why is 19 Gauge Metal Important for HVAC Systems?

In HVAC systems, 19 gauge metal is extensively used in ductwork fabrication. Its robust nature allows for improved energy efficiency and effective airflow management, which are critical for maintaining indoor climate control. Buyers must emphasize precision cutting and custom sizing to fit specific installations, ensuring that the metal meets the required dimensions for optimal performance.

How is 19 Gauge Metal Utilized in Appliances?

19 gauge metal serves as a fundamental component in the manufacturing of household appliances, providing both durability and aesthetic appeal. It can be found in items ranging from refrigerators to washing machines, where it contributes to the overall design and functionality. B2B buyers should verify compatibility with various appliance designs and ensure compliance with energy standards to meet consumer expectations.

What Benefits Does 19 Gauge Metal Offer in Agricultural Equipment?

In agricultural equipment, 19 gauge metal is used to fabricate components that must endure harsh conditions, such as tractors and harvesters. Its durability enhances the longevity and performance of machinery, which is vital for productivity in the agricultural sector. Buyers should assess the need for rust resistance and specific weight specifications to ensure that the equipment performs effectively in various environments.

3 Common User Pain Points for ’19 gauge metal’ & Their Solutions

Scenario 1: Understanding Gauge Thickness Variations

The Problem:

A common challenge B2B buyers face when sourcing 19 gauge metal is the confusion surrounding gauge thickness across different materials. The gauge system is non-linear, meaning that the actual thickness of 19 gauge can vary significantly depending on whether it’s steel, aluminum, or another metal. For instance, 19 gauge steel measures approximately 1.062 mm, while 19 gauge aluminum is only about 0.0418 inches (1.062 mm). This discrepancy can lead to miscalculations in project specifications, resulting in structural integrity issues or increased material costs due to excess waste or reordering.

The Solution:

To overcome this issue, buyers should utilize comprehensive gauge conversion charts specific to the materials they are working with. It’s crucial to understand the precise measurements associated with each metal type. B2B buyers can also implement a thorough quality assurance process that involves verifying gauge thickness upon delivery. When placing orders, clearly specify the type of metal along with the gauge, and request confirmation of thickness in both millimeters and inches. By maintaining open communication with suppliers, buyers can ensure that they receive the correct material for their projects, reducing the risk of costly errors.

Scenario 2: Sourcing Reliable Suppliers for 19 Gauge Metal

The Problem:

Finding reliable suppliers for 19 gauge metal can be a daunting task, especially for businesses operating in regions with less established supply chains. Buyers often encounter inconsistent quality, delayed deliveries, and inflated prices. These issues can severely disrupt production schedules and lead to project delays, especially in industries that rely heavily on timely materials, such as construction or manufacturing.

The Solution:

To effectively source 19 gauge metal, B2B buyers should conduct thorough research on potential suppliers, considering their reputation, product range, and customer reviews. Engaging with local and international suppliers can provide a broader selection and potentially better pricing. Establishing long-term partnerships with a few trusted suppliers can lead to better negotiation terms and priority service. Additionally, utilizing platforms that specialize in connecting buyers with manufacturers can streamline the sourcing process. When negotiating contracts, consider including clauses that ensure timely delivery and quality guarantees to mitigate risks associated with supply chain disruptions.

Scenario 3: Ensuring Proper Fabrication Techniques for 19 Gauge Metal

The Problem:

When working with 19 gauge metal, buyers often face challenges related to proper fabrication techniques. Inadequate knowledge of cutting, bending, and welding methods can lead to structural weaknesses or aesthetic issues in the final product. This problem is particularly pronounced when companies attempt to work with this gauge without the necessary equipment or expertise, resulting in wasted materials and increased labor costs.

The Solution:

To ensure effective fabrication of 19 gauge metal, companies should invest in training for their workforce regarding the best practices for handling this thickness. This includes understanding appropriate cutting methods, such as laser or plasma cutting, which provide cleaner edges and reduce material stress. Bending techniques should also be optimized, as improper bends can compromise the integrity of the metal. Engaging with experienced fabricators or consultants during the initial design phase can provide valuable insights into the most efficient methods for working with 19 gauge metal. Additionally, investing in high-quality tools and equipment specifically designed for working with this gauge can significantly enhance the quality of the finished product, ultimately saving time and resources.

Strategic Material Selection Guide for 19 gauge metal

When selecting the appropriate material for 19 gauge metal applications, it is essential to consider various factors such as mechanical properties, cost, and specific application requirements. This analysis will focus on four common materials: cold-rolled steel, galvanized steel, stainless steel, and aluminum. Each material offers unique advantages and disadvantages that can significantly impact product performance and suitability for international markets.

What are the Key Properties of Cold-Rolled Steel for 19 Gauge Metal?

Cold-rolled steel is known for its excellent strength-to-weight ratio and surface finish. It typically exhibits good mechanical properties, including a tensile strength of approximately 40,000 psi and yield strength around 30,000 psi. Cold-rolled steel is also easy to machine and weld, making it suitable for various fabrication processes. However, it has limited corrosion resistance, which can be a drawback in humid or corrosive environments.

Pros: High strength, good surface finish, ease of fabrication.

Cons: Limited corrosion resistance, may require additional coatings for outdoor applications.

Impact on Application: Best suited for structural applications and indoor environments where corrosion is not a primary concern.

Considerations for International Buyers: Compliance with ASTM standards is crucial, especially in regions with strict quality regulations.

How Does Galvanized Steel Perform as 19 Gauge Metal?

Galvanized steel is cold-rolled steel that has been coated with zinc to enhance its corrosion resistance. This material is particularly effective in outdoor applications where exposure to moisture and environmental elements is a concern. Galvanized steel typically retains the mechanical properties of cold-rolled steel while offering improved durability.

Pros: Excellent corrosion resistance, retains strength properties, cost-effective.

Cons: The zinc coating can be damaged during fabrication, exposing the underlying steel to corrosion.

Impact on Application: Ideal for outdoor structures, roofing, and automotive applications.

Considerations for International Buyers: Familiarity with local standards for galvanized coatings (such as ASTM A123) is essential for ensuring compliance.

What Are the Advantages of Using Stainless Steel for 19 Gauge Metal?

Stainless steel is renowned for its superior corrosion resistance, making it an ideal choice for applications in harsh environments. It typically has a tensile strength of around 70,000 psi and excellent temperature resistance. Stainless steel is also non-reactive, which is crucial for food processing and medical applications.

Pros: Exceptional corrosion resistance, high strength, and temperature tolerance.

Cons: Higher cost compared to other metals, more challenging to machine and weld.

Impact on Application: Suitable for food processing, chemical storage, and medical equipment.

Considerations for International Buyers: Compliance with specific standards like ASTM A240 for stainless steel is vital, especially in regulated industries.

Why is Aluminum a Popular Choice for 19 Gauge Metal Applications?

Aluminum is lightweight and offers good corrosion resistance, making it a popular choice for various applications, including automotive and aerospace. Its tensile strength is lower than that of steel, but it compensates with high ductility and ease of fabrication. Aluminum is also non-magnetic and has excellent thermal conductivity.

Pros: Lightweight, good corrosion resistance, easy to work with.

Cons: Lower strength compared to steel, can be more expensive.

Impact on Application: Ideal for applications where weight savings are critical, such as in transportation and packaging.

Considerations for International Buyers: Understanding local preferences for aluminum alloys and compliance with standards like ASTM B209 is important for ensuring product quality.

Summary Table of Material Selection for 19 Gauge Metal

| Material | Typical Use Case for 19 Gauge Metal | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cold-Rolled Steel | Structural applications | High strength | Limited corrosion resistance | Medium |

| Galvanized Steel | Outdoor structures | Excellent corrosion resistance | Zinc coating can be damaged | Medium |

| Stainless Steel | Food processing, medical equipment | Exceptional corrosion resistance | Higher cost, harder to machine | High |

| Aluminum | Automotive, aerospace | Lightweight | Lower strength compared to steel | Medium to High |

This guide provides a comprehensive overview of the strategic material selection for 19 gauge metal, enabling B2B buyers to make informed decisions based on application requirements and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for 19 gauge metal

What Are the Key Manufacturing Processes for 19 Gauge Metal?

The manufacturing of 19 gauge metal involves several critical stages that ensure the final product meets the desired specifications for strength, durability, and functionality. Understanding these processes is essential for B2B buyers who aim to source high-quality metal products.

How Is Material Prepared for 19 Gauge Metal Production?

The initial stage in the manufacturing process is material preparation, which includes selecting the appropriate type of steel or other metals based on the intended application. For 19 gauge metal, the thickness typically measures 0.0418 inches (1.062 mm). The chosen material is often cold-rolled steel, known for its improved surface finish and tighter tolerances compared to hot-rolled alternatives.

Once the material is selected, it undergoes cutting to size, where large sheets are trimmed down to manageable dimensions. This step may involve shearing or laser cutting techniques, depending on the precision required. The cut pieces are then subjected to cleaning processes to remove any contaminants, such as oils or residues from manufacturing.

What Forming Techniques Are Used in 19 Gauge Metal Fabrication?

Forming is a pivotal stage where the prepared metal is shaped into the desired form. Common techniques include bending, stamping, and deep drawing, which allow manufacturers to create complex geometries and designs. For example, bending operations may use press brakes to achieve precise angles and curves, while stamping can produce intricate patterns or holes.

Die cutting is another prevalent method, particularly in high-volume production, as it allows for efficient and consistent shaping of metal sheets. Each technique demands specific machinery and tooling, which must be calibrated to handle the thickness and properties of 19 gauge metal.

How Is Assembly Conducted for 19 Gauge Metal Products?

Assembly can involve various methods, including welding, riveting, or fastening, depending on the application. For instance, when producing components for automotive or construction applications, welding is often the preferred method due to its ability to create strong, permanent joints. Riveting may be used in situations where disassembly is necessary for maintenance or repair.

Quality at this stage is crucial, as improper assembly can lead to structural failures. Therefore, manufacturers often implement jigs and fixtures to ensure parts are aligned correctly during the assembly process, reducing the risk of defects.

What Finishing Processes Are Applied to 19 Gauge Metal?

Finishing processes enhance both the aesthetic and functional qualities of the metal. Common techniques include powder coating, galvanizing, or applying a protective sealant. These processes not only improve the appearance but also offer resistance to corrosion, wear, and other environmental factors.

Additionally, surface treatments such as polishing or anodizing may be employed to achieve specific surface qualities. B2B buyers should inquire about the finishing processes used by suppliers, as these can significantly impact the product’s longevity and performance.

How Is Quality Assurance Managed in 19 Gauge Metal Manufacturing?

Quality assurance (QA) is integral to the manufacturing of 19 gauge metal, ensuring that products meet international standards and customer specifications. B2B buyers should be aware of the various QA methodologies employed by manufacturers.

What International Standards Should B2B Buyers Know?

Manufacturers often adhere to international quality standards such as ISO 9001, which outlines requirements for a quality management system. This certification indicates a commitment to consistent quality and customer satisfaction. Additionally, industry-specific standards like CE marking (for European markets) and API specifications (for the oil and gas sector) may apply, depending on the product’s end use.

Understanding these standards allows buyers to assess a supplier’s commitment to quality and compliance with international regulations.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves several checkpoints throughout the manufacturing process to identify and rectify defects. These checkpoints typically include:

- Incoming Quality Control (IQC): Inspects raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Monitors production processes to catch defects early, thereby minimizing waste and rework.

- Final Quality Control (FQC): Conducts thorough inspections of finished products before shipment, ensuring they comply with specifications.

Implementing these checkpoints provides a systematic approach to maintaining quality throughout the production cycle.

What Testing Methods Are Commonly Used for 19 Gauge Metal?

Several testing methods are employed to verify the quality and performance of 19 gauge metal products. These may include:

- Visual Inspections: To identify surface defects, such as scratches or dents.

- Dimensional Testing: Ensures that the finished product meets specified dimensions using tools like calipers and gauges.

- Mechanical Testing: Evaluates properties such as tensile strength, yield strength, and hardness through standardized tests.

B2B buyers should inquire about the specific testing methods used by suppliers to ensure products meet the necessary performance criteria.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that a supplier maintains high-quality standards, B2B buyers should consider several verification strategies:

- Supplier Audits: Conducting regular audits of suppliers can provide insights into their quality management practices and compliance with international standards.

- Quality Reports: Requesting detailed quality reports can help buyers understand the supplier’s performance history and any corrective actions taken.

- Third-Party Inspections: Engaging third-party inspectors can provide an unbiased assessment of the supplier’s quality control processes and the final products.

What Are the Quality Control Nuances for International Buyers?

International B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control. Variations in local regulations, standards, and testing methods can impact product compliance.

Buyers should also consider logistical factors, such as shipping and customs regulations, which may affect delivery timelines and product integrity. Establishing clear communication with suppliers about these factors is vital to ensure a smooth procurement process.

In conclusion, understanding the manufacturing processes and quality assurance protocols for 19 gauge metal is crucial for B2B buyers aiming to source reliable products. By considering these factors, buyers can make informed decisions that align with their quality requirements and operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ’19 gauge metal’

Introduction

This guide is designed to assist B2B buyers in sourcing 19 gauge metal effectively. As this material is widely used in various applications, understanding the key steps in procurement can streamline your buying process, ensuring you receive high-quality products that meet your specifications.

Step 1: Define Your Technical Specifications

Before starting your search for suppliers, clearly define the technical specifications of the 19 gauge metal you need. This includes the type of metal (e.g., cold-rolled steel, stainless steel), dimensions, and any specific treatments (e.g., galvanized, powder-coated). Providing precise specifications helps suppliers understand your requirements and reduces the risk of receiving incorrect materials.

Step 2: Research Reputable Suppliers

Conduct thorough research to identify reputable suppliers who specialize in 19 gauge metal. Utilize platforms like industry directories, trade shows, and online reviews to compile a list of potential vendors. Look for suppliers with a proven track record and positive feedback from previous clients in similar markets or industries.

Step 3: Evaluate Supplier Certifications

Verify that your shortlisted suppliers hold the necessary certifications, such as ISO 9001 or other relevant quality management standards. These certifications demonstrate a commitment to quality and compliance with industry regulations. Additionally, check if they adhere to environmental standards, which can be particularly important for buyers in regions with strict environmental laws.

Step 4: Request Samples for Quality Assessment

Before placing a bulk order, request samples of the 19 gauge metal from potential suppliers. Inspect these samples for thickness, finish, and overall quality. This step is vital to ensure the metal meets your technical specifications and to assess the supplier’s manufacturing capabilities.

Step 5: Inquire About Lead Times and Delivery Options

Discuss lead times and delivery options with your suppliers to ensure they can meet your project timelines. Understanding their production capacity and shipping methods helps you plan your project effectively and avoid delays. Ask about their logistics partners to gauge reliability.

Step 6: Negotiate Pricing and Terms

Once you’ve identified a suitable supplier, engage in negotiations regarding pricing, payment terms, and order quantities. Be clear about your budget and seek volume discounts if applicable. A transparent discussion about pricing will help establish a good working relationship and prevent misunderstandings later.

Step 7: Establish a Clear Communication Channel

Set up a reliable communication channel with your chosen supplier to facilitate ongoing discussions about orders, deliveries, and any issues that may arise. Regular communication helps ensure that both parties are aligned and can swiftly address any concerns, leading to a smoother procurement process.

By following these steps, B2B buyers can effectively navigate the sourcing process for 19 gauge metal, ensuring they obtain high-quality materials that meet their specific needs.

Comprehensive Cost and Pricing Analysis for 19 gauge metal Sourcing

What Are the Key Cost Components in Sourcing 19 Gauge Metal?

When sourcing 19 gauge metal, various cost components come into play that can significantly influence the final price. The primary components include:

-

Materials: The cost of raw materials is a major factor. For 19 gauge steel, the price can vary based on market conditions, the type of steel (e.g., cold-rolled, galvanized), and regional price fluctuations. It’s essential to understand the current market trends for steel to anticipate costs.

-

Labor: Labor costs will vary depending on the region and the complexity of the fabrication required. Higher labor costs in developed markets can be offset by lower costs in developing regions, but this may affect lead times and quality.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, equipment maintenance, and administrative costs. Efficient manufacturing processes can help minimize overhead, which in turn lowers the overall price of the metal.

-

Tooling: If custom tooling is required for specific projects, this can add to initial costs. Understanding the tooling needs early in the sourcing process can help in budgeting accurately.

-

Quality Control (QC): Implementing stringent QC processes ensures that the metal meets required specifications and standards. While this adds to costs, it can prevent expensive mistakes later in the production process.

-

Logistics: Transportation and handling costs are critical, especially for international shipments. Factors like distance, shipping method, and local tariffs can significantly impact the final pricing.

-

Margin: Suppliers typically include a margin that reflects their profit expectations. Understanding the typical margins in the industry can help buyers negotiate better.

What Price Influencers Should International Buyers Consider for 19 Gauge Metal?

Several factors can influence the pricing of 19 gauge metal, particularly for international buyers from regions like Africa, South America, the Middle East, and Europe:

-

Volume and Minimum Order Quantities (MOQ): Buying in bulk often leads to lower per-unit costs. However, ensure that the volume aligns with your production needs to avoid excess inventory.

-

Specifications and Customization: Custom specifications may drive up costs. Standard sizes and specifications tend to be more cost-effective, so consider whether customization is essential for your project.

-

Material Quality and Certifications: Higher quality materials or those with specific certifications (e.g., ISO, ASTM) can command premium prices. Evaluate if these certifications are necessary for your application.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more due to their reliability, while new entrants might offer lower prices to attract business.

-

Incoterms: Understanding Incoterms is crucial for international transactions. They define responsibilities for shipping, risk, and costs, affecting the total landed cost of the metal.

How Can Buyers Negotiate and Achieve Cost Efficiency in Sourcing 19 Gauge Metal?

Buyers can adopt several strategies to ensure cost efficiency when sourcing 19 gauge metal:

-

Negotiation: Engage suppliers in discussions about pricing. Presenting competitive quotes from other suppliers can often lead to better offers. Leverage long-term relationships for better pricing and terms.

-

Total Cost of Ownership (TCO): Rather than just focusing on the purchase price, consider the TCO, which includes acquisition, maintenance, and operational costs. A higher upfront cost might be justified if it leads to lower long-term expenses.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import duties, and tariffs that may affect total costs. Building relationships with local suppliers can sometimes mitigate these issues.

-

Market Research: Staying informed about market trends and price fluctuations can help you time your purchases more effectively. Utilize online tools and market reports to gauge the best times to buy.

Disclaimer on Indicative Prices

Prices for 19 gauge metal can fluctuate based on market conditions, material availability, and geopolitical factors. As such, the figures discussed in this analysis are indicative and should be verified with suppliers for accurate and current pricing. Always consult multiple sources to ensure you are getting the best possible deal.

Alternatives Analysis: Comparing 19 gauge metal With Other Solutions

Exploring Alternatives to 19 Gauge Metal: A Comparative Analysis

In the realm of metal fabrication and construction, choosing the right material is crucial for achieving desired performance and cost-effectiveness. While 19 gauge metal is a popular choice for various applications, there are alternative solutions that may better suit specific needs. This analysis compares 19 gauge metal against two viable alternatives: aluminum and high-strength steel. Each option presents distinct advantages and challenges, making it essential for B2B buyers to evaluate them carefully.

| Comparison Aspect | 19 Gauge Metal | Aluminum | High-Strength Steel |

|---|---|---|---|

| Performance | Good structural integrity, moderate weight | Lightweight, corrosion-resistant, but less structural integrity compared to steel | Exceptional strength and durability, higher weight |

| Cost | Generally affordable, but varies by region | Higher initial cost but lower lifecycle costs due to durability | Higher initial investment, but long-term savings on maintenance |

| Ease of Implementation | Easily fabricated and welded | Requires specialized techniques for joining | Standard fabrication methods apply but may require more robust equipment |

| Maintenance | Moderate; prone to rust without treatment | Low; corrosion-resistant | Moderate; requires periodic inspection and maintenance |

| Best Use Case | Structural applications, HVAC, automotive | Lightweight structures, aerospace, marine applications | Heavy-duty construction, automotive frames, industrial applications |

An In-Depth Look at Alternatives

Aluminum: Lightweight and Versatile

Aluminum is a lightweight metal that offers excellent corrosion resistance, making it a preferred choice for applications where weight savings are crucial. Its ease of fabrication allows for intricate designs, especially in aerospace and marine applications. However, aluminum’s lower structural integrity compared to steel can be a drawback in high-stress environments. Additionally, while initial costs may be higher, the long-term savings due to its durability can offset this.

High-Strength Steel: Superior Strength for Heavy-Duty Applications

High-strength steel is engineered to provide exceptional strength and durability, making it ideal for demanding environments such as construction and heavy machinery. Its ability to withstand high stress means it is often used in structural components that require maximum load-bearing capacity. However, the initial investment is typically higher, and while it offers long-term savings, maintenance and inspection are necessary to ensure longevity. The weight of high-strength steel can also be a consideration in applications where weight is a factor.

Conclusion: Choosing the Right Solution for Your Needs

When evaluating whether to use 19 gauge metal or explore alternatives like aluminum and high-strength steel, B2B buyers should consider the specific requirements of their projects. Factors such as performance needs, cost constraints, ease of implementation, and maintenance capabilities play a significant role in the decision-making process. By aligning material choices with project goals, businesses can optimize their operations and ensure the durability and efficacy of their applications.

Essential Technical Properties and Trade Terminology for 19 gauge metal

What Are the Key Technical Properties of 19 Gauge Metal?

When considering 19 gauge metal, several critical specifications influence its applicability in various industries. Understanding these properties can guide B2B buyers in making informed decisions.

-

Material Grade

– The material grade indicates the specific composition and quality of the metal. Common grades for 19 gauge steel include ASTM A1008 for cold-rolled steel and ASTM A36 for structural applications. Knowing the grade is crucial for assessing strength, corrosion resistance, and suitability for specific applications. -

Thickness

– The thickness of 19 gauge metal measures approximately 0.0418 inches or 1.062 mm. This specification directly impacts the metal’s strength and weight, which are vital for structural integrity in construction and manufacturing. Buyers must ensure that the thickness meets their project requirements to avoid underperformance. -

Tolerance

– Tolerance refers to the allowable variation in metal thickness and dimensions. For 19 gauge metal, typical tolerances might range from ±0.005 inches. Understanding tolerance is essential for ensuring that parts fit together correctly, especially in precision engineering applications. -

Weight Per Unit Area

– The weight per unit area for 19 gauge steel is about 8.326 lb/ft² (40.44 kg/m²). This property is significant for logistics and transportation considerations, as it affects shipping costs and structural support requirements in installations. -

Corrosion Resistance

– Depending on the finishing process, such as galvanization, 19 gauge metal can exhibit varying levels of corrosion resistance. Buyers should consider environmental factors—such as humidity and exposure to chemicals—when selecting the appropriate finish to prolong the lifespan of the metal.

What Are Common Trade Terms Associated with 19 Gauge Metal?

Understanding industry-specific terminology is vital for effective communication and negotiation. Here are several key terms frequently encountered in the B2B metal industry.

-

OEM (Original Equipment Manufacturer)

– An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. For buyers, partnering with an OEM can ensure access to high-quality components tailored for specific applications. -

MOQ (Minimum Order Quantity)

– MOQ refers to the smallest amount of product a supplier is willing to sell. Understanding the MOQ is essential for budgeting and inventory management, particularly for international buyers who may face additional shipping costs. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting a quote for specific quantities and specifications of products. This term is crucial for buyers to facilitate competitive bidding and ensure they receive the best prices and terms. -

Incoterms (International Commercial Terms)

– Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms helps prevent misunderstandings and financial risks in cross-border transactions. -

Lead Time

– Lead time is the time taken from placing an order to the delivery of goods. In the context of 19 gauge metal, understanding lead times can help businesses plan their projects more effectively, ensuring that production schedules align with material availability. -

Fabrication

– Fabrication refers to the process of creating metal structures by cutting, bending, and assembling. Knowing the fabrication capabilities of suppliers can help buyers determine whether a provider can meet their specific project requirements.

By understanding these technical properties and trade terms, B2B buyers can navigate the complexities of sourcing 19 gauge metal more effectively, ensuring they meet their project specifications while optimizing costs and timelines.

Navigating Market Dynamics and Sourcing Trends in the 19 gauge metal Sector

What Are the Current Market Trends in the 19 Gauge Metal Sector?

The 19 gauge metal sector is witnessing significant growth driven by various global dynamics. Increased demand for durable materials in construction, automotive, and manufacturing sectors is propelling the market. In regions like Africa, South America, the Middle East, and Europe, infrastructure development projects are particularly influential. The trend towards lightweight materials without compromising strength is leading to a rise in the use of 19 gauge metals, especially in applications where structural integrity is critical, such as in roofing and wall panels.

Emerging B2B technologies are also shaping sourcing practices. Digital platforms are enhancing transparency in supply chains, allowing international buyers to access real-time data on pricing, availability, and supplier reliability. Additionally, the trend towards localized sourcing is gaining traction, as businesses seek to mitigate risks associated with global supply chain disruptions. For buyers in regions like Nigeria and Brazil, engaging with suppliers who offer both quality and sustainability can provide a competitive advantage.

Furthermore, the increase in automation and advanced manufacturing techniques is changing the landscape of metal fabrication. Buyers can now leverage technologies such as CNC machining and laser cutting, which not only improve precision but also reduce waste, aligning with the growing demand for efficient production processes.

How Is Sustainability Shaping the Sourcing of 19 Gauge Metal?

Sustainability has become a cornerstone in the sourcing of 19 gauge metal, as environmental impact considerations increasingly influence purchasing decisions. The production of metals, particularly steel, has significant energy consumption and carbon emissions associated with it. International buyers are now prioritizing suppliers who adopt eco-friendly practices, including the use of recycled materials and renewable energy sources in their operations.

Ethical sourcing is equally crucial, with an emphasis on supply chains that respect labor rights and community welfare. Certifications such as ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) are becoming essential criteria for B2B partnerships. Buyers looking to enhance their brand image and meet regulatory requirements are increasingly seeking suppliers who can provide documentation of their sustainability practices.

Moreover, the rise of green building initiatives globally is creating demand for ‘green’ certified materials. For instance, 19 gauge metal products that meet specific environmental standards can be a deciding factor for businesses involved in construction and architecture. Buyers should ensure that their suppliers not only provide high-quality materials but also demonstrate a commitment to sustainable practices, thus aligning with the growing market demand for environmentally responsible products.

What Is the Historical Context of 19 Gauge Metal in B2B Sourcing?

The gauge system for metals has a rich history, originating from the British wire industry before the adoption of standardized measurement systems. The concept of gauge was initially used to indicate the thickness of wire, with the scale evolving to encompass sheet metals, including 19 gauge steel. Over the years, the gauge system has been adapted to various materials, with specific standards established for steel, aluminum, and other metals.

In the B2B context, understanding the historical significance of gauge measurements can enhance sourcing strategies. The development of gauge charts has facilitated better communication between buyers and suppliers, ensuring that specifications meet the required dimensions for various applications. As the market continues to evolve, so too does the importance of these historical standards in guiding purchasing decisions and fostering reliable supplier relationships.

By integrating these insights into sourcing strategies, international buyers can navigate the complexities of the 19 gauge metal sector, ensuring they make informed decisions that align with current market trends and sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of 19 gauge metal

-

How do I determine the appropriate thickness for 19 gauge metal in my project?

To determine the appropriate thickness for 19 gauge metal, you should first consider the specific requirements of your project. The thickness of 19 gauge metal is approximately 0.0418 inches (1.062 mm). Assess factors like the intended application, load-bearing requirements, and environmental conditions. Consulting with a materials engineer or supplier can provide insights tailored to your specific needs and ensure that you select the right gauge for optimal performance and durability. -

What is the best application for 19 gauge metal in various industries?

19 gauge metal is versatile and commonly used in industries such as automotive, construction, and manufacturing. It is ideal for applications that require a balance of strength and weight, such as HVAC ductwork, shelving, and brackets. Additionally, its moderate thickness makes it suitable for both indoor and outdoor use, particularly in environments where corrosion resistance is essential. Understanding your industry’s specific requirements will help you leverage 19 gauge metal effectively. -

How can I vet suppliers of 19 gauge metal for international trade?

When vetting suppliers for international trade, consider their industry reputation, certifications, and compliance with international standards. Request references and samples to evaluate product quality. It’s also beneficial to check their production capabilities and lead times, especially if you have specific requirements. Engaging in direct communication can help assess their responsiveness and reliability. Using platforms like Alibaba or industry-specific directories can aid in finding reputable suppliers. -

What are common customization options for 19 gauge metal?

Customization options for 19 gauge metal typically include cutting, bending, coating, and surface finishing. Suppliers often offer services to tailor the metal to specific dimensions and shapes based on your project needs. Additionally, you can request protective coatings or finishes to enhance corrosion resistance or aesthetic appeal. Discussing your requirements with suppliers can help identify the best customization options available to meet your unique specifications. -

What is the minimum order quantity (MOQ) for purchasing 19 gauge metal?

The minimum order quantity (MOQ) for 19 gauge metal varies by supplier and can range from a few sheets to several tons. Factors affecting MOQ include supplier capabilities, production schedules, and shipping logistics. It’s advisable to communicate directly with potential suppliers to understand their MOQ policies. If you require a smaller quantity, some suppliers may offer cut-to-size options or allow for bulk purchasing with shared orders from multiple clients. -

What payment terms should I expect when sourcing 19 gauge metal internationally?

Payment terms for international metal sourcing can vary widely, but common practices include upfront deposits, net 30 or net 60 terms, and letters of credit. Suppliers may require a deposit (typically 30-50%) upon order confirmation, with the balance due before shipment. Negotiating favorable terms based on your relationship with the supplier and order size is advisable. Always ensure that payment methods are secure and that you have a clear understanding of any additional fees related to currency exchange or transaction processing. -

How can I ensure quality assurance (QA) for my 19 gauge metal orders?

To ensure quality assurance for your 19 gauge metal orders, establish clear specifications and quality standards upfront. Request documentation, such as mill test reports or certificates of compliance, to verify the material’s properties. Conduct inspections at various stages of production, if possible, and consider third-party quality assurance services for added reliability. Open communication with your supplier about your QA expectations can help maintain product quality throughout the manufacturing process. -

What logistics considerations should I keep in mind when importing 19 gauge metal?

When importing 19 gauge metal, consider logistics factors such as shipping methods, customs regulations, and delivery timelines. Choose a reliable freight forwarder experienced in handling metal shipments to navigate complex international logistics. Ensure that you have the necessary documentation, including bills of lading and customs declarations, to avoid delays. Additionally, factor in potential tariffs or duties that may apply to your import, and plan for warehousing needs upon arrival.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 19 Gauge Metal Manufacturers & Suppliers List

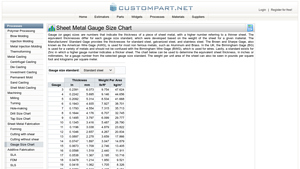

1. Custom Part Net – Sheet Metal Gauge Size Chart

Domain: custompartnet.com

Registered: 2006 (19 years)

Introduction: Sheet Metal Gauge Size Chart: Gauge sizes indicate the thickness of sheet metal, with higher numbers referring to thinner sheets. Different gauge size standards exist, including: 1. Manufacturers’ Standard Gage for standard steel, galvanized steel, and stainless steel. 2. Brown and Sharpe Gage (American Wire Gage) for non-ferrous metals like Aluminum and Brass. 3. Birmingham Gage (UK) for various …

2. MK Metal – CRS Sheet 19 Ga X 48 X 120

Domain: mkmetal.net

Registered: 1999 (26 years)

Introduction: {“Product Name”: “CRS SHEET 19 GA X 48 X 120”, “Alloy”: “1008”, “Thickness”: “19 ga”, “Width”: “48 inches”, “Length”: “120 inches”, “Weight per Foot (Square Foot)”: “0.7”, “Price per Piece”: “$63.53”, “Price Each”: “$162.99”}

3. Metal Supermarkets – Sheet Metal Gauge Chart

Domain: metalsupermarkets.com

Registered: 1996 (29 years)

Introduction: Sheet Metal Gauge Chart – Metal Supermarkets offers a variety of metals including Mild Steel, Aluminum, Stainless Steel, Alloy Steel, Brass, Bronze, and Copper. The gauge system is used to specify the thickness of sheet metal, with different thicknesses for different metals. The chart includes gauge numbers and their corresponding thickness in inches and millimeters for Mild Steel, Aluminum, Stain…

4. Metals Depot – Hot Rolled Steel Sheet

Domain: metalsdepot.com

Registered: 1999 (26 years)

Introduction: {“products”:[{“type”:”Hot Rolled Steel Sheet”,”specification”:”(ASTM A1011 CS Type B)”,”description”:”Economical steel sheets with a slightly grainy surface, ideal for painting.”,”applications”:[“general fabrication”,”equipment panels”,”tool boxes”,”hoppers”,”drip pans”],”thicknesses”:[{“gauge”:16,”thickness”:”.060″,”weight”:”2.50 lb/sqft”},{“gauge”:14,”thickness”:”.075″,”weight”:”3.13 lb/sqft”},{…

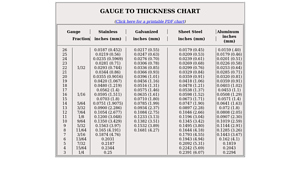

5. Stainless Supply – Gauge to Thickness Chart

Domain: stainlesssupply.com

Registered: 2000 (25 years)

Introduction: Gauge to Thickness Chart for Stainless, Galvanized Sheet Steel, and Aluminum. Includes measurements in inches and millimeters for gauges 26 to 3. For example, gauge 26 stainless steel is 0.0187 inches (0.452 mm), while gauge 3 is 0.25 inches (6.07 mm).

6. Metal Designz – Stainless Steel Jump Rings

Domain: metaldesignz.com

Registered: 2003 (22 years)

Introduction: {“product_type”:”Jump Rings”,”material”:”Stainless Steel”,”gauge”:”19 Gauge”,”sizes”:[{“id”:”5/16″”,”price_range”:”$6.30 – $46.95″},{“id”:”9/32″”,”price_range”:”$6.20 – $46.20″},{“id”:”17/64″”,”price_range”:”$6.10 – $45.46″},{“id”:”15/64″”,”price_range”:”$5.90 – $43.97″},{“id”:”13/64″”,”price_range”:”$5.70 – $42.48″},{“id”:”11/64″”,”price_range”:”$5.50 – $40.99″},{“id”:”1/8″”,”price_range”:”$5.20 …

7. Hamilton Company – Hub Needle 91019

Domain: hamiltoncompany.com

Registered: 1998 (27 years)

Introduction: {“gauge”: “19”, “hub_material”: “Metal”, “needle_type”: “Hub Needle”, “part_number”: “91019”, “manufacturer”: “Hamilton Company”}

Strategic Sourcing Conclusion and Outlook for 19 gauge metal

In today’s competitive landscape, strategic sourcing of 19 gauge metal offers significant advantages for international B2B buyers across diverse markets, including Africa, South America, the Middle East, and Europe. Understanding the specific applications and properties of 19 gauge metal—such as its optimal thickness, weight, and versatility—enables buyers to make informed decisions that align with their operational needs. This gauge is particularly favored in industries such as automotive, construction, and manufacturing due to its balance of strength and weight.

Investing in strategic sourcing not only enhances supply chain efficiency but also mitigates risks associated with fluctuating prices and availability. Establishing long-term relationships with reliable suppliers can lead to better pricing structures and improved quality control, which are essential for maintaining competitive advantage.

As we look to the future, the demand for 19 gauge metal is expected to grow, driven by advancements in manufacturing technologies and increasing global trade. B2B buyers are encouraged to explore new sourcing opportunities and leverage innovative procurement strategies. By staying ahead of market trends and fostering partnerships with reputable suppliers, businesses can position themselves for success in a dynamic marketplace.