Introduction: Navigating the Global Market for 16 d nail size

In the competitive world of construction and manufacturing, sourcing the right materials is pivotal for success. One key component that often presents a challenge is the 16 d nail size, a staple for professionals engaged in framing and structural work. With its unique specifications—3 1/2 inches in length and a diameter of 0.162 inches—this nail type is critical for ensuring the strength and durability of various constructions. However, navigating the complexities of sourcing 16 d nails can be daunting, especially for B2B buyers from diverse regions such as Africa, South America, the Middle East, and Europe, including markets like Saudi Arabia and Nigeria.

This comprehensive guide demystifies the 16 d nail size, covering essential aspects such as types, applications, supplier vetting processes, and cost considerations. By providing insights into the specific uses of 16 d nails—ranging from stud walls to roof trusses—this resource empowers international buyers to make informed purchasing decisions. Furthermore, the guide highlights best practices for assessing suppliers, ensuring that quality and reliability are prioritized in your procurement strategy.

With a focus on actionable insights tailored for the global market, this guide equips B2B buyers with the knowledge necessary to source the right framing nails, ultimately leading to enhanced project outcomes and greater operational efficiency.

Understanding 16 d nail size Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Common 16d Nail | Standard shank, 0.162 inches in diameter | Framing, structural applications | Pros: Strong holding power; Cons: Higher cost; less availability in some regions. |

| Ring Shank 16d Nail | Ringed shank for enhanced grip | Heavy-duty framing, outdoor projects | Pros: Superior pull-out resistance; Cons: More expensive than common nails. |

| Smooth Shank 16d Nail | Smooth surface for easier driving | Interior applications, cabinetry | Pros: Easy to drive; Cons: Lower holding power compared to ringed nails. |

| Galvanized 16d Nail | Coated for corrosion resistance | Outdoor use, treated wood structures | Pros: Durable in harsh environments; Cons: Higher price due to coating. |

| Stainless Steel 16d Nail | High corrosion resistance and aesthetic appeal | Coastal areas, high-end projects | Pros: Long-lasting; Cons: Significantly more expensive than other options. |

What are the Characteristics of Common 16d Nails?

Common 16d nails are the standard choice for framing and structural applications, measuring 3.5 inches in length with a diameter of 0.162 inches. They are widely used in construction projects due to their balance of strength and cost-effectiveness. B2B buyers should consider their availability and pricing, as these nails may be less prevalent in certain regions, impacting procurement strategies.

How Do Ring Shank 16d Nails Enhance Performance?

Ring shank 16d nails feature a unique ringed shank design that provides enhanced grip, making them ideal for heavy-duty framing and outdoor projects. The rings increase friction, reducing the likelihood of pull-out under stress. Buyers should assess the additional costs associated with ring shank nails against their project requirements, especially in high-stress environments.

When to Use Smooth Shank 16d Nails?

Smooth shank 16d nails are characterized by their sleek surface, making them easy to drive into wood. They are commonly used in interior applications, such as cabinetry and trim work. While they are easier to work with, they offer less holding power than their ringed counterparts. Buyers should weigh ease of installation against the potential need for additional fasteners in load-bearing applications.

Why Choose Galvanized 16d Nails for Outdoor Projects?

Galvanized 16d nails are treated with a corrosion-resistant coating, making them suitable for outdoor use and in environments where moisture is a concern. They are particularly effective for fastening treated wood, which can be prone to corrosion when using standard nails. B2B buyers should consider the longevity and durability of galvanized nails, despite their higher cost, especially in regions with harsh weather conditions.

What are the Advantages of Stainless Steel 16d Nails?

Stainless steel 16d nails offer exceptional corrosion resistance and are aesthetically pleasing, making them a preferred choice for high-end projects and coastal areas. Their durability ensures long-lasting performance, even in challenging environments. However, the significantly higher price point may deter some buyers. When selecting stainless steel nails, B2B purchasers should evaluate project budgets and the long-term benefits of investing in premium materials.

Key Industrial Applications of 16 d nail size

| Industry/Sector | Specific Application of 16 d nail size | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Structural framing in residential and commercial buildings | Provides strong and durable connections for structural integrity | Quality assurance, availability in bulk, and competitive pricing |

| Furniture Manufacturing | Assembly of large wooden furniture pieces | Enhances durability and longevity of furniture products | Sourcing from reliable suppliers with appropriate certifications |

| Roofing | Attaching roof trusses and sheathing | Ensures stability and resistance to weather-related damage | Compliance with local building codes and weather resistance standards |

| Timber Engineering | Creating wooden structures and frameworks | Supports heavy loads and provides safety in engineered designs | Material compatibility and sourcing of treated vs. untreated nails |

| DIY and Home Improvement | General carpentry projects | Versatile use for various home projects, ensuring strength | Accessibility in local markets and cost-effectiveness for small-scale buyers |

In the construction industry, 16 d nails are crucial for structural framing, used extensively in both residential and commercial buildings. Their length and diameter provide the necessary holding power to secure studs, joists, and beams, which is essential for maintaining structural integrity. B2B buyers must consider quality assurance to ensure the nails meet safety standards, as well as availability in bulk to accommodate large projects.

In furniture manufacturing, 16 d nails are employed for assembling large wooden pieces, such as tables and cabinets. The strength of these nails enhances the durability and longevity of furniture, making them a preferred choice for manufacturers aiming to deliver high-quality products. Buyers should prioritize sourcing from suppliers who provide reliable certifications and can meet production demands.

The roofing sector utilizes 16 d nails to attach roof trusses and sheathing, critical for ensuring stability and resistance to adverse weather conditions. The ability of these nails to withstand heavy loads is vital for the safety of the structure. Buyers in this sector must ensure compliance with local building codes and consider the nails’ weather resistance properties, particularly in regions prone to extreme weather.

In timber engineering, 16 d nails are essential for creating wooden structures and frameworks that support significant weight. Their robust design allows for safe and effective load-bearing applications. B2B buyers should focus on sourcing nails that are compatible with various wood types and consider whether treated or untreated nails are more suitable for their projects.

Finally, in the DIY and home improvement sector, 16 d nails are versatile for a range of carpentry projects, from building decks to installing trim. Their strength ensures that DIY projects can withstand everyday use, appealing to both hobbyists and professional contractors. Buyers should seek out local suppliers that offer competitive pricing and accessibility, especially in regions where DIY projects are popular.

3 Common User Pain Points for ’16 d nail size’ & Their Solutions

Scenario 1: Sourcing Quality 16 d Nails in Diverse Markets

The Problem: B2B buyers in regions like Africa and South America often face challenges in sourcing high-quality 16 d nails. The local supply chain may be limited, leading to difficulties in obtaining nails that meet the required specifications for strength and durability. This can result in delays in construction projects and potential safety issues if inferior nails are used, compromising the integrity of structures.

The Solution: To overcome sourcing challenges, buyers should establish relationships with reputable suppliers who specialize in construction materials. Look for manufacturers or distributors that have a proven track record of providing high-quality fasteners. Utilizing platforms like Alibaba or local trade shows can help identify trustworthy suppliers. Additionally, consider importing nails from regions with robust manufacturing standards, ensuring they meet international quality certifications. When placing orders, specify the exact requirements such as length, diameter, and coating type to ensure the nails will perform adequately for the intended structural applications.

Scenario 2: Understanding the Technical Specifications of 16 d Nails

The Problem: Many buyers lack a comprehensive understanding of the technical specifications of 16 d nails, such as the implications of shank diameter and the impact of different coatings. This can lead to misapplication in projects, where nails may not perform as required, resulting in structural failures or increased maintenance costs over time. For instance, using a nail with inadequate holding power can result in the nail bending or pulling out under stress.

The Solution: Education is key to addressing this knowledge gap. Buyers should invest time in training sessions or workshops that cover the specifications and applications of various nails, including the 16 d size. Collaborating with manufacturers or industry experts to conduct such sessions can provide valuable insights. Additionally, create a resource library with technical datasheets and usage guidelines to help teams understand when to use 16 d nails versus other sizes. By fostering a culture of informed decision-making, buyers can significantly reduce the risks associated with improper nail selection.

Scenario 3: Cost Management When Purchasing 16 d Nails

The Problem: In competitive markets, cost management is a critical concern for B2B buyers. The price of 16 d nails can vary significantly based on factors such as material quality, supplier location, and shipping costs. This variability can lead to budget overruns, particularly for large construction projects where thousands of nails are required. Buyers often struggle to balance quality with cost-effectiveness, leading to potential trade-offs that can affect the project’s overall success.

The Solution: To effectively manage costs, buyers should adopt a strategic sourcing approach. Start by conducting a thorough market analysis to understand pricing trends and identify multiple suppliers. Implement bulk purchasing agreements to negotiate better prices, and consider establishing long-term contracts with selected suppliers to lock in favorable rates. Additionally, consider using alternative materials or coatings for specific applications where appropriate to reduce costs without compromising structural integrity. Regularly reviewing supplier performance and material quality against project needs will help maintain a balance between cost and quality, ensuring project budgets remain intact while still achieving high standards.

Strategic Material Selection Guide for 16 d nail size

When selecting materials for 16d nails, it is essential to consider their properties, advantages, and limitations to ensure optimal performance in various applications. Here’s a detailed analysis of four common materials used for 16d nails: steel, galvanized steel, stainless steel, and aluminum.

What Are the Key Properties of Steel for 16d Nails?

Steel is the most common material for 16d nails, known for its strength and durability. Standard steel nails can withstand significant mechanical stress, making them suitable for structural applications. However, they have limited corrosion resistance and can rust when exposed to moisture or harsh environments.

Pros: Steel nails are relatively inexpensive and widely available, making them a cost-effective choice for large-scale construction projects. Their high tensile strength ensures they can hold heavy loads.

Cons: The main drawback is their susceptibility to rust, which can compromise the integrity of the structure over time. This limitation makes them less suitable for outdoor applications or areas with high humidity.

How Does Galvanized Steel Enhance the Performance of 16d Nails?

Galvanized steel nails are coated with a layer of zinc, which provides enhanced corrosion resistance compared to standard steel. This makes them ideal for applications where exposure to moisture is a concern, such as in roofing or framing in humid climates.

Pros: The galvanization process significantly extends the lifespan of the nails, making them suitable for outdoor use. They maintain the strength of steel while offering better protection against rust.

Cons: The cost of galvanized nails is higher than that of standard steel nails due to the additional manufacturing processes involved. They may also be less effective in environments with highly corrosive materials, such as saltwater.

What Are the Advantages of Using Stainless Steel for 16d Nails?

Stainless steel nails are known for their exceptional corrosion resistance and durability. They are particularly beneficial in marine environments or areas with high exposure to chemicals.

Pros: The primary advantage of stainless steel nails is their longevity; they do not rust or corrode, ensuring structural integrity over time. They are also aesthetically pleasing, making them suitable for visible applications.

Cons: The downside is their relatively high cost, which can be a limiting factor for large projects. Additionally, stainless steel nails can be more challenging to work with due to their hardness, which may require specialized tools.

When Is Aluminum the Best Choice for 16d Nails?

Aluminum nails are lightweight and resistant to corrosion, making them suitable for specific applications like siding, roofing, and other exterior projects. They are particularly advantageous in environments where rust is a significant concern.

Pros: Aluminum nails are lightweight, making them easy to handle and install. They also resist corrosion effectively, ensuring long-lasting performance in outdoor applications.

Cons: The main limitation is their lower tensile strength compared to steel, which can make them less suitable for heavy-duty structural applications. They can also be more expensive than standard steel nails.

Summary Table of Material Selection for 16d Nails

| Material | Typical Use Case for 16 d nail size | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | General construction and framing | High tensile strength | Susceptible to rust | Low |

| Galvanized Steel | Outdoor framing and roofing | Enhanced corrosion resistance | Higher cost than standard steel | Med |

| Stainless Steel | Marine and chemical exposure | Exceptional corrosion resistance | High cost and harder to work with | High |

| Aluminum | Siding and roofing | Lightweight and corrosion resistant | Lower tensile strength | Med |

This strategic material selection guide provides insights into the various materials suitable for 16d nails, helping international B2B buyers make informed decisions based on their specific application needs and environmental considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for 16 d nail size

What Are the Key Stages in the Manufacturing Process of 16 d Nails?

Manufacturing 16 d nails involves a series of intricate processes that ensure high quality and performance. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with the selection of high-quality steel wire, which is typically cold drawn to achieve the desired diameter of 0.162 inches. This wire is then cut into appropriate lengths, specifically 3.5 inches for 16 d nails. The choice of steel is crucial, as it affects the nail’s strength and durability.

-

Forming: In this stage, the cut wire is fed into a nail-making machine, where it undergoes a series of mechanical operations. The wire is first pointed at one end and then shaped into a nail. Techniques such as cold heading are commonly used to form the head of the nail, which is essential for optimal holding power.

-

Assembly: After forming, nails may be assembled into specific packaging formats, such as collated strips for use in nail guns. This step ensures that the nails are easy to handle and ready for efficient use in construction.

-

Finishing: The final stage involves surface treatment, which may include galvanization or coating with rust-resistant materials. This enhances the nails’ corrosion resistance and overall longevity. Quality control checks are performed throughout the manufacturing process to ensure compliance with specifications.

How Do Quality Control Measures Ensure the Reliability of 16 d Nails?

Quality assurance is a critical aspect of the nail manufacturing process. International standards, such as ISO 9001, provide a framework for ensuring consistent quality across all stages of production.

-

International Standards: Compliance with ISO 9001 signifies that the manufacturer adheres to quality management principles, ensuring that products meet customer and regulatory requirements. Additional certifications, such as CE marking in Europe or API standards in the oil and gas sector, may also be relevant depending on the specific application of the nails.

-

Quality Checkpoints: The manufacturing process typically incorporates several quality control checkpoints, including:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet predefined specifications.

– In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify and rectify issues before the final product is completed.

– Final Quality Control (FQC): A thorough inspection of the finished nails is conducted to verify dimensions, strength, and surface treatment. -

Common Testing Methods: Testing methods may include tensile strength tests, hardness tests, and corrosion resistance evaluations. These tests are crucial for confirming that the nails can withstand the stresses they will face in real-world applications.

What Steps Can B2B Buyers Take to Verify Supplier Quality Control?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is essential to ensure product reliability.

-

Supplier Audits: Conducting on-site audits of potential suppliers can provide valuable insights into their manufacturing processes and quality control measures. During these audits, buyers can assess compliance with international standards and evaluate the overall operational efficiency.

-

Requesting Quality Reports: Buyers should request detailed quality assurance reports from suppliers. These documents should outline the quality control measures in place, results of testing, and any certifications obtained.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. These inspections can occur at various stages of production, ensuring that the nails meet specified standards before shipment.

-

Understanding Regional Certification Nuances: Buyers should be aware of specific quality certifications required in their regions. For instance, in Europe, compliance with CE marking is essential, while other regions may have different regulatory requirements. Understanding these nuances will help buyers make informed decisions and ensure that the products are suitable for their markets.

How Do Different Markets Impact the Quality Assurance of 16 d Nails?

The quality assurance process for 16 d nails can vary significantly across different regions, influenced by local regulations, market demands, and customer expectations.

-

Market-Specific Standards: In Europe, stringent regulations often dictate the quality and performance standards for construction materials, including nails. Compliance with EN standards is critical for market entry. In contrast, markets in Africa or South America may have different regulatory frameworks, which can impact the quality assurance processes.

-

Cultural Expectations: Different regions may have varying expectations regarding durability and performance. For example, in areas with high humidity, corrosion-resistant coatings might be prioritized, whereas in dry climates, the focus may be on tensile strength.

-

Supply Chain Considerations: Buyers should consider the stability and reliability of the supply chain when sourcing nails. Fluctuations in material availability or changes in local manufacturing capabilities can affect the overall quality of the nails produced.

Conclusion: Ensuring Quality in Your Sourcing of 16 d Nails

In summary, the manufacturing processes and quality assurance measures for 16 d nails are vital components that ensure product reliability and performance. By understanding these processes and actively engaging in quality verification, B2B buyers can secure high-quality nails that meet their specific construction needs. Prioritizing suppliers who adhere to international standards and demonstrate robust quality control practices will ultimately enhance project outcomes and foster long-term partnerships.

Practical Sourcing Guide: A Step-by-Step Checklist for ’16 d nail size’

Introduction

Sourcing the right 16d nails is crucial for ensuring the structural integrity of your construction projects. This guide provides a practical checklist to help B2B buyers navigate the procurement process effectively. By following these steps, you can secure high-quality nails that meet your specific requirements while fostering strong supplier relationships.

Step 1: Define Your Technical Specifications

Clearly outline your project needs regarding the 16d nails. Specifications should include the required length (3.5 inches), diameter (0.162 inches), and any specific coatings or treatments (e.g., galvanized for corrosion resistance). Defining these parameters upfront helps in filtering suppliers who can meet your exact needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers of 16d nails. Utilize online platforms, industry directories, and trade shows to gather a list of manufacturers and distributors. Look for suppliers with a strong reputation in the market, as this often translates to product quality and reliability.

Step 3: Evaluate Supplier Certifications

Before committing, it’s crucial to vet suppliers thoroughly. Verify that they hold relevant certifications, such as ISO 9001 for quality management systems or specific industry standards pertinent to fasteners. This step ensures that the supplier adheres to quality and safety regulations, minimizing the risk of product failure.

Step 4: Request Samples and Specifications

Once you’ve shortlisted suppliers, request samples of their 16d nails along with detailed specifications. Testing samples allows you to assess the nails’ strength, durability, and suitability for your projects. Ensure that the technical data sheets include information about tensile strength, corrosion resistance, and other relevant factors.

Step 5: Analyze Pricing and Payment Terms

Compare the pricing structures of different suppliers, keeping in mind that the cheapest option may not always be the best. Evaluate bulk pricing, shipping costs, and payment terms. Understanding the total cost of ownership, including potential tariffs or import duties, is essential for budgeting accurately.

Step 6: Assess Supply Chain Reliability

Investigate the supplier’s ability to fulfill orders consistently and promptly. Inquire about their production capacity, lead times, and logistics capabilities. A reliable supply chain is critical, especially for large-scale projects where delays can lead to significant cost overruns.

Step 7: Establish Communication Channels

Effective communication is key to a successful supplier relationship. Establish clear points of contact and preferred methods for ongoing communication. Ensure that the supplier can provide timely updates on order status, inventory levels, and any potential issues that may arise.

By following this checklist, you can streamline the procurement process for 16d nails and ensure that your construction projects maintain their structural integrity. Prioritize quality, reliability, and strong supplier relationships to enhance the overall success of your projects.

Comprehensive Cost and Pricing Analysis for 16 d nail size Sourcing

What Are the Key Cost Components in Sourcing 16d Nails?

When sourcing 16d nails, several cost components contribute to the overall pricing structure. Materials form the largest portion of the cost, with steel being the primary raw material. The cost fluctuates based on global steel prices, which can be affected by tariffs and trade policies in different regions. Labor costs also play a significant role, varying by country. For instance, labor costs in South America may differ considerably from those in Europe or the Middle East.

Manufacturing overhead includes expenses such as factory utilities, equipment maintenance, and administrative costs. The tooling costs for specialized machinery used in the production of 16d nails can be significant, particularly for manufacturers producing customized or high-quality nails. Quality control (QC) processes ensure that the nails meet industry standards, adding another layer of cost. Lastly, logistics expenses, including shipping and handling, are critical, especially for international buyers. The choice of shipping methods and the distance from the supplier can greatly influence these costs.

How Do Price Influencers Affect the Sourcing of 16d Nails?

Several factors can influence the pricing of 16d nails in the B2B marketplace. Volume and minimum order quantities (MOQ) often dictate pricing tiers; larger orders typically secure lower per-unit costs. Buyers should assess their needs carefully to take advantage of these pricing structures. Specifications and customization can also affect pricing; nails with special coatings or unique features may incur additional costs.

Material quality and certifications are crucial, particularly for projects requiring compliance with specific safety or structural standards. Suppliers with verified certifications may charge a premium, but this can translate to higher durability and reliability in the long run. Supplier factors, such as reputation, production capacity, and location, can also affect pricing dynamics. Lastly, the choice of Incoterms can significantly influence the total cost, impacting who bears responsibility for shipping, insurance, and tariffs.

What Are Effective Buyer Tips for Sourcing 16d Nails Internationally?

For B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, negotiating effectively is key to securing favorable pricing. Understanding the local market conditions and supplier capabilities can provide leverage during negotiations. Additionally, buyers should focus on cost-efficiency by evaluating the Total Cost of Ownership (TCO). This includes not just the purchase price but also shipping, potential tariffs, and long-term durability of the nails.

Pricing nuances may arise from local demand fluctuations or seasonal variations in supply chains. Buyers should stay informed about market trends and global commodity prices to make timely purchasing decisions. Engaging with multiple suppliers can also yield competitive quotes, allowing buyers to compare and negotiate better terms.

What Should Buyers Keep in Mind Regarding Indicative Prices?

It is essential for buyers to understand that prices for 16d nails can vary widely based on the factors discussed. Indicative prices are often subject to change due to market volatility, changes in material costs, and shifts in demand. Buyers should be prepared to conduct thorough market research and maintain flexibility in their sourcing strategies to accommodate these fluctuations. Establishing strong relationships with suppliers can also lead to more stable pricing arrangements and improved terms over time.

Alternatives Analysis: Comparing 16 d nail size With Other Solutions

Introduction: Understanding Alternatives to 16 D Nail Size

When it comes to construction and carpentry, choosing the right fastening solution is crucial. The 16 d nail size is a popular choice for framing due to its strength and durability. However, there are alternative solutions that may suit different project requirements or budget constraints. This analysis will compare the 16 d nail against other viable fastening methods, helping B2B buyers make informed decisions tailored to their specific needs.

Comparison Table

| Comparison Aspect | 16 D Nail Size | Collated Screws | Adhesive Fasteners |

|---|---|---|---|

| Performance | High holding power; ideal for structural applications | Excellent for load-bearing joints, less prone to loosening over time | Strong initial bond; suitable for non-load-bearing applications |

| Cost | Higher material cost; often more expensive than screws | Moderate cost; can vary based on type and brand | Generally lower cost for large volumes |

| Ease of Implementation | Requires a hammer or nail gun; skill needed for accurate placement | Requires a drill or screwdriver; easy to use with proper tools | Simple application, but requires curing time |

| Maintenance | Minimal; durable under various conditions | Low maintenance; can be removed and reused | Can weaken over time; not easily removable |

| Best Use Case | Large structures, framing, and heavy-duty applications | Wood-to-wood connections, cabinetry, and furniture | Non-structural applications, crafts, and repairs |

Detailed Breakdown of Alternatives

Collated Screws: A Versatile Alternative

Collated screws are a strong alternative to 16 d nails, especially in applications requiring high load-bearing capacity. These screws are designed for use with power tools, enhancing efficiency on the job site. Their primary advantage lies in their resistance to loosening over time, making them ideal for structures subjected to movement or vibration. However, they may require more specialized tools, and their cost can vary based on the type and brand.

Adhesive Fasteners: A Cost-Effective Solution

Adhesive fasteners, including construction adhesives, provide a strong initial bond and are particularly effective for non-load-bearing applications. They are easy to use and can save time on labor-intensive tasks. However, they do have limitations; the bond may weaken over time, especially if exposed to moisture or extreme temperatures. Adhesives are not suitable for structural connections, making them less versatile than nails or screws in heavy-duty construction.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the appropriate fastening solution involves assessing the specific requirements of your project. For large-scale framing and structural integrity, the 16 d nail remains a top choice due to its strength and durability. In contrast, collated screws offer versatility and ease of use, particularly for wood-to-wood connections. Adhesive fasteners can be a cost-effective option for non-structural applications. By weighing the performance, cost, ease of implementation, maintenance, and best use cases, B2B buyers can make informed decisions that align with their project goals and budget constraints.

Essential Technical Properties and Trade Terminology for 16 d nail size

What Are the Key Technical Properties of a 16d Nail Size?

When sourcing 16d nails, understanding their technical properties is essential for ensuring the right choice for your construction projects. Here are some critical specifications:

-

Length and Diameter: A 16d nail measures 3.5 inches in length and has a diameter of 0.162 inches. This size is designed for heavy-duty applications, providing sufficient holding power in structural framing. The larger diameter helps reduce the likelihood of bending under stress, which is crucial for maintaining structural integrity.

-

Material Grade: Typically, 16d nails are made from high-carbon steel or galvanized steel. High-carbon steel nails offer excellent strength and durability, while galvanized options provide corrosion resistance, making them suitable for outdoor use or in humid environments. Understanding material grades allows buyers to select nails that meet specific environmental and structural demands.

-

Coating: Coatings such as galvanized or polymer can enhance the performance of 16d nails. Galvanization prevents rust and corrosion, extending the lifespan of the nails. In contrast, polymer-coated nails reduce friction during driving, allowing for easier penetration into harder woods. Evaluating the right coating can lead to significant long-term cost savings through reduced maintenance and repairs.

-

Load Capacity: The load capacity of a 16d nail is critical for any construction project. The thicker shank provides superior holding power, making these nails ideal for securing heavy framing components like beams and trusses. Understanding load capacity helps buyers ensure that their chosen nails can withstand the stresses of the intended application.

-

Tolerance Levels: Tolerance refers to the acceptable variations in length and diameter during manufacturing. For 16d nails, tight tolerances ensure consistent performance across batches, which is vital for large-scale projects. Buyers should inquire about tolerance standards to guarantee that the nails will perform as expected in their applications.

What Are Common Trade Terms Related to 16d Nails?

Familiarity with industry terminology enhances communication and facilitates smoother transactions. Here are several common trade terms:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of nails, an OEM may supply specialized nails to a construction firm, ensuring that they meet specific project requirements.

-

MOQ (Minimum Order Quantity): MOQ indicates the smallest number of units a supplier is willing to sell. For 16d nails, understanding the MOQ is crucial for procurement, particularly for smaller companies that may not need large quantities but still want to ensure they can secure the nails at a reasonable price.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers to request pricing information for specific products. When dealing with 16d nails, a well-structured RFQ can help buyers obtain competitive quotes, ensuring they find the best value for their needs.

-

Incoterms (International Commercial Terms): These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for buyers sourcing 16d nails from different regions, as it clarifies shipping responsibilities, risk, and costs involved.

-

Lead Time: This term refers to the time from placing an order to its delivery. For construction projects, understanding lead times for 16d nails can help in planning and ensuring that materials arrive on time, avoiding project delays.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing 16d nails, ultimately enhancing the quality and efficiency of their construction projects.

Navigating Market Dynamics and Sourcing Trends in the 16 d nail size Sector

What Are the Current Market Dynamics Influencing the 16d Nail Size Sector?

The market for 16d nails is witnessing significant evolution driven by several global factors. As construction activities rebound post-pandemic, there is a rising demand for robust and reliable fasteners, particularly in emerging economies across Africa, South America, the Middle East, and Europe. The increasing focus on sustainable construction practices is shaping buyer preferences, leading to a shift towards high-quality materials that ensure structural integrity.

Moreover, the advent of digital platforms and B2B marketplaces is changing how international buyers source 16d nails. Suppliers are increasingly leveraging technology to enhance transparency in pricing and availability, allowing buyers to make informed decisions. In regions like Saudi Arabia and Nigeria, where rapid urbanization is occurring, there is a growing reliance on framing nails for residential and commercial projects, emphasizing the need for suppliers to maintain a consistent quality and supply chain reliability.

Emerging trends include the growing adoption of automated inventory management systems, which help suppliers optimize stock levels and meet fluctuating demands effectively. Additionally, buyers are becoming more discerning, seeking nails that not only meet technical specifications but also align with their project timelines and budgets.

How Is Sustainability Influencing Sourcing Decisions for 16d Nails?

As global awareness of environmental issues rises, sustainability is becoming a critical factor in the sourcing of 16d nails. International B2B buyers are increasingly prioritizing suppliers that demonstrate a commitment to ethical sourcing practices. This includes sourcing materials from forests certified by organizations like the Forest Stewardship Council (FSC), ensuring that the wood used in nail production is harvested sustainably.

The environmental impact of production processes is also under scrutiny. Buyers are looking for manufacturers that employ eco-friendly practices, such as reducing carbon emissions and minimizing waste during the manufacturing process. The use of ‘green’ materials, such as recycled steel for nails, is gaining traction, particularly among companies committed to reducing their carbon footprint.

Furthermore, certifications related to sustainability are becoming essential for suppliers. Buyers are more inclined to partner with manufacturers who can provide proof of sustainability certifications, as these can enhance their own brand reputation and meet regulatory requirements in their respective markets.

What Is the Historical Context of 16d Nails and Their Evolution in the Market?

The term “16d” originates from the Roman denarius, a currency used in ancient times, where the cost of 100 nails measuring 3.5 inches was 16 pennies. This historical context underscores the long-standing significance of nails in construction and carpentry. Over the years, the use of nails has evolved from basic fastening tools to highly engineered products designed for specific applications.

In recent decades, advancements in metallurgy and manufacturing processes have improved the performance characteristics of 16d nails, making them stronger and more reliable. The introduction of various coatings and treatments has also enhanced their resistance to corrosion, expanding their applicability in diverse environments. This evolution reflects broader trends in the construction industry, where quality and durability are paramount.

As the market continues to grow, understanding the historical significance of 16d nails provides valuable insights into their current application and the ongoing innovations that shape their production and usage in modern construction projects.

Frequently Asked Questions (FAQs) for B2B Buyers of 16 d nail size

-

How do I choose the right supplier for 16d nails?

Selecting the right supplier for 16d nails involves several key factors. Start by assessing the supplier’s reputation in the industry through reviews and testimonials. Ensure they have a proven track record of delivering high-quality products consistently. It’s also important to verify their certifications and compliance with international standards, particularly for markets in Africa, South America, and the Middle East. Request samples to evaluate the quality of the nails. Lastly, consider their production capacity to meet your volume requirements and their ability to provide timely delivery. -

What is the best type of 16d nail for structural applications?

For structural applications, the best type of 16d nail is typically a common nail with a ring shank design. This design enhances holding power, reducing the risk of nail withdrawal due to movement or stress in the structure. Additionally, consider nails with a galvanized or coated finish for improved corrosion resistance, especially in humid or outdoor environments. These features ensure durability and reliability in critical building components like framing, making them suitable for both residential and commercial projects. -

What are the minimum order quantities (MOQs) for 16d nails?

Minimum order quantities for 16d nails can vary significantly based on the supplier and your location. Many manufacturers set MOQs ranging from 1,000 to 5,000 pieces, especially for bulk orders. However, some suppliers may offer lower MOQs for first-time buyers or smaller businesses. It’s advisable to negotiate MOQs based on your specific needs, especially if you require a customized order. Always clarify the MOQ during initial discussions to avoid any surprises later in the procurement process. -

What payment terms should I expect when sourcing 16d nails internationally?

Payment terms for international sourcing of 16d nails typically include options like upfront payment, net 30/60 days, or letter of credit. Many suppliers require a deposit (often 30%) upon order confirmation, with the balance due before shipment. It’s crucial to establish clear payment terms upfront to ensure both parties are aligned on expectations. Additionally, consider using secure payment methods that provide buyer protection, especially when dealing with new suppliers in regions such as Africa or South America. -

How do I ensure quality assurance (QA) for 16d nails sourced internationally?

To ensure quality assurance for 16d nails, request detailed product specifications and certifications from your supplier. Conduct factory audits or third-party inspections to verify that manufacturing processes meet international standards. Additionally, consider implementing a quality control plan that includes sampling and testing of the nails upon arrival. Establishing a clear communication channel for addressing quality issues promptly will help maintain a strong relationship with your supplier and ensure that the products meet your expectations. -

What logistics considerations should I be aware of when importing 16d nails?

Logistics for importing 16d nails involve several considerations, including shipping methods, customs clearance, and delivery timelines. Choose between air freight for speed or sea freight for cost-effectiveness, depending on your urgency and budget. Ensure that your supplier can provide necessary shipping documentation to facilitate smooth customs clearance. Additionally, factor in any import duties or taxes applicable in your country, particularly in regions with varying trade regulations, such as the Middle East or Europe. -

Can I customize my order of 16d nails?

Yes, many suppliers offer customization options for 16d nails, including variations in length, diameter, and coating types. Custom orders may also include specific packaging requirements tailored to your operational needs. When considering customization, communicate your specifications clearly to the supplier and request samples if possible. Keep in mind that custom orders may have longer lead times and potentially higher costs, so plan accordingly in your procurement timeline. -

What factors affect the pricing of 16d nails in international markets?

The pricing of 16d nails in international markets is influenced by several factors, including raw material costs, manufacturing processes, and market demand. Currency fluctuations can also impact pricing, especially when dealing with suppliers in different regions. Additionally, factors like shipping costs, import tariffs, and local market competition play significant roles. To secure competitive pricing, conduct market research and consider multiple suppliers, ensuring that quality is not compromised in favor of lower costs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 16 D Nail Size Manufacturers & Suppliers List

1. HP Eng – Framing Nails

Domain: hp-eng.com

Registered: 2021 (4 years)

Introduction: Framing nails are essential for fastening structural components in construction. Key details include:

– 16d nail: 3 1/2 inches long, diameter of 0.162 inches.

– .131 framing nail: diameter of 0.131 inches, length varies by manufacturer.

– 16d nails offer greater strength and durability due to their larger diameter, providing more holding power and reducing the likelihood of bending or breaking….

2. Build My Own Cabin – Nail Size Chart

Domain: buildmyowncabin.com

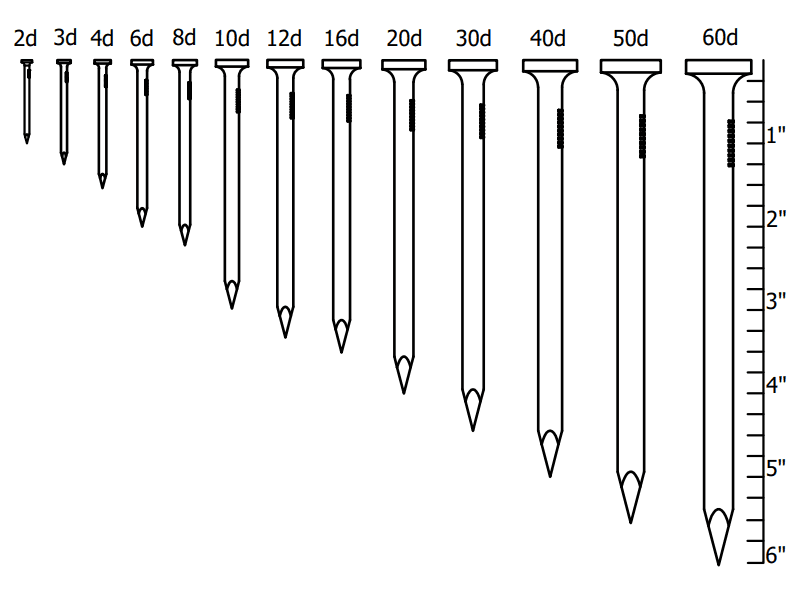

Registered: 2009 (16 years)

Introduction: Nail Size Chart: The guide helps in selecting proper nail sizes for framing projects. The letter ‘d’ denotes ‘penny’. Nail Measurements: 2d (1 inch), 3d (1.25 inches), 4d (1.5 inches), 5d (1.75 inches), 6d (2 inches), 8d (2.5 inches), 12d (3.25 inches), 16d (3.5 inches). Nails for Framing: 8d and 16d coated sinkers cover 95% of framing needs. 16d nails are preferred for framing 2x lumber. Types of…

3. Dock Builders – 16d Common Nail

Domain: dockbuilders.com

Registered: 1998 (27 years)

Introduction: {‘item_number’: ‘N-16DGC-25’, ‘type’: ‘Common nail’, ‘penny_size’: ’16d’, ‘length’: ‘3-1/2″‘, ‘gauge’: ‘8’, ‘head_diameter’: ’11/32″‘, ‘head_pattern’: ‘Smooth head’, ‘head_type’: ‘Full round head’, ‘shank_type’: ‘Smooth shank’, ‘shank_diameter’: ‘.165″‘, ‘point_type’: ‘Diamond point’, ‘material’: ‘Steel’, ‘finish’: ‘Hot dipped galvanized’, ‘approx_count_per_lb’: ’43’, ‘approx_count_per_package’: ‘…

4. Simpson Strong-Tie – 16D5HDG-R 16d x 3-1/2 Strong-Drive HDG Nail

Domain: fastenersplus.com

Registered: 2003 (22 years)

Introduction: {“Product Name”: “Simpson 16D5HDG-R 16d x 3-1/2″ Strong-Drive HDG Nail”, “SKU”: “16D5HDG-R”, “Diameter”: “0.162 inch”, “Length”: “3-1/2 inch”, “Material”: “Carbon Steel”, “Quantity”: “5 lb (Approx 200 Fasteners)”, “Price”: “$21.97”, “Manufacturer”: “Simpson Strong-Tie”, “Features”: “Hot-dip galvanized (HDG) protection for corrosion resistance in high-exposure environments, ideal for wood framing a…

5. MCSW USA – Framing Nails Guide

Domain: mcswusa.com

Registered: 2016 (9 years)

Introduction: Common sizes for framing nails: 16d (3 ½ inches), 10d (3 inches), 8d (2 ½ inches). Types of 16d nails: Common nails (0.162 inches diameter) and Sinker nails (0.148 inches diameter, textured head). 8d nails are used for attachments like furring strips and subfloors. For roof decking: 1/2-inch plywood or OSB requires 8d common or ring-shank nails; 5/8-inch plywood or OSB requires 10d common or ring-…

6. Building Code Forum – 16D Nails Discussion

Domain: thebuildingcodeforum.com

Registered: 2012 (13 years)

Introduction: 16D nails are specified as 3.5″ in length and 0.135″ in diameter according to IRC 602.3(1). There is a discussion regarding the acceptability of gun nails that are 16D with a diameter of 0.131″, which may not meet the minimum requirements for certain applications. Common nails are typically 0.162″ in diameter, while sinkers are 0.148″. The forum emphasizes the importance of adhering to code specif…

Strategic Sourcing Conclusion and Outlook for 16 d nail size

In summary, the strategic sourcing of 16d nails offers significant advantages for international B2B buyers, particularly in construction-heavy markets such as Africa, South America, the Middle East, and Europe. Understanding the unique characteristics of 16d nails, including their length (3-1/2 inches) and diameter (0.162 inches), is essential for ensuring the structural integrity of building projects. The choice between 16d nails and alternatives, such as .131 framing nails, hinges on the specific demands of the project, with 16d nails providing superior strength and durability necessary for larger frameworks.

As buyers seek to optimize their supply chains, focusing on sourcing high-quality 16d nails can lead to enhanced project outcomes and long-term cost savings. The market for these nails is evolving, and establishing relationships with reliable suppliers can facilitate access to competitively priced, high-performance products.

Looking ahead, international buyers are encouraged to leverage strategic sourcing to not only meet immediate construction needs but also to anticipate future market trends. By prioritizing quality and durability in their fastener selections, businesses can position themselves for success in an increasingly competitive landscape. Explore partnerships with trusted manufacturers and distributors to secure the best materials for your projects today.