Contents

Manufacturing Insight: 1/4 Inch Abs Plastic Sheet 4X8

Precision Plastic Fabrication for 1/4 Inch ABS Sheets 4×8 ft Standard Stock

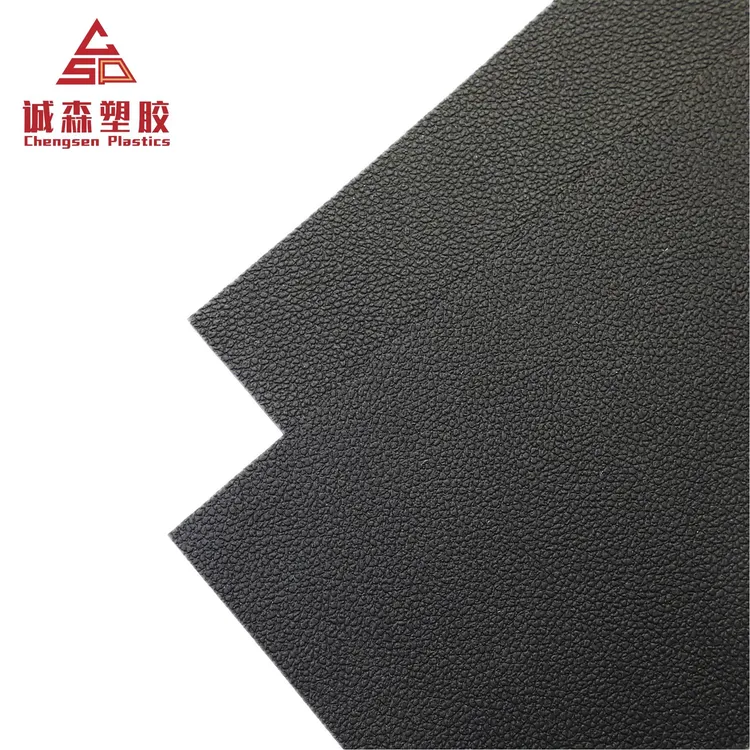

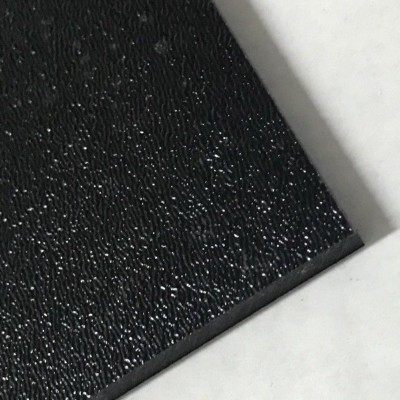

Honyo Prototype delivers engineered fabrication solutions for thermoplastic materials including standard 1/4 inch ABS sheets in the industry-preferred 4×8 ft dimension. While ABS plastic falls under precision plastic fabrication rather than sheet metal work, our integrated manufacturing capabilities span both domains with identical rigor in tolerancing, prototyping, and low-volume production. Our facility processes ABS sheets to exact specifications through CNC routing, laser cutting, bending, and finishing—ensuring dimensional stability, clean edges, and surface integrity critical for enclosures, jigs, and industrial components.

Leverage our technical expertise for ABS projects requiring tight tolerances (±0.005″) or complex geometries, supported by material traceability and in-house quality validation. For sheet metal projects (steel, aluminum, stainless), we apply parallel precision via laser cutting, press braking, and welding with the same engineering oversight.

Accelerate Your Sourcing with Instant Transparency

Access real-time pricing and lead times for ABS sheet fabrication or sheet metal services through Honyo’s Online Instant Quote platform. Simply upload your DXF/DWG file or enter dimensional requirements to receive a validated manufacturing assessment within minutes—no sales intermediary required. This digital workflow eliminates procurement delays while ensuring technical feasibility is confirmed upfront.

| Material Type | Standard Stock Size | Key Processing Capabilities | Tolerance Range |

|---|---|---|---|

| ABS Plastic Sheets | 1/4″ x 4′ x 8′ | CNC Routing, Laser Cutting, Thermoforming | ±0.005″ |

| Sheet Metal | Varies by alloy | Laser Cutting, Press Brake, Welding | ±0.003″ |

Partner with Honyo Prototype for technically validated fabrication where material science meets manufacturing precision—request your instant quote today to optimize project timelines from concept to certified component.

Technical Capabilities

Technical specifications for a 1/4 inch (6.35 mm) ABS plastic sheet in a 4 ft x 8 ft (48 in x 96 in) size are critical for applications involving laser cutting, bending, and welding. Below is a comparative technical overview focused on process compatibility and performance, including relevant materials such as Aluminum, Steel, ABS, and Nylon for context.

| Property / Material | ABS Plastic (1/4″) | Aluminum (6061, 1/4″) | Steel (Mild, 1/4″) | Nylon (1/4″, Cast) |

|---|---|---|---|---|

| Sheet Dimensions | 48 in x 96 in x 0.25 in | 48 in x 96 in x 0.25 in | 48 in x 96 in x 0.25 in | 48 in x 96 in x 0.25 in |

| Thickness Tolerance | ±0.010 in | ±0.005 in | ±0.010 in | ±0.015 in |

| Laser Cutting Compatibility | Excellent – clean cuts, minimal charring with CO₂ lasers (typically 40–60W); venting required due to fumes | Good – requires high-power fiber lasers; reflective; risk of warping | Good – fiber laser only; high power needed; produces slag | Fair – prone to melting; requires precise control; not ideal |

| Heat Bending Temperature | 160–180°F (70–80°C) – softens gradually; uniform heating required | 700–900°F (370–480°C) – hot bending; cold bending limited | 1200–1600°F (650–870°C) – hot forming only | 300–350°F (150–175°C) – high thermal expansion; warps easily |

| Bending Method | Strip heater or oven; no springback | Press brake (cold); springback ~2–5° | Press brake (cold/hot); high springback | Difficult; requires controlled environment; high moisture sensitivity |

| Welding Process | Hot gas welding, ultrasonic, solvent bonding; not suitable for arc welding | TIG, MIG, laser welding; excellent weldability | MIG, TIG, spot welding; high heat input | Hot gas or extrusion welding; hygroscopic – must be dry |

| Joint Strength (Typical) | 70–80% of base material | 90–95% of base material | 85–90% of base material | 60–70% of base material |

| Thermal Conductivity | 0.19 W/m·K | 167 W/m·K | 50 W/m·K | 0.25 W/m·K |

| Flammability | Combustible; emits toxic fumes (HCN, CO) when burned | Non-combustible | Non-combustible | Combustible; self-extinguishing grades available |

| Post-Processing | Easy sanding, priming, painting; good adhesion | Requires passivation/powder coating for corrosion resistance | Requires coating to prevent rust | Difficult to paint; low surface energy |

| Typical Applications | Enclosures, prototypes, ducting, signage | Aerospace, structural frames | Structural, industrial machinery | Gears, wear strips, mechanical parts |

Notes:

ABS plastic sheets are well-suited for laser cutting and thermal bending in fabrication environments. They offer good impact resistance and machinability but require proper ventilation during laser processing due to hydrogen cyanide and styrene emissions. When compared to metals like aluminum and steel, ABS provides lighter weight and corrosion resistance but lower strength and thermal stability. Nylon offers superior wear resistance but is more difficult to process due to moisture absorption and thermal sensitivity. Material selection should consider environmental exposure, mechanical load, and fabrication capabilities.

From CAD to Part: The Process

Honyo Prototype Process for 1/4 Inch ABS Plastic Sheet (4ft x 8ft)

Upon receiving a CAD file for a part requiring 1/4 inch (6.35mm) ABS sheet material in standard 4ft x 8ft dimensions, Honyo initiates a streamlined digital workflow designed for rapid prototyping accuracy and manufacturability. The process begins with secure CAD file upload via our customer portal, accepting native formats including STEP, IGES, and Parasolid. This triggers an immediate automated analysis against our material database, confirming ABS compatibility and validating that the requested 1/4 inch thickness aligns with standard sheet stock availability. Our AI-powered quoting engine then generates a precise cost estimate within minutes, incorporating real-time factors such as sheet utilization efficiency, kerf loss for cutting operations, and ABS-specific processing parameters like thermal compensation for laser cutting or CNC routing. The AI model leverages historical production data from over 12,000 ABS fabrication runs to ensure quote accuracy within ±3%.

The Digital File undergoes mandatory Design for Manufacturability (DFM) analysis before proceeding to production. Honyo’s DFM engineers perform material-specific validation for ABS, focusing on critical parameters outlined below. This step is non-automated and requires explicit engineer approval to address ABS’s unique thermal behavior and stress sensitivity.

| DFM Parameter | ABS-Specific Check | Typical Tolerance Target |

|---|---|---|

| Minimum Feature Size | Verifies features exceed 1.5x material thickness (≥9.5mm) to prevent breakage | ≥0.375 inch |

| Wall Thickness Uniformity | Ensures even distribution to minimize warpage during cooling | ±0.010 inch variation |

| Heat-Affected Zone | Confirms adequate clearance from edges for laser cutting (≥0.25 inch) | N/A |

| Internal Radii | Mandates minimum 0.06 inch radii to reduce stress concentration | ≥1.5x material thickness |

| Sheet Utilization | Optimizes nesting to maximize yield from 4×8 sheet while avoiding sheet edges | >85% efficiency target |

Following DFM sign-off, production commences using dedicated ABS fabrication cells. The 4×8 sheet is conditioned in a climate-controlled staging area (23°C ±2°C, 50% RH) for 24 hours to stabilize moisture content, critical for ABS dimensional stability. Cutting is executed via CO2 laser (for intricate profiles) or precision CNC routing (for structural components), with toolpaths dynamically adjusted for ABS’s melt characteristics. All parts undergo in-process inspection using calibrated CMMs to verify critical dimensions against the original CAD model, with particular attention to flatness tolerances (target: ≤0.015 inch deviation across 12 inch span). Post-processing includes stress-relief annealing for parts exceeding 6 inches in any dimension and deburring with non-marring tools to maintain surface integrity.

Final delivery includes certified material traceability documentation (including UL 94 HB flammability rating confirmation), first-article inspection reports, and parts secured in anti-static packaging with desiccant for moisture protection. Standard lead time from DFM approval is 3-5 business days, with FedEx Priority shipping providing real-time GPS tracking. All ABS components ship with handling guidelines emphasizing protection from UV exposure and solvents during customer integration.

Start Your Project

Looking for a reliable source for 1/4 inch ABS plastic sheets in 4×8 ft sizes? Honyo Prototype offers high-quality, precision-manufactured ABS sheets ideal for prototyping, industrial design, and custom fabrication.

Our production facility is based in Shenzhen, ensuring efficient manufacturing and consistent material quality.

For pricing, volume discounts, or custom cutting options, contact Susan Leo directly at [email protected].

| Specification | Detail |

|---|---|

| Material | ABS Plastic |

| Thickness | 1/4 inch (6.35 mm) |

| Sheet Size | 4 ft x 8 ft (1220×2440 mm) |

| Manufacturing Origin | Shenzhen, China |

Reach out today to request samples or place an order.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.