Introduction: Navigating the Global Market for 12l14 material

In today’s competitive landscape, sourcing 12L14 material poses significant challenges for B2B buyers across various sectors, including automotive, aerospace, and construction. This free-machining steel, known for its excellent machinability due to the addition of sulfur, phosphorus, and lead, is often required in high-speed screw machining applications. However, with a multitude of suppliers across Africa, South America, the Middle East, and Europe, navigating the global market can be daunting.

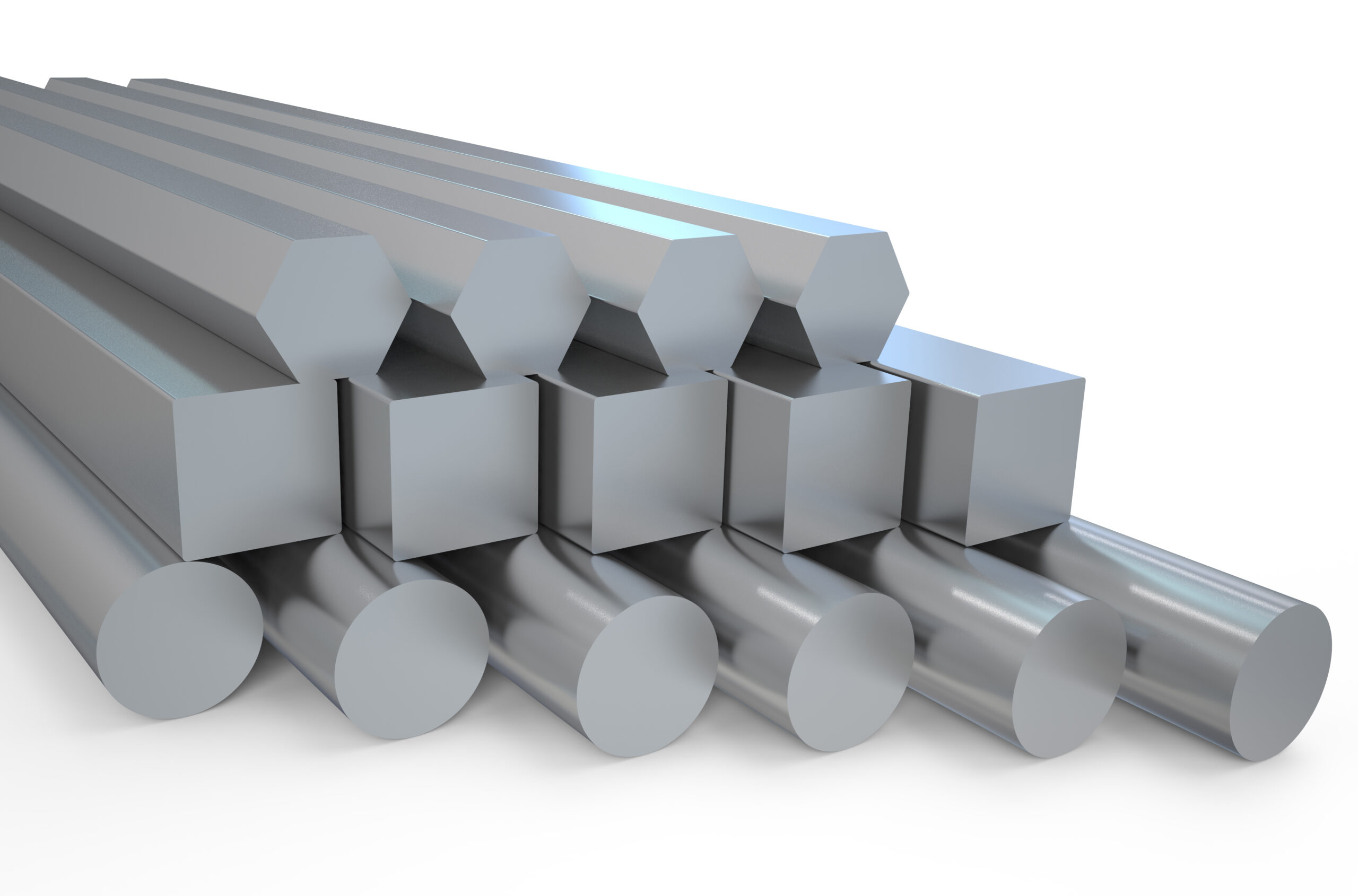

This comprehensive guide serves as an essential resource for international B2B buyers seeking to understand the nuances of 12L14 material. It delves into various forms of the material, such as round, hexagonal, and square bars, and outlines its diverse applications from fittings to hydraulic components. Additionally, it provides insights on how to effectively vet suppliers, ensuring that buyers partner with reputable manufacturers who meet stringent quality standards.

Furthermore, the guide explores cost considerations, helping businesses make informed purchasing decisions that align with their budgetary constraints. By equipping buyers with the knowledge needed to navigate the complexities of sourcing 12L14 material, this guide empowers organizations to enhance their operational efficiency and competitive edge in the market.

Understanding 12l14 material Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 12L14 Cold Drawn Steel Bar | Resulfurized and rephosphorized carbon steel; high machinability | Automotive, Aerospace, Oil & Gas | Pros: Excellent machinability; various sizes available. Cons: Lower strength compared to other grades. |

| 12L14 Cold Rolled Steel Bar | Similar to cold drawn but with different processing; smooth surface finish | High-speed screw machining, manufacturing | Pros: Superior surface finish; ideal for precision parts. Cons: Slightly higher cost than cold drawn. |

| 12L14 Hex Bar | Hexagonal shape; maintains high machinability | Fittings, couplings, hydraulic components | Pros: Unique shape for specific applications; easy to handle. Cons: Limited availability in certain regions. |

| 12L14 Square Bar | Square shape; suitable for various machining applications | Structural components, fixtures, and supports | Pros: Versatile shape for many applications; good strength. Cons: May require custom cutting for specific sizes. |

| 12L14 Round Bar | Circular cross-section; excellent for machining | Pins, studs, bushings | Pros: Widely used; high ductility and machinability. Cons: May not be suitable for high-stress applications. |

What Are the Key Characteristics of 12L14 Cold Drawn Steel Bar?

The 12L14 Cold Drawn Steel Bar is a resulfurized and rephosphorized carbon steel known for its exceptional machinability, making it a preferred choice in industries such as automotive and aerospace. With a low carbon content, it boasts lower strength than other cold-drawn grades, which can be a consideration for B2B buyers needing high-strength materials. It’s typically available in various diameters and shapes, allowing for quick fulfillment of orders, which is crucial for manufacturers with tight deadlines.

How Does 12L14 Cold Rolled Steel Bar Differ from Other Variants?

The 12L14 Cold Rolled Steel Bar undergoes a different processing method than cold drawn bars, resulting in a smoother surface finish. This quality makes it particularly suitable for high-speed screw machining and manufacturing precision parts. Buyers should note that while it offers a superior finish, the cost may be slightly higher than that of cold drawn bars. This trade-off can be worthwhile for applications requiring a high level of precision and aesthetic quality.

What Are the Advantages of Using 12L14 Hex Bars in Manufacturing?

12L14 Hex Bars are characterized by their unique hexagonal shape, which is often favored for specific applications such as fittings and couplings. The hexagonal form allows for easy handling and provides a secure grip during machining processes. However, availability may be limited in certain regions, which could affect supply chain considerations for international buyers. When sourcing, it’s essential to confirm stock levels and lead times to avoid production delays.

Why Consider 12L14 Square Bars for Structural Applications?

The 12L14 Square Bar offers versatility in structural applications, making it suitable for fixtures and supports. Its square shape provides good strength and stability, essential for construction and manufacturing environments. Buyers should be aware that while square bars are versatile, they may require custom cutting for specific sizes, which could impact lead times and costs. Understanding the specific needs of your application will help in making informed purchasing decisions.

What Makes 12L14 Round Bars a Popular Choice in Various Industries?

The 12L14 Round Bar is widely used in applications such as pins, studs, and bushings due to its excellent ductility and machinability. This material is particularly beneficial for high-speed machining processes. However, while it offers good performance, it may not be the best option for high-stress applications, so buyers should evaluate their specific requirements carefully. The availability of round bars in various sizes enhances their usability across different projects, making them a staple in many manufacturing settings.

Key Industrial Applications of 12l14 material

| Industry/Sector | Specific Application of 12l14 material | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Production of fittings and valves | Enhanced machinability reduces manufacturing time and costs, ensuring reliable performance in high-pressure environments. | Ensure compliance with industry standards like ASTM A108; consider lead content for specific applications. |

| Automotive | Manufacturing of precision components | High precision and durability improve vehicle performance and safety, while reducing overall weight. | Look for suppliers with a wide range of sizes and shapes to meet specific automotive component requirements. |

| Aerospace | Creation of hydraulic fittings | Lightweight yet strong components are crucial for aircraft efficiency and safety; 12L14 meets stringent aerospace standards. | Verify certifications and quality control processes to ensure compliance with aerospace regulations. |

| Machining/Manufacturing | High-speed screw machine products | Fast machining capabilities lead to increased production rates and lower operational costs. | Assess suppliers for their ability to provide large quantities and consistent quality to meet production demands. |

| Construction | Fabrication of bushings and pins | Provides strength and reliability in structural applications, contributing to overall project safety and durability. | Prioritize sourcing from certified manufacturers with a proven track record in construction applications. |

In the Oil & Gas sector, 12L14 material is widely used for producing fittings and valves that require high precision and reliability under extreme conditions. Its excellent machinability allows for quick production, which is crucial in this fast-paced industry. Buyers should ensure that the material meets industry standards like ASTM A108 and consider the implications of lead content for specific applications, particularly in regions with stringent regulations.

Within the Automotive industry, 12L14 is utilized in manufacturing precision components such as studs and pins. The material’s strength and lightweight properties enhance vehicle performance and safety, making it a preferred choice for parts that endure significant stress. International buyers should look for suppliers that offer various sizes and shapes to accommodate specific automotive requirements, ensuring compatibility with existing designs.

In the Aerospace sector, 12L14 is essential for creating hydraulic fittings, where lightweight and robust materials are paramount for aircraft efficiency and safety. The material’s machinability allows for intricate designs that meet stringent aerospace standards. Buyers in this sector must verify that their suppliers have the necessary certifications and quality control processes to comply with aerospace regulations, especially when sourcing from different regions.

The Machining and Manufacturing industries benefit from 12L14’s application in high-speed screw machine products. Its fast machining capabilities lead to increased production rates and reduced operational costs, making it ideal for mass production. Companies should assess suppliers for their capacity to provide large quantities and maintain consistent quality, ensuring uninterrupted production processes.

Finally, in Construction, 12L14 is used for fabricating bushings and pins that provide strength and reliability in various structural applications. This contributes to the overall safety and durability of construction projects. Buyers should prioritize sourcing from certified manufacturers with a solid track record in construction applications, ensuring that the material meets the necessary specifications for their projects.

3 Common User Pain Points for ’12l14 material’ & Their Solutions

Scenario 1: Inconsistent Quality in Supply Chain

The Problem: B2B buyers often face challenges with inconsistent quality when sourcing 12L14 material. This inconsistency can lead to delays in production, increased costs, and potential failures in the final product. For instance, a manufacturer in the automotive sector might receive a batch of 12L14 bars that do not meet the specified mechanical properties, jeopardizing the integrity of their components and resulting in costly rework or replacements.

The Solution: To mitigate quality issues, buyers should prioritize sourcing from reputable suppliers who provide comprehensive mill test reports (MTRs) with each shipment. These reports should detail the chemical composition and mechanical properties of the steel, ensuring that the material meets industry standards like ASTM A108. Additionally, establishing a solid relationship with suppliers can facilitate better communication regarding quality expectations and any potential concerns. Buyers should also consider implementing a quality assurance process, including random inspections of incoming materials and conducting tests on samples to confirm compliance with specifications. This proactive approach not only protects production schedules but also enhances product reliability.

Scenario 2: Difficulty in Machining and Fabrication

The Problem: While 12L14 material is known for its excellent machinability, not all buyers experience the same ease in machining and fabrication. For example, a machining company may struggle with the tool wear or unexpected tool breakage when working with 12L14 bars due to incorrect machining practices or inadequate equipment. This can lead to increased operational costs and delays in delivery schedules.

The Solution: To optimize machining processes with 12L14 material, buyers should invest in the right tooling and cutting parameters. Utilizing high-speed steel or carbide tooling can significantly enhance performance and reduce wear. It’s crucial to follow the manufacturer’s recommendations for cutting speeds and feeds specific to 12L14, which typically has a machinability rating of around 170%. Implementing coolant strategies can also help manage heat and prolong tool life. Additionally, conducting pilot runs with new setups can identify potential issues before full-scale production. Collaborating with experienced machinists and leveraging industry best practices will further streamline operations, resulting in improved efficiency and cost savings.

Scenario 3: Limited Availability and Size Options

The Problem: Many B2B buyers encounter challenges related to the limited availability of specific sizes and shapes of 12L14 material. This limitation can disrupt project timelines, especially when custom dimensions are required for particular applications, such as hydraulic fittings or specialized automotive parts. Buyers often find themselves scrambling to find alternative materials, which can lead to compromises in quality and performance.

The Solution: To address availability issues, buyers should engage with multiple suppliers who offer a diverse range of sizes and shapes of 12L14 material. Creating a comprehensive inventory management system can help track usage patterns and forecast needs, allowing buyers to place orders ahead of time and avoid shortages. Additionally, exploring partnerships with suppliers that offer custom machining services can provide access to tailored solutions without the need for extensive lead times. For urgent projects, establishing a network of local suppliers can expedite sourcing processes. By taking these steps, buyers can ensure they have the right material on hand when needed, maintaining production flow and minimizing delays.

Strategic Material Selection Guide for 12l14 material

What Are the Key Properties of 12L14 Material?

12L14 material is a resulfurized and rephosphorized carbon steel that exhibits excellent machinability due to the addition of sulfur, phosphorus, and lead. It is characterized by a low carbon content, which results in lower strength compared to other cold-drawn steels. The material typically has a tensile strength ranging from 70,000 to 80,000 psi and a yield strength between 65,000 and 75,000 psi. Its composition enables it to perform well in high-speed machining applications, making it suitable for parts such as fittings, couplings, and hydraulic components.

What Are the Pros and Cons of Using 12L14 Material?

The advantages of 12L14 material include its exceptional machinability, which is crucial for high-speed screw machining and manufacturing processes. It is available in various shapes and sizes, allowing for flexibility in production. However, its lower strength and ductility can be a limitation in applications requiring high tensile strength. Additionally, the presence of lead can raise environmental and regulatory concerns, particularly in regions with stringent compliance requirements.

How Does 12L14 Material Impact Application Performance?

In applications where high-speed machining is required, 12L14 material excels due to its ability to be easily shaped and cut. However, its lower strength may not be suitable for components subjected to high stress or extreme conditions. Its compatibility with various media makes it a popular choice in industries such as automotive and aerospace. International buyers should consider the specific operational conditions and media compatibility when selecting 12L14 material for their applications.

What Should International B2B Buyers Consider When Sourcing 12L14 Material?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, it is essential to ensure compliance with local and international standards such as ASTM, DIN, or JIS. Understanding the specific requirements of their market, including any environmental regulations regarding lead content, is critical. Additionally, buyers should consider the availability of the material in their region and the associated shipping costs, as this can impact overall project budgets and timelines.

| Material | Typical Use Case for 12L14 material | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| 12L14 Carbon Steel | Fittings, couplings, valves, and hydraulic components | Excellent machinability for high-speed machining | Lower strength compared to other carbon steels | Medium |

| Cold Drawn Steel | Precision parts in automotive and aerospace industries | High precision and dimensional accuracy | May not withstand extreme conditions | Medium |

| Free-Machining Steel | High-speed screw machine products | Fast production rates due to easy machining | Environmental concerns due to lead content | Medium |

| Resulfurized Steel | Components in oil and gas industries | Good surface finish and ease of fabrication | Limited strength in high-stress applications | Medium |

This analysis provides a comprehensive overview of 12L14 material, highlighting its properties, advantages, disadvantages, and considerations for international B2B buyers. Understanding these factors can aid in making informed decisions when selecting materials for specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for 12l14 material

What Are the Key Stages in the Manufacturing Process of 12L14 Material?

The manufacturing process of 12L14 cold drawn steel bars involves several critical stages, each designed to enhance the material’s machinability and ensure it meets the specific requirements of various industries. Understanding these stages can help international B2B buyers make informed decisions when sourcing this material.

1. Material Preparation: What Steps Are Involved?

The first stage of manufacturing 12L14 material begins with the selection and preparation of raw materials. This steel grade is characterized by its resulfurized and rephosphorized composition, which includes the addition of lead to improve machinability. The materials typically undergo the following steps:

-

Melting and Alloying: The raw steel is melted in an electric arc furnace. During this stage, specific amounts of sulfur, phosphorus, and lead are added to achieve the desired chemical composition.

-

Casting: The molten steel is then cast into various forms, such as billets or slabs, which serve as the starting point for further processing.

-

Hot Rolling: The cast billets are hot-rolled to reduce their cross-section and improve their mechanical properties. This process also helps in achieving uniformity in the material.

2. Forming: How Is 12L14 Material Shaped?

Once the material is prepared, it undergoes several forming processes to create the final shape. Key techniques include:

-

Cold Drawing: This is the primary method used for 12L14 steel bars. Cold drawing involves pulling the hot-rolled bars through a die to reduce their diameter and improve surface finish. This method enhances tensile strength and dimensional accuracy.

-

Finishing Processes: After cold drawing, the bars may undergo additional treatments such as surface polishing or shot blasting to enhance surface quality and remove any defects.

3. Assembly: What Does This Involve for 12L14 Components?

While 12L14 material is primarily used in the form of bars, some applications may require assembly into final products. This typically involves:

-

Machining: Given its excellent machinability, 12L14 is often processed using CNC machining to create precision components such as fittings, couplings, and valves.

-

Heat Treatment: Depending on the application, some components may undergo heat treatment to improve hardness and strength.

What Quality Assurance Measures Are Essential for 12L14 Material?

Quality assurance (QA) is crucial in ensuring that 12L14 material meets the required specifications and standards. For international B2B buyers, understanding these QA measures can provide confidence in their sourcing decisions.

1. What International Standards Apply to 12L14 Material?

Manufacturers of 12L14 material often adhere to various international quality standards. Key standards include:

-

ISO 9001: This standard outlines requirements for a quality management system and is essential for manufacturers aiming to ensure consistent quality and customer satisfaction.

-

ASTM A108 and A576: These specifications detail the requirements for cold drawn and hot rolled carbon steel bars, including 12L14 grade.

-

Industry-Specific Standards: Depending on the application, additional certifications may be required, such as CE marking for European markets or API standards for oil and gas applications.

2. What Are the Key Quality Control Checkpoints?

The quality control process for 12L14 material typically includes several checkpoints:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival at the manufacturing facility to ensure compliance with specifications.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular checks are performed to monitor dimensional accuracy, surface quality, and mechanical properties.

-

Final Quality Control (FQC): After the manufacturing process is complete, final inspections are conducted to ensure that the finished product meets all relevant standards and specifications.

3. What Testing Methods Are Commonly Used?

To verify the quality of 12L14 material, several testing methods are employed, including:

-

Mechanical Testing: Tensile strength, yield strength, and elongation tests are conducted to assess the material’s mechanical properties.

-

Chemical Analysis: Spectrometry or other methods are used to verify the chemical composition of the steel, ensuring it meets specified standards.

-

Non-Destructive Testing (NDT): Techniques such as ultrasonic testing may be used to detect internal flaws without damaging the material.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential.

1. What Audit Practices Should Be Considered?

-

Supplier Audits: Conducting on-site audits of potential suppliers can provide insight into their manufacturing processes, quality control measures, and adherence to international standards.

-

Certification Verification: Buyers should request copies of relevant certifications, such as ISO 9001, and verify their validity.

2. How Can Buyers Access Quality Control Reports?

-

Documentation Requests: Buyers should always request mill test reports (MTRs) or certificates of compliance that detail the results of quality tests conducted on the material.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an additional layer of assurance. These organizations can conduct independent inspections and testing to verify that the material meets specified standards.

What Are the Quality Control Nuances for International Buyers?

For international B2B buyers, particularly from diverse regions, it’s crucial to be aware of the following nuances:

-

Regulatory Compliance: Different regions may have unique regulatory requirements. Buyers must ensure that their suppliers can meet these requirements, including CE marking for products sold in Europe or adherence to specific standards in the Middle East.

-

Cultural and Language Barriers: Effective communication is essential. Buyers should consider potential language barriers and cultural differences that may affect negotiations and quality expectations.

By understanding the manufacturing processes and quality assurance measures associated with 12L14 material, international B2B buyers can make informed sourcing decisions, ensuring they acquire high-quality materials that meet their specific needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ’12l14 material’

Introduction

This practical sourcing guide is designed to assist B2B buyers in procuring 12L14 material, a high-performance cold-drawn steel known for its excellent machinability. By following this step-by-step checklist, buyers can ensure they meet their technical requirements while selecting reliable suppliers, ultimately facilitating a smoother procurement process.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements for 12L14 material. Consider factors such as dimensions, shapes (round, hexagonal, square), and mechanical properties (e.g., tensile strength and hardness).

– Why it Matters: Precise specifications help in obtaining accurate quotes and ensure that the material meets the intended application, reducing the risk of costly rework or delays.

Step 2: Research Supplier Options

Conduct comprehensive research to identify potential suppliers of 12L14 material. Utilize online directories, industry publications, and trade shows to gather a list of candidates.

– Why it Matters: A diverse supplier pool increases competition and provides options that may better meet your pricing and quality needs. Focus on suppliers with a strong reputation in your region of interest, whether in Africa, Europe, or the Middle East.

Step 3: Verify Supplier Certifications

Ensure that potential suppliers possess the necessary certifications and adhere to industry standards, such as ASTM A108 or A576.

– Why it Matters: Certifications guarantee that the supplier complies with quality and safety standards, which is crucial for industries like automotive and aerospace where material reliability is paramount.

Step 4: Request Material Samples

Before placing a large order, request samples of the 12L14 material. Evaluate the samples for quality, machinability, and compliance with your specifications.

– Why it Matters: Testing samples allows you to assess the material’s performance in your specific applications, ensuring it meets your operational requirements before committing to a bulk purchase.

Step 5: Compare Pricing and Terms

Collect detailed quotes from multiple suppliers and compare not just the pricing but also the terms of sale, including minimum order quantities, lead times, and payment options.

– Why it Matters: Understanding the total cost of ownership, including shipping and handling, allows you to make an informed decision and negotiate better terms that can enhance your profit margins.

Step 6: Evaluate Supplier Support and Communication

Assess the level of customer service and support provided by potential suppliers. Consider their responsiveness to inquiries and their willingness to assist with technical questions.

– Why it Matters: Strong communication can ease the procurement process and provide reassurance that any issues can be quickly addressed, which is vital for maintaining project timelines.

Step 7: Establish a Relationship and Monitor Performance

Once you select a supplier, work to build a strong, collaborative relationship. Regularly monitor their performance in terms of quality, delivery times, and responsiveness.

– Why it Matters: A solid partnership with your supplier can lead to better pricing, priority service, and access to new products, enhancing your operational efficiency and competitiveness in the market.

Comprehensive Cost and Pricing Analysis for 12l14 material Sourcing

What Are the Key Cost Components for Sourcing 12L14 Material?

When evaluating the costs associated with sourcing 12L14 material, several key components come into play. The primary cost factors include raw materials, labor, manufacturing overhead, tooling, quality control, logistics, and the supplier’s margin.

-

Materials: The cost of 12L14 material itself varies based on market fluctuations in steel prices and the specific chemical composition required. Typically, the inclusion of sulfur, phosphorus, and lead increases the cost due to enhanced machinability, which is a significant advantage for buyers in machining-heavy industries.

-

Labor: Labor costs can vary significantly depending on the region and the skill level required for machining and processing the 12L14 material. In regions with higher labor costs, such as Western Europe, the overall expense can increase.

-

Manufacturing Overhead: This includes costs related to facilities, equipment maintenance, and utilities. Overhead costs are often more pronounced in high-quality manufacturing environments that adhere to stringent quality standards, such as those required for aerospace and automotive applications.

-

Tooling: The need for specialized tooling to work with 12L14 can impact pricing, especially for custom orders. Tooling costs can add up quickly, particularly for small-batch orders where the economies of scale are not realized.

-

Quality Control (QC): Maintaining high standards in quality control can lead to additional costs, particularly when certifications (like ASTM standards) are required. Suppliers may pass these costs onto buyers, which is crucial for industries where failure can have serious consequences.

-

Logistics: Transportation costs must also be factored in, especially for international shipments. The choice of Incoterms will influence these costs and the responsibilities of buyers and sellers regarding freight and insurance.

-

Margin: Finally, the supplier’s margin will vary based on market conditions, competition, and the perceived value of the 12L14 material being offered.

How Do Volume and Specifications Influence Pricing?

Pricing for 12L14 material is heavily influenced by volume and specifications. Suppliers often impose minimum order quantities (MOQ) that can affect cost per unit. For instance, a typical MOQ for 12L14 can start at 10,000 lbs. Bulk orders usually allow for lower unit prices due to reduced handling and production costs.

Customization also plays a critical role. Buyers requiring specific dimensions or finishes will incur additional costs, as custom machining requires more time and resources. International buyers must also consider additional specifications related to regional standards and certifications, which can further impact pricing.

What Buyer Tips Can Enhance Cost Efficiency When Sourcing 12L14 Material?

B2B buyers should consider several strategies to enhance cost efficiency in sourcing 12L14 material:

-

Negotiate Terms: Engage in discussions with suppliers to negotiate terms that can reduce costs, such as extended payment terms or lower prices for larger orders.

-

Assess Total Cost of Ownership: Rather than focusing solely on the purchase price, evaluate the total cost of ownership, including shipping, handling, and potential waste or rework due to material quality.

-

Consider Pricing Nuances for International Transactions: Be aware that shipping costs, tariffs, and local taxes can significantly affect the total cost when importing 12L14 material from different regions. Understanding Incoterms is essential to clarify responsibilities and costs between buyers and suppliers.

-

Build Relationships with Suppliers: Establishing long-term relationships with suppliers can lead to better pricing and service. Suppliers may offer discounts or more favorable terms to loyal customers.

What Should Buyers Keep in Mind Regarding Indicative Prices?

It’s essential for buyers to understand that prices for 12L14 material can fluctuate based on market conditions, supplier availability, and geopolitical factors. Therefore, while indicative prices can provide a general idea, they should always confirm current pricing with suppliers. Keeping abreast of industry trends and engaging in regular market analysis can help buyers make informed decisions and optimize their sourcing strategies.

Alternatives Analysis: Comparing 12l14 material With Other Solutions

Introduction: Evaluating Alternatives to 12L14 Material

When considering materials for manufacturing, it’s crucial for B2B buyers to evaluate various options that meet their specific needs. 12L14 material, a free-machining carbon steel, is known for its excellent machinability and is often used in high-speed machining applications. However, alternative materials and methods may offer advantages in certain scenarios. This analysis will compare 12L14 material with two viable alternatives: A36 Hot Rolled Steel and 1018 Cold Rolled Steel.

Comparison Table

| Comparison Aspect | 12L14 Material | A36 Hot Rolled Steel | 1018 Cold Rolled Steel |

|---|---|---|---|

| Performance | High machinability; lower strength | Good weldability; moderate strength | Good strength; decent machinability |

| Cost | Moderate to high | Generally low | Moderate |

| Ease of Implementation | Easy to machine | Standard processes; easy to work | Requires more precise machining |

| Maintenance | Low maintenance | Low maintenance | Moderate maintenance |

| Best Use Case | Precision parts in machining | Structural applications | Parts needing balance of strength |

Detailed Breakdown of Alternatives

A36 Hot Rolled Steel

A36 steel is a structural steel grade that is widely used in construction and manufacturing. Its primary advantage lies in its excellent weldability and formability, making it suitable for a variety of structural applications. However, while it offers good mechanical properties, its machinability is not as high as that of 12L14. This means that while A36 can be used in structural applications, it may require more time and effort when machining intricate components. In terms of cost, A36 is generally more affordable, making it an attractive option for large-scale projects where budget constraints are a concern.

1018 Cold Rolled Steel

1018 steel is known for its good balance of strength and ductility. It is often used in applications requiring high strength and toughness. Compared to 12L14, 1018 has better overall mechanical properties, but its machinability is slightly lower, making it less ideal for high-speed machining applications. This material is also moderately priced, providing a cost-effective solution for parts that do not require the extreme precision of 12L14. However, 1018 may require more precise machining processes to achieve desired tolerances, which could increase production time and costs.

Conclusion: Choosing the Right Solution for Your Needs

In selecting the right material for your manufacturing needs, consider the specific requirements of your project, including performance, cost, and ease of implementation. If precision machining is paramount, 12L14 material may be the best choice. However, for structural applications or when budget constraints are significant, A36 Hot Rolled Steel could offer a more economical solution. Meanwhile, 1018 Cold Rolled Steel serves as a solid middle ground, balancing strength and machinability. Ultimately, the decision should align with your operational goals and the specific demands of your applications.

Essential Technical Properties and Trade Terminology for 12l14 material

What Are the Key Technical Properties of 12L14 Material?

When considering 12L14 steel for your applications, understanding its technical specifications is essential. Here are some critical properties:

-

Material Grade: 12L14 is a resulfurized and rephosphorized carbon steel, classified under ASTM A108 and ASTM A576. The addition of lead enhances machinability, making it ideal for high-speed machining applications. This grade is particularly favored in sectors such as automotive, aerospace, and oil & gas, where precision and efficiency are paramount.

-

Tensile Strength: The tensile strength of 12L14 ranges from 70,000 to 80,000 psi. This property indicates the material’s ability to withstand pulling forces without breaking. For B2B buyers, selecting materials with adequate tensile strength ensures durability and longevity in critical components, reducing the risk of failure.

-

Yield Strength: Yield strength for 12L14 is typically between 65,000 and 75,000 psi. This measure reflects the maximum stress that the material can endure without permanent deformation. Understanding yield strength is crucial for engineers and buyers alike, as it helps in the design of components that must maintain their shape under operational stress.

-

Machinability Index: With a machinability index of approximately 170%, 12L14 is one of the most machinable steels available. This high machinability translates into lower manufacturing costs and faster production times, making it a preferred choice for high-volume production environments.

-

Chemical Composition: The chemical composition includes carbon (max 0.15%), manganese (0.85-1.15%), phosphorus (0.04-0.09%), sulfur (0.26-0.35%), and lead (0.15-0.35%). Understanding these elements helps buyers evaluate the material’s performance in various conditions, ensuring it meets specific application requirements.

-

Elongation and Reduction of Area: The elongation percentage in 2 inches is 15-20%, with a reduction of area ranging from 50-60%. These metrics indicate the material’s ductility and ability to deform before fracture, which is essential for applications requiring bending or shaping.

What Are the Common Trade Terminology and Their Importance in B2B Transactions?

Familiarity with industry jargon can significantly streamline communication and negotiations. Here are some essential terms:

-

OEM (Original Equipment Manufacturer): An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is vital for buyers looking for reliable suppliers and ensuring compatibility with existing systems.

-

MOQ (Minimum Order Quantity): MOQ defines the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers to understand their purchasing limits and negotiate better terms, particularly when dealing with suppliers in different regions.

-

RFQ (Request for Quotation): An RFQ is a formal process where buyers solicit price quotes from multiple suppliers. This process helps companies compare pricing, delivery times, and terms, ultimately leading to better purchasing decisions.

-

Incoterms (International Commercial Terms): Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding these terms is essential for international transactions, ensuring clarity and reducing disputes.

-

Lead Time: This term refers to the amount of time it takes from placing an order to receiving the product. For B2B operations, knowing lead times is crucial for planning production schedules and inventory management.

-

Tolerances: Tolerances specify the allowable limits of variation in a physical dimension. This information is critical for ensuring that parts fit together properly, minimizing the risk of defects in manufacturing processes.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions regarding the procurement and application of 12L14 material, ultimately enhancing operational efficiency and product quality.

Navigating Market Dynamics and Sourcing Trends in the 12l14 material Sector

What Are the Key Market Dynamics and Trends Influencing the 12L14 Material Sector?

The 12L14 material sector is currently experiencing a dynamic shift influenced by various global drivers, including technological advancements, increased demand for precision machining, and a growing focus on sustainability. As industries across Africa, South America, the Middle East, and Europe ramp up production capabilities, the demand for free-machining steel grades like 12L14 has surged. Key sectors such as automotive, aerospace, and oil and gas are particularly driving this trend due to their need for high-speed machining components that require less processing time and deliver precision results.

Emerging B2B technologies, such as advanced manufacturing processes and digital supply chain management tools, are reshaping sourcing strategies. Buyers are increasingly leveraging data analytics and AI-driven platforms to optimize procurement, ensuring they can source 12L14 steel efficiently and at competitive prices. Additionally, the rise of e-commerce in industrial sectors is enabling easier access to suppliers, allowing international buyers from regions like Saudi Arabia and Germany to compare prices and specifications quickly.

The market is also witnessing a trend toward customization, with suppliers offering various shapes and sizes of 12L14 steel bars to meet specific application requirements. With the shift towards just-in-time manufacturing practices, maintaining a robust inventory and a responsive supply chain has become critical for buyers looking to remain competitive.

How Is Sustainability Shaping B2B Sourcing in the 12L14 Material Sector?

Sustainability is becoming a central theme in the B2B landscape, influencing sourcing decisions in the 12L14 material sector. The environmental impact of steel production is significant, leading companies to seek suppliers that adhere to sustainable practices. This includes reducing carbon emissions, managing waste effectively, and utilizing energy-efficient manufacturing processes.

Ethical sourcing is increasingly important for businesses looking to enhance their corporate social responsibility profiles. Buyers are prioritizing suppliers who can demonstrate transparency in their supply chains, ensuring that the materials sourced are not only of high quality but also produced responsibly. Certifications like ISO 14001 for environmental management and compliance with local and international regulations are becoming essential criteria for procurement decisions.

Moreover, the demand for ‘green’ materials is on the rise. Suppliers who can offer 12L14 steel that is produced using recycled content or innovative processes that minimize environmental impact are likely to gain a competitive advantage. As global buyers become more conscious of their environmental footprint, aligning sourcing strategies with sustainability goals will be crucial for long-term success.

What Is the Historical Context of 12L14 Material in B2B Applications?

The evolution of 12L14 material can be traced back to the need for high-performance, machinable steel grades in industrial applications. Developed as a resulfurized and rephosphorized carbon steel, 12L14 was introduced to provide enhanced machinability, making it a preferred choice for high-speed screw machining and other precision applications. The addition of lead, sulfur, and phosphorus not only improved machinability but also allowed for greater ductility, catering to the specific needs of industries such as automotive and aerospace.

Over the years, as machining technologies advanced, the demand for 12L14 material grew, particularly among manufacturers looking to optimize production efficiency. Its widespread adoption can be attributed to its ability to produce complex components with minimal processing time, thus reducing operational costs. Today, 12L14 continues to play a vital role in various sectors, and its significance is expected to grow as industries increasingly focus on automation and precision engineering.

In conclusion, understanding the market dynamics, sustainability imperatives, and historical context of 12L14 material is essential for international B2B buyers navigating this sector. By leveraging these insights, businesses can make informed sourcing decisions that align with their operational goals and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of 12l14 material

-

How do I determine the right specifications for 12L14 material?

To choose the right specifications for 12L14 material, consider your project’s requirements, including mechanical properties, chemical composition, and intended applications. Review the ASTM standards, particularly ASTM A108 and A576, which outline the performance and quality criteria for 12L14 steel. Additionally, consult with suppliers to understand the available shapes, sizes, and tolerances. This ensures you select a product that meets your operational needs while optimizing for cost and performance. -

What industries commonly use 12L14 steel, and why?

12L14 steel is widely utilized in industries such as automotive, aerospace, oil and gas, and machining due to its excellent machinability and ductility. Its free-machining characteristics make it ideal for high-speed screw machine products and components requiring intricate machining, such as fittings, valves, and bushings. Buyers in these sectors appreciate 12L14 for its ability to reduce machining time and costs while maintaining precision and quality. -

What are the minimum order quantities (MOQs) for 12L14 steel?

Minimum order quantities for 12L14 steel can vary by supplier, but they often require a minimum purchase of 10,000 lbs. This MOQ is set to ensure cost-effectiveness and efficient production runs. International buyers should confirm MOQs with their suppliers upfront, especially when sourcing from different regions, as logistics and shipping costs can significantly impact total expenses. -

What payment terms should I expect when sourcing 12L14 material internationally?

Payment terms for international orders of 12L14 steel typically include options such as advance payment, letters of credit, or net payment terms (e.g., net 30 or net 60). It’s crucial to negotiate these terms with your supplier early in the process. Additionally, consider the implications of currency exchange rates and transaction fees, especially if dealing with suppliers in different currencies. -

How can I vet suppliers of 12L14 material effectively?

To vet suppliers of 12L14 material, start by checking their certifications (e.g., ISO 9001) and compliance with industry standards. Request references and case studies from previous clients to assess their reliability and quality of service. Additionally, evaluate their production capabilities, lead times, and inventory levels. Visiting their facility or reviewing their quality assurance processes can also provide valuable insights into their operational standards. -

What are the logistics considerations for importing 12L14 steel?

When importing 12L14 steel, consider factors such as shipping methods, lead times, and customs regulations. Collaborate with suppliers to understand their shipping practices and ensure that they comply with international trade laws. Additionally, factor in the cost of duties and taxes, which can vary by destination. A clear logistics plan can help you manage timelines and budget effectively, reducing the risk of delays in your supply chain. -

Can I customize 12L14 material to meet specific project needs?

Yes, customization of 12L14 material is often possible. Many suppliers offer tailored solutions regarding dimensions, shapes, and surface finishes. To initiate this process, clearly communicate your project requirements to the supplier, including any specific tolerances or additional treatments needed. Customization may impact lead times and costs, so it’s essential to discuss these factors during your initial negotiations. -

What quality assurance measures should I look for when sourcing 12L14 steel?

When sourcing 12L14 steel, inquire about the supplier’s quality assurance protocols, including material testing and inspection processes. Look for suppliers that provide mill test reports (MTRs) to verify compliance with specified mechanical and chemical properties. Additionally, assess their track record for quality control and customer satisfaction. A robust quality assurance program ensures that the material meets your specifications and reduces the risk of defects in your final products.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 12L14 Material Manufacturers & Suppliers List

1. AISI 12L14 Carbon Steel – Fastest Machining Bar Product

Domain: azom.com

Registered: 1999 (26 years)

Introduction: AISI 12L14 Carbon Steel (UNS G12144) is known as the fastest machining bar product.

**Chemical Composition:**

– Iron (Fe): 97.91 – 98.7%

– Manganese (Mn): 0.85 – 1.15%

– Sulfur (S): 0.260 – 0.35%

– Lead (Pb): 0.15 – 0.35%

– Carbon (C): 0.15%

– Phosphorous (P): 0.040 – 0.090%

**Physical Properties:**

– Density: 7.87 g/cm³ (0.284 lb/in³)

**Mechanical Properties:**

– Tensile S…

2. Online Metals – 12L14 Carbon Steel

Domain: onlinemetals.com

Registered: 1997 (28 years)

Introduction: {“name”: “12L14 Carbon Steel”,”description”: “12L14 is a standard resulfurized and rephosphorized carbon steel. Lead is added to increase machinability, allowing it to be bent, riveted, or crimped. It is slightly weaker than comparable carbon steel alloys and is typically used in high-speed screw machine products and other high-speed machines.”,”common_trade_names”: [“UNS G12144”, “AISI 12L14”, “F…

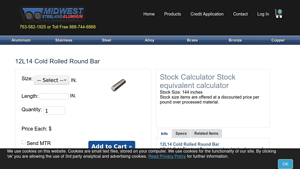

3. Midwest Steel Supply – 12L14 Cold Rolled Round Bar

Domain: midweststeelsupply.com

Registered: 2005 (20 years)

Introduction: {“product_name”: “12L14 Cold Rolled Round Bar”, “category”: “Steel”, “sub_category”: “Round Bar”, “sizes_available”: [“1/8”, “5/32”, “3/16”, “1/4”, “5/16”, “3/8”, “7/16”, “1/2”, “9/16”, “5/8”, “3/4”, “13/16”, “7/8”, “1”, “1-1/16”, “1-1/8”, “1-1/4”, “1-3/8”, “1-1/2”, “1-5/8”, “1-3/4”, “1-7/8”, “2”, “2-1/4”, “2-3/8”, “2-1/2”, “2-5/8”, “2-3/4”, “3”, “3-1/4”, “3-1/2”, “3-5/8”, “3-3/4”, “4”, “4-1/4”, “…

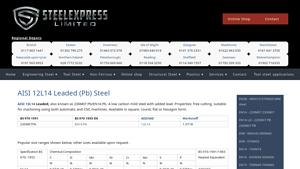

4. Steel Express – AISI 12L14 Leaded Low Carbon Steel

Domain: steelexpress.co.uk

Registered: 2003 (22 years)

Introduction: AISI 12L14 Leaded low carbon mild Steel 230M07 PB; also known as 230M07 Pb/EN1A Pb; properties: free cutting, suitable for machining using both automatic and CNC machines; available in square, round, flat or hexagon form; specification: BS 970 1991, BS 970 1955; chemical composition: C 0.07/0.15%, Si 0.10 Max%, Mn 0.80/1.20%, S 0.20/0.30%, P 0.07 Max%; nearest equivalent: EN 1A.

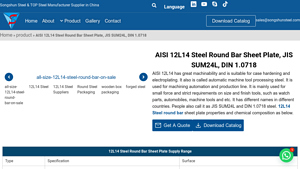

5. Songshun Steel – AISI 12L14 Round Bar and Sheet

Domain: songshunsteel.com

Registered: 2014 (11 years)

Introduction: AISI 12L14 Steel – JIS SUM24L – DIN 1.0718

– Type: Round Bar, Sheet, Plate

– Diameter: 1-2000mm (customizable length)

– Surface Options: Black Surface, Bright Surface, Grinded, Peeled, Turned

– Chemical Composition:

– C: ≤0.15%

– Mn: 0.85-1.15%

– P: ≤0.04-0.09%

– S: 0.26-0.35%

– Si: Max 0.10%

– Pb: 0.15-0.35%

– Physical Properties:

– Density: 7.87 g/cc

– Mechanical Properties:

– H…

Strategic Sourcing Conclusion and Outlook for 12l14 material

How Can International B2B Buyers Leverage 12L14 Material for Competitive Advantage?

In conclusion, 12L14 material stands out as a premier choice for industries requiring high machinability and versatility. Its unique composition—resulfurized and rephosphorized carbon steel—ensures excellent performance in applications ranging from automotive to aerospace. For international B2B buyers in regions like Africa, South America, the Middle East, and Europe, the strategic sourcing of 12L14 can lead to significant operational efficiencies and cost savings.

By focusing on suppliers that offer a variety of shapes, sizes, and compliance with industry standards such as ASTM A108, businesses can ensure they meet specific project requirements while maintaining quality. The ability to source this material in bulk also provides leverage in negotiations, enhancing supplier relationships and ensuring timely deliveries.

As we look toward the future, the demand for precision-engineered components will only increase. Investing in 12L14 material now positions businesses to capitalize on emerging market opportunities. Engage with reputable suppliers today to explore how 12L14 can enhance your production capabilities and drive your business forward.