Introduction: Navigating the Global Market for 13 gauge metal

Navigating the global market for 13 gauge metal presents significant challenges for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. The sourcing process can be daunting, with varying specifications, suppliers, and applications to consider. This guide aims to demystify the complexities associated with 13 gauge metal, which typically measures 0.090 inches in thickness and is widely used across various industries, including construction, manufacturing, and automotive sectors.

Throughout this comprehensive resource, readers will explore the different types of 13 gauge metal, including cold-rolled steel and stainless steel options, as well as their specific applications. We will also delve into essential considerations for supplier vetting, ensuring quality and compliance with international standards. Additionally, the guide will provide insights into pricing structures and cost factors that influence purchasing decisions.

By leveraging the information presented in this guide, international B2B buyers can make informed decisions that not only enhance their procurement strategies but also streamline their supply chain processes. Whether you’re operating in Brazil, Nigeria, or any other global market, understanding the nuances of 13 gauge metal will empower you to secure the best materials for your projects while optimizing costs and supplier relationships.

Understanding 13 gauge metal Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cold Rolled Steel Sheet | Smooth finish, high strength, low carbon content | Automotive parts, construction | Pros: Cost-effective, good formability. Cons: Prone to rust without coating. |

| Stainless Steel Sheet | Corrosion-resistant, durable, maintains strength at high temperatures | Food processing, medical equipment | Pros: Long-lasting, hygienic. Cons: Higher cost compared to carbon steel. |

| Aluminum Sheet | Lightweight, good corrosion resistance, non-magnetic | Aerospace, packaging, automotive | Pros: Lightweight, excellent machinability. Cons: Less strength than steel. |

| Expanded Metal | Mesh-like structure, lightweight, high strength-to-weight ratio | Fencing, flooring, filtration | Pros: Versatile, allows airflow. Cons: Limited load-bearing capacity. |

| Galvanized Steel Sheet | Coated with zinc for corrosion resistance | Roofing, HVAC systems | Pros: Durable, low maintenance. Cons: Zinc coating can be damaged in processing. |

What are the Characteristics of Cold Rolled Steel Sheets?

Cold rolled steel sheets are known for their smooth surface finish and high strength. They are produced by rolling steel at room temperature, which enhances their mechanical properties. This type of metal is widely used in automotive parts and construction due to its excellent formability and weldability. Buyers should consider its susceptibility to rust, necessitating protective coatings in humid environments.

How Does Stainless Steel Sheet Stand Out?

Stainless steel sheets offer exceptional corrosion resistance and durability, making them ideal for industries like food processing and medical equipment. Their ability to maintain strength at high temperatures adds to their appeal. While they are more expensive than carbon steel, the long-term savings from reduced maintenance and replacement costs often justify the investment for B2B buyers.

Why Choose Aluminum Sheets for Your Projects?

Aluminum sheets are favored for their lightweight nature and good corrosion resistance. They are commonly used in aerospace and automotive applications where weight reduction is crucial. Their excellent machinability allows for intricate designs, but buyers should note that aluminum generally has lower strength compared to steel, making it less suitable for high-stress applications.

What are the Benefits of Expanded Metal?

Expanded metal is characterized by its mesh-like structure, which provides a high strength-to-weight ratio. It is commonly used in fencing, flooring, and filtration applications. This type of metal allows for airflow and visibility, making it versatile for various uses. However, B2B buyers should be aware of its limited load-bearing capacity, which may not be suitable for heavy-duty applications.

How Does Galvanized Steel Sheet Enhance Durability?

Galvanized steel sheets are coated with zinc to enhance corrosion resistance, making them ideal for roofing and HVAC systems. This protective layer helps to extend the lifespan of the metal in harsh environments. While galvanized steel requires less maintenance, buyers should consider the potential for damage to the zinc coating during processing, which can compromise its protective qualities.

Key Industrial Applications of 13 gauge metal

| Industry/Sector | Specific Application of 13 gauge metal | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Structural supports and frames | Provides strength and durability for buildings | Quality certifications, compliance with local codes |

| Automotive | Vehicle body panels and components | Lightweight yet robust, enhancing fuel efficiency | Material specifications, corrosion resistance |

| Manufacturing | Equipment housings and enclosures | Protects sensitive machinery from environmental factors | Custom sizes, machining capabilities |

| Energy | Wind turbine components | High strength-to-weight ratio for efficiency | Supplier reliability, adherence to industry standards |

| HVAC | Ductwork and ventilation systems | Efficient airflow and energy savings | Gauge consistency, thermal properties |

How is 13 Gauge Metal Utilized in the Construction Sector?

In the construction industry, 13 gauge metal is frequently used for structural supports and frames. Its thickness provides the necessary strength to withstand various loads while ensuring durability over time. This application is critical in regions prone to extreme weather, where structural integrity is paramount. Buyers must ensure that the metal complies with local building codes and standards to avoid costly rework. Additionally, sourcing from suppliers that provide quality certifications can mitigate risks associated with material failure.

What Role Does 13 Gauge Metal Play in the Automotive Industry?

The automotive sector employs 13 gauge metal for manufacturing vehicle body panels and components. This gauge offers a balance between weight and strength, which is essential for improving fuel efficiency without compromising safety. Buyers in this sector should prioritize sourcing materials that meet specific automotive standards for performance and durability. Furthermore, it’s crucial to consider suppliers’ capabilities to deliver consistent quality and timely shipments, especially for international projects in emerging markets like Brazil and Nigeria.

How is 13 Gauge Metal Applied in Manufacturing Equipment?

In manufacturing, 13 gauge metal is commonly used for equipment housings and enclosures, safeguarding sensitive machinery from environmental factors such as dust and moisture. This application not only enhances the longevity of the equipment but also ensures operational efficiency. B2B buyers should focus on suppliers that can provide custom sizes and machining services to meet specific design requirements. Additionally, understanding the local market’s lead times and logistics can significantly impact project timelines.

Why is 13 Gauge Metal Important for Energy Sector Components?

The energy industry, particularly in wind energy, utilizes 13 gauge metal for components like turbine blades and frames. Its high strength-to-weight ratio allows for efficient energy production while minimizing material costs. Buyers should consider the reliability of suppliers and their adherence to industry standards to ensure that the materials can withstand the rigors of outdoor environments. Additionally, understanding regional regulations around renewable energy components can facilitate smoother procurement processes.

How is 13 Gauge Metal Beneficial in HVAC Systems?

In HVAC applications, 13 gauge metal is used for ductwork and ventilation systems, providing efficient airflow and energy savings. Its durability ensures that systems can operate effectively over extended periods without significant maintenance issues. Buyers should evaluate the thermal properties of the metal to ensure optimal performance in their specific climate conditions. Moreover, consistency in gauge thickness is essential to maintain system integrity, making it crucial to source from reputable suppliers with a proven track record.

3 Common User Pain Points for ’13 gauge metal’ & Their Solutions

Scenario 1: Inconsistent Quality and Specifications of 13 Gauge Metal

The Problem: B2B buyers often face challenges in ensuring the consistent quality and specifications of 13 gauge metal. This inconsistency can lead to production delays, increased costs, and potential failures in projects. For example, a manufacturer in Brazil may order a batch of 13 gauge steel sheets for a construction project but find that the thickness or alloy composition does not meet the specified ASTM standards. This discrepancy can result in wasted materials and resources, not to mention the potential impact on the project’s timeline and budget.

The Solution: To mitigate this issue, B2B buyers should prioritize sourcing from reputable suppliers who provide material certifications and adhere to recognized standards such as ASTM A1008 for cold-rolled steel. Buyers should request detailed technical data sheets before placing orders and establish clear communication about their specifications. Additionally, implementing a quality assurance process, including random sampling and testing of incoming materials, can help ensure that the received products meet the required specifications. This proactive approach not only protects the integrity of the projects but also fosters stronger relationships with suppliers through transparency and accountability.

Scenario 2: High Shipping Costs and Long Lead Times for 13 Gauge Metal

The Problem: International buyers, particularly in regions like Africa and the Middle East, often encounter high shipping costs and extended lead times when sourcing 13 gauge metal. These factors can significantly affect project timelines and overall costs. For instance, a construction firm in Nigeria may need steel sheets urgently for an ongoing project but finds that the shipping delays from overseas suppliers disrupt their schedule and inflate costs due to expedited shipping fees.

The Solution: To address this pain point, buyers should explore local suppliers or manufacturers that can provide 13 gauge metal closer to their operations. This not only reduces shipping costs but also shortens lead times. Additionally, buyers can consider consolidating orders to maximize shipping efficiency or negotiating bulk purchase agreements with suppliers to lower unit costs. Utilizing logistics software to optimize shipping routes and delivery schedules can further enhance efficiency. By strategically sourcing materials and leveraging local markets, companies can improve their project management and cost-effectiveness.

Scenario 3: Difficulty in Customization and Sizing of 13 Gauge Metal

The Problem: Many B2B buyers face challenges when it comes to customizing the size and shape of 13 gauge metal sheets to fit specific project needs. For example, a manufacturer in South America may require custom-cut sheets for a specialized application but finds that many suppliers only offer standard sizes. This limitation can lead to increased scrap metal and additional processing costs, ultimately affecting the bottom line.

The Solution: To effectively navigate this issue, buyers should seek out suppliers who offer customizable options and can accommodate specific requirements. When engaging with potential suppliers, buyers should clearly communicate their needs regarding dimensions, shapes, and any specific machining or finishing processes required. Additionally, leveraging technology such as CAD (Computer-Aided Design) can help buyers provide precise specifications, ensuring that suppliers can fulfill custom requests accurately. Establishing a partnership with a supplier that specializes in custom fabrication can also lead to better pricing and turnaround times, making it easier for companies to meet unique project demands without incurring excessive costs.

Strategic Material Selection Guide for 13 gauge metal

What Are the Key Properties of 13 Gauge Cold Rolled Steel?

Cold rolled steel is a popular choice for 13 gauge applications due to its enhanced mechanical properties. This material typically exhibits a thickness of 0.090 inches, providing a balance between strength and weight. Cold rolled steel is known for its superior surface finish and dimensional accuracy, which makes it ideal for applications requiring precision. It also offers good tensile strength, with ultimate tensile strengths around 51 KSI and yield strengths of approximately 31 KSI, making it suitable for various structural applications.

What Are the Advantages and Disadvantages of Using 13 Gauge Cold Rolled Steel?

The primary advantage of cold rolled steel is its durability and strength, making it suitable for heavy-duty applications. It is relatively cost-effective compared to other metals, which is a significant consideration for B2B buyers looking to optimize their budgets. However, it has limitations in terms of corrosion resistance; without proper coatings or treatments, it can rust when exposed to moisture. Additionally, the manufacturing complexity can increase if specific finishes or coatings are required, which may impact lead times.

How Does 13 Gauge Stainless Steel Compare for Corrosion Resistance?

Stainless steel, particularly grades like 304 and 316, is renowned for its excellent corrosion resistance, making it a preferred choice in environments prone to moisture or chemicals. The 13 gauge stainless steel sheets maintain a thickness of 0.090 inches, similar to cold rolled steel, but offer significantly better longevity in harsh conditions. The 316 grade, for example, provides superior resistance to chlorides, making it ideal for marine applications.

What Are the Pros and Cons of 13 Gauge Stainless Steel?

The key advantage of stainless steel is its resistance to corrosion and staining, which enhances the durability of products made from it. This makes it particularly suitable for applications in food processing, chemical handling, and outdoor structures. However, the cost of stainless steel is generally higher than that of cold rolled steel, which could be a limiting factor for budget-conscious buyers. Additionally, the machining and welding processes for stainless steel can be more complex, requiring specialized equipment and skills.

What Are the Characteristics of 13 Gauge Aluminum?

Aluminum, specifically alloys like 5052 and 6061, is another viable option for 13 gauge applications. Aluminum is lightweight yet strong, with a thickness of 0.090 inches. It is also highly resistant to corrosion and oxidation, making it suitable for outdoor and marine applications. The thermal and electrical conductivity of aluminum is superior, which can be beneficial in specific industrial applications.

What Are the Benefits and Drawbacks of Using 13 Gauge Aluminum?

The primary advantage of aluminum is its lightweight nature, which can significantly reduce shipping costs and ease handling during manufacturing. Its corrosion resistance also means less maintenance over time. However, aluminum generally has lower tensile strength compared to steel, which may limit its use in heavy-duty applications. Additionally, the cost of aluminum can be higher than that of cold rolled steel, which may influence purchasing decisions for international buyers.

Summary Table of Material Selection for 13 Gauge Metal

| Material | Typical Use Case for 13 gauge metal | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cold Rolled Steel | Automotive parts, structural frames | High strength and durability | Prone to rust without coatings | Medium |

| Stainless Steel | Food processing, marine applications | Excellent corrosion resistance | Higher cost and complex machining | High |

| Aluminum | Aerospace components, outdoor structures | Lightweight and corrosion-resistant | Lower tensile strength than steel | High |

| Expanded Metal | Grating, security fencing | Good airflow and visibility | Limited load-bearing capabilities | Medium |

This strategic material selection guide provides B2B buyers with essential insights into the properties, advantages, and limitations of various 13 gauge metal options. Understanding these factors can help inform purchasing decisions, ensuring that the selected material aligns with the specific requirements of their applications.

In-depth Look: Manufacturing Processes and Quality Assurance for 13 gauge metal

What are the Key Manufacturing Processes for 13 Gauge Metal?

The manufacturing of 13 gauge metal involves several critical stages, each essential to ensuring the final product meets specifications and quality standards. The main stages include material preparation, forming, assembly, and finishing.

How is Material Prepared for 13 Gauge Metal Production?

Material preparation begins with the selection of high-quality steel or other metals that meet specific standards, such as ASTM A1008 for cold-rolled steel. The raw material is typically delivered in coils or sheets, which are then inspected for defects. This initial inspection is crucial as it sets the foundation for the manufacturing process. The material is cut to size, often using techniques such as shearing or laser cutting, to prepare it for the forming stage.

What Forming Techniques are Used in 13 Gauge Metal Fabrication?

Forming processes are vital to shaping the metal into the desired forms. Common techniques for 13 gauge metal include:

- Cold Rolling: This process involves passing the metal through rollers at room temperature, which increases its strength through strain hardening. Cold rolling is particularly beneficial for achieving precise thickness and surface finish.

- Stamping: Used for creating complex shapes, stamping involves pressing the metal into a die. This method is efficient for high-volume production and ensures uniformity across parts.

- Bending and Forming: This includes processes like brake bending, where the metal is bent at specific angles to create components such as brackets or frames.

These techniques are complemented by modern machinery and automated systems, which enhance precision and reduce production time.

What Quality Assurance Practices are Essential for 13 Gauge Metal?

Quality assurance is a non-negotiable aspect of manufacturing 13 gauge metal. Adhering to international and industry-specific standards is crucial for ensuring product reliability and safety.

Which International Standards Should B2B Buyers Be Aware Of?

International standards such as ISO 9001 are critical for maintaining a quality management system. This standard emphasizes continuous improvement and customer satisfaction, which are vital for B2B relationships. Additionally, specific certifications like CE marking indicate compliance with European health, safety, and environmental protection standards.

Industry-specific standards may also apply, such as API (American Petroleum Institute) for products used in oil and gas applications. Understanding these certifications can help buyers assess the credibility and reliability of their suppliers.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control (QC) involves several checkpoints to ensure that the product meets specifications at various stages of production:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to verify compliance with specifications. Any defective materials are rejected at this stage.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, regular inspections are conducted to monitor dimensions, surface quality, and mechanical properties. This step helps identify issues early, minimizing waste and rework.

- Final Quality Control (FQC): Before shipment, finished products undergo comprehensive testing, including dimensional verification, surface inspection, and mechanical testing to ensure they meet all specified standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

Verifying a supplier’s quality control practices is essential for international B2B buyers to ensure they are receiving reliable products. There are several strategies to achieve this:

- Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes and QC measures. This can be done by the buyer’s quality assurance team or through third-party auditing firms.

- Quality Reports: Requesting detailed quality reports that outline the results of inspections and tests can help buyers assess a supplier’s compliance with industry standards.

- Third-Party Inspections: Engaging third-party inspection services can add an additional layer of assurance. These organizations can conduct independent tests and audits, ensuring that the products meet the required specifications.

What Common Testing Methods Are Used in Quality Assurance for 13 Gauge Metal?

Testing methods for quality assurance are diverse and tailored to specific requirements. Common methods include:

- Tensile Testing: This test measures the strength of the metal and its ability to withstand pulling forces. It provides essential data on yield strength, ultimate tensile strength, and elongation.

- Hardness Testing: Methods like Rockwell or Brinell hardness tests assess the material’s resistance to deformation, which is critical for applications requiring durability.

- Visual and Surface Inspection: This involves checking for surface defects, such as scratches or dents, which could affect the product’s performance. Advanced techniques like ultrasonic testing may also be used to detect internal flaws.

What Nuances Should International Buyers Consider Regarding QC and Certification?

For international buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification is crucial. Different regions may have varying standards and regulations, which can impact product acceptance.

- Cultural and Regulatory Differences: Buyers should familiarize themselves with local regulations that may affect importation and product usage. For example, compliance with local safety standards is often mandatory for market entry.

- Supplier Relationships: Building strong relationships with suppliers can facilitate better communication regarding quality expectations and compliance. This is particularly important in regions where personal relationships play a significant role in business dealings.

- Documentation and Traceability: Ensuring that all quality documentation is in order and traceable is essential for compliance and can prevent potential issues during audits or inspections.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing 13 gauge metal, ultimately ensuring they receive high-quality materials that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ’13 gauge metal’

In the world of B2B procurement, sourcing 13 gauge metal requires a strategic approach. This guide will provide you with a practical checklist to ensure a successful purchasing process, tailored for international buyers across diverse regions such as Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the first step in sourcing 13 gauge metal. This includes determining the exact thickness (0.090 inches or 2.29 mm), material type (such as cold-rolled steel, stainless steel, or aluminum), and any specific standards (e.g., ASTM A1008) that the metal must meet. Having these specifications helps streamline communication with suppliers and minimizes the risk of receiving substandard materials.

Step 2: Identify Your Quality Requirements

Quality assurance is paramount when sourcing metal. Define the mechanical properties you require, such as tensile strength, yield strength, and hardness, which are critical for your intended applications. Additionally, ensure that the metal complies with international quality certifications relevant to your industry, such as ISO or ASTM standards.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s essential to conduct a thorough evaluation. Request company profiles, case studies, and references from buyers in similar industries or regions. Look for suppliers who have a proven track record in providing high-quality 13 gauge metal, and consider their production capabilities, lead times, and customer service history.

Step 4: Request and Compare Quotes

Once you have a shortlist of potential suppliers, request detailed quotes. Ensure that these quotes include specifications, pricing, lead times, and shipping costs. Comparing these elements across different suppliers will help you identify the best value for your investment. Be cautious of quotes that appear unusually low, as they may indicate compromised quality or hidden costs.

Step 5: Verify Supplier Certifications

Certifications can provide assurance of quality and compliance with industry standards. Verify that your chosen supplier holds relevant certifications, such as ISO 9001 for quality management systems or specific material certifications like ASTM or EN standards. This step protects your business from potential risks associated with substandard materials.

Step 6: Check Shipping and Logistics

Logistics can significantly impact your procurement process, especially for international shipments. Confirm the supplier’s shipping methods, costs, and estimated delivery times. Additionally, consider customs regulations and any potential tariffs that may apply to your shipment, as these factors can affect your overall budget and timeline.

Step 7: Establish Payment Terms and Contracts

Finally, establish clear payment terms and contractual agreements with your supplier. Define the payment method, timelines, and conditions for order cancellations or returns. A well-drafted contract protects both parties and sets expectations for quality, delivery, and payment, ensuring a smooth procurement experience.

By following this checklist, you can enhance your sourcing strategy for 13 gauge metal, ensuring that you make informed decisions that align with your business needs and objectives.

Comprehensive Cost and Pricing Analysis for 13 gauge metal Sourcing

What Are the Key Components of Cost Structure for 13 Gauge Metal Sourcing?

When considering the procurement of 13 gauge metal, it is essential to understand the various cost components that contribute to the total price. These typically include raw materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The cost of raw materials, such as cold-rolled steel or stainless steel, is a significant portion of the overall price. Prices can fluctuate based on market demand, availability, and the specific type of metal required.

-

Labor: Labor costs encompass the wages paid to workers involved in the manufacturing and processing of the metal. This can vary by region, with labor costs typically higher in developed countries compared to emerging markets.

-

Manufacturing Overhead: This includes costs related to utilities, equipment maintenance, and facility expenses. Efficient production processes can help minimize these costs.

-

Tooling: Depending on the complexity of the desired specifications, tooling costs can vary significantly. Custom tools may be necessary for specific cuts or shapes, increasing initial investment but potentially reducing per-unit costs over larger volumes.

-

Quality Control: Ensuring that the metal meets required specifications involves testing and inspection, which can add to the overall cost but is crucial for maintaining quality standards.

-

Logistics: Transportation costs are particularly vital for international buyers. Factors such as distance, shipping method, and customs duties can significantly impact final pricing.

-

Margin: Suppliers will add a margin to cover their operational costs and profit. This can vary widely based on the supplier’s positioning and market competition.

How Do Price Influencers Affect 13 Gauge Metal Costs?

Several factors can influence the price of 13 gauge metal, impacting overall procurement strategies:

-

Volume/MOQ: Larger orders often benefit from economies of scale, reducing the per-unit cost. Suppliers may offer lower prices for high-volume contracts, which can be advantageous for businesses with consistent needs.

-

Specifications and Customization: Custom specifications, such as unique dimensions or treatments, can lead to higher costs due to the need for specialized production processes. Standard sizes may be more cost-effective.

-

Material Quality and Certifications: Higher quality materials often come at a premium. Certifications (e.g., ISO, ASTM) can also influence pricing, as they ensure compliance with industry standards.

-

Supplier Factors: Supplier reputation, reliability, and production capabilities can affect pricing. Established suppliers with proven track records may charge more for their assurance of quality and timely delivery.

-

Incoterms: The choice of Incoterms can significantly impact total costs. Terms that place more responsibility on the buyer may reduce initial prices but increase logistical risks and potential costs.

What Are the Best Buyer Tips for Cost-Efficiency in 13 Gauge Metal Sourcing?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, maximizing cost-efficiency in sourcing 13 gauge metal involves several strategies:

-

Negotiate Effectively: Understand market rates and be prepared to negotiate prices based on your volume and long-term needs. Building strong relationships with suppliers can also lead to better pricing.

-

Consider Total Cost of Ownership: Evaluate not just the initial purchase price but also the total cost of ownership, which includes logistics, installation, maintenance, and potential wastage.

-

Be Aware of Pricing Nuances: International buyers should be mindful of currency fluctuations, tariffs, and local market conditions that can affect pricing. Researching local suppliers can sometimes yield better pricing than relying solely on international sources.

-

Utilize Local Expertise: Leverage local agents or consultants familiar with regional market dynamics to help navigate sourcing complexities.

Disclaimer on Indicative Prices

It is important to note that prices mentioned in this analysis are indicative and subject to change based on market conditions, supplier negotiations, and other variables. Always seek updated quotes and consider multiple suppliers to ensure competitive pricing.

Alternatives Analysis: Comparing 13 gauge metal With Other Solutions

Exploring Alternatives to 13 Gauge Metal

In the industrial sector, selecting the right material for a project is crucial for optimizing performance, cost-effectiveness, and durability. While 13 gauge metal, specifically cold-rolled steel, is a popular choice due to its balance of strength and weight, there are several alternative materials and methods available. This section compares 13 gauge metal against aluminum sheets and expanded metal, both of which can serve similar applications but come with distinct advantages and disadvantages.

| Comparison Aspect | 13 Gauge Metal | Aluminum Sheets | Expanded Metal |

|---|---|---|---|

| Performance | High strength, good ductility | Lightweight, corrosion-resistant | Offers ventilation and lightness |

| Cost | Moderate cost | Higher cost than steel | Generally lower cost |

| Ease of Implementation | Requires specific cutting tools | Easier to cut and shape | Simple to install, versatile |

| Maintenance | Requires periodic maintenance to prevent rust | Low maintenance, resistant to corrosion | Minimal maintenance |

| Best Use Case | Structural applications, automotive | Aerospace, automotive, marine | Fencing, grating, and decorative applications |

What Are the Advantages and Disadvantages of Using Aluminum Sheets?

Aluminum sheets are often lauded for their lightweight properties and excellent corrosion resistance. This makes them particularly suitable for applications in environments where moisture is a concern, such as marine settings or outdoor structures. However, the cost of aluminum can be significantly higher than that of 13 gauge steel, which may deter budget-conscious buyers. Additionally, while aluminum is easier to work with in terms of cutting and shaping, it may not provide the same level of strength for heavy-duty applications.

How Does Expanded Metal Compare as an Alternative?

Expanded metal is another alternative that offers unique benefits. It is created by cutting and stretching metal sheets, resulting in a mesh-like structure that provides strength while reducing weight. This makes it ideal for applications where ventilation or visibility is required, such as in grates or fencing. The cost of expanded metal is generally lower than that of 13 gauge steel, making it an attractive option for large-scale projects. However, its structural integrity may not be sufficient for all applications, particularly those requiring high load-bearing capacity.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When considering alternatives to 13 gauge metal, B2B buyers should evaluate their specific requirements, including the application environment, budget constraints, and performance expectations. For projects requiring robust structural support, 13 gauge metal remains a solid choice. In contrast, if weight reduction and corrosion resistance are paramount, aluminum sheets may be more appropriate. Meanwhile, expanded metal serves well for applications where cost-effectiveness and airflow are crucial. By aligning material properties with project needs, buyers can make informed decisions that enhance their operational efficiency and cost-effectiveness.

Essential Technical Properties and Trade Terminology for 13 gauge metal

What Are the Essential Technical Properties of 13 Gauge Metal?

When evaluating 13 gauge metal, several technical properties are crucial for B2B buyers to understand, as these specifications directly impact material selection and project outcomes.

1. Material Grade

The most common material grade for 13 gauge metal is A1008 for cold-rolled carbon steel. This grade is essential for applications requiring a balance of strength, ductility, and weldability. Understanding the material grade allows buyers to assess compatibility with project requirements and ensure compliance with industry standards.

2. Thickness Tolerance

Thickness tolerance for 13 gauge metal typically ranges from ±0.005 inches to ±0.125 inches, depending on the manufacturer. This specification is critical because it influences the precision of fabrication processes. Tighter tolerances can lead to higher costs but are necessary for applications demanding exact dimensions, such as in automotive or aerospace industries.

3. Ultimate Tensile Strength (UTS)

The ultimate tensile strength for 13 gauge carbon steel is usually around 51 KSI (Kilo-Pounds per Square Inch). UTS measures how much force the metal can withstand before failure. This property is vital for buyers to evaluate the metal’s suitability for load-bearing applications, ensuring safety and reliability in structural designs.

4. Yield Strength

Yield strength, typically around 31 KSI for 13 gauge metal, indicates the maximum stress that can be applied without permanent deformation. Knowing the yield strength helps B2B buyers understand how the material will perform under stress, which is particularly important in manufacturing and construction applications.

5. Brinell Hardness

The Brinell hardness for 13 gauge steel can be around 55 on the Rockwell B scale. Hardness relates to wear resistance and durability, making it a key consideration for industries that require long-lasting materials. Buyers should assess this property to ensure that the metal can withstand the operational conditions it will face.

6. Machinability Percentage

With a machinability rating of approximately 55%, 13 gauge metal is relatively easy to machine. This characteristic is crucial for manufacturers who require the material to be cut, shaped, or otherwise processed efficiently, impacting production timelines and costs.

What Are Common Trade Terminology and Jargon Associated with 13 Gauge Metal?

Understanding industry-specific terminology is essential for effective communication in the B2B metal supply chain.

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand. In the context of 13 gauge metal, knowing whether a supplier is an OEM can help buyers understand the quality and reliability of the materials they are purchasing.

2. MOQ (Minimum Order Quantity)

MOQ signifies the smallest amount of a product that a supplier is willing to sell. For 13 gauge metal, MOQs can vary significantly between suppliers. Knowing the MOQ is critical for buyers to budget appropriately and avoid excess inventory.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific quantities of products. For B2B buyers, issuing an RFQ for 13 gauge metal can streamline the procurement process and ensure competitive pricing from multiple suppliers.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms is essential for international transactions involving 13 gauge metal, as they clarify who is liable for costs and risks at each stage of transport.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. For 13 gauge metal, understanding lead times is crucial for project planning and ensuring timely completion of manufacturing processes.

6. Certification

Certification indicates that the metal meets specific industry standards, such as ASTM or ISO certifications. For B2B buyers, verifying certification is essential to ensure compliance with regulations and to maintain quality assurance in their projects.

These technical properties and trade terminologies are foundational for B2B buyers in effectively navigating the procurement of 13 gauge metal, ensuring they make informed decisions that align with their operational needs.

Navigating Market Dynamics and Sourcing Trends in the 13 gauge metal Sector

What are the Key Market Dynamics and Trends in the 13 Gauge Metal Sector?

The 13 gauge metal sector is witnessing significant transformations driven by global economic conditions and technological advancements. Increased demand for durable construction materials in developing regions, particularly in Africa and South America, is a primary driver. The construction and manufacturing industries are expanding rapidly, leading to a surge in the need for materials like 13 gauge steel. Additionally, the rise of renewable energy projects in the Middle East and Europe is boosting demand for robust metal components in wind and solar installations.

Emerging technologies such as automation and digital supply chain management are reshaping sourcing practices. B2B buyers can leverage online platforms that offer real-time inventory data, enabling more informed purchasing decisions. Digital tools enhance supply chain transparency, allowing buyers to track shipments and manage logistics more effectively. Furthermore, the ongoing shift toward just-in-time (JIT) inventory systems is compelling suppliers to maintain leaner inventories, which can lead to cost savings and faster delivery times for international buyers.

Another trend gaining traction is the customization of metal products. Many suppliers now offer tailored solutions to meet specific customer requirements, improving efficiency in industries such as automotive and aerospace. As global trade barriers fluctuate, international buyers must also stay abreast of tariffs and trade agreements that could impact sourcing costs and strategies.

How is Sustainability Influencing Sourcing Trends in the 13 Gauge Metal Sector?

The emphasis on sustainability is reshaping sourcing strategies in the 13 gauge metal sector. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to environmentally responsible practices. The extraction and processing of metals have significant environmental impacts, including greenhouse gas emissions and resource depletion. As a result, companies are turning to suppliers who can provide sustainable sourcing options.

Ethical supply chains are becoming paramount, with buyers seeking materials that are responsibly sourced. Certifications such as ISO 14001 (Environmental Management Systems) and LEED (Leadership in Energy and Environmental Design) are indicators of a supplier’s commitment to sustainability. Furthermore, the use of recycled materials is gaining popularity, as it reduces the demand for virgin resources and minimizes waste.

In addition, the industry is witnessing a growing interest in ‘green’ certifications for 13 gauge metal products. Suppliers who can provide traceability for their materials and demonstrate compliance with environmental regulations are more likely to attract international buyers. This trend not only aligns with corporate social responsibility (CSR) goals but also meets the increasing demand from consumers for sustainable products.

What is the Historical Context of 13 Gauge Metal in B2B Transactions?

The use of 13 gauge metal has evolved significantly over the decades, reflecting changes in industrial needs and technological advancements. Historically, the gauge system was developed as a standard for measuring metal thickness, with 13 gauge representing a thickness of approximately 0.090 inches. This specific gauge has become a staple in various industries, including construction and manufacturing, due to its balance of strength and weight.

The industrial revolution marked a turning point, as the demand for reliable and durable metal products surged. With advancements in steel production methods, including cold rolling and alloying, the properties of 13 gauge metal improved, making it suitable for a wider array of applications. As global markets expanded, the metal sector adapted to meet the needs of diverse industries, leading to the versatile and essential role that 13 gauge metal plays today in B2B transactions worldwide.

In conclusion, understanding the current market dynamics, embracing sustainability, and recognizing the historical context are essential for international B2B buyers navigating the 13 gauge metal sector. These insights can drive informed decision-making and foster stronger supplier relationships, ensuring a competitive edge in a rapidly evolving marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of 13 gauge metal

-

How do I determine the right specifications for 13 gauge metal for my project?

To determine the right specifications for 13 gauge metal, consider the specific requirements of your project, including strength, corrosion resistance, and weight. Assess the environmental conditions where the metal will be used, as this may dictate the need for stainless steel versus carbon steel. Additionally, consult with your supplier about the available finishes, dimensions, and compliance with relevant industry standards such as ASTM specifications. Providing detailed project specifications in your request for quotes (RFQ) can also help suppliers recommend the best material for your needs. -

What is the best type of 13 gauge metal for construction applications?

For construction applications, cold-rolled carbon steel is typically the best choice for 13 gauge metal due to its strength and durability. It is widely used in structural applications, such as framing and supports, because it offers good machinability and weldability. If corrosion resistance is a concern, consider using stainless steel options, which provide enhanced longevity in harsh environments. Always assess the specific requirements of your project, including load-bearing capacities and environmental factors, before making a decision. -

What are the minimum order quantities (MOQ) for 13 gauge metal?

Minimum order quantities for 13 gauge metal can vary significantly depending on the supplier and the type of metal. Typically, MOQs can range from as low as 100 kg to several tons for bulk orders. It’s advisable to discuss your needs with potential suppliers, especially if you are looking for customized sizes or special finishes. Some suppliers may also offer flexible terms for first-time buyers or specific projects, so it’s worth inquiring about any promotional options or discounts. -

How can I vet suppliers of 13 gauge metal effectively?

To effectively vet suppliers of 13 gauge metal, start by researching their reputation in the industry. Look for reviews, testimonials, and case studies from previous clients. Ensure that the supplier holds relevant certifications, such as ISO or ASTM compliance, which indicate adherence to quality standards. Additionally, request samples to evaluate the material’s quality and discuss their production processes, lead times, and after-sales support. Establishing a relationship and open communication with potential suppliers can also provide insights into their reliability and customer service. -

What are the payment terms typically offered by suppliers for bulk orders?

Payment terms for bulk orders of 13 gauge metal can vary widely among suppliers. Common options include upfront payment, net 30 or net 60 terms, and letters of credit for international transactions. Some suppliers may offer discounts for early payment or larger orders. Always clarify the payment terms before placing an order, including any potential penalties for late payments. Establishing a good relationship with your supplier can also lead to more favorable terms over time. -

What logistics considerations should I keep in mind when sourcing 13 gauge metal internationally?

When sourcing 13 gauge metal internationally, consider logistics factors such as shipping methods, customs clearance, and import duties. Evaluate the cost-effectiveness of air freight versus ocean freight based on your delivery timelines. Work closely with your supplier to understand packaging requirements and ensure that the metal arrives in good condition. Additionally, familiarize yourself with local regulations regarding imports, as compliance with safety and environmental standards is crucial to avoid delays or fines. -

How do I ensure quality assurance for my order of 13 gauge metal?

To ensure quality assurance for your order of 13 gauge metal, request material test reports (MTRs) from your supplier, which verify that the metal meets specified standards. It’s also beneficial to conduct inspections at the manufacturing facility if possible or before shipment. Establish clear quality criteria in your contract, and discuss any necessary certifications or testing methods that are relevant to your industry. Building a strong relationship with your supplier can also help facilitate better quality control practices. -

What are the common applications for 13 gauge metal in various industries?

13 gauge metal is widely used in various industries for applications such as construction, automotive, and manufacturing. In construction, it serves as structural support, roofing, and wall panels. In the automotive industry, it is used for chassis and body components due to its strength and lightweight properties. Additionally, manufacturing sectors utilize 13 gauge metal for fabrication of components, machinery parts, and furniture. Understanding the specific requirements of your industry will help you identify the most suitable applications for this versatile material.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 13 Gauge Metal Manufacturers & Suppliers List

1. Speedy Metals – 13ga Cold Rolled Steel Sheet

Domain: speedymetals.com

Registered: 2001 (24 years)

Introduction: {“Product Name”: “13ga (.090″) Cold Rolled Steel Sheet”, “Material”: “Steel”, “Shape”: “Sheet”, “Finish”: “Cold Rolled”, “Dimensions”: [{“Size”: “12×12”, “Weight”: “3.7440 lbs”, “Price”: “$20.06”}, {“Size”: “12×18”, “Weight”: “5.6160 lbs”, “Price”: “$26.33”}, {“Size”: “12×24”, “Weight”: “7.4880 lbs”, “Price”: “$32.09”}], “Cutting Tolerance”: “+/- 1/4″}”}

2. Forney – 49613 Expanded Metal

Domain: forneyind.com

Registered: 1997 (28 years)

Introduction: Forney 49613 Expanded Metal, 1/2 in x 13 Gauge, 16 in x 32 in

3. Online Metals – 13 Ga Carbon Steel Sheet A1008 Cold Roll

Domain: onlinemetals.com

Registered: 1997 (28 years)

Introduction: {“product_name”:”13 Ga 0.0897 Carbon Steel Sheet A1008 Cold Roll”,”material”:”Carbon Steel”,”thickness”:”13 Gauge (0.0897 inches)”,”type”:”Cold Rolled”,”standard”:”A1008″,”dimensions”:”48 x 96 inches”,”weight”:”Approximately 50 lbs”,”finish”:”Smooth”,”application”:”General fabrication, automotive, and construction”}

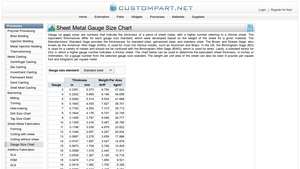

4. Custom Part Net – Sheet Metal Gauge Size Chart

Domain: custompartnet.com

Registered: 2006 (19 years)

Introduction: Sheet Metal Gauge Size Chart provides gauge sizes indicating the thickness of sheet metal, with a higher number representing a thinner sheet. Different gauge size standards include: Manufacturers’ Standard Gage for standard steel, galvanized steel, and stainless steel; Brown and Sharpe Gage (AWG) for non-ferrous metals like Aluminum and Brass; Birmingham Gage (BG) in the UK for various metals; and…

5. Metals Depot – Hot Rolled Steel Sheet

Domain: metalsdepot.com

Registered: 1999 (26 years)

Introduction: {“products”:[{“type”:”Hot Rolled Steel Sheet”,”specification”:”ASTM A1011 CS Type B”,”description”:”Economical steel sheets with a slightly grainy surface, ideal for painting.”,”uses”:[“general fabrication”,”equipment panels”,”tool boxes”,”hoppers”,”drip pans”],”thicknesses”:[{“gauge”:16,”thickness”:”.060″,”weight”:”2.50 lb/sqft”},{“gauge”:14,”thickness”:”.075″,”weight”:”3.13 lb/sqft”},{“gauge”:12…

6. MK Metal – CRS Sheet 13 Ga 48×120

Domain: mkmetal.net

Registered: 1999 (26 years)

Introduction: {“Product Name”: “CRS SHEET 13 GA X 48 X 120”, “Alloy”: “1008”, “Thickness”: “13 ga”, “Width”: “48 inches”, “Length”: “120 inches”, “Weight per Foot (SQFT)”: “3.75”, “Price per Piece”: “$113.85”, “Price Each”: “$383.82”}

7. Unbranded – Cold Rolled Steel Sheet

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Condition”:”New”,”Quantity Available”:”More than 10 available”,”Item Number”:”197345511325″,”Brand”:”Unbranded”,”Metal/Alloy Type”:”Cold Rolled Steel”,”Dimensions”:”3 inches x 24 inches”,”Thickness”:”0.090 inches”,”Sales Status”:”5 have already sold”}

Strategic Sourcing Conclusion and Outlook for 13 gauge metal

As international B2B buyers explore the potential of 13 gauge metal, it is crucial to recognize the strategic advantages of sourcing this material effectively. With its versatility and durability, 13 gauge metal serves a wide array of applications, from construction to automotive manufacturing. Understanding the specifications, such as thickness and material standards, allows buyers to make informed decisions that align with their project needs and budget constraints.

Moreover, leveraging strategic sourcing practices can lead to cost efficiencies and improved supply chain management. By building relationships with reliable suppliers and exploring bulk purchasing options, businesses can not only secure favorable pricing but also ensure consistent quality and timely delivery.

Looking ahead, the demand for 13 gauge metal is poised to grow, particularly in developing markets across Africa, South America, the Middle East, and Europe. Buyers are encouraged to take proactive steps in evaluating their sourcing strategies, exploring local suppliers, and considering innovative procurement solutions. By doing so, they can position themselves to capitalize on emerging opportunities in this dynamic market. Embrace strategic sourcing today to enhance your competitive edge in the global landscape of 13 gauge metal.