Introduction: Navigating the Global Market for 17 4 ph hardness

When it comes to sourcing optimal 17-4 PH hardness materials, international B2B buyers face a critical challenge: identifying reliable suppliers that deliver on quality, performance, and cost-effectiveness while navigating the intricacies of different markets. This guide is designed to empower decision-makers in Africa, South America, the Middle East, and Europe (notably Germany and Brazil) by providing comprehensive insights into the diverse aspects of 17-4 stainless steel. From exploring types and strength properties to examining applications across various industries—such as aerospace, oil and gas, and chemical processing—this resource covers everything you need to understand this versatile alloy.

In addition to product specifics, our guide offers valuable strategies for vetting suppliers, helping you discern the most trustworthy partners in the global market. We delve into cost considerations and market trends, allowing buyers to align their purchasing decisions with broader economic indicators and assess the competitiveness of different offerings. By equipping you with all the necessary tools and information, this guide ensures informed purchasing decisions that align with operational goals and project requirements. With a solid grasp of the attributes and applications of 17-4 PH hardness, you can enhance your procurement strategy, ultimately fostering growth and innovation in your business.

Understanding 17 4 ph hardness Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| H900 | Highest strength, good toughness, and moderate corrosion resistance | Aerospace components, military applications | Pros: Exceptional tensile and yield strength. Cons: Less weldable compared to other grades. |

| H1025 | Reduced strength compared to H900 but better ductility and toughness | Pump parts, petrochemical applications | Pros: More formable and weldable. Cons: Lower ultimate strength than H900. |

| H1075 | Balances strength and workability, moderate toughness | Oil and gas equipment, industrial machinery | Pros: Good machinability and moderate cost. Cons: Lower fatigue resistance compared to H900. |

| H1150 | Designed for high toughness and good corrosion resistance | Chemical processing, food processing equipment | Pros: Excellent stress corrosion resistance. Cons: Lower strength than H900 and H1025. |

| H1150D | Enhanced stress corrosion resistance and lower hardness | Storage containers for radioactive materials | Pros: Superior corrosion resistance in aggressive environments. Cons: Reduced hardness and wear resistance. |

What are the Characteristics and Suitability of H900?

H900 is characterized by its exceptional tensile strength of approximately 190,000 PSI, making it ideal for applications that require high loads and stress resistance. While it exhibits moderate corrosion resistance, its primary advantage lies in its high hardness after heat treatment. Industries such as aerospace and military frequently opt for H900 due to its strength under extreme conditions. Buyers should consider the reduced weldability when selecting H900 for applications that require extensive fabrication.

How Does H1025 Benefit Industrial Applications?

H1025 offers enhanced ductility and toughness, achieving a good balance between strength and formability at approximately 155,000 PSI tensile strength. This makes it suitable for applications needing regular machining and welding, such as pump parts and components within the petrochemical industry. Buyers can appreciate its versatility; however, they should note that it does not match the strength of H900, which can be a trade-off depending on the application requirements.

What Makes H1075 a Good Choice for Manufacturing?

H1075 presents a balanced approach between strength and machinability, with a tensile strength of around 145,000 PSI. It is particularly suited for oil and gas equipment and industrial machinery, where moderate durability is necessary. This grade is cost-effective and convenient for machining, offering unique advantages for high-volume production. Buyers should keep in mind that while it provides good operational strength, it may not endure extensive fatigue conditions compared to higher grades like H900.

Why Opt for H1150 in Chemical Processing?

H1150, with a tensile strength of 135,000 PSI, excels in applications that require high toughness and excellent resistance to stress corrosion, such as in chemical and food processing equipment. Its ability to withstand corrosive environments makes it a favored choice among industries focusing on durability. While it provides a lower yield strength than its counterparts, its cost-effectiveness and reliability in harsh environments appeal to many B2B buyers.

What Advantages Does H1150D Offer for Specialized Environments?

H1150D is formulated for applications that demand outstanding stress corrosion resistance with lower hardness. With tensile strength around 125,000 PSI, it is increasingly used in specialized industries such as radioactive material storage. This grade offers unique attributes that allow it to perform well in aggressive environments, ensuring safety and durability. However, buyers need to be aware of its reduced hardness, which may not be ideal for applications requiring high wear resistance.

Key Industrial Applications of 17 4 ph hardness

| Industry/Sector | Specific Application of 17 4 ph hardness | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Engine Components and Fasteners | High strength-to-weight ratio, corrosion resistance | Certification for aerospace applications (e.g., AS9100), compliance with materials standards. |

| Oil and Gas | Pump Shafts and Valves | Durability under harsh conditions, reduced downtime | Requirements for high tensile strength and chemical resistance, sourcing from certified suppliers. |

| Chemical Processing | Reactor Vessels and Heat Exchangers | Excellent corrosion resistance, longevity | Need for custom machining and heat treatment services, adherence to safety standards. |

| Food Processing | Equipment like Pumps and Mixers | Hygiene and corrosion resistance, ease of cleaning | Compliance with food safety standards (e.g., FDA), need for specific grades of 17-4 PH. |

| Defense and Military | High-pressure Components | Reliability in extreme conditions, enhanced toughness | Requirements for durability and corrosion resistance, certification for military applications. |

What Are the Key Aerospace Applications of 17 4 PH Hardness?

In the aerospace sector, 17-4 PH stainless steel is extensively utilized for engine components and fasteners. Its impressive strength-to-weight ratio ensures that it can withstand extreme conditions while minimizing excess weight, crucial for improving efficiency in flight operations. Buyers in this sector must seek suppliers who provide certification for aerospace standards (such as AS9100) and thorough compliance with material specifications.

How Does 17 4 PH Serve the Oil and Gas Industry?

The oil and gas industry demands materials that excel in harsh environments. Here, 17-4 PH is commonly used for pump shafts and valves, where its durability and corrosion resistance are invaluable. This alloy minimizes downtime due to failure, significantly reducing costs associated with repairs. When sourcing, companies should ensure their suppliers can provide products that meet high tensile strength and chemical resistance parameters.

What Role Does 17 4 PH Play in Chemical Processing?

In chemical processing, 17-4 PH is often incorporated into reactor vessels and heat exchangers due to its exceptional corrosion resistance. These characteristics enable the material to perform effectively even in harsh chemical environments, ensuring longevity and safety. Buyers need to consider suppliers that can provide custom machining and heat treatment services, as well as adherence to stringent safety regulations in their sourcing decisions.

Why is 17 4 PH Critical in Food Processing Equipment?

For food processing, equipment such as pumps and mixers made from 17-4 PH stainless steel is essential. The alloy’s high corrosion resistance ensures that the equipment maintains hygiene standards, while its ease of cleaning is critical in maintaining food safety. Companies should focus on sourcing from suppliers who comply with food safety regulations (e.g., FDA), as specific grades may be required for different applications.

How is 17 4 PH Utilized in Defense and Military Applications?

In the defense sector, high-pressure components benefit from the reliability and enhanced toughness provided by 17-4 PH. This alloy’s ability to withstand extreme conditions makes it ideal for military applications where performance reliability is non-negotiable. Companies must prioritize sourcing from certified manufacturers that can deliver robust materials compliant with military standards.

3 Common User Pain Points for ’17 4 ph hardness’ & Their Solutions

Scenario 1: Challenges in Meeting Aerospace Quality Standards with 17-4 PH Hardness

The Problem: International B2B buyers often face difficulties ensuring that their 17-4 PH stainless steel products meet rigorous aerospace quality standards. With varying specifications and certifications, such as AS9100 and AMS 5643, manufacturers must navigate a complex landscape of documentation and compliance. These challenges can result in delays in project timelines, increased costs, and potential penalties for non-compliance, which can significantly strain relationships with end clients.

The Solution: To address these concerns, buyers should prioritize sourcing from suppliers who emphasize compliance with industry standards and possess relevant certifications. Conduct due diligence by requesting comprehensive quality documentation, including certifications and material test reports, before purchasing. Establish clear communication with your supplier about the specific applications and standards required, ensuring that the material is tailored to meet those needs. Additionally, consider utilizing suppliers that offer value-added services like pre-fabrication, machining, or heat treatment, as these can enhance the material’s properties while ensuring it remains compliant with industry standards and optimized for performance.

Scenario 2: Difficulty in Adjusting 17-4 PH Hardness for Specific Applications

The Problem: When using 17-4 PH stainless steel, many B2B buyers encounter challenges in manipulating hardness levels to match specific application requirements. The precipitation hardening process adds complexity, as different tempering temperatures lead to vastly different mechanical properties. Without a strong understanding of how to adjust hardness appropriately, manufacturers can jeopardize product performance and reliability, leading to costly errors in later production stages.

The Solution: Buyers should invest time in understanding the heat treatment process for 17-4 PH stainless steel. Providing detailed specifications to your heat treatment partner, including desired hardness and anticipated application conditions, is crucial. Consulting relevant guidelines, like ASTM A564, will also provide clarity on heat treatment methodologies. Furthermore, collaborating with metallurgical experts can help you tailor the alloy’s properties to the specific requirements of your applications. Explore options such as varying the solution treatment temperature and aging times to identify the optimal hardness range that balances strength, ductility, and corrosion resistance for your unique use cases.

Scenario 3: Corrosion Issues Despite Using 17-4 PH Stainless Steel

The Problem: Despite its touted corrosion resistance, buyers often experience unexpected corrosion issues with 17-4 PH stainless steel in certain environments, particularly in harsh chemical or marine applications. This inconsistency can stem from improper surface finishing, insufficient quality control, or a misunderstanding of the alloy’s limitations regarding corrosion mechanisms. The result is not only product failure but also potential liability issues, particularly in sensitive sectors like food processing or pharmaceuticals.

The Solution: To mitigate corrosion risks, it is essential to collaborate with suppliers who provide thorough surface finishing options that enhance the corrosion resistance of 17-4 PH stainless steel. Solutions can include passivation processes that increase the oxide layer on the metal’s surface, thus providing better protection against corrosive elements. Moreover, educating your team on the environmental conditions in which the alloy will be used can help inform the selection process. For critical applications, consider conducting thorough corrosion testing in the same conditions where your components will operate. This approach will ensure that the alloy’s performance meets your expectations and reduces the likelihood of premature failure due to environmental factors.

Strategic Material Selection Guide for 17 4 ph hardness

What Are the Key Properties of 17-4 PH Stainless Steel for B2B Applications?

17-4 PH stainless steel is a versatile material known for its impressive hardness characteristics, making it suitable for various demanding applications. This alloy exhibits a combination of high strength, excellent corrosion resistance, and good machinability, which are critical for industries that require reliable performance in challenging environments such as aerospace, chemical processing, and oil and gas.

What Are the Advantages and Disadvantages of Using 17-4 PH Stainless Steel?

When considering 17-4 PH stainless steel, buyers must evaluate both its advantages and limitations. Notably, the alloy provides exceptional durability, easily withstands corrosive conditions, and can be tailored through heat treatment to enhance its hardness and strength (with variations such as H900 and H1150). However, the manufacturing complexity involved in achieving desired hardness levels can lead to higher production costs and longer lead times, which may not be suitable for all applications.

How Does 17-4 PH Stainless Steel Impact Application Performance?

In applications requiring high tensile strength, such as pump shafts or mechanical seals, 17-4’s hardness plays a critical role. Its ability to retain strength at elevated temperatures makes it particularly useful in aerospace components that face extreme conditions. However, it is essential to consider media compatibility; while 17-4 PH performs well in various environments, specific corrosive agents may still affect its performance, necessitating further evaluation.

What Should International B2B Buyers Consider When Selecting 17-4 PH Stainless Steel?

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, must adhere to industry certifications and standards in their material selection. Common standards for 17-4 PH stainless steel include ASTM A564 and DIN 17440. Compliance with these specifications ensures that the material meets the necessary quality and safety requirements. Furthermore, regional preferences for sourcing and supply chain logistics can influence selection processes, making it crucial to establish reliable partnerships with suppliers who have an established reputation in their respective markets.

Summary Table of Strategic Material Selection for 17-4 PH Hardness

| Material | Typical Use Case for 17-4 PH Hardness | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| 17-4 PH Stainless Steel | Aerospace components, pump shafts | Excellent corrosion resistance and strength | Higher production costs due to complexity | High |

| 316L Stainless Steel | Marine applications, chemical processing | Superior corrosion resistance in saline environments | Lower strength compared to 17-4 PH | Medium |

| Alloy 600 | Heat exchangers, nuclear applications | High-temperature performance | Vulnerable to corrosion in specific environments | High |

| Carbon Steel | General-purpose industrial components | Cost-effective and widely available | Limited corrosion resistance; may require protective coatings | Low |

This structured approach to understanding the strategic material selection for 17-4 PH hardness offers valuable insights to B2B buyers, enabling informed decisions that align with their specific operational requirements and regulatory commitments.

In-depth Look: Manufacturing Processes and Quality Assurance for 17 4 ph hardness

What Are the Key Stages in the Manufacturing Process of 17-4 PH Stainless Steel?

The manufacturing process of 17-4 PH stainless steel involves several critical stages, ensuring that the material characteristics meet the high-performance requirements of various industries, including aerospace, oil and gas, and food processing. Each stage is crucial for maintaining the alloy’s properties and functionality.

Material Preparation: How Is 17-4 PH Alloy Processed?

The initial phase involves careful selection and preparation of raw materials. The main components—chromium, nickel, copper, and other elements—are sourced as per the required specifications. Material preparation includes:

- Melting and Alloying: Raw materials are melted in a vacuum induction furnace to produce homogeneous melt characteristics.

- Casting: The molten alloy is cast into ingots or billets. Continuous casting methods may also be employed to produce larger sections suited for further processing.

- Heat Treatment: Following casting, the alloy undergoes solution treatment at approximately 1050 °C (1920 °F) to dissolve intermetallic phases and enhance ductility.

Forming: What Techniques Are Used to Shape 17-4 PH Stainless Steel?

Forming processes are employed to shape the material into the desired form and size, adapting it for specific applications. The techniques include:

- Forging: Hot forging is often utilized to improve mechanical properties and refine the microstructure. This stage enhances toughness and strength.

- Machining: Precision machining techniques like CNC turning, milling, and grinding help achieve tight tolerances necessary for demanding applications.

- Cold Working: This is done post-heat treatment to increase strength and improve surface finish.

How Is Quality Controlled During Manufacturing?

Quality assurance in the manufacturing of 17-4 PH stainless steel is vital to ensure compliance and reliability of the product. International and industry-specific standards guide the quality control process.

Which International Standards and Certifications Are Relevant?

Quality assurance processes adhere to several widely recognized standards, including:

- ISO 9001: This specifies requirements for a quality management system (QMS). Manufacturers must demonstrate their ability to provide consistent products that meet customer and regulatory requirements.

- ISO 14001: Companies may also follow this environmental management system to enhance sustainability in production.

- ASTM Standards: Compliance with standards like ASTM A564 and ASTM A693 ensures that the material meets specific mechanical and chemical properties.

What Are the Key Quality Control Checkpoints?

QC checkpoints throughout the manufacturing process include:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to verify compliance with specifications.

- In-Process Quality Control (IPQC): During manufacturing, processes are monitored to detect any potential issues early, enforcing corrective measures when necessary.

- Final Quality Control (FQC): Completed products undergo rigorous testing to ensure they meet the specified mechanical, chemical, and physical standards.

What Common Testing Methods Are Used for 17-4 PH Stainless Steel?

Quality assessment employs various testing methods, such as:

- Tensile Tests: Measuring yield strength, ultimate tensile strength, and elongation helps ascertain the material’s strength characteristics.

- Hardness Tests: Brinell or Rockwell hardness testing assesses resistance to deformation.

- Corrosion Resistance Tests: Techniques like salt spray tests evaluate the alloy’s resistance to corrosion in hostile environments.

- Non-destructive testing (NDT): Methods like ultrasonic and magnetic particle testing are important for detecting flaws without damaging the material.

How Can B2B Buyers Verify the Quality Control of Suppliers?

B2B buyers must ensure that their suppliers maintain high-quality standards. Here are practical steps they can take:

- Supplier Audits: Conduct audits to assess the supplier’s adherence to quality standards, production processes, and overall reliability.

- Quality Assurance Reports: Request detailed QA reports, including data on testing methods, outcomes, and any corrective actions taken.

- Third-party Inspection: Engaging independent agencies to conduct thorough inspections can further validate supplier claims and enhance confidence in the product.

Are There Any QC and Certification Nuances for International Buyers?

B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, could face specific challenges:

- Regulatory Variations: Different countries might have specific regulations regarding steel imports, necessitating awareness of local laws and compliance requirements.

- Certification Recognition: Verify whether international certifications (like CE for European markets) are recognized and adhered to by suppliers, ensuring the material’s acceptability within the intended market.

- Cultural Considerations: Understanding the cultural context and business practices in regions might be critical in maintaining effective communication and successful transactions.

What Is the Importance of Customization in 17-4 PH Stainless Steel?

Customization plays a crucial role in meeting the specific needs of diverse applications. The flexibility of 17-4 PH allows for adjustments in composition and processing techniques to enhance particular characteristics such as corrosion resistance or mechanical strength. This adaptability provides significant value for industries ranging from aerospace to medical technology, where precise specifications are critical for product performance.

Conclusion: How Do Manufacturing Processes and Quality Assurance Enhance 17-4 PH Hardness?

The robust manufacturing and quality control processes employed for 17-4 PH stainless steel are pivotal in delivering high-performance materials that meet the demanding standards of various industries. Understanding these processes and quality assurance measures not only equips B2B buyers with critical knowledge but also enables them to make informed decisions when sourcing materials globally. Through diligent quality verification and emphasis on certification, buyers can ensure they receive the exceptional quality that 17-4 PH stainless steel promises.

Practical Sourcing Guide: A Step-by-Step Checklist for ’17 4 ph hardness’

Introduction

This guide serves as a comprehensive checklist for B2B buyers seeking to procure 17-4 PH stainless steel, known for its exceptional strength, toughness, and corrosion resistance. By following these steps, buyers will be equipped to make informed sourcing decisions that meet their specific application needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential for sourcing 17-4 PH stainless steel. Document the required conditions, such as tensile strength, hardness parameters, and corrosion resistance levels. Be explicit about the application, whether for aerospace, oil and gas, or food processing, as these specifics will facilitate a more targeted supplier search.

Step 2: Research Reputable Suppliers

Identifying reliable suppliers in the market is critical. Focus on companies that specialize in stainless steel alloys, particularly those recognized for their 17-4 PH offerings. Look for suppliers who have relevant industry certifications such as ISO 9001 to ensure adherence to quality standards.

- Review customer testimonials and case studies to gauge reputation.

- Consider geographical proximity if local sourcing offers logistical advantages.

Step 3: Verify Supplier Certifications

Ensure that potential suppliers hold valid certifications relevant to your industry. Certifications like AS9100 for aerospace applications or ISO 14001 for environmental management indicate that a supplier maintains high operational standards. Certification verification can help mitigate risks associated with quality and compliance failures.

Step 4: Request Detailed Technical Data

When evaluating possible suppliers, request comprehensive technical data for the 17-4 PH stainless steel they offer. This should include chemical composition, mechanical properties, and heat treatment processes. Understanding these data points helps you confirm that the material meets your project specifications.

- Seek samples or test reports if possible to verify material properties.

- Pay attention to the availability of multiple heat treatment conditions (H900, H1025, etc.).

Step 5: Evaluate Supplier Capabilities

Before finalizing a supplier, assess their manufacturing and customization capabilities. Determine if they can meet specific fabrication, machining, or finishing needs you might have for the steel.

- Check if they have advanced machinery and technologies, which can enhance precision and efficiency.

- Discuss their lead times and how quickly they can respond to changes in demand.

Step 6: Compare Pricing and Payment Terms

Once you have identified several potential suppliers, compare their pricing structures while factoring in quality and service levels. Discuss payment terms in detail as favorable terms can significantly impact cash flow.

- Look for bulk purchasing discounts if you intend to source large volumes.

- Clarify warranty and return policies as they can affect long-term costs and relationships.

Step 7: Conduct Supply Chain Risk Assessment

Finally, analyze potential supply chain risks associated with your selected suppliers. Assess factors like geopolitical stability, logistics capabilities, and market fluctuations that could affect availability or cost continuity.

- Develop contingency plans in case of supply disruptions.

- Ensure that your suppliers have robust crisis management strategies in place.

This checklist aims to empower B2B buyers with a strategic approach to sourcing 17-4 PH stainless steel, increasing not just procurement efficiency but also ensuring long-term satisfaction with their material choices.

Comprehensive Cost and Pricing Analysis for 17 4 ph hardness Sourcing

When sourcing 17-4 PH stainless steel, understanding the intricate cost structure and pricing elements is crucial for international B2B buyers. This alloy offers high strength and corrosion resistance but also involves several key cost factors that need to be evaluated to ensure an optimal purchase.

What Are the Key Cost Components Associated with 17-4 PH Hardness?

The cost structure for sourcing 17-4 PH stainless steel comprises several components:

-

Materials: The base material cost is influenced by the alloy composition, including chromium, nickel, and copper. Current market conditions and the availability of raw materials can lead to price fluctuations.

-

Labor: Labor costs may vary significantly based on the manufacturing location. Regions with higher labor standards tend to have increased costs, but they can also offer better-skilled labor, impacting overall quality.

-

Manufacturing Overhead: This includes fixed and variable costs related to production facilities, utilities, and administrative expenses. Efficient manufacturing processes can help keep these costs down.

-

Tooling: The expense of producing the required tooling for machining 17-4 PH can be significant, especially for custom or specialized parts. This upfront investment should be factored into the overall cost.

-

Quality Control (QC): Ensuring the material meets specific standards and certifications (e.g., ASTM A564, AMS 5643) incurs additional costs. Rigorous QC can prevent costly rework later.

-

Logistics: Transportation, insurance, and storage fees all contribute to the total cost. This is especially critical for international shipping, where Incoterms can affect who bears these costs.

-

Margin: The profit margin set by suppliers varies; higher competition may reduce margins, whereas niche suppliers may maintain higher margins due to specialization.

What Influences Pricing for 17-4 PH Stainless Steel?

Several key factors can influence pricing for buyers sourcing 17-4 PH:

-

Volume/MOQ (Minimum Order Quantity): Purchasing larger volumes usually results in discounted prices per unit. It is common for suppliers to incentivize bulk buyers.

-

Specifications and Customization: Customizing alloys or modifying existing specifications can lead to additional costs. Specific hardening treatments or custom certifications may also factor into the pricing equation.

-

Quality and Certifications: Higher quality materials or those with additional certifications typically demand higher prices. Buyers must ensure that they receive the necessary documentation to verify material properties.

-

Supplier Factors: The reputation and reliability of the supplier can significantly impact pricing. Established suppliers may charge more due to perceived quality or superior service.

-

Incoterms: Understanding the terms of shipping (FOB, CIF, etc.) is vital. These terms dictate who is responsible for transportation costs and risk, affecting the total landed cost of the material.

What Are Effective Buyer Strategies for Sourcing 17-4 PH?

To optimize sourcing costs for 17-4 PH, B2B buyers should consider the following strategies:

-

Negotiation Techniques: Always engage in negotiations. Even if a supplier’s price appears firm, exploring flexibility on terms or pricing can lead to savings—especially for large contracts.

-

Total Cost of Ownership (TCO): Don’t just focus on initial pricing; analyze the TCO, including lifespan, maintenance, and operational costs associated with using the material.

-

Regional Pricing Nuances for International Buyers: Buyers from different regions must be aware of local market conditions, trade duties, and tariffs that could affect the overall price and availability.

-

Stay Informed on Market Trends: Keeping up with market trends and fluctuations in raw material prices can provide leverage during negotiations and help in timely purchasing decisions.

Conclusion

When sourcing 17-4 PH stainless steel, a comprehensive understanding of cost components and influencing factors can significantly enhance decision-making. Practical strategies and informed negotiation can result in more favorable terms, ensuring that B2B buyers maximize both value and performance from their purchases. Prices are indicative and can vary greatly based on market conditions. Always confirm current rates and terms with suppliers before finalizing any transactions.

Alternatives Analysis: Comparing 17 4 ph hardness With Other Solutions

Exploring Alternatives to 17-4 PH Hardness

Within the realm of industrial applications requiring high strength and corrosion resistance, 17-4 PH stainless steel has earned its reputation as a reliable solution. However, diverse manufacturing needs may lead B2B buyers to explore alternative materials or methods that might better suit specific requirements. Here, we will discuss and compare 17-4 PH hardness with two viable alternatives: Cronidur® 30 and AISI 316L.

| Comparison Aspect | 17-4 PH Hardness | Cronidur® 30 | AISI 316L |

|---|---|---|---|

| Performance | Excellent strength and toughness; good corrosion resistance | Superior corrosion resistance; high toughness and wear resistance | Very good corrosion resistance; good strength |

| Cost | Moderate cost, depending on heat treatment processes | Higher cost due to superior performance | Generally lower cost, widely available |

| Ease of Implementation | Flexible machining and welding, heat treatment required for optimal hardness | Good machinability; may require specialized processes | Easy to weld and form, limited hardening options |

| Maintenance | Regular inspections needed due to wear | Low maintenance; excellent for harsh environments | Moderate maintenance; less resistant to pitting |

| Best Use Case | Aerospace, oil and gas applications | Aerospace, medical devices, and components needing high corrosion resistance | Maritime applications, chemical processing |

How Does Cronidur® 30 Compare to 17-4 PH?

Cronidur® 30 is a stainless martensitic steel known for its enhanced corrosion resistance compared to 440C. It excels in environments where toughness and wear resistance are crucial, particularly in industries like aerospace and medical engineering. Its heat-treatment process produces a system that retains strength under significant static and dynamic stresses. However, it can come at a higher cost and may necessitate specialized fabrication techniques. For B2B buyers focused on maximizing corrosion resistance without sacrificing toughness, Cronidur® 30 presents a strong alternative.

What About AISI 316L as an Alternative?

AISI 316L stainless steel is a widely recognized alternative characterized by its excellent corrosion resistance, particularly in chloride environments. Its advantageous cost-to-performance ratio makes it a popular choice across various sectors, including maritime and chemical processing. While it provides good strength, it lacks the hardness and tensile strength comparative to 17-4 PH. Moreover, AISI 316L does not undergo significant hardening through heat treatment, making it less suitable for high-stress applications. However, its ease of fabrication and lower initial costs can appeal to projects focused on budget constraints rather than extreme mechanical demands.

How Can B2B Buyers Choose the Right Solution?

Selecting the optimal material or method depends primarily on the specific requirements of your project. For applications demanding a combination of high strength and decent corrosion resistance, 17-4 PH emerges as a valuable choice. However, if corrosion resistance is paramount, Cronidur® 30 might offer advantages at a higher cost. Conversely, for projects with budget limitations, AISI 316L serves as a reliable alternative with decent performance in less aggressive environments.

Consider conducting a thorough needs assessment to evaluate these aspects: performance requirements, cost constraints, compatibility with existing processes, and long-term maintenance capabilities. An informed decision will ultimately ensure that the chosen material aligns with the project’s demands.

Essential Technical Properties and Trade Terminology for 17 4 ph hardness

What Are the Key Technical Properties of 17-4 PH Hardness That Buyers Should Know?

Understanding the essential technical properties of 17-4 PH stainless steel is crucial for B2B buyers looking to utilize this material effectively across various industries. Here are some of the critical specifications that are paramount for decision-makers.

1. Material Grade (UNS S17400)

17-4 PH stainless steel is identified under the Universal Numbering System (UNS) as S17400. This designation is critical for suppliers and manufacturers as it signifies the specific alloying elements and their proportions, ensuring that the material meets predefined standards for applications such as aerospace and chemical processing. Buyers should ensure they are procuring products that conform to this certification to guarantee quality and performance.

2. Precipitation Hardening

The “PH” in 17-4 PH indicates that the alloy undergoes precipitation hardening, a heat treatment process that enhances its strength and hardness significantly. For B2B buyers, this property is crucial as it allows for the customization of the material’s mechanical properties through various heat treatment conditions—like H900, H1025, and H1150—enabling optimal performance in specific applications.

3. Tensile Strength (Ultimate and Yield)

Tensile strength refers to the maximum amount of tensile (pulling) stress that a material can handle before failure. For 17-4 PH, the ultimate tensile strength can reach up to 190,000 PSI, while the yield strength is around 170,000 PSI in the H900 condition. High tensile strength is critical for applications demanding durability, such as in aerospace and heavy equipment, making it essential for buyers to assess these values to ensure suitability for their needs.

4. Corrosion Resistance

One of the defining characteristics of 17-4 PH stainless steel is its excellent resistance to corrosion, attributed to its chromium content (15-17.5%). For international buyers, particularly in humid or corrosive environments, this property can significantly impact the longevity and maintenance costs of components, making this an essential factor in the sourcing decision.

5. Hardness Ratings

Hardness is a measure of a material’s resistance to deformation or scratching. For 17-4 PH, hardness can vary depending on the heat-treated state, ranging from 25 HRC to 40 HRC in different conditions. Buyers should evaluate the hardness requirements of their applications to choose the appropriate treatment state and to ensure that they obtain the right product for their operational demands.

What Are the Common Trade Terms Relevant to 17-4 PH Stainless Steel?

Familiarity with industry jargon enhances communication and transaction efficiency for B2B buyers. Here are some vital terms that play a critical role in negotiations and procurement.

1. OEM (Original Equipment Manufacturer)

An OEM develops products that other companies use as part of their offerings. Understanding who the OEM is will help you gauge the quality and reliability of the 17-4 PH stainless steel components you intend to purchase. Working with reputable OEMs ensures compliance with industry standards.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest amount of product that a supplier is willing to sell. It is an important consideration for buyers as it can affect inventory management and cash flow. Negotiating favorable MOQs based on volume needs can lead to cost efficiencies.

3. RFQ (Request for Quote)

An RFQ is a formal process where buyers invite suppliers to submit pricing and terms for specific products. This term is crucial as it sets the stage for price negotiations and can significantly impact procurement costs for components like 17-4 PH stainless steel.

4. Incoterms (International Commercial Terms)

These are a set of internationally recognized rules that define the responsibilities of sellers and buyers for the delivery of goods. Familiarity with Incoterms is essential for buyers operating globally, including in regions like South America and Africa, as it clarifies who is responsible for shipping costs and risks during transit.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions, ensuring they acquire the right specifications to meet their industry needs efficiently.

Navigating Market Dynamics and Sourcing Trends in the 17 4 ph hardness Sector

What Are the Global Drivers Influencing the 17-4 PH Hardness Market?

The market for 17-4 PH hardness stainless steel is predominantly driven by advancements in aerospace, chemical processing, and oil and gas industries, which demand materials exhibiting high strength and corrosion resistance. Countries across Africa, South America, the Middle East, and Europe are increasingly investing in infrastructure and industrial development, fueling demand for this versatile alloy. The rise of Industry 4.0 technologies—like additive manufacturing and smart manufacturing processes—has enhanced the efficiency of how products made from 17-4 PH are sourced and produced, leading to quicker turnaround times and lower costs. Additionally, the increasing adoption of lightweight materials for energy efficiency is further propelling the popularity of 17-4 PH in high-temperature applications.

Furthermore, as global competition intensifies, companies are looking for materials that can be customized to specific requirements, making the unique properties of 17-4 PH particularly attractive. With its ability to be manipulated through heat treatment, various sectors can tailor the alloy to meet stringent demands. Ongoing innovations in metallurgical processes aim to enhance the alloy’s mechanical properties, allowing for potential applications in even more demanding environments.

How Are Sustainability and Ethical Sourcing Becoming Essential in the 17-4 PH Hardness Sector?

In recent years, sustainability and ethical sourcing have grown increasingly important in the B2B sector, particularly within industries reliant on 17-4 PH stainless steel. Companies are becoming more conscious of their environmental impact, driving demand for responsibly sourced materials. Ethical supply chains focus on transparency and traceability, ensuring that raw materials are not only sourced sustainably but also produced in facilities that uphold ethical labor practices.

The certification of ‘green’ materials is gaining traction across various industries. Buyers are considering materials that reduce carbon footprints and are produced with lower energy consumption, successfully aligning profitability with sustainability objectives. For 17-4 PH hardness, pursuing certifications such as ISO 14001 (Environmental Management) can provide a competitive edge while reassuring end-users about responsible sourcing practices. Emphasizing compliance with these standards not only enhances brand reputation but also meets the expectations of an increasingly conscientious consumer base.

What Is the Brief Evolution of 17-4 PH Hardness Stainless Steel in Global Markets?

Since its introduction in the early 1960s, 17-4 PH hardness stainless steel has evolved significantly, quickly becoming one of the most widely used precipitation-hardening stainless steel alloys. Original applications predominantly focused on the aerospace sector due to its high strength-to-weight ratio and favorable mechanical properties at elevated temperatures. Over the decades, advancements in metallurgical techniques have expanded its applications into various industries, including automotive, chemical processing, and medical technology.

The alloy’s versatility in being able to achieve different hardness levels depending on heat treatment conditions has cemented its place as a go-to material for engineers and manufacturers aiming to design robust products. Today, as global industries continue to push for innovations focusing on strength, durability, and sustainability, the evolution of 17-4 PH hardness is expected to resonate well with future market requirements, further solidifying its position in B2B supply chains internationally.

By focusing on the evolving landscape of demand and advancements in technology, stakeholders can make informed decisions that create competitive advantages in the international market for 17-4 PH hardness stainless steel.

Frequently Asked Questions (FAQs) for B2B Buyers of 17 4 ph hardness

-

How can I choose the right grade of 17-4 PH stainless steel for my application?

To select the appropriate grade of 17-4 PH stainless steel, consider your application’s specific requirements such as strength, corrosion resistance, and working conditions. Different heat-treated conditions (H900, H1025, etc.) offer varying properties in terms of yield strength and hardness. Assess the environment the material will operate in, along with any temperature or pressure considerations. Consulting with a supplier who can provide samples and expert guidance tailored to your situation can also help in making an informed choice. -

What advantages does 17-4 PH stainless steel offer for international projects?

17-4 PH stainless steel provides excellent strength, versatility, and corrosion resistance, making it ideal for diverse applications in aerospace, oil and gas, and chemical processing sectors. These properties mean that the material maintains performance even under extreme conditions, reducing the risk of failure in critical components. Furthermore, its wide availability from international suppliers ensures that companies across Africa, South America, the Middle East, and Europe can source it with ease, promoting efficient supply chain management. -

What are the typical lead times for obtaining 17-4 PH stainless steel from suppliers?

Lead times for 17-4 PH stainless steel can vary depending on the supplier, order size, and specific customization required. Typically, you can expect lead times ranging from 4 to 12 weeks for standard orders, while customized items might take longer. It’s advisable to communicate directly with suppliers for estimated timelines and to ensure they can meet your project deadlines, especially when planning international shipments that may encounter additional customs delays. -

How do I vet suppliers of 17-4 PH stainless steel in the international market?

Vetting suppliers involves investigating their certifications (ISO, AS9100, etc.), reviewing their experience and reputation in the industry, and evaluating their production capabilities. Request samples to assess material quality and ensure they meet your specifications. Additionally, check for customer references and feedback. Establishing clear communication and understanding their logistical capabilities can further help in assessing their reliability. Utilizing third-party verification services may also add an extra layer of security. -

What customization options are available for 17-4 PH stainless steel?

17-4 PH stainless steel is highly customizable, accommodating various specifications like dimensions, mechanical properties, and surface finishes. Depending on the supplier, you may able to specify heat treatment conditions to achieve desired hardness levels or tailor chemical compositions for specific corrosion resistance. Engaging with a supplier early in the design process can help ensure the material’s capabilities align with your specific requirements, potentially leading to enhanced performance in your application. -

What are the common minimum order quantities (MOQs) for 17-4 PH stainless steel?

Minimum order quantities for 17-4 PH stainless steel generally depend on the supplier and the specific product characteristics. MOQs can range from as low as 100 kg for standard grades to several tons for specialized materials. When discussing orders, consider both your needs and the supplier’s capacity, and explore possibilities for splitting orders if necessary. Flexibility in shipping or combining orders with other materials may help you meet MOQs without excessive upfront commitment. -

What payment terms are typically offered for B2B transactions involving 17-4 PH stainless steel?

Payment terms for purchasing 17-4 PH stainless steel can vary widely among suppliers, ranging from upfront payment to net 30, net 60, or net 90-day terms depending on your relationship with the supplier and order volume. Larger orders may qualify for more favorable terms. It’s crucial to discuss payment options upfront and understand the implications of different terms on your cash flow and budgeting. Also, consider how currency fluctuations or international transfer fees could affect overall costs. -

What quality assurance measures should I expect when ordering 17-4 PH stainless steel?

When sourcing 17-4 PH stainless steel, look for suppliers that implement stringent quality assurance (QA) measures, including adherence to international standards (like ASTM or AMS), material traceability, and rigorous testing of mechanical properties. Request certificates of compliance and relevant testing reports upon delivery to ensure the material meets specified standards. Regular audits and third-party inspections can also validate the consistency of quality, providing peace of mind for critical applications.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 17 4 Ph Hardness Manufacturers & Suppliers List

1. AZOM – 17-4 Stainless Steel

Domain: azom.com

Registered: 1999 (26 years)

Introduction: Grade: 17-4 (UNS S17400)

Chemical Composition:

– Iron, Fe: 73%

– Chromium, Cr: 15.0 – 17.5%

– Nickel, Ni: 3.0 – 5.0%

– Copper, Cu: 3.0 – 5.0%

– Manganese, Mn: 1.0%

– Silicon, Si: 1.0%

– Tantalum, Ta: 0.45%

– Niobium, Nb: 0.45%

– Carbon, C: 0.070%

– Phosphorous, P: 0.040%

– Sulfur, S: 0.030%

Physical Properties:

– Density: 7.75 g/cm³ (0.280 lb/in³)

Mechanical Properties:

– Shear modulus: 77.4 GPa (…

2. Premium Alloys – 17-4 Stainless Steel

Domain: premiumalloys.com

Registered: 2017 (8 years)

Introduction: {“Product Name”: “17-4 Stainless Steel”, “Description”: “A type of alloy with excellent corrosion resistance, strength, and versatility, ideal for high-temperature applications.”, “Composition”: {“Chromium”: “15%-17.5%”, “Nickel”: “3%-5%”, “Copper”: “3%-5%”, “Carbon”: “0.07% (Max)”, “Silicon”: “1.00% (Max)”, “Manganese”: “1.00% (Max)”, “Phosphorous”: “0.040% (Max)”, “Sulfur”: “0.030% (Max)”, “Moly…

3. Progressive Alloy – 17-4 PH Stainless Steel

Domain: progressivealloy.com

Registered: 2000 (25 years)

Introduction: 17-4 PH Stainless Steel, UNS S17400, AMS 5643, ASTM A564, ASTM A693, Grade 630. Precipitation hardening martensitic stainless steel known for high strength and moderate corrosion resistance. Heat treatment process manipulates strength and toughness. Typical applications include pump shafts, oil patch, mechanical seals, and aerospace.

Mechanical Properties:

– Condition: H900

– Ultimate Tensile …

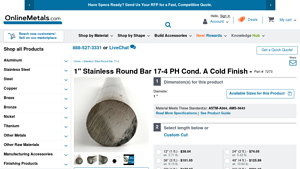

4. Online Metals – 1 Stainless Round Bar 17-4 PH Cond. A Cold Finish

Domain: onlinemetals.com

Registered: 1997 (28 years)

Introduction: {‘name’: ‘1″ Stainless Round Bar 17-4 PH Cond. A Cold Finish’, ‘part_number’: ‘7273’, ‘diameter’: ‘1 inch’, ‘available_lengths’: [{‘length’: ’12 inches’, ‘price’: ‘$38.04’, ‘weight’: ‘2.71 lb’}, {‘length’: ’24 inches’, ‘price’: ‘$74.05’, ‘weight’: ‘5.42 lb’}, {‘length’: ’36 inches’, ‘price’: ‘$101.05’, ‘weight’: ‘8.13 lb’}, {‘length’: ’48 inches’, ‘price’: ‘$125.99’, ‘weight’: ‘10.84 lb’}, {‘lengt…

5. Virgamet – 17-4PH Stainless Steel

Domain: virgamet.com

Registered: 2016 (9 years)

Introduction: Product Name: 17-4PH, 1.4542, AISI 630, 1.4548 Stainless Steel

Standards: EN 10088-1, ASTM A564

Chemical Composition:

– Carbon (C): <0.07%

– Manganese (Mn): <1.0% to <1.5%

– Silicon (Si): <1.0% to <0.7%

– Phosphorus (P): <0.04% to <0.025%

– Sulfur (S): <0.03% to <0.025%

– Chromium (Cr): 15.0 – 17.5%

– Nickel (Ni): 3.0 – 5.0%

– Molybdenum (Mo): –

– Niobium (Nb): <0.6%

– Copper (Cu): 3.0 – 5.0%

– Ni…

Strategic Sourcing Conclusion and Outlook for 17 4 ph hardness

Strategic sourcing of 17-4 PH stainless steel presents a unique opportunity for international B2B buyers across various regions, including Africa, South America, the Middle East, and Europe. This high-performance alloy combines outstanding corrosion resistance and exceptional strength, making it the preferred choice for applications in demanding industries such as aerospace, oil and gas, and chemical processing. Effective sourcing strategies should focus on reliable suppliers that can provide consistent quality and adhere to rigorous certifications, such as ISO standards, to ensure compliance with industry requirements.

Engaging in strategic sourcing allows businesses to tailor their procurement processes to specific project needs while optimizing material costs. By leveraging established relationships with suppliers, companies can negotiate favorable terms and ensure a steady supply chain, which is critical in competitive markets.

Looking forward, as industries evolve and the demand for high-performance materials grows, the importance of sourcing 17-4 PH stainless steel will continue to rise. International buyers should take proactive steps to align with trusted suppliers who can meet their quality and delivery expectations. Embrace the future of strategic sourcing to enhance your operational efficiency and maintain a competitive edge in your industry.