Introduction: Navigating the Global Market for 12l14 steel material properties

In today’s competitive manufacturing landscape, sourcing the right materials is crucial for ensuring product quality and operational efficiency. For international B2B buyers, understanding the material properties of 12L14 steel is particularly vital, as this resulfurized and rephosphorized carbon steel offers exceptional machinability and versatility. However, navigating the complexities of specifications, applications, and supplier reliability can pose significant challenges, especially for buyers from regions such as Africa, South America, the Middle East, and Europe, including countries like Saudi Arabia and Vietnam.

This comprehensive guide delves into the essential properties of 12L14 steel, including its chemical composition, mechanical characteristics, and suitability for various applications ranging from automotive components to precision machined parts. It also provides critical insights into the different forms and sizes available in the market, enabling buyers to make informed decisions based on their specific project needs. Furthermore, the guide offers valuable information on vetting suppliers, understanding cost implications, and ensuring compliance with international standards.

By equipping B2B buyers with actionable insights and in-depth knowledge, this guide empowers them to confidently navigate the global market for 12L14 steel. Whether you are looking to optimize production processes or enhance product quality, understanding the nuances of this material will be a key factor in your procurement strategy.

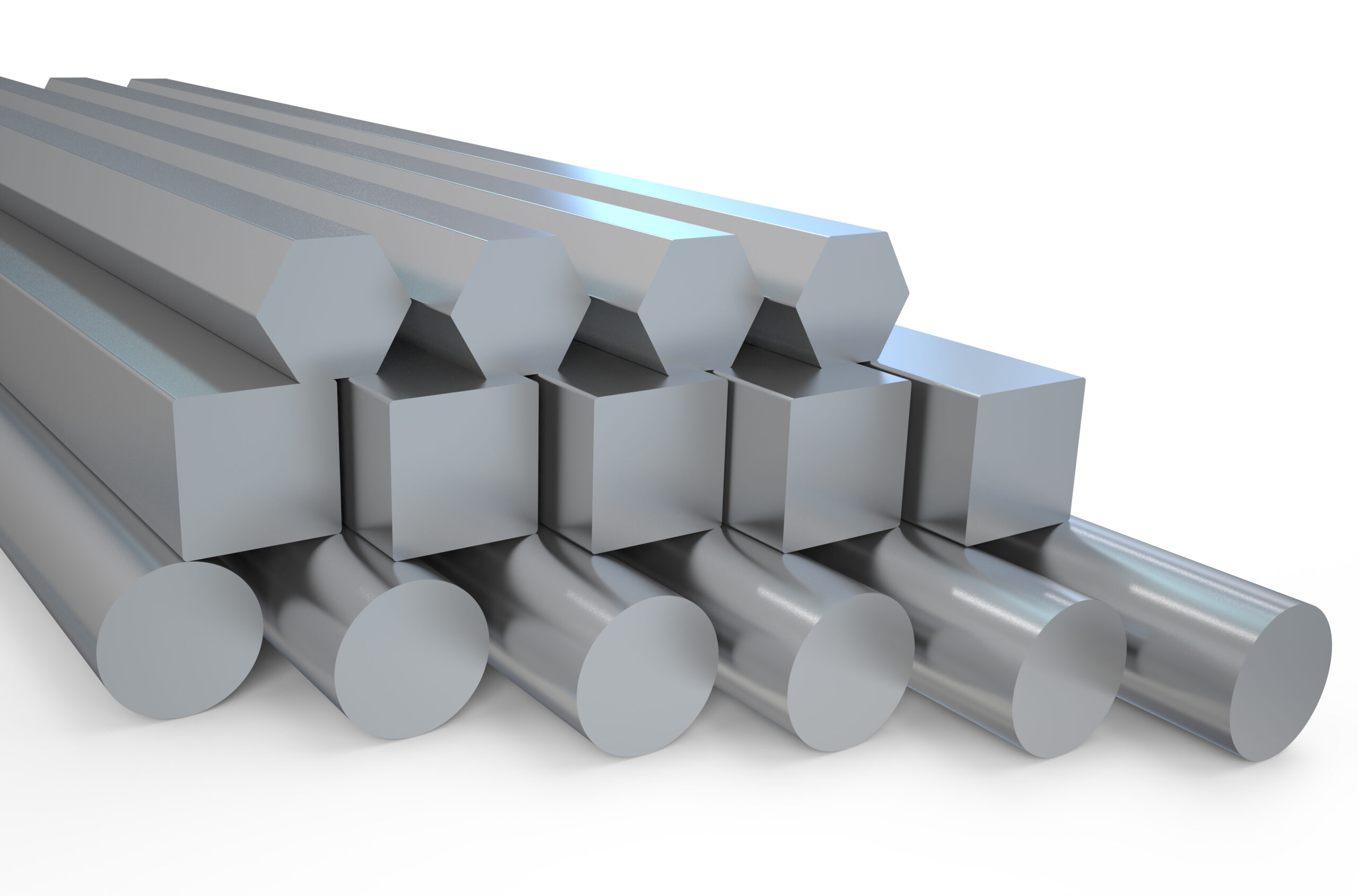

Understanding 12l14 steel material properties Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cold Drawn 12L14 | High dimensional accuracy; enhanced surface finish | Automotive, aerospace, machining | Pros: Excellent machinability, precision; Cons: Lower strength compared to other grades. |

| Leaded 12L14 | Contains lead for superior machinability | High-speed screw machines, fittings | Pros: Increased tool life and productivity; Cons: Environmental concerns due to lead content. |

| Resulfurized 12L14 | Enhanced machinability through sulfur addition | Manufacturing of precision parts | Pros: High-speed machining capabilities; Cons: Lower mechanical strength. |

| Electroplated 12L14 | Suitable for surface coatings and treatments | Medical instruments, automotive components | Pros: Good for applications requiring surface finish; Cons: Limited mechanical properties. |

| Case-Hardened 12L14 | Improved surface hardness while maintaining ductility | Gear manufacturing, high-wear applications | Pros: Combines toughness with wear resistance; Cons: More complex processing required. |

What are the Characteristics and Suitability of Cold Drawn 12L14 Steel?

Cold Drawn 12L14 steel is characterized by its high dimensional accuracy and superior surface finish achieved through the cold drawing process. This variant is ideal for applications requiring precise tolerances, such as automotive and aerospace components. Buyers should consider the availability of various shapes and sizes, as well as the enhanced machinability that allows for efficient production cycles. However, it is important to note that the lower strength compared to other cold drawn grades may limit its use in high-stress applications.

How Does Leaded 12L14 Steel Benefit High-Speed Machining?

Leaded 12L14 steel is specifically designed for high-speed machining applications, incorporating lead to significantly improve machinability. This type is commonly used in high-speed screw machines and fittings, where quick, efficient production is essential. While the benefits include increased tool life and reduced machining time, buyers must weigh these advantages against environmental regulations concerning lead usage. This consideration is particularly relevant for companies operating in regions with stringent environmental laws.

Why Choose Resulfurized 12L14 Steel for Precision Manufacturing?

Resulfurized 12L14 steel features enhanced machinability due to the addition of sulfur, making it suitable for manufacturing precision parts in various industries. Its ability to be machined at high speeds makes it a preferred choice for manufacturers looking to optimize production efficiency. However, the trade-off is a reduction in mechanical strength, which may not be suitable for all applications. Buyers should assess their specific requirements to determine if this material meets their performance criteria.

What Are the Advantages of Using Electroplated 12L14 Steel?

Electroplated 12L14 steel is well-suited for applications requiring surface coatings, such as medical instruments and automotive components. The electroplating process enhances the surface finish, providing additional corrosion resistance and aesthetic appeal. While this variant offers significant advantages in terms of surface quality, its mechanical properties may be limited, making it less suitable for heavy-duty applications. B2B buyers should evaluate the balance between surface performance and mechanical strength based on their product needs.

How Does Case-Hardened 12L14 Steel Improve Wear Resistance?

Case-hardened 12L14 steel combines the ductility of the base material with enhanced surface hardness, making it an excellent choice for applications where wear resistance is critical, such as gear manufacturing. This type undergoes a complex heat treatment process to achieve its properties, which allows it to withstand high-stress conditions. While the benefits are significant, buyers should be prepared for the additional processing costs associated with case hardening. Understanding the specific application requirements will help in making an informed purchasing decision.

Key Industrial Applications of 12l14 steel material properties

| Industry/Sector | Specific Application of 12l14 steel material properties | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Manufacturing of precision components like gears and bushings | High machinability leads to reduced production time and costs | Ensure compliance with international quality standards and specifications |

| Aerospace | Production of fittings and couplings for aircraft systems | Lightweight yet strong material enhances performance and safety | Consider sourcing from certified suppliers with aerospace-grade materials |

| Oil & Gas | Fabrication of hydraulic fittings and valves | Exceptional machinability allows for efficient production of complex parts | Evaluate the supplier’s ability to meet rigorous industry standards and certifications |

| Medical Devices | Creation of surgical instruments and dental tools | Precision and high-quality finish improve functionality and safety | Focus on suppliers that adhere to medical-grade material standards |

| Machining/Manufacturing | High-speed screw machine products | Increased productivity and tool life due to superior cutting performance | Look for suppliers with a diverse inventory and quick delivery capabilities |

How is 12L14 Steel Utilized in the Automotive Industry?

In the automotive sector, 12L14 steel is widely used for manufacturing precision components such as gears, bushings, and pins. Its excellent machinability allows manufacturers to produce complex shapes efficiently, reducing production times and costs. This is particularly beneficial for international buyers who require high-quality parts with fast turnaround times. When sourcing, it’s crucial to ensure that suppliers comply with international quality standards, as automotive components must meet stringent safety and performance regulations.

What Role Does 12L14 Steel Play in Aerospace Applications?

The aerospace industry leverages 12L14 steel for producing critical components like fittings and couplings. The material’s lightweight yet strong properties help enhance the overall performance and safety of aircraft systems. International buyers, especially from regions like the Middle East and Europe, should prioritize suppliers with aerospace-grade certifications. This ensures that the materials used can withstand the demanding conditions of flight while meeting rigorous industry standards.

Why is 12L14 Steel Important in Oil & Gas Sector?

In the oil and gas industry, 12L14 steel is essential for fabricating hydraulic fittings and valves. Its exceptional machinability allows for the efficient production of intricate parts that are vital for the operation of drilling and extraction equipment. Buyers should consider the supplier’s ability to meet the rigorous standards required in this sector, including certifications and quality assurance processes, to ensure reliability and safety in their operations.

How is 12L14 Steel Used in Medical Devices?

12L14 steel is extensively utilized in the medical sector for creating surgical instruments and dental tools. The precision and high-quality finish of 12L14 steel improve the functionality and safety of these instruments, making them critical for effective medical procedures. Buyers in this field should focus on suppliers that adhere to medical-grade material standards, ensuring that all products are safe and effective for use in healthcare environments.

What Benefits Does 12L14 Steel Offer in Machining and Manufacturing?

In machining and manufacturing, 12L14 steel is favored for high-speed screw machine products due to its superior cutting performance. The material’s high machinability translates to increased productivity and extended tool life, which is a significant advantage in high-volume production environments. International buyers should look for suppliers with a diverse inventory and quick delivery capabilities to meet their operational demands efficiently.

3 Common User Pain Points for ’12l14 steel material properties’ & Their Solutions

Scenario 1: Difficulty in Achieving Precision Machining with 12L14 Steel

The Problem: B2B buyers in the machining and manufacturing sectors often encounter challenges when working with 12L14 steel, particularly in achieving the desired precision and finish. This steel, while known for its excellent machinability, can sometimes lead to variations in dimensions due to its ductility. Buyers may find that parts produced from 12L14 do not consistently meet the tight tolerances required for high-performance applications, such as in the aerospace or automotive industries. This inconsistency can result in increased scrap rates and rework, leading to project delays and added costs.

The Solution: To overcome these challenges, it is essential for buyers to implement strict quality control measures and precise machining parameters. When sourcing 12L14 steel, ensure that the supplier provides thorough documentation on the material’s properties, including hardness and tensile strength. Additionally, employing advanced CNC machining techniques can help achieve better consistency. Utilizing a slower feed rate and optimized cutting speeds will minimize tool wear and enhance the overall surface finish. Furthermore, consider conducting regular calibration of machining equipment to maintain the accuracy of cuts. Collaborating with suppliers who specialize in 12L14 steel can also provide valuable insights into best practices for machining this material effectively.

Scenario 2: Misalignment Between Material Properties and Application Needs

The Problem: Another common pain point for B2B buyers is the misalignment between the properties of 12L14 steel and the specific needs of their applications. For instance, while 12L14 is praised for its machinability, it has lower tensile strength compared to other steel grades, which may not be suitable for high-stress components like gears or load-bearing fixtures. This mismatch can lead to premature failure of parts, resulting in costly downtime and repairs in manufacturing operations.

The Solution: To mitigate this issue, it is crucial to conduct a thorough analysis of the application requirements before selecting 12L14 steel. Buyers should engage in a detailed discussion with engineering teams to understand the load, stress, and environmental conditions that the components will face. If 12L14 is deemed necessary for its machining advantages, consider using it in combination with heat treatment processes like carburizing or case hardening to enhance its surface hardness and wear resistance. This hybrid approach can improve performance in demanding applications while retaining the benefits of easy machinability. Always request samples and conduct in-house testing to validate that the chosen material meets the specified criteria before full-scale production.

Scenario 3: Limited Availability of Custom Sizes and Shapes

The Problem: Many international B2B buyers face the challenge of sourcing 12L14 steel in custom sizes and shapes to fit specific design requirements. The standard diameters and forms offered by suppliers may not always align with the unique specifications of a project, leading to delays and increased costs as companies either modify their designs or seek alternative materials. This limitation can be particularly frustrating for buyers in regions with less access to diverse suppliers.

The Solution: To address the issue of limited availability, buyers should establish strong relationships with suppliers who offer flexibility in their manufacturing processes. When placing orders, clearly communicate the specific dimensions and shapes needed, and inquire about the possibility of custom fabrication. Suppliers with advanced capabilities may be able to accommodate requests for non-standard sizes or shapes, allowing for better alignment with project requirements. Additionally, consider leveraging partnerships with local fabricators who may offer additional customization options for 12L14 steel. This collaborative approach can streamline the procurement process and ensure that materials arrive on time and fit for purpose, ultimately enhancing project efficiency and reducing lead times.

Strategic Material Selection Guide for 12l14 steel material properties

What Are the Key Properties of 12L14 Steel Material?

12L14 steel is a resulfurized and rephosphorized carbon steel known for its exceptional machinability. The addition of sulfur, phosphorus, and lead enhances its cutting capabilities, making it ideal for high-speed machining applications. However, its low carbon content results in lower strength compared to other cold-drawn grades. This material typically exhibits a tensile strength range of 70,000 to 80,000 psi and a yield strength of 65,000 to 75,000 psi, making it suitable for various applications, including fittings, couplings, and hydraulic components.

What Are the Pros and Cons of Using 12L14 Steel?

The primary advantage of 12L14 steel is its excellent machinability, which can enhance productivity and extend tool life by up to 40% during machining processes. This makes it a preferred choice in industries requiring precision components, such as automotive and aerospace. Additionally, the availability of various shapes and sizes allows for flexibility in design and manufacturing.

On the downside, 12L14’s lower strength and ductility may limit its use in high-stress applications. It is also less suitable for components subjected to fatigue stress, such as gears and bearings, due to its reduced mechanical properties. Furthermore, the presence of lead raises concerns regarding environmental compliance, especially in regions with stringent regulations.

How Does 12L14 Steel Impact Specific Applications?

12L14 steel is particularly compatible with applications requiring high precision and surface finish but lower mechanical strength. Industries such as oil and gas, automotive, and machining benefit from its properties, as it can be easily formed into intricate shapes and sizes. However, international buyers should consider the specific media compatibility of their applications. For instance, in corrosive environments, additional protective measures or coatings may be necessary to prevent degradation.

What Should International B2B Buyers Consider When Selecting 12L14 Steel?

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of compliance with local and international standards such as ASTM, DIN, and JIS. Understanding the specific requirements for material certifications and mechanical properties is crucial for ensuring product suitability. Additionally, buyers should consider the availability of the material in their region, as well as potential shipping costs and lead times, which can vary significantly based on geographic location.

Summary Table of 12L14 Steel Material Properties

| Material | Typical Use Case for 12L14 Steel Material Properties | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| 12L14 Steel | Fittings, couplings, hydraulic components | Excellent machinability | Lower strength compared to other steels | Medium |

| 12L14 Steel | Automotive parts, precision tools | High precision and surface finish | Not suitable for high-stress applications | Medium |

| 12L14 Steel | Aerospace components, small force applications | Versatile shapes and sizes | Environmental concerns due to lead | Medium |

| 12L14 Steel | High-speed screw machine products | Increased productivity | Limited fatigue resistance | Medium |

This table summarizes the essential properties and considerations for 12L14 steel, aiding international B2B buyers in making informed decisions tailored to their specific needs.

In-depth Look: Manufacturing Processes and Quality Assurance for 12l14 steel material properties

What Are the Main Stages in the Manufacturing Process for 12L14 Steel?

The manufacturing process for 12L14 steel involves several critical stages, including material preparation, forming, assembly, and finishing. Each stage is essential in ensuring the material’s properties align with industry standards and customer specifications.

How Is Material Prepared for 12L14 Steel Production?

The initial step in manufacturing 12L14 steel involves the careful selection of raw materials, primarily carbon steel, along with added elements such as sulfur, phosphorus, and lead. These additives significantly enhance the machinability of the steel. The raw materials are typically sourced from reputable suppliers who adhere to international standards like ASTM A108, ensuring quality right from the start.

Once the materials are selected, they undergo processes such as melting and casting. The steel is melted in an electric arc furnace and then cast into billets or ingots. This step is crucial for achieving a uniform chemical composition and eliminating impurities, which can adversely affect the final product’s performance.

What Forming Techniques Are Used in 12L14 Steel Manufacturing?

After material preparation, the next stage is forming. For 12L14 steel, this typically involves cold drawing or cold finishing processes. Cold drawing reduces the diameter of the steel bars while enhancing their mechanical properties through strain hardening. This process also allows for precise dimensional control, which is essential for applications that demand tight tolerances.

Other techniques such as machining, turning, and milling may also be employed depending on the final specifications required by the customer. The choice of technique often depends on the intended application, whether it be for automotive parts, fittings, or other high-precision components.

What Quality Assurance Measures Are Essential for 12L14 Steel?

Quality assurance is paramount in the production of 12L14 steel to ensure it meets the rigorous demands of various industries, including automotive, aerospace, and construction. The quality assurance process typically adheres to international standards such as ISO 9001, which provides a framework for consistent quality management.

Which International Standards Apply to 12L14 Steel Quality Control?

ISO 9001 is a widely recognized standard that outlines the requirements for a quality management system. Companies producing 12L14 steel should be certified to this standard, demonstrating their commitment to quality and customer satisfaction. Additionally, industry-specific certifications such as API (American Petroleum Institute) for oil and gas applications or CE marking for products sold in the European market are crucial for ensuring compliance with regulatory requirements.

What Are the Key Quality Control Checkpoints in 12L14 Steel Manufacturing?

Quality control (QC) checkpoints are integral to maintaining the integrity of 12L14 steel throughout the manufacturing process. These checkpoints typically include:

- Incoming Quality Control (IQC): This step involves inspecting raw materials upon receipt to ensure they meet specified standards and specifications.

- In-Process Quality Control (IPQC): During manufacturing, periodic checks are performed to monitor the production process and ensure adherence to quality standards. This may involve testing for dimensional accuracy and mechanical properties at various stages of production.

- Final Quality Control (FQC): Before shipment, finished products undergo rigorous testing to verify that they meet all required specifications. This may include tensile strength testing, hardness testing, and dimensional inspections.

How Can B2B Buyers Verify Supplier Quality Assurance for 12L14 Steel?

B2B buyers must ensure that their suppliers maintain high-quality standards throughout the manufacturing process. One effective way to verify this is through supplier audits. These audits can assess compliance with international standards, check for proper documentation, and ensure that quality control measures are effectively implemented.

Buyers should also request detailed quality assurance reports, including results from tests conducted at various stages of production. Additionally, third-party inspections can provide an unbiased assessment of the supplier’s quality practices. Engaging with suppliers who are open to sharing their quality assurance protocols and certifications can further enhance trust and reliability.

What Common Testing Methods Are Used for 12L14 Steel Quality Assurance?

Several common testing methods are employed to ensure the quality of 12L14 steel. These include:

- Tensile Testing: To determine the ultimate tensile strength and yield strength, essential for understanding the material’s performance under load.

- Hardness Testing: Methods such as Brinell or Rockwell hardness tests provide insights into the material’s resistance to deformation.

- Elongation and Reduction of Area Testing: These tests measure ductility and toughness, which are crucial for applications that require bending or forming.

- Microstructural Analysis: Conducted using metallographic techniques, this testing assesses the internal structure of the steel, revealing information about grain size and distribution, which can affect performance.

What Are the Quality Control Nuances for International B2B Buyers?

For international buyers, understanding the nuances of quality control is vital. Different regions may have varying standards and regulations. For example, European buyers may require CE marking, while buyers in the Middle East may prioritize compliance with local standards.

Additionally, language barriers and differing practices in quality assurance can pose challenges. Buyers should seek suppliers with experience in international trade and who are familiar with the specific quality requirements of their target markets. This familiarity can streamline the procurement process and minimize risks associated with quality discrepancies.

In conclusion, the manufacturing processes and quality assurance measures for 12L14 steel are complex and integral to ensuring the material meets the high standards required for various applications. By understanding these processes, B2B buyers can make informed decisions and establish reliable partnerships with suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ’12l14 steel material properties’

Introduction

Navigating the procurement of 12L14 steel requires a clear understanding of its properties, applications, and sourcing best practices. This guide provides a step-by-step checklist designed to assist international B2B buyers in evaluating their needs and selecting the right suppliers for 12L14 steel material. By following these steps, you can ensure that you procure high-quality materials that meet your operational requirements.

Step 1: Define Your Technical Specifications

Understanding your technical requirements is the first step in sourcing 12L14 steel. This includes specifying the desired dimensions, tolerances, and mechanical properties such as tensile strength and hardness. Clearly defined specifications will help you communicate effectively with potential suppliers and ensure that the material meets your application needs.

Step 2: Research 12L14 Steel Properties

Familiarize yourself with the mechanical and chemical properties of 12L14 steel. Key properties to consider include:

– Tensile Strength: Typically ranges from 70,000 to 80,000 psi.

– Machinability Index: Notable for its high machinability (around 170%), making it suitable for precision machining.

Understanding these properties helps you assess whether the material is suitable for your applications, such as automotive components or precision tools.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Look for companies with a proven track record in supplying 12L14 steel, and request documentation that demonstrates their capability to meet your specifications.

– Check References: Ask for references from other clients in similar industries or regions to gauge reliability and quality.

– Assess Certifications: Ensure suppliers comply with relevant standards such as ASTM A108, which governs the quality of steel bars.

Step 4: Request Samples and Test Materials

Once you have shortlisted potential suppliers, request samples of the 12L14 steel. Testing these samples can provide insight into the material’s machinability, finish, and overall quality.

– Conduct Machinability Tests: Evaluate how the steel performs under your specific machining conditions.

– Verify Hardness and Strength: Use industry-standard methods to confirm that the samples meet your specified mechanical properties.

Step 5: Negotiate Terms and Conditions

Once you are satisfied with the supplier’s capabilities, proceed to negotiate terms. Discuss pricing, delivery schedules, payment terms, and any other conditions that are crucial for your procurement process.

– Volume Discounts: Inquire about bulk purchasing options to reduce costs.

– Lead Times: Ensure that delivery timelines align with your project schedules to avoid delays.

Step 6: Establish Quality Assurance Protocols

Implementing a quality assurance protocol is vital to ensure that the steel received meets your specifications. Outline procedures for inspection upon delivery to confirm compliance with your standards.

– Incoming Material Inspections: Develop a checklist for receiving and inspecting the material.

– Documentation Review: Ensure all accompanying documentation, such as mill test reports, is complete and accurate.

Step 7: Plan for Long-Term Relationships

Building a long-term relationship with a reliable supplier can lead to better pricing, priority service, and improved communication over time.

– Regular Communication: Maintain open lines of communication to discuss future needs and any potential issues.

– Feedback Loop: Provide feedback on material performance to help suppliers improve their offerings.

By following this practical checklist, B2B buyers can effectively navigate the complexities of sourcing 12L14 steel, ensuring they secure the right materials for their specific applications.

Comprehensive Cost and Pricing Analysis for 12l14 steel material properties Sourcing

Understanding the cost structure and pricing dynamics for sourcing 12L14 steel is essential for international B2B buyers, especially those operating in diverse markets across Africa, South America, the Middle East, and Europe. This guide provides a comprehensive analysis of the key components and influences on pricing, along with practical tips for buyers looking to optimize their sourcing strategies.

What Are the Key Cost Components for 12L14 Steel?

When sourcing 12L14 steel, buyers should be aware of several critical cost components that contribute to the overall pricing:

-

Materials: The primary cost driver is the raw materials used in producing 12L14 steel, including carbon, manganese, phosphorus, sulfur, and lead. The prices of these raw materials can fluctuate based on market demand and availability, impacting the overall cost of steel.

-

Labor: Labor costs vary depending on the region and the complexity of the machining processes required for 12L14 steel. Regions with higher wage standards may see increased labor costs that can influence pricing.

-

Manufacturing Overhead: This includes costs related to energy consumption, maintenance of machinery, and factory operations. Efficient manufacturing processes can help mitigate these costs.

-

Tooling: The expense of tools and dies used in the production of 12L14 steel can be significant, especially for customized orders. Buyers should consider whether the tooling costs are included in the quoted price.

-

Quality Control (QC): Ensuring that the steel meets required specifications involves quality testing and certifications, which can add to the overall cost. Certifications such as ASTM compliance are often sought after in international markets.

-

Logistics: Shipping and handling costs are critical, particularly for international shipments. Factors such as distance, freight options, and customs duties can significantly impact total costs.

-

Margin: Suppliers will include a profit margin in their pricing, which can vary widely based on market conditions and competition.

How Do Price Influencers Impact the Cost of 12L14 Steel?

Several factors can influence the pricing of 12L14 steel, which buyers should consider when negotiating:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often offer better pricing for larger orders. Understanding the MOQ can help buyers plan their purchases effectively.

-

Specifications and Customization: Custom orders or specific tolerances can increase costs. Buyers should clarify their requirements upfront to avoid unexpected expenses.

-

Quality and Certifications: Higher quality steel and recognized certifications can command premium prices. Buyers should assess their specific needs against available certifications.

-

Supplier Factors: The supplier’s reputation, reliability, and production capabilities can influence pricing. Established suppliers may charge more but offer better quality assurance.

-

Incoterms: The terms of shipment (such as FOB, CIF, etc.) will affect the total landed cost. Buyers should negotiate Incoterms that align with their logistical capabilities and cost expectations.

What Tips Can Help Buyers Negotiate Better Prices for 12L14 Steel?

Effective negotiation and strategic sourcing can help buyers achieve cost-efficiency when sourcing 12L14 steel:

-

Negotiate Volume Discounts: If possible, consolidate orders to meet or exceed MOQs for better pricing. Long-term contracts may also lead to favorable pricing arrangements.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider logistics, quality, and potential rework costs in your TCO analysis.

-

Stay Informed About Market Trends: Understanding market trends and fluctuations in raw material prices can provide leverage in negotiations.

-

Build Relationships with Suppliers: Establishing strong partnerships with suppliers can lead to better terms, priority service, and insight into upcoming changes in pricing.

-

Be Aware of Regional Pricing Nuances: Understand the regional market dynamics, including tariffs and local demand, as these can significantly affect pricing in different markets.

Disclaimer on Pricing

The prices for 12L14 steel are indicative and can vary based on numerous factors, including market conditions, supplier pricing strategies, and fluctuations in raw material costs. It is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure competitive pricing for their specific requirements.

Alternatives Analysis: Comparing 12l14 steel material properties With Other Solutions

Understanding Alternatives for 12L14 Steel Material Properties

When evaluating materials for precision machining and manufacturing, it’s essential to consider various alternatives to 12L14 steel. Each alternative comes with its own set of properties, advantages, and limitations. Understanding these differences can help B2B buyers make informed decisions tailored to their specific applications and operational requirements.

Comparison Table

| Comparison Aspect | 12L14 Steel Material Properties | Alternative 1: 1018 Steel | Alternative 2: Brass |

|---|---|---|---|

| Performance | High machinability, moderate strength | Good machinability, higher tensile strength | Excellent machinability, corrosion resistance |

| Cost | Moderate cost | Generally lower cost | Higher cost |

| Ease of Implementation | Easy to machine with standard tools | Requires similar tools | Requires specialized tools for machining |

| Maintenance | Low maintenance, stable performance | Low maintenance | Moderate maintenance due to corrosion |

| Best Use Case | Precision parts in automotive and aerospace | General manufacturing, automotive components | Decorative elements, plumbing fittings |

Detailed Breakdown of Alternatives

What are the Advantages and Disadvantages of 1018 Steel?

1018 steel is a low-carbon steel that is widely used for its balance between strength and machinability. It typically has higher tensile strength compared to 12L14, making it suitable for applications requiring more durability. However, while it is easier to machine than higher alloy steels, it does not match the exceptional machinability of 12L14 due to the absence of lead. Additionally, 1018 steel is often more cost-effective, making it a preferred choice for larger production runs where budget constraints are a factor. However, it may not perform as well in applications requiring extremely fine tolerances or surface finishes.

How Does Brass Compare to 12L14 Steel?

Brass is an alloy of copper and zinc that offers superior corrosion resistance and excellent machinability, often favored for applications in plumbing and electrical components. Its ability to withstand harsh environments makes it an attractive alternative to 12L14 in specific scenarios. However, brass is typically more expensive and may not possess the same strength characteristics as steel. While it is easier to machine, the specialized tools required for brass can lead to higher operational costs. Buyers should consider brass when corrosion resistance is a priority, but should weigh the cost against the potential benefits.

Conclusion: Which Material Should B2B Buyers Choose?

Selecting the right material depends on the specific requirements of the application. For high-precision components in industries like automotive and aerospace, 12L14 steel remains an excellent choice due to its exceptional machinability and performance. If cost is a significant factor, 1018 steel may be suitable for less demanding applications, offering a balance of strength and machinability at a lower price point. Conversely, for applications requiring resistance to corrosion and aesthetic appeal, brass could be the preferred material, albeit at a higher cost. Ultimately, B2B buyers should assess their operational needs, budget constraints, and performance requirements to choose the most appropriate material solution for their projects.

Essential Technical Properties and Trade Terminology for 12l14 steel material properties

What Are the Key Technical Properties of 12L14 Steel?

Understanding the technical properties of 12L14 steel is essential for B2B buyers looking to make informed purchasing decisions. Here are some critical specifications:

-

Material Grade

12L14 is a resulfurized and rephosphorized carbon steel known for its exceptional machinability. The designation “12” indicates a maximum carbon content of 0.15%, while the “L” denotes the addition of lead to enhance cutting performance. For buyers, selecting the right material grade is crucial as it affects machinability, strength, and overall performance in applications. -

Tensile Strength

The tensile strength of 12L14 steel typically ranges from 70,000 to 80,000 psi. This property measures the material’s ability to withstand tension before failure. For industries such as automotive and aerospace, understanding tensile strength helps in selecting materials that can endure operational stresses without deformation. -

Machinability Index

With a machinability rating of around 170%, 12L14 steel is one of the most machinable steel grades available. This high index means that it can be processed at faster speeds and with greater efficiency, which translates to reduced production costs and improved tool life for manufacturers. B2B buyers should prioritize this property when sourcing materials for high-speed machining applications. -

Yield Strength

Yield strength measures the maximum stress that a material can withstand without permanent deformation, with 12L14 steel typically exhibiting a yield strength of 65,000 to 75,000 psi. This specification is particularly relevant for components that must maintain precise tolerances under load, such as fittings and valves. -

Elongation Percentage

Elongation indicates ductility, with values for 12L14 steel ranging from 15% to 20%. This property is vital for applications requiring bending or forming, as it ensures that the material can be manipulated without cracking. For buyers, this translates to flexibility in design and manufacturing processes.

What Common Trade Terms Should B2B Buyers Know?

Familiarity with industry jargon can greatly enhance communication and negotiation effectiveness in B2B transactions. Here are some essential terms related to steel procurement:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for buyers who need to source specific components that meet particular standards or specifications. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers determine if a supplier’s terms align with their project needs and budget constraints. For 12L14 steel, suppliers may set a minimum order of 10,000 lbs, making it important for buyers to plan accordingly. -

RFQ (Request for Quote)

An RFQ is a document sent to suppliers to solicit pricing and terms for specific quantities of products. Crafting a well-defined RFQ for 12L14 steel can streamline the procurement process, ensuring that buyers receive accurate quotes that reflect their requirements. -

Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in shipping and delivery. Familiarity with terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is essential for B2B buyers to understand their obligations and mitigate risks during international transactions. -

Heat Treatment

This refers to the process of heating and cooling metals to alter their physical and sometimes chemical properties. For 12L14 steel, processes like annealing or case hardening can enhance performance characteristics, making it vital for buyers to understand the implications of heat treatment on their orders.

By grasping these technical properties and trade terms, B2B buyers can better navigate the complexities of sourcing 12L14 steel, ultimately leading to more effective procurement strategies and enhanced operational efficiencies.

Navigating Market Dynamics and Sourcing Trends in the 12l14 steel material properties Sector

What Are the Key Drivers Influencing the 12L14 Steel Material Properties Market?

The market for 12L14 steel, a resulfurized and rephosphorized carbon steel known for its exceptional machinability, is experiencing several significant trends driven by global demands. One primary factor is the increasing automation in manufacturing processes, particularly in sectors like automotive, aerospace, and oil & gas. As industries seek to enhance productivity, the demand for materials that can be machined rapidly without compromising quality is rising. In regions such as Africa and South America, where industrialization is gaining momentum, the need for reliable and cost-effective steel solutions is paramount.

Additionally, the expansion of international trade networks is facilitating easier access to 12L14 steel products across continents. B2B buyers are increasingly leveraging digital platforms for sourcing, leading to greater transparency in pricing and availability. This trend is particularly evident in Europe and the Middle East, where companies are adopting advanced procurement technologies to streamline their supply chains. Furthermore, the push for customization in product offerings is driving suppliers to stock a wider variety of shapes and sizes, catering to specific industry requirements.

How Are Sustainability and Ethical Sourcing Impacting the 12L14 Steel Market?

Sustainability is becoming a critical consideration for B2B buyers in the steel sector, including those sourcing 12L14 steel. The environmental impact of steel production, particularly concerning carbon emissions, is under scrutiny. Buyers are increasingly prioritizing suppliers who can demonstrate adherence to sustainable practices, such as recycling scrap steel and employing energy-efficient manufacturing processes.

Ethical sourcing is also gaining traction, as companies recognize the importance of transparency in their supply chains. Certifications such as ISO 14001 for environmental management and ISO 9001 for quality management are becoming essential for suppliers aiming to attract discerning buyers. In addition, the trend towards “green” materials is prompting manufacturers to explore alternatives to traditional steel production methods, including the use of electric arc furnaces that reduce carbon footprints. By choosing suppliers that emphasize sustainability, B2B buyers can not only enhance their corporate social responsibility profiles but also respond to increasing consumer demand for ethically produced goods.

What Is the Historical Context of 12L14 Steel and Its B2B Relevance?

The development of 12L14 steel can be traced back to the mid-20th century when the need for high machinability in production environments became more pronounced. As industries began to adopt more sophisticated machinery, the demand for materials that could withstand high-speed processing without excessive wear became critical. The addition of sulfur, phosphorus, and lead in the formulation of 12L14 steel significantly improved its machinability, making it a preferred choice for applications requiring precision and efficiency.

Over the years, 12L14 steel has evolved to meet the diverse needs of various industries. Its applications range from hydraulic fittings to automotive components, reflecting its versatility and reliability. As global markets continue to expand, the historical significance of 12L14 steel underscores its ongoing relevance in modern manufacturing, particularly for B2B buyers seeking materials that deliver both performance and cost-effectiveness.

Conclusion

Navigating the complexities of the 12L14 steel market requires a keen understanding of current trends, sustainability considerations, and historical context. By staying informed, B2B buyers can make strategic sourcing decisions that not only meet their operational needs but also align with broader industry shifts towards sustainability and ethical practices.

Frequently Asked Questions (FAQs) for B2B Buyers of 12l14 steel material properties

-

1. How do I select the right supplier for 12L14 steel?

When sourcing 12L14 steel, it’s crucial to vet suppliers based on their reputation, certifications, and experience in the industry. Look for suppliers who can provide detailed product specifications, including compliance with international standards like ASTM A108. Request samples to assess quality and inquire about their capabilities for customization, inventory levels, and delivery timelines. Establishing communication with their customer service can also provide insight into their responsiveness and reliability. -

2. What are the key properties of 12L14 steel?

12L14 steel is a resulfurized and rephosphorized carbon steel that offers excellent machinability due to its lead, sulfur, and phosphorus content. It typically has a tensile strength of 70,000 to 80,000 psi and a yield strength of 65,000 to 75,000 psi, making it suitable for precision machining applications. It exhibits good ductility and is often used in the production of components such as fittings, valves, and pins. However, its lower strength compared to other steels should be considered in design applications. -

3. What are common applications for 12L14 steel?

12L14 steel is widely used in industries requiring high-speed machining and precision components. Common applications include fittings, couplings, valves, bushings, hydraulic fittings, and various automotive parts. Its excellent machinability makes it ideal for producing intricate shapes and designs, especially in the automotive, aerospace, and manufacturing sectors. However, it is not recommended for high-stress components like gears due to its lower strength. -

4. What are the minimum order quantities (MOQ) for 12L14 steel?

The minimum order quantity for 12L14 steel often varies by supplier. Generally, it can range from 10,000 lbs to larger bulk quantities. It’s essential to discuss MOQs upfront when negotiating with suppliers, as this can affect pricing and availability. Some suppliers may offer flexibility on MOQs based on your specific requirements or long-term contracts, so it’s beneficial to explore these options. -

5. What are the payment terms typically offered by suppliers?

Payment terms can vary significantly among suppliers, but common practices include net 30, net 60, or payment upon delivery. Some suppliers may require a deposit upfront, especially for large orders or customized products. It’s advisable to clarify payment methods accepted (e.g., bank transfer, credit card) and any potential discounts for early payment or bulk orders. Understanding these terms can help you manage cash flow effectively. -

6. How can I ensure the quality of 12L14 steel before purchase?

To ensure quality, request mill test reports (MTRs) that provide details on chemical composition and mechanical properties. Additionally, inquire about quality assurance processes and certifications the supplier holds, such as ISO 9001. If possible, conduct inspections or audits of the supplier’s facility to verify their manufacturing practices. Establishing a clear quality agreement can also help set expectations regarding tolerances and performance. -

7. What logistics considerations should I be aware of when importing 12L14 steel?

Logistics for importing 12L14 steel involve understanding shipping costs, lead times, and customs regulations in your country. Ensure that the supplier can provide a reliable shipping method that aligns with your delivery timelines. Familiarize yourself with import duties and tariffs that may apply to steel products in your region. Working with a logistics partner who has experience in international trade can streamline this process and mitigate risks. -

8. Can I customize 12L14 steel products based on my specifications?

Yes, many suppliers offer customization options for 12L14 steel, including different shapes, sizes, and surface finishes. When placing an order, specify your requirements clearly, including dimensions, tolerances, and any special treatments needed (like heat treatment or coating). Discussing your needs with the supplier early in the process will ensure they can meet your specifications and help avoid delays in production and delivery.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 12L14 Steel Material Properties Manufacturers & Suppliers List

1. AISI 12L14 – Fastest Machining Carbon Steel

Domain: azom.com

Registered: 1999 (26 years)

Introduction: AISI 12L14 Carbon Steel (UNS G12144) is known as the fastest machining bar product. Its chemical composition includes: Iron (Fe) 97.91 – 98.7%, Manganese (Mn) 0.85 – 1.15%, Sulfur (S) 0.260 – 0.35%, Lead (Pb) 0.15 – 0.35%, Carbon (C) 0.15%, and Phosphorous (P) 0.040 – 0.090%. Physical properties include a density of 7.87 g/cm³ (0.284 lb/in³). Mechanical properties are: Tensile strength 540 MPa (78…

2. Eaton Steel – 12L14 Cold Drawn Steel Bar

Domain: eatonsteel.com

Registered: 1996 (29 years)

Introduction: {‘product_name’: ’12L14 Cold Drawn Steel Bar’, ‘description’: ‘Cold-drawn or cold finished 12L14 steel bar is a resulfurized and rephosphorized carbon steel known for its excellent machinability due to added sulfur, phosphorus, and lead.’, ‘applications’: [‘Fittings’, ‘Couplings’, ‘Valves’, ‘Bushings’, ‘Hydraulic Fittings’, ‘Studs’, ‘Pins’], ‘advantages’: [‘Excellent machinability’, ‘Various shape…

3. Online Metals – 12L14 Carbon Steel

Domain: onlinemetals.com

Registered: 1997 (28 years)

Introduction: 12L14 is a standard resulfurized and rephosphorized carbon steel. Lead is added to increase machinability, allowing it to be bent, riveted, or crimped. It is slightly weaker than comparable carbon steel alloys and is typically used in high-speed screw machine products. Common trade names include UNS G12144, AISI 12L14, Free-Machining Steel, and Ledloy™. Specifications include ASTM A108. Physical p…

4. MatWeb – Material Property Database

Domain: matweb.com

Registered: 1997 (28 years)

Introduction: This company, MatWeb – Material Property Database, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Song Shun Steel – AISI 12L14 Round Bar, Sheet, Plate

Domain: songshunsteel.com

Registered: 2014 (11 years)

Introduction: AISI 12L14 Steel – JIS SUM24L – DIN 1.0718

– Type: Round Bar, Sheet, Plate

– Diameter: 1-2000mm (customizable length)

– Surface: Black Surface, Bright Surface, Grinded, Peeled, Turned

– Chemical Composition:

– Carbon (C): ≤0.15%

– Manganese (Mn): 0.85-1.15%

– Phosphorus (P): ≤0.04-0.09%

– Sulfur (S): 0.26-0.35%

– Silicon (Si): Max 0.10%

– Lead (Pb): 0.15-0.35%

– Physical Properties:

…

6. Make It From – SAE-AISI 12L14 Carbon Steel

Domain: makeitfrom.com

Registered: 2009 (16 years)

Introduction: {‘material_name’: ‘SAE-AISI 12L14 (G12144) Carbon Steel’, ‘type’: ‘Resulfurized Carbon Steel’, ‘formulation’: ‘Wrought products’, ‘SAE_designation’: ’12L14′, ‘AISI_designation’: ’12L14′, ‘UNS_number’: ‘G12144’, ‘mechanical_properties’: {‘Brinell_Hardness’: ‘140 to 170’, ‘Elastic_Modulus’: ‘190 GPa (27 x 10^6 psi)’, ‘Elongation_at_Break’: ’11 to 25 %’, ‘Fatigue_Strength’: ‘190 to 290 MPa (28 to 41 …

7. CoreMark Metals – 12L14 Cold Rolled Steel Round Bar

Domain: coremarkmetals.com

Registered: 2018 (7 years)

Introduction: {‘name’: ’12L14 Cold Rolled Steel Round Bar’, ‘description’: ’12L14 cold rolled steel round bars are an excellent candidate for most processing techniques. They have a smooth grey oiled surface and accurate dimensions throughout. 12L14 has a higher tensile and yield strength compared to hot rolled bars. It is a low carbon steel with good case hardening qualities, extensively used in automatic scre…

8. Alro – 12L14 Cold Finish Steel Bar

Domain: alro.com

Registered: 1996 (29 years)

Introduction: 12L14 Cold Finish Steel Bar, Chemical Composition: Carbon (C) Max 0.15, Manganese (Mn) 0.85-1.15, Lead (Pb) 0.15-0.35, Phosphorus (P) 0.04-0.09, Sulfur (S) 0.26-0.35. Features: Good strength, Excellent machinability, Precision grade, Various shape options (round, hex, square), Increased part life. Properties: Tensile Strength 78 ksi, Yield Strength 60 ksi, Elongation in 2″ 10%, Reduction of Area 3…

Strategic Sourcing Conclusion and Outlook for 12l14 steel material properties

As the global demand for high-quality materials continues to rise, 12L14 steel stands out due to its exceptional machinability and versatility. This resulfurized and rephosphorized carbon steel is particularly advantageous for industries such as automotive, aerospace, and manufacturing, where precision and efficiency are paramount. The ability to quickly source various shapes and sizes of 12L14 steel bars enables businesses to streamline production processes and meet tight deadlines.

Strategic sourcing of 12L14 steel can provide significant cost savings and enhance operational efficiency for international buyers. With its high tensile strength and suitability for a range of applications—from fittings to valves—12L14 steel is an ideal choice for companies looking to improve their product offerings while maintaining quality standards.

Looking ahead, B2B buyers from Africa, South America, the Middle East, and Europe should seize the opportunity to leverage the advantages of 12L14 steel. By establishing strong partnerships with reliable suppliers, businesses can not only secure favorable pricing but also ensure a consistent supply chain. Engage with trusted steel manufacturers today to explore how 12L14 steel can elevate your production capabilities and drive competitive advantage in your market.