Introduction: Navigating the Global Market for 13 gauge sheet metal

In the dynamic landscape of global manufacturing, sourcing high-quality 13 gauge sheet metal presents a significant challenge for international B2B buyers. As industries across Africa, South America, the Middle East, and Europe increasingly rely on this versatile material for applications ranging from construction to automotive, understanding the nuances of sourcing becomes paramount. This comprehensive guide is designed to equip decision-makers with the essential knowledge needed to navigate the complexities of the 13 gauge sheet metal market.

Within these pages, you will discover detailed insights into the various types of 13 gauge sheet metal available, their specific applications, and the critical factors to consider when vetting suppliers. We will delve into cost structures, shipping logistics, and the importance of quality certifications, ensuring that you are well-prepared to make informed purchasing decisions.

By empowering international buyers with actionable information and strategic insights, this guide aims to streamline the sourcing process, reduce risks, and enhance overall procurement efficiency. Whether you are looking to establish long-term supplier relationships or simply seeking the best pricing options, our goal is to provide you with the tools necessary to succeed in today’s competitive global market.

Understanding 13 gauge sheet metal Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cold Rolled Steel Sheet | Smooth finish, tighter tolerances, higher strength | Automotive parts, machinery components | Pros: Superior surface finish, excellent strength. Cons: Prone to rust if not coated. |

| Hot Rolled Steel Sheet | Rough surface, lower production costs | Construction, structural applications | Pros: Cost-effective, easy to work with. Cons: Less precise dimensions, can warp. |

| Stainless Steel Sheet | Corrosion-resistant, aesthetic appeal | Food processing, medical equipment | Pros: Long-lasting, hygienic. Cons: Higher cost, can be harder to machine. |

| Aluminum Sheet | Lightweight, good corrosion resistance | Aerospace, automotive, packaging | Pros: Lightweight, excellent strength-to-weight ratio. Cons: More expensive than steel. |

| Galvanized Steel Sheet | Coated with zinc for corrosion resistance | Roofing, outdoor structures | Pros: Enhanced durability, lower maintenance. Cons: Limited high-temperature applications. |

What Are the Characteristics of Cold Rolled Steel Sheet for B2B Buyers?

Cold rolled steel sheets are known for their smooth surface and high strength due to the cold working process. This type of sheet metal is often utilized in applications requiring precise dimensions, such as automotive parts and machinery components. B2B buyers should consider the need for protective coatings to prevent rust, as cold rolled sheets are susceptible to corrosion if exposed to moisture.

How Does Hot Rolled Steel Sheet Compare in Terms of Cost and Applications?

Hot rolled steel sheets are typically less expensive than their cold rolled counterparts, making them a popular choice for construction and structural applications. The manufacturing process results in a rough surface and less precise dimensions, which can be advantageous in applications where exact measurements are less critical. Buyers should weigh the lower cost against the potential for warping and less favorable surface characteristics.

Why Choose Stainless Steel Sheet for Specific B2B Applications?

Stainless steel sheets offer excellent corrosion resistance and are often used in industries like food processing and medical equipment due to their hygienic properties. Their aesthetic appeal also makes them suitable for architectural applications. However, they come at a higher price point and can be more challenging to machine, which B2B buyers must factor into their procurement decisions.

What Are the Benefits and Drawbacks of Using Aluminum Sheet?

Aluminum sheets are favored in industries such as aerospace and automotive for their lightweight and corrosion-resistant properties. They provide an excellent strength-to-weight ratio, making them ideal for applications where weight savings are crucial. However, B2B buyers should be aware that aluminum tends to be more expensive than steel, which can impact budget considerations.

How Does Galvanized Steel Sheet Enhance Durability for Buyers?

Galvanized steel sheets are coated with zinc, providing enhanced corrosion resistance that makes them suitable for outdoor structures and roofing. This added durability reduces maintenance needs over time, making them an attractive option for B2B buyers focused on long-term investments. However, their use in high-temperature applications may be limited, so buyers should assess their specific needs before procurement.

Key Industrial Applications of 13 gauge sheet metal

| Industry/Sector | Specific Application of 13 gauge sheet metal | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Fabrication of industrial equipment | Provides strength and durability in heavy machinery | Ensure compliance with international standards (ISO, ASTM) |

| Construction | Structural components for buildings | Offers reliable support and stability in construction | Consider local regulations and material sourcing logistics |

| Automotive | Production of vehicle body panels | Enhances vehicle safety and performance | Look for suppliers with experience in automotive-grade materials |

| HVAC | Manufacturing of ductwork and ventilation systems | Improves energy efficiency and air quality | Verify material specifications for thermal performance |

| Agricultural Equipment | Construction of farming machinery | Increases operational lifespan and reduces maintenance costs | Assess availability of custom cuts and sizes for specific needs |

How is 13 Gauge Sheet Metal Used in Manufacturing?

In the manufacturing sector, 13 gauge sheet metal is crucial for fabricating industrial equipment such as machinery frames, brackets, and enclosures. Its significant thickness provides the necessary strength and durability to withstand heavy loads and rigorous operational conditions. For international buyers, particularly those in Africa and South America, ensuring compliance with international standards like ISO and ASTM is vital to guarantee quality and reliability in their operations. Additionally, sourcing from reputable suppliers who can provide detailed specifications and certifications is essential to avoid production delays.

What Role Does 13 Gauge Sheet Metal Play in Construction?

In construction, 13 gauge sheet metal is often utilized for structural components, including framing, roofing, and siding. Its robust properties ensure reliable support and stability, making it a preferred choice for both commercial and residential projects. For buyers in the Middle East and Europe, it is crucial to consider local building codes and regulations that may dictate material specifications and performance standards. Furthermore, logistical considerations such as shipping and availability of local suppliers can impact project timelines and costs.

How is 13 Gauge Sheet Metal Beneficial in Automotive Applications?

The automotive industry relies heavily on 13 gauge sheet metal for producing vehicle body panels and structural components. Its thickness contributes to enhanced safety features, crash resistance, and overall vehicle performance. International buyers, particularly in regions like Vietnam and Saudi Arabia, should seek suppliers experienced in automotive-grade materials to ensure compliance with stringent industry standards. Additionally, the ability to customize sizes and shapes can significantly enhance manufacturing efficiency and reduce waste.

Why is 13 Gauge Sheet Metal Important in HVAC Systems?

In HVAC applications, 13 gauge sheet metal is commonly used for manufacturing ductwork and ventilation systems. Its strength and durability contribute to improved energy efficiency and air quality in buildings. Buyers should prioritize sourcing materials that meet specific thermal performance standards, especially in regions with extreme climates. Understanding the local market for HVAC components and ensuring compatibility with existing systems can also enhance sourcing effectiveness.

How is 13 Gauge Sheet Metal Used in Agricultural Equipment?

For agricultural equipment, 13 gauge sheet metal is essential in constructing robust machinery that can withstand the rigors of farming operations. Its durability increases the operational lifespan of equipment, reducing maintenance costs and downtime. Buyers in agricultural sectors should assess suppliers’ capabilities to provide custom cuts and sizes tailored to specific machinery needs, ensuring optimal performance in the field. Furthermore, understanding the agricultural landscape in their respective regions can help buyers make informed sourcing decisions.

3 Common User Pain Points for ’13 gauge sheet metal’ & Their Solutions

Scenario 1: Sourcing Quality 13 Gauge Sheet Metal for Diverse Applications

The Problem: Many B2B buyers struggle to find suppliers who provide consistent quality and specifications for 13 gauge sheet metal. The inconsistency in material thickness, strength, and finish can lead to significant issues in manufacturing processes, especially for businesses in construction, automotive, and industrial applications. For instance, a buyer may receive a shipment that does not meet the ASTM standards required for their project, leading to production delays and increased costs.

The Solution: To ensure quality and consistency, buyers should establish relationships with reputable suppliers who provide detailed material certifications and specifications. When sourcing 13 gauge sheet metal, request documentation that verifies compliance with relevant standards such as ASTM A1008 for cold-rolled steel. Additionally, consider using a supplier that offers customizable options, allowing you to specify exact thickness and finish according to your project needs. Establishing a clear communication channel with suppliers can also help address concerns before they escalate into problems.

Scenario 2: Managing Shipping Costs and Logistics for Large Orders

The Problem: Buyers often face challenges related to the logistics and shipping costs when ordering large quantities of 13 gauge sheet metal. The weight and bulk of metal sheets can lead to hefty freight charges, which can erode profit margins. Moreover, delays in shipping can disrupt production schedules, particularly when time-sensitive projects are involved.

The Solution: To mitigate shipping costs, buyers should consider ordering smaller, more manageable sizes rather than oversized sheets. Many suppliers offer custom cutting services that can help optimize shipping efficiency by allowing for the selection of dimensions that fit standard shipping requirements. Additionally, explore suppliers that provide consolidated shipping options or local pickup to reduce freight costs. Establishing a logistics plan that factors in lead times and potential delays can also help in maintaining the flow of materials and keeping projects on schedule.

Scenario 3: Understanding the Best Uses and Applications of 13 Gauge Sheet Metal

The Problem: A common issue faced by B2B buyers is a lack of clarity on the most appropriate applications for 13 gauge sheet metal. This can lead to misapplication, where buyers use it in projects where a different gauge or material would be more suitable, resulting in structural failures or increased costs due to rework.

The Solution: Buyers should invest time in understanding the mechanical properties and recommended uses of 13 gauge sheet metal. This gauge is versatile and is commonly used for applications like structural supports, automotive parts, and HVAC systems. Consulting with engineers or material specialists can provide insights into the material’s strength, ductility, and welding capabilities. Additionally, consider leveraging supplier resources, such as technical datasheets and application guides, to make informed decisions. Establishing a feedback loop with your engineering team can also help refine material choices based on project outcomes and experiences.

Strategic Material Selection Guide for 13 gauge sheet metal

What Are the Key Materials for 13 Gauge Sheet Metal in B2B Applications?

When selecting 13 gauge sheet metal, it’s essential to consider the specific materials available, each with its unique properties and applications. This guide analyzes four common materials: cold-rolled carbon steel, stainless steel, aluminum, and hot-rolled steel, focusing on their performance, advantages, limitations, and considerations for international buyers.

What Are the Key Properties of Cold-Rolled Carbon Steel for 13 Gauge Sheet Metal?

Cold-rolled carbon steel, such as ASTM A1008, is a popular choice for 13 gauge sheet metal due to its strength and smooth finish. This material typically has a yield strength of around 31 KSI and an ultimate tensile strength of 51 KSI, making it suitable for structural applications. It offers good machinability and can be easily formed and welded.

Pros: The cost-effectiveness and high strength-to-weight ratio make cold-rolled carbon steel an attractive option for many applications, including automotive parts, appliances, and construction components.

Cons: However, it has limited corrosion resistance unless treated, which can be a significant drawback in humid or corrosive environments.

Impact on Application: Cold-rolled carbon steel is compatible with various media but may require protective coatings for applications exposed to moisture or chemicals.

How Does Stainless Steel Perform as a 13 Gauge Sheet Metal Option?

Stainless steel, particularly grades like 304 and 316, is known for its excellent corrosion resistance and aesthetic appeal. It can withstand temperatures up to 1500°F and is often used in applications requiring hygiene and durability, such as food processing and medical equipment.

Pros: The primary advantage of stainless steel is its resistance to rust and staining, making it ideal for outdoor and marine applications.

Cons: The higher cost and manufacturing complexity, including challenges in welding and machining, can limit its use in budget-sensitive projects.

Impact on Application: For international buyers, compliance with health and safety standards is crucial, especially in food-related industries. Stainless steel is often preferred in regions with stringent regulations.

What Are the Benefits of Using Aluminum for 13 Gauge Sheet Metal?

Aluminum, particularly grades like 5052 and 6061, is lightweight and offers excellent corrosion resistance. It is also non-magnetic and has good thermal and electrical conductivity, making it suitable for various applications, including aerospace and automotive.

Pros: The lightweight nature of aluminum allows for easy handling and installation, reducing overall project costs.

Cons: However, aluminum is generally less strong than steel and can be more expensive, particularly for thicker gauges.

Impact on Application: Buyers in regions with high humidity or coastal environments will find aluminum advantageous due to its corrosion resistance. Compliance with international standards for aerospace applications is also a consideration.

What Are the Key Characteristics of Hot-Rolled Steel for 13 Gauge Sheet Metal?

Hot-rolled steel is produced at high temperatures, which allows for easier shaping and forming. It is often used in applications where surface finish is less critical, such as in structural components and frames.

Pros: The material is generally less expensive than cold-rolled steel and is easier to work with in terms of welding and forming.

Cons: However, it has a rougher surface finish and lower dimensional accuracy compared to cold-rolled options, which can be a disadvantage in precision applications.

Impact on Application: Hot-rolled steel is suitable for applications where aesthetics are not a priority, but buyers should be aware of potential surface rust in humid climates.

Summary Table of Material Options for 13 Gauge Sheet Metal

| Material | Typical Use Case for 13 gauge sheet metal | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cold-Rolled Carbon Steel | Automotive parts, appliances | High strength-to-weight ratio | Limited corrosion resistance | Medium |

| Stainless Steel | Food processing, medical equipment | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Aluminum | Aerospace, automotive | Lightweight and corrosion-resistant | Less strength compared to steel | Medium to High |

| Hot-Rolled Steel | Structural components, frames | Easier to work with and cost-effective | Rough surface finish and lower accuracy | Low |

This strategic material selection guide provides valuable insights for international B2B buyers, helping them make informed decisions based on their specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for 13 gauge sheet metal

What Are the Key Stages in the Manufacturing Process of 13 Gauge Sheet Metal?

The manufacturing process for 13 gauge sheet metal involves several critical stages, each designed to ensure the final product meets the required specifications for strength, durability, and application suitability.

-

Material Preparation

The process begins with the selection of high-quality raw materials, typically cold-rolled or hot-rolled steel, conforming to standards such as ASTM A1008 for cold-rolled steel. The steel is usually received in coils or sheets, which are then inspected for surface defects and dimensional accuracy. Prior to forming, the material is cleaned to remove any contaminants that could affect the final finish. -

Forming

In this stage, the cleaned sheets undergo various forming techniques, such as stamping, shearing, or cutting to size. The choice of technique largely depends on the end-use of the sheet metal. For instance, stamping is often used for intricate designs, while shearing is preferred for cutting sheets to specific dimensions. Precision is vital, and manufacturers often employ CNC (Computer Numerical Control) machinery to ensure high accuracy. -

Assembly

If the sheet metal is part of a larger assembly, it will be combined with other components. This may involve welding, riveting, or using fasteners. The assembly process requires careful alignment and securing to ensure structural integrity and performance. -

Finishing

The final stage involves applying surface finishes, such as painting, galvanizing, or powder coating, to enhance corrosion resistance and aesthetic appeal. The choice of finish can also impact the metal’s performance in different environments, making it essential for buyers to specify their requirements clearly.

What Quality Control Measures Are Commonly Implemented in 13 Gauge Sheet Metal Manufacturing?

Quality assurance is paramount in the manufacturing of 13 gauge sheet metal, ensuring that products meet international standards and customer expectations.

-

International and Industry-Specific Standards

Many manufacturers adhere to ISO 9001, which outlines requirements for a quality management system, and CE marking for products sold in Europe. These standards assure buyers of consistent quality and compliance with regulatory requirements. Industry-specific certifications, such as API for oil and gas applications, may also be relevant depending on the end-use of the sheet metal. -

Quality Control Checkpoints

– Incoming Quality Control (IQC): This initial inspection stage verifies the quality of raw materials upon arrival. Suppliers may provide mill test reports (MTRs) to confirm material specifications.

– In-Process Quality Control (IPQC): Throughout the manufacturing process, various checkpoints are established to monitor the quality of work in progress. This includes dimensional checks and visual inspections to catch defects early.

– Final Quality Control (FQC): The finished product undergoes a final inspection before shipment, ensuring it meets specified dimensions, weight, and surface finish criteria. -

Common Testing Methods

Various testing methods are employed to evaluate the mechanical properties and structural integrity of the sheet metal. Common tests include tensile testing, hardness testing, and visual inspections for surface defects. Non-destructive testing (NDT) methods such as ultrasonic or magnetic particle testing may also be utilized to identify internal flaws.

How Can B2B Buyers Verify Supplier Quality Control Procedures?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential to ensure product reliability.

-

Supplier Audits

Conducting supplier audits is a proactive approach to assess the manufacturing processes and quality management systems in place. Buyers can evaluate the supplier’s adherence to international standards and their overall commitment to quality. -

Documentation and Reports

Requesting detailed documentation, including quality control reports, certificates of compliance, and MTRs, can provide insights into the supplier’s quality practices. These documents can help assess whether the supplier consistently meets quality standards. -

Third-Party Inspections

Engaging third-party inspection services can provide an unbiased evaluation of the manufacturing process and final product quality. These inspections can be particularly beneficial for buyers unfamiliar with local suppliers or those sourcing from regions with varying quality standards.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers face unique challenges when sourcing 13 gauge sheet metal, often influenced by regional standards, regulations, and logistical considerations.

-

Understanding Regional Standards

Familiarity with regional regulations and standards is crucial. For example, CE marking is mandatory for products sold in the European Union, while other regions may have different compliance requirements. Buyers should communicate their specific standards clearly to suppliers to avoid compliance issues. -

Logistical Considerations

Shipping and logistics can impact product quality. Buyers should ensure that suppliers have robust packaging and handling procedures to prevent damage during transit. Additionally, understanding the shipping process, including customs regulations, can help mitigate delays and potential quality issues. -

Cultural and Communication Factors

Effective communication is essential in international transactions. Buyers should establish clear channels of communication with suppliers, ensuring that all quality expectations are explicitly defined and understood. This may involve regular updates and feedback throughout the manufacturing process.

In conclusion, understanding the manufacturing processes and quality assurance measures for 13 gauge sheet metal is vital for B2B buyers. By focusing on these critical areas, buyers can make informed decisions, ensuring they source high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ’13 gauge sheet metal’

When sourcing 13 gauge sheet metal, it is essential to have a structured approach to ensure quality, reliability, and cost-effectiveness. This checklist serves as a practical guide for international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Clearly outline your requirements for 13 gauge sheet metal. This includes the type of steel (e.g., cold rolled, hot rolled), dimensions, and any specific standards (like ASTM-A1008). Accurate specifications help suppliers understand your needs and facilitate better quotes.

- Thickness: Ensure you specify the exact thickness, as there can be slight variations.

- Finish: Consider whether you need a specific surface finish, which can affect usability and aesthetics.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers who specialize in 13 gauge sheet metal. Look for companies with a proven track record and positive customer reviews.

- Industry Experience: Suppliers with relevant experience in your sector will likely understand your needs better.

- Geographical Presence: Consider suppliers who can ship to your location efficiently to minimize shipping costs and delays.

Step 3: Evaluate Supplier Certifications

Before finalizing a supplier, verify their certifications and compliance with industry standards. This step is crucial for ensuring product quality and safety.

- Quality Management: Look for ISO certifications or similar, which indicate adherence to quality standards.

- Material Certifications: Request Material Test Reports (MTRs) to confirm the chemical and mechanical properties of the sheet metal.

Step 4: Request Samples

Always ask for samples before placing a large order. This allows you to assess the quality and suitability of the material for your intended application.

- Physical Inspection: Check for defects, surface finish, and gauge accuracy.

- Testing: If applicable, conduct tests for tensile strength, yield strength, and other mechanical properties relevant to your project.

Step 5: Compare Pricing and Payment Terms

Collect quotes from multiple suppliers to compare pricing. Be mindful of the total cost, including shipping, taxes, and any potential tariffs.

- Transparent Pricing: Ensure that quotes are itemized to avoid hidden costs.

- Payment Flexibility: Discuss payment terms and options, such as credit terms or discounts for bulk orders.

Step 6: Assess Lead Times and Delivery Options

Understand the lead times for production and delivery from each supplier. This is vital for planning your project timeline.

- Production Time: Confirm how long it will take to manufacture the sheets based on your specifications.

- Shipping Methods: Evaluate shipping options and their associated costs to avoid unexpected delays.

Step 7: Build a Relationship with Your Supplier

Once you’ve selected a supplier, focus on building a strong working relationship. Open communication can lead to better service, timely deliveries, and potential discounts on future orders.

- Regular Updates: Maintain communication regarding order status and any changes in your requirements.

- Feedback Loop: Provide feedback on product quality and service to foster mutual improvement.

By following this checklist, B2B buyers can streamline the sourcing process for 13 gauge sheet metal, ensuring they select the right suppliers and materials for their projects.

Comprehensive Cost and Pricing Analysis for 13 gauge sheet metal Sourcing

What Are the Key Cost Components in Sourcing 13 Gauge Sheet Metal?

When sourcing 13 gauge sheet metal, several cost components significantly influence the final pricing. The primary components include material costs, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The type of steel (e.g., cold-rolled, hot-rolled, or stainless) directly impacts the material cost. For instance, cold-rolled steel tends to be more expensive due to the processing involved. Additionally, fluctuations in global steel prices can lead to variability in costs.

-

Labor and Manufacturing Overhead: Labor costs vary by region and can significantly affect the price. Countries with higher wages will typically see increased costs. Manufacturing overhead, which includes utilities, maintenance, and facility costs, also contributes to the overall expense.

-

Tooling: If the sheet metal requires custom shapes or sizes, tooling costs will increase. These costs can be amortized over larger production runs, making it crucial to consider the quantity being ordered.

-

Quality Control: Ensuring that the sheet metal meets specific standards (e.g., ASTM specifications) incurs additional QC costs. This is especially important for international buyers who may need certifications for compliance.

-

Logistics: Transportation and shipping costs are vital, particularly for international transactions. The choice between air freight and sea freight can greatly influence total costs, with sea freight typically being more economical for larger volumes.

-

Supplier Margin: Each supplier will have its markup, which can vary based on their market positioning, relationship with manufacturers, and the competitive landscape.

How Do Price Influencers Affect 13 Gauge Sheet Metal Pricing?

Numerous factors can influence the pricing of 13 gauge sheet metal, which is essential for buyers to understand:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Suppliers may offer discounts for bulk purchases, which can be a significant cost-saving opportunity.

-

Specifications and Customization: Custom sizes or additional processing (e.g., bending, cutting) will increase costs. Standard sizes are typically more cost-effective, so buyers should assess their needs carefully.

-

Materials and Quality Certifications: Higher-quality materials or those that meet specific certifications will command a premium price. Buyers must balance the quality required with budget constraints.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers with strong relationships may offer better pricing and terms compared to less experienced vendors.

-

Incoterms: Understanding the implications of different Incoterms (e.g., FOB, CIF) is crucial as they define the responsibilities of buyers and sellers regarding shipping costs and risk transfer.

What Tips Can Help Buyers Negotiate Better Prices for 13 Gauge Sheet Metal?

B2B buyers can adopt several strategies to improve their cost-efficiency when sourcing 13 gauge sheet metal:

-

Negotiation: Engage suppliers in discussions about pricing, especially if you are a repeat customer. Leverage your purchasing power to negotiate better terms or discounts.

-

Total Cost of Ownership (TCO): Look beyond initial pricing and consider the total cost of ownership, including shipping, potential tariffs, and future maintenance. This holistic view can lead to better decision-making.

-

Pricing Nuances for International Transactions: Be mindful of currency fluctuations, import duties, and taxes that may apply to international shipments. These can significantly affect the overall cost.

-

Supplier Diversification: Avoid relying on a single supplier. By sourcing from multiple vendors, you can compare prices and negotiate more effectively.

-

Stay Informed: Regularly monitor market trends in steel prices and global supply chain conditions. Being informed can provide leverage during negotiations and help in making timely purchasing decisions.

Disclaimer

The prices referenced in this analysis are indicative and may vary based on market conditions, supplier pricing strategies, and specific order requirements. Always consult with suppliers for the most accurate and up-to-date pricing information.

Alternatives Analysis: Comparing 13 gauge sheet metal With Other Solutions

Exploring Alternative Solutions to 13 Gauge Sheet Metal

In the realm of industrial applications, selecting the right material is crucial. While 13 gauge sheet metal is a popular choice for its strength and versatility, there are alternative materials that may better suit specific needs depending on the context. This analysis will compare 13 gauge sheet metal with two viable alternatives: aluminum sheet metal and fiberglass reinforced plastic (FRP). Each option presents unique benefits and limitations that can impact decision-making for B2B buyers.

| Comparison Aspect | 13 Gauge Sheet Metal | Aluminum Sheet Metal | Fiberglass Reinforced Plastic (FRP) |

|---|---|---|---|

| Performance | High tensile strength, good formability, and weldability. | Lightweight, excellent corrosion resistance, lower strength than steel. | High tensile strength, good impact resistance, and low weight. |

| Cost | Generally lower cost per unit than aluminum but higher than FRP. | Higher initial costs, especially for thicker gauges. | Moderate cost, often more economical for large-scale applications. |

| Ease of Implementation | Requires specialized tools for cutting and welding. | Easier to cut and shape, can be formed with standard tools. | Simple installation, often requires no special tools. |

| Maintenance | Requires regular maintenance to prevent rust and corrosion. | Low maintenance, especially when anodized or painted. | Minimal maintenance, resistant to rot and corrosion. |

| Best Use Case | Structural applications, automotive parts, and heavy-duty fabrication. | Aerospace, automotive, and architectural applications where weight is critical. | Marine applications, chemical storage, and environments prone to corrosion. |

In-Depth Analysis of Alternatives

Aluminum Sheet Metal

Aluminum sheet metal is renowned for its lightweight nature and excellent corrosion resistance. It is often used in applications where reducing weight is essential, such as in the aerospace and automotive industries. The ability to easily cut and shape aluminum with standard tools makes it an attractive option for many manufacturers. However, its higher cost and lower tensile strength compared to steel can be limiting factors in applications where strength is paramount. Buyers should consider whether the weight savings justify the additional expense.

Fiberglass Reinforced Plastic (FRP)

FRP is a composite material that offers a unique combination of strength and lightweight properties. Its resistance to corrosion and chemicals makes it ideal for marine applications and environments where traditional metals would fail. Installation is straightforward, often requiring no specialized tools, which can reduce labor costs. However, FRP may not provide the same level of structural integrity as metals in heavy-duty applications. B2B buyers should assess the specific environmental conditions and mechanical requirements of their projects to determine if FRP is suitable.

Making the Right Choice for Your Needs

When selecting between 13 gauge sheet metal and its alternatives, B2B buyers must carefully evaluate their specific application requirements, budget constraints, and long-term maintenance considerations. Each material has distinct advantages and potential drawbacks that can influence performance and costs. Engaging in thorough analysis and consulting with suppliers can help ensure the chosen solution aligns with project goals and operational efficiencies. Ultimately, the right choice will balance performance, cost, and practicality, leading to successful project outcomes.

Essential Technical Properties and Trade Terminology for 13 gauge sheet metal

What Are the Key Technical Properties of 13 Gauge Sheet Metal?

When considering the procurement of 13 gauge sheet metal, understanding its technical specifications is crucial for making informed purchasing decisions. Here are several essential properties to consider:

-

Material Grade: Commonly, 13 gauge sheet metal is made from carbon steel, specifically grades like ASTM A1008 for cold-rolled steel. The material grade affects not only the mechanical properties but also the suitability for various applications. For instance, A1008 is known for its excellent formability and surface finish, making it ideal for manufacturing components that require bending or shaping.

-

Thickness: The thickness of 13 gauge sheet metal is approximately 0.090 inches (2.29 mm). This specification is critical as it influences the material’s strength, weight, and suitability for applications such as automotive parts, structural components, or appliances. B2B buyers should assess the required thickness based on load-bearing needs and the desired durability of the final product.

-

Tolerances: Tolerances specify the permissible limits of variation in the dimensions of the sheet metal. For example, a common tolerance might be ±0.125 inches for length and width. Understanding these tolerances is vital for ensuring compatibility with other components and for maintaining quality control during manufacturing processes.

-

Weight: The weight of 13 gauge sheet metal is approximately 3.75 pounds per square foot. This property is significant for shipping considerations and structural calculations. Buyers need to account for weight when planning logistics and ensuring that the receiving facilities can handle the materials safely.

-

Mechanical Properties: Key mechanical properties include yield strength (around 31 KSI) and tensile strength (approximately 51 KSI). These values indicate how much load the metal can withstand before deforming or breaking, which is essential for applications requiring structural integrity.

What Are Common Trade Terms Used in the Procurement of 13 Gauge Sheet Metal?

Familiarity with industry terminology enhances communication and negotiation processes. Here are several commonly used terms in the B2B metal procurement landscape:

-

OEM (Original Equipment Manufacturer): An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is vital for B2B buyers, as it often determines the quality and compatibility of parts in assembly processes.

-

MOQ (Minimum Order Quantity): MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers manage inventory and budget constraints, especially when sourcing materials like 13 gauge sheet metal, where bulk purchasing may lead to cost savings.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers to request pricing and terms for a specified quantity of products. Utilizing RFQs allows buyers to compare offers and negotiate better deals, ensuring they receive competitive pricing for their sheet metal needs.

-

Incoterms (International Commercial Terms): These are a series of predefined commercial terms published by the International Chamber of Commerce, which define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for managing logistics, shipping costs, and risk during the procurement process.

-

CNC (Computer Numerical Control): CNC refers to the automated control of machining tools and 3D printers by means of a computer. Knowledge of CNC capabilities can be beneficial for buyers seeking to integrate advanced manufacturing processes with their 13 gauge sheet metal products.

By grasping these technical properties and trade terminologies, B2B buyers can navigate the complexities of sourcing 13 gauge sheet metal more effectively, ensuring that they make choices that align with their operational needs and strategic goals.

Navigating Market Dynamics and Sourcing Trends in the 13 gauge sheet metal Sector

What Are the Global Drivers Influencing the 13 Gauge Sheet Metal Market?

The 13 gauge sheet metal sector is currently shaped by several key global drivers that B2B buyers must consider. First, the increasing demand for durable materials in construction and manufacturing, particularly in emerging markets in Africa, South America, and the Middle East, is propelling the market. Countries like Vietnam and Saudi Arabia are investing heavily in infrastructure development, which creates a robust need for high-quality sheet metal products.

Additionally, technological advancements in metal processing and sourcing are transforming how companies engage with suppliers. The rise of e-commerce platforms and digital marketplaces enables buyers to access a broader range of products, compare prices easily, and streamline the procurement process. Moreover, the integration of advanced inventory management systems and data analytics helps businesses optimize their supply chains, ensuring that they can respond swiftly to market changes and customer demands.

Another critical trend is the emphasis on customization and flexibility. As industries increasingly require specific dimensions and properties, suppliers who can offer tailored solutions for 13 gauge sheet metal will hold a competitive edge. This adaptability is vital for businesses looking to maintain operational efficiency while navigating fluctuating market conditions.

How Are Sustainability and Ethical Sourcing Impacting the 13 Gauge Sheet Metal Sector?

Sustainability and ethical sourcing have become integral to the procurement strategies of B2B buyers in the 13 gauge sheet metal market. Environmental impact is a growing concern as industries face pressure to reduce their carbon footprint and comply with stricter regulations. This has led to an increased interest in recycled materials and sustainable production practices. Buyers are now more inclined to source from suppliers who utilize eco-friendly processes and materials, as these choices not only align with corporate social responsibility goals but also appeal to environmentally-conscious consumers.

The importance of ethical supply chains cannot be overstated. Ensuring that suppliers adhere to fair labor practices and environmental standards is crucial for businesses looking to enhance their brand reputation and avoid potential supply chain disruptions. Certifications such as ISO 14001 for environmental management and Fair Trade can serve as indicators of a supplier’s commitment to sustainability and ethical practices. By prioritizing suppliers with these credentials, companies can foster trust and transparency in their procurement processes.

Furthermore, the adoption of ‘green’ materials in the production of 13 gauge sheet metal is gaining traction. Buyers are encouraged to seek out products that meet sustainability criteria, such as low emissions and minimal waste during manufacturing. This not only benefits the environment but also positions companies favorably in an increasingly competitive market.

What Is the Historical Context of 13 Gauge Sheet Metal in B2B Sourcing?

The evolution of 13 gauge sheet metal in the B2B landscape can be traced back to its initial applications in industrial settings, where strength and durability were paramount. Traditionally, this gauge of metal was favored for its balance between weight and structural integrity, making it ideal for various construction and manufacturing applications.

Over time, advancements in metallurgy and processing techniques have enhanced the properties of 13 gauge sheet metal, making it more versatile and accessible. The introduction of cold rolling processes has improved surface finishes and dimensional accuracy, further expanding its use in diverse industries. Today, international B2B buyers can find a wide range of options, from carbon steel to stainless steel variations, catering to specific project requirements.

As global trade dynamics continue to shift, understanding the historical context of 13 gauge sheet metal helps buyers appreciate its value proposition and the ongoing innovations that shape its future in the marketplace. This awareness is essential for making informed purchasing decisions that align with both current trends and long-term sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of 13 gauge sheet metal

-

How do I determine the right supplier for 13 gauge sheet metal?

To choose the right supplier, assess their experience in the industry, certifications, and customer reviews. Request samples to evaluate the quality of their 13 gauge sheet metal and check for compliance with international standards such as ASTM. Ensure they can meet your volume requirements and delivery timelines. Additionally, consider their transparency in pricing and the availability of customization options. Engaging in direct communication can also provide insights into their customer service approach and responsiveness. -

What are the common uses for 13 gauge sheet metal?

13 gauge sheet metal is widely utilized in various industries, including construction, automotive, and manufacturing. Its thickness makes it suitable for applications such as structural components, machinery parts, and metal enclosures. Additionally, it is often used in HVAC systems and for creating durable outdoor furniture. Understanding your specific requirements can help you identify the best type of 13 gauge sheet metal for your projects, whether you need cold-rolled or hot-rolled variations. -

What is the minimum order quantity (MOQ) for 13 gauge sheet metal?

Minimum order quantities for 13 gauge sheet metal can vary significantly by supplier and region. Some suppliers may have an MOQ as low as 100 kg, while others may require larger orders. When sourcing internationally, consider the implications of shipping costs and lead times associated with smaller orders. It’s advisable to negotiate the MOQ upfront and inquire about any flexibility based on your needs, especially if you are a new customer or exploring a long-term partnership. -

How can I customize my order for 13 gauge sheet metal?

Customization options for 13 gauge sheet metal often include specific dimensions, finishes, and even pre-fabricated shapes. When placing your order, clearly communicate your specifications to the supplier, including thickness, length, width, and desired surface treatment. Some suppliers may also offer services such as cutting, bending, or welding. Be sure to ask about additional costs and lead times associated with custom orders to ensure they align with your project timelines. -

What payment terms should I expect when sourcing 13 gauge sheet metal internationally?

Payment terms can vary by supplier and region but typically include options such as upfront payment, net 30, or letter of credit for larger orders. For international transactions, ensure that you understand currency fluctuations and any additional fees related to cross-border payments. It is advisable to negotiate terms that provide both parties with security. Always confirm the accepted payment methods and verify the supplier’s payment policies to avoid any misunderstandings. -

What quality assurance measures should I expect for 13 gauge sheet metal?

Reputable suppliers of 13 gauge sheet metal should have quality assurance processes in place, including material testing and certification. Inquire about their quality control practices, such as inspections for thickness, tensile strength, and surface quality. Request documentation of compliance with international standards to ensure that the material meets your specifications. Establishing clear quality expectations upfront can prevent issues during production and delivery. -

How do logistics and shipping impact the sourcing of 13 gauge sheet metal?

Logistics and shipping play a critical role in the sourcing process, especially for international buyers. Factors such as shipping methods, lead times, and costs can significantly affect your overall expenses. Discuss shipping options with your supplier, including freight services and delivery timelines. It’s also important to understand any customs regulations and duties applicable to your shipment. Planning your logistics strategy ahead of time can help avoid delays and additional costs. -

What are the environmental considerations when sourcing 13 gauge sheet metal?

Sourcing 13 gauge sheet metal requires consideration of environmental impact, particularly in terms of sustainability and recyclability. Inquire about the supplier’s practices regarding material sourcing, waste management, and energy consumption. Many suppliers are moving towards more sustainable practices, including using recycled materials and reducing emissions during production. Opting for environmentally responsible suppliers not only supports sustainability but can also enhance your brand reputation in the market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 13 Gauge Sheet Metal Manufacturers & Suppliers List

1. Speedy Metals – 13ga Cold Rolled Steel Sheet

Domain: speedymetals.com

Registered: 2001 (24 years)

Introduction: {“Product Name”: “13ga (.090″) Cold Rolled Steel Sheet”, “Material”: “Steel”, “Shape”: “Sheet”, “Finish”: “Cold Rolled”, “Dimensions”: [{“Size”: “12×12”, “Weight”: “3.7440 lbs”, “Price”: “$20.06”}, {“Size”: “12×18”, “Weight”: “5.6160 lbs”, “Price”: “$26.33”}, {“Size”: “12×24”, “Weight”: “7.4880 lbs”, “Price”: “$32.09”}], “Cutting Tolerance”: “+/- 1/4″}”}

2. Online Metals – Cold Rolled Carbon Steel Sheet/Plate

Domain: onlinemetals.com

Registered: 1997 (28 years)

Introduction: {“Thickness”:”0.0897 inches”,”Gauge”:”13 Gauge”,”Max Width”:”48 inches”,”Max Length”:”120 inches”,”Alloy”:”A1008″,”Production Method”:”Cold Rolled”,”Material”:”Carbon Steel”,”Shape”:”Sheet/Plate”,”MTR Availability”:”Yes”,”Weight/Lineal Foot”:”3.75 pounds”,”Mechanical Properties”:{“Density (g/cm^3)”:”8″,”Ultimate Tensile Strength (KSI)”:”51″,”Yield Tensile Strength (KSI)”:”31″,”Brinell Hardness (50…

3. Metals Depot – Hot Rolled Steel Sheets

Domain: metalsdepot.com

Registered: 1999 (26 years)

Introduction: {“products”:[{“type”:”Hot Rolled Steel Sheet”,”specification”:”(ASTM A1011 CS Type B)”,”description”:”Economical steel sheets with slightly grainy surface, ideal for painting.”,”applications”:[“general fabrication”,”equipment panels”,”tool boxes”,”hoppers”,”drip pans”],”thickness_options”:[{“gauge”:”16 GA.”,”thickness”:”.060″,”weight_per_sqft”:”2.50 lb/sqft”},{“gauge”:”14 GA.”,”thickness”:”.075″,”…

4. MK Metal – 1008 Alloy Steel Sheet

Domain: mkmetal.net

Registered: 1999 (26 years)

Introduction: {“Alloy”:”1008″,”Thickness”:”13 GA”,”Width”:”48 inches”,”Length”:”120 inches”,”Weight per Foot (SQFT)”:”3.75″,”Price per Piece”:”$113.85″,”Price Each”:”$383.82″}

5. Competitive Metals – 13 Gauge Cold Rolled Sheet

Domain: competitivemetals.com

Registered: 2006 (19 years)

Introduction: {“Product Name”: “13 Gauge Cold Rolled Sheet”, “Product Code”: “CRSHT13”, “Thickness”: “13ga (.0847″-.0947″)”, “Sheet Size”: “48”x48″”, “Industries Served”: [“DIY/Hobbyists”, “Education”, “Energy”, “Fabrication & Machining”], “Contact Number”: “619-442-4130”}

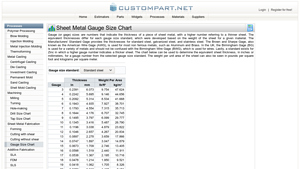

6. Custom Part Net – Sheet Metal Gauge Size Chart

Domain: custompartnet.com

Registered: 2006 (19 years)

Introduction: Sheet Metal Gauge Size Chart provides gauge sizes indicating the thickness of sheet metal, with higher numbers representing thinner sheets. Different gauge size standards exist: Manufacturers’ Standard Gage for standard steel, galvanized steel, and stainless steel; Brown and Sharpe Gage (AWG) for non-ferrous metals like Aluminum and Brass; Birmingham Gage (BG) in the UK for various metals; and a s…

7. Bobco Metals – Hot Rolled Sheet 13 Gauge

Domain: bobcometal.com

Registered: 1996 (29 years)

Introduction: {“Product Name”: “Hot Rolled Sheet – 13 Gauge”, “Supplier”: “Bobco Metals”, “Location”: “Los Angeles, CA, USA”, “Price”: “$33.16”, “Thickness”: “13 Ga”, “Weight”: “3.75 lbs”, “SKU”: “HRSH134X10”, “Dimensions”: {“Height”: “0.1 inches”, “Length”: “120 inches”, “Width”: “48 inches”}, “Material”: “Low carbon rimming, capped, or semi-killed steel”, “Usage”: “Intended for uses involving simple bending o…

Strategic Sourcing Conclusion and Outlook for 13 gauge sheet metal

In the competitive landscape of metal sourcing, 13 gauge sheet metal stands out as a versatile and cost-effective material suitable for various applications across industries. The strategic sourcing of this material not only enhances operational efficiency but also drives significant cost savings for businesses. By leveraging reliable suppliers and understanding the specifications of 13 gauge sheet metal, companies can optimize their supply chains, ensuring timely delivery and consistent quality.

International buyers from regions such as Africa, South America, the Middle East, and Europe must focus on establishing strong relationships with reputable manufacturers and distributors. This approach facilitates access to superior materials while mitigating risks associated with fluctuating prices and supply shortages. Additionally, staying informed about global market trends and technological advancements can empower businesses to make informed purchasing decisions.

As we look ahead, the demand for 13 gauge sheet metal is projected to grow, driven by expanding industries and infrastructure development. Now is the time for international buyers to engage proactively in strategic sourcing, ensuring they are well-positioned to meet future demands. Embrace the opportunity to enhance your operations—connect with suppliers today and secure your competitive edge in the marketplace.