Introduction: Navigating the Global Market for 12l14 carbon steel

In the competitive landscape of industrial materials, sourcing 12L14 carbon steel presents unique challenges for international B2B buyers. This grade of cold-drawn steel, known for its exceptional machinability, is essential for various applications across industries such as automotive, aerospace, and oil and gas. However, navigating the complexities of supply chains, varying quality standards, and fluctuating costs can make procurement a daunting task.

This comprehensive guide aims to equip buyers from regions including Africa, South America, the Middle East, and Europe—such as Vietnam and Brazil—with the insights necessary to make informed purchasing decisions. We will explore the different types of 12L14 steel available, delve into its specific applications, and provide practical advice on supplier vetting and cost considerations. Moreover, we will address potential regulatory challenges, particularly regarding lead content, which may affect sourcing strategies in certain markets.

By synthesizing critical information on the properties, advantages, and limitations of 12L14 carbon steel, this guide empowers buyers to streamline their procurement processes. Understanding these elements will not only enhance operational efficiency but also ensure compliance with local regulations, thus fostering a sustainable and profitable sourcing strategy. Whether you are a seasoned procurement professional or new to the field, our guide will serve as a valuable resource in your quest for quality materials.

Understanding 12l14 carbon steel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 12L14 Cold Drawn Steel | Resulfurized and rephosphorized; excellent machinability | Automotive, aerospace, oil & gas fittings | Pros: High machinability, precision; Cons: Lower strength compared to other grades. |

| 12L14 Hexagonal Bar | Hexagonal shape ideal for specific applications | Fasteners, bushings, precision tools | Pros: Specialized shape for unique applications; Cons: Limited availability in some regions. |

| 12L14 Square Bar | Square profile for enhanced grip and stability | Structural components, mounting brackets | Pros: Provides better surface contact; Cons: May require additional machining for specific needs. |

| 12L14 Round Bar | Standard round shape for versatile applications | Pins, studs, hydraulic fittings | Pros: Widely available and easy to source; Cons: Less suitable for applications requiring non-circular profiles. |

| 12L14 Lead-Free Variant | Alternative with similar machinability but no lead | Medical devices, food processing equipment | Pros: Safer for applications with strict regulations; Cons: Potentially higher cost compared to standard 12L14. |

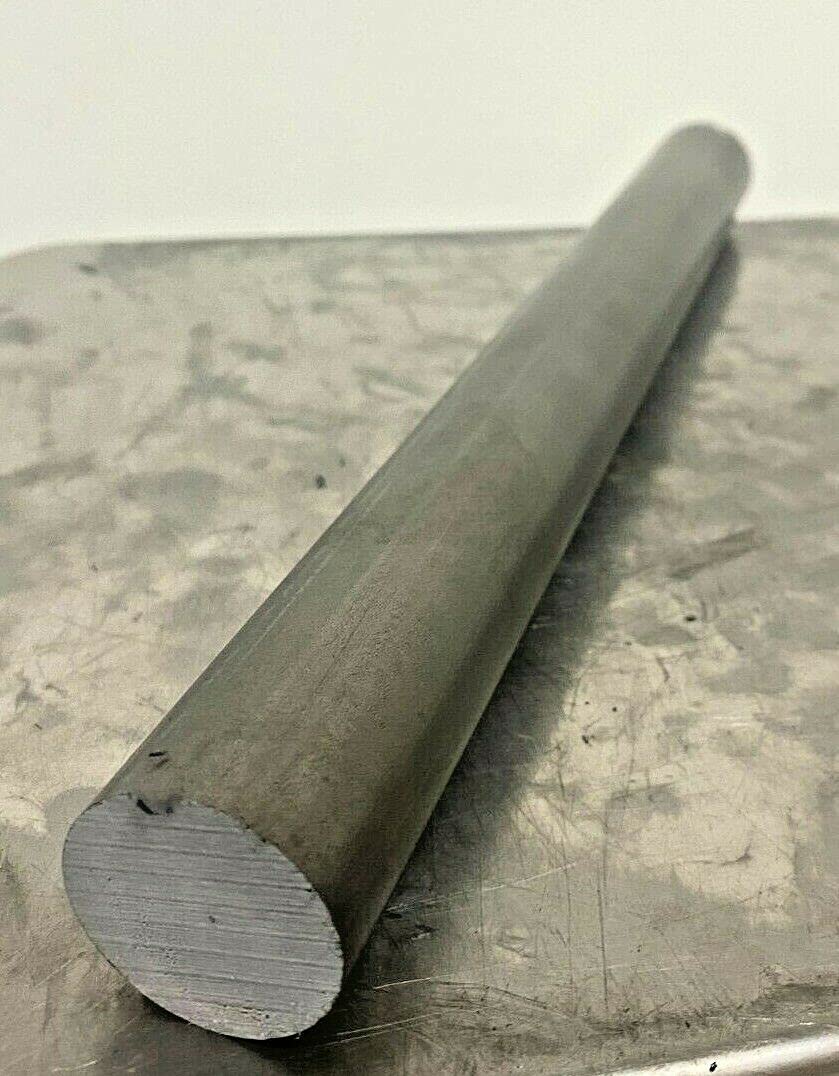

What are the Characteristics of 12L14 Cold Drawn Steel?

12L14 Cold Drawn Steel is a resulfurized and rephosphorized carbon steel known for its exceptional machinability. This grade is often utilized in industries such as automotive and aerospace for manufacturing fittings and precision components. Its low carbon content results in lower strength compared to other cold drawn grades, making it suitable for applications where intricate machining is prioritized over high strength. B2B buyers should consider its availability in various diameters and shapes to meet specific production needs.

How Does 12L14 Hexagonal Bar Stand Out?

The 12L14 Hexagonal Bar is specifically designed for applications that require a hexagonal shape, providing enhanced grip and stability in fastening components. This type is commonly used in the production of fasteners and precision tools. Buyers should note that while this shape offers unique advantages, its availability may be limited in certain regions, potentially impacting lead times. Understanding the specific requirements of your application will help in deciding whether this variant is the right choice.

What are the Benefits of 12L14 Square Bar?

The 12L14 Square Bar is favored for its ability to provide better surface contact, making it ideal for structural components and mounting brackets. This shape allows for enhanced grip and stability in applications where alignment is critical. However, buyers should be aware that additional machining may be necessary to achieve specific dimensions, which could impact project timelines and costs. Evaluating the balance between the need for stability and the machining requirements is essential for effective procurement.

Why Choose 12L14 Round Bar?

The 12L14 Round Bar is the most versatile option among the 12L14 types, widely used for pins, studs, and hydraulic fittings. Its standard round shape ensures ease of sourcing and compatibility with various manufacturing processes. While it is readily available, it may not be suitable for applications that require non-circular profiles. Buyers should assess their design specifications and consider the implications of using a round bar versus other shapes.

What is the Advantage of 12L14 Lead-Free Variant?

The 12L14 Lead-Free Variant offers similar machinability to standard 12L14 but eliminates lead content, making it a safer choice for applications in medical devices and food processing equipment. This variant aligns with increasing regulatory requirements concerning lead in materials. Although it may come at a higher cost, the long-term benefits of compliance and safety can outweigh the initial investment. B2B buyers should evaluate their compliance needs and budget constraints when considering this option.

Key Industrial Applications of 12l14 carbon steel

| Industry/Sector | Specific Application of 12l14 carbon steel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Hydraulic fittings and valves | High machinability allows for precise components | Ensure compliance with ASTM standards and specifications. |

| Aerospace | Engine components and fittings | Lightweight yet strong materials enhance performance | Verify certifications for aerospace-grade materials. |

| Automotive | Engine parts and precision fasteners | Reduces production costs due to excellent machinability | Assess lead content regulations in target markets. |

| Construction | Structural components and connectors | Provides durability and strength in construction applications | Consider local sourcing options to reduce lead times. |

| Machining/Manufacturing | Custom machined parts and prototypes | Shorter lead times and cost-effective production | Look for suppliers with diverse inventory and quick turnaround. |

How is 12L14 Carbon Steel Used in the Oil & Gas Industry?

In the oil and gas sector, 12L14 carbon steel is commonly utilized for manufacturing hydraulic fittings and valves. These components require high precision and durability to withstand extreme pressures and corrosive environments. The excellent machinability of 12L14 allows manufacturers to produce intricate designs quickly and efficiently. For international buyers, ensuring that suppliers adhere to ASTM standards is critical to guarantee the reliability and performance of these components in demanding applications.

What Role Does 12L14 Carbon Steel Play in Aerospace Applications?

Aerospace applications often demand materials that combine lightweight properties with exceptional strength. 12L14 carbon steel is used for engine components and fittings, where its low carbon content and added lead enhance machinability, allowing for the production of complex geometries. Buyers in this sector must verify that the steel meets specific aerospace certifications, ensuring compliance with stringent safety and performance standards.

Why is 12L14 Carbon Steel Preferred in Automotive Manufacturing?

In the automotive industry, 12L14 carbon steel is favored for producing engine parts and precision fasteners due to its superior machinability. This characteristic reduces production costs while maintaining high-quality standards. However, international buyers should be aware of lead content regulations in their respective markets, which may affect the acceptance of this material in certain applications.

How is 12L14 Carbon Steel Beneficial for Construction?

In construction, 12L14 carbon steel is utilized for structural components and connectors, where its strength and durability are paramount. The material’s ability to be precisely machined allows for the creation of reliable and robust connections in various structural applications. Buyers should consider sourcing locally to mitigate lead times, ensuring that projects stay on schedule without compromising on quality.

What Advantages Does 12L14 Carbon Steel Offer in Machining and Manufacturing?

For machining and manufacturing, 12L14 carbon steel is often used to create custom machined parts and prototypes. Its free-machining properties enable quicker production cycles and cost-effective solutions for complex designs. Buyers should prioritize suppliers with a diverse inventory and quick turnaround capabilities to meet fluctuating project demands effectively.

3 Common User Pain Points for ’12l14 carbon steel’ & Their Solutions

Scenario 1: Challenges with Machinability Consistency

The Problem: B2B buyers often encounter inconsistencies in the machinability of 12L14 carbon steel, which can lead to unpredictable production outcomes. This inconsistency is particularly frustrating when working on high-precision components, such as fittings or hydraulic parts. Variations in sulfur and lead content can affect how the material behaves during machining, leading to tool wear, surface finish issues, and ultimately increased production costs. Buyers may find themselves needing to adjust their machining processes frequently, which disrupts workflows and affects overall efficiency.

The Solution: To mitigate these issues, it’s essential to establish a reliable relationship with reputable suppliers who adhere to strict quality control measures. When sourcing 12L14 carbon steel, request material certifications that specify the chemical composition and mechanical properties. Additionally, consider conducting small batch trials with the selected supplier to evaluate the machinability before committing to larger orders. Implementing a consistent machining strategy, including using optimized cutting speeds and feeds tailored for 12L14, can also help maintain quality. Investing in high-quality cutting tools designed for free-machining steels will further enhance production consistency and reduce tool wear.

Scenario 2: Concerns Over Lead Content and Regulatory Compliance

The Problem: With growing environmental regulations, particularly in regions like Europe and North America, many B2B buyers are increasingly concerned about the lead content in 12L14 carbon steel. The potential for lead-related restrictions can create uncertainty in the supply chain, leading companies to worry about future compliance and the ability to meet international standards. This concern can complicate procurement strategies, as buyers may hesitate to invest in materials that could soon be restricted or require costly changes to their production processes.

The Solution: To address these regulatory concerns, buyers should proactively seek suppliers who offer lead-free alternatives or are developing compliant versions of 12L14 carbon steel. Engaging with suppliers early in the design phase can help in selecting materials that meet both performance requirements and regulatory standards. Additionally, staying informed about local and international regulations will allow buyers to adjust their sourcing strategies accordingly. Consider specifying materials that provide similar machinability and performance characteristics without the lead content, such as 1144 or other free-machining alternatives. This proactive approach can safeguard against future disruptions while still meeting production needs.

Scenario 3: Limitations in Material Availability and Variety

The Problem: B2B buyers often face challenges related to the availability of specific shapes and sizes of 12L14 carbon steel. Many manufacturers require precise dimensions for their applications, yet stock shortages or limited options can lead to delays in production schedules. This limitation can be particularly pressing in industries such as aerospace and automotive, where stringent specifications are critical. Buyers may find themselves in a position where they cannot meet deadlines due to the unavailability of the necessary materials.

The Solution: To overcome these availability issues, it is crucial for buyers to establish relationships with multiple suppliers to create a more resilient supply chain. Diversifying suppliers can ensure access to a broader range of shapes and sizes, even during peak demand periods. Additionally, buyers can work with suppliers to customize orders based on specific project requirements, thus ensuring that they receive exactly what they need. It’s also beneficial to forecast demand and maintain a safety stock of critical sizes to prevent production disruptions. Engaging in long-term contracts with suppliers can also secure priority access to materials, further minimizing the risk of delays.

Strategic Material Selection Guide for 12l14 carbon steel

What are the Key Properties of 12L14 Carbon Steel?

12L14 carbon steel is known for its excellent machinability, primarily due to its unique composition that includes sulfur, phosphorus, and lead. These elements enhance the material’s cutting characteristics, making it a preferred choice in manufacturing applications that require precision machining. However, it is essential to note that while it offers high tensile strength (70,000 – 80,000 psi) and yield strength (65,000 – 75,000 psi), its low carbon content results in lower overall strength compared to other cold-drawn steels. This characteristic makes it suitable for applications where high strength is not the primary concern.

What are the Pros and Cons of Using 12L14 Carbon Steel?

Pros:

– Exceptional Machinability: The lead content significantly enhances the machining process, allowing for faster production rates and reduced tool wear. This is particularly advantageous in high-volume manufacturing environments.

– Cost-Effective: Due to its widespread availability and ease of machining, 12L14 is often more cost-effective than higher-strength alternatives, which can be critical for budget-conscious projects.

– Versatile Applications: It is widely used in various industries, including automotive, aerospace, and oil & gas, for components such as fittings, valves, and pins.

Cons:

– Limited Strength: The lower carbon content results in reduced strength, making it unsuitable for high-stress applications.

– Lead Content Concerns: The presence of lead raises health and environmental concerns, particularly in regions with stringent regulations regarding lead usage. This may limit its acceptance in certain markets.

– Welding Limitations: While it can be welded, the lead content complicates the welding process, requiring specialized techniques to ensure quality, which may increase manufacturing complexity.

How Does 12L14 Carbon Steel Impact Specific Applications?

The specific media compatibility of 12L14 carbon steel is generally favorable for non-corrosive environments. However, its performance may be compromised in applications involving aggressive chemicals or high temperatures. For instance, in the oil and gas industry, while it can be used for fittings and couplings, the choice of material must consider the media being transported and the potential for corrosion. In such cases, additional coatings or alternative materials may be recommended.

What Should International B2B Buyers Consider When Selecting 12L14 Carbon Steel?

International buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of compliance with local standards such as ASTM, DIN, or JIS. The lead content in 12L14 steel may pose regulatory challenges in certain countries, necessitating careful consideration of material specifications. Additionally, buyers should evaluate the availability of the material in their region, as logistical considerations can impact delivery times and costs. Understanding the local market preferences for materials and the potential for alternative grades, such as 1144SP, which offers similar machinability without lead, can also be beneficial.

Summary Table of Material Selection Insights

| Material | Typical Use Case for 12L14 Carbon Steel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| 12L14 Carbon Steel | Fittings, valves, and pins in automotive and aerospace | Excellent machinability and cost-effective | Limited strength and welding challenges | Medium |

| 1144SP (Alternative) | High-stress applications requiring precision | Higher strength without lead | More expensive and limited shapes | High |

| Stainless Steel | Corrosive environments in oil and gas | Superior corrosion resistance | Higher cost and machining complexity | High |

| 4140 Alloy Steel | Heavy-duty applications requiring strength | High tensile strength and durability | More challenging to machine | Medium |

This strategic material selection guide provides insights into the properties, advantages, and limitations of 12L14 carbon steel, enabling B2B buyers to make informed decisions tailored to their specific application needs.

In-depth Look: Manufacturing Processes and Quality Assurance for 12l14 carbon steel

What Are the Main Stages in the Manufacturing Process of 12L14 Carbon Steel?

The manufacturing process for 12L14 carbon steel encompasses several critical stages: material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage involves sourcing high-quality raw materials that conform to specifications outlined by ASTM A108 and ASTM A576. The steel is typically produced through the Electric Arc Furnace (EAF) method, which allows for precise control over the chemical composition, particularly the sulfur, phosphorus, and lead content that contribute to its free machining properties.

-

Forming: In this phase, the prepared steel is subjected to cold drawing or cold finishing processes. Cold drawing enhances the mechanical properties of the steel by improving its dimensional accuracy and surface finish. The bars are drawn through a die to achieve the desired diameter and shape, such as hexagonal, square, or round bars. This process also imparts strength and hardness to the steel while maintaining its machinability.

-

Assembly: Although 12L14 carbon steel is commonly supplied in bar form, it may undergo assembly processes when utilized in complex components. This can involve cutting, threading, or machining to create parts that fit specific applications, such as fittings, couplings, and valves. Precision machining is essential to ensure that the final products meet rigorous industry standards.

-

Finishing: The finishing stage may include surface treatments to enhance corrosion resistance or improve aesthetics. Techniques such as plating, painting, or passivation may be employed, depending on the end-use requirements. This stage is vital for ensuring the longevity and performance of components made from 12L14 carbon steel, particularly in demanding environments like oil and gas or aerospace.

What Quality Assurance Standards Are Relevant for 12L14 Carbon Steel?

Quality assurance is paramount in the production of 12L14 carbon steel, particularly for international B2B buyers who require adherence to specific standards.

-

International Standards: The primary standard for quality management is ISO 9001, which sets out the criteria for a quality management system. It emphasizes customer satisfaction and continuous improvement. Manufacturers of 12L14 carbon steel should be certified to this standard to ensure they meet customer and regulatory requirements consistently.

-

Industry-Specific Standards: Additional certifications may be necessary depending on the application. For instance, the API (American Petroleum Institute) standards are critical for materials used in the oil and gas sector. Similarly, CE marking is essential for products sold in the European market, indicating compliance with EU safety, health, and environmental protection standards.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Implementing a robust quality control (QC) system is essential to ensure the integrity of 12L14 carbon steel products. Key QC checkpoints include:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon receipt. This includes verifying chemical composition and mechanical properties against specifications to ensure compliance before production begins.

-

In-Process Quality Control (IPQC): During the manufacturing process, continuous monitoring is conducted to identify any deviations from standards. This includes measuring dimensions, surface finish, and mechanical properties at various stages, particularly during cold drawing and machining.

-

Final Quality Control (FQC): Once the manufacturing process is complete, a final inspection is conducted. This includes a comprehensive review of the product’s dimensions, surface quality, and mechanical properties. Testing methods may include tensile strength tests, hardness tests, and non-destructive testing (NDT) techniques to detect any internal flaws.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several steps to verify the quality control measures employed by their suppliers:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the supplier’s quality management systems and manufacturing processes directly. This can provide insight into the supplier’s commitment to quality and adherence to international standards.

-

Quality Reports and Certifications: Requesting detailed quality reports that outline testing methods, results, and compliance with relevant standards is crucial. Certifications such as ISO 9001, API, or CE should also be verified to ensure the supplier meets industry expectations.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the manufacturer’s quality control processes. This is particularly beneficial for international buyers who may not have the resources to conduct on-site evaluations.

What Testing Methods Are Commonly Used for 12L14 Carbon Steel?

Various testing methods are employed to ensure the quality and reliability of 12L14 carbon steel products. Common testing techniques include:

-

Mechanical Testing: This involves evaluating the tensile strength, yield strength, and elongation of the steel. Such tests are essential for confirming that the material meets the specified mechanical properties outlined in ASTM standards.

-

Chemical Analysis: Spectrometric analysis is often used to determine the chemical composition of the steel. This ensures that the levels of sulfur, phosphorus, lead, and other elements fall within acceptable ranges, which is critical for maintaining the material’s machinability.

-

Non-Destructive Testing (NDT): Techniques such as ultrasonic testing and magnetic particle testing are used to detect internal and surface defects without damaging the material. These methods are particularly valuable for components subject to high stress and critical applications.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International B2B buyers must navigate various quality control and certification nuances when sourcing 12L14 carbon steel:

-

Regulatory Compliance: Different countries may have specific regulations regarding the use of materials containing lead, such as 12L14. Buyers must ensure that the products comply with local regulations to avoid potential legal and safety issues.

-

Documentation and Traceability: Buyers should request comprehensive documentation that provides traceability of the material from production to delivery. This includes certificates of compliance, test reports, and material safety data sheets (MSDS).

-

Cultural and Market Differences: Understanding the cultural nuances and market expectations in regions such as Africa, South America, the Middle East, and Europe is crucial. Buyers should be aware of local standards and practices to ensure successful transactions and long-term partnerships.

By focusing on these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions when sourcing 12L14 carbon steel, ensuring they receive high-quality materials that meet their operational requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ’12l14 carbon steel’

In the competitive landscape of industrial materials, sourcing 12L14 carbon steel requires careful planning and execution. This guide outlines a step-by-step checklist to help B2B buyers streamline their procurement process, ensuring they obtain quality materials that meet their specific needs.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for your 12L14 carbon steel, including dimensions, tolerances, and chemical composition. This step is vital as it sets the foundation for your procurement process, ensuring that the material will meet the performance standards required for your applications. Pay attention to the specific properties of 12L14, such as its excellent machinability and lower strength compared to other cold-drawn grades.

Step 2: Research Potential Suppliers

Begin by identifying suppliers that specialize in 12L14 carbon steel. Utilize online directories, industry forums, and trade shows to compile a list of potential vendors. Look for suppliers with a proven track record in your industry and those who can provide detailed product information and certifications, such as ASTM compliance.

Step 3: Evaluate Supplier Certifications

Before making a commitment, verify that your selected suppliers hold relevant certifications, such as ISO 9001 or specific material certifications. Certifications indicate adherence to quality management standards and material specifications, which is essential for ensuring the reliability and safety of the steel you purchase. Request copies of certifications and check their validity.

Step 4: Request Samples and Specifications

Ask potential suppliers for material samples and detailed specifications of their 12L14 carbon steel offerings. This step allows you to assess the quality of the steel and confirm that it meets your defined technical specifications. Pay attention to the chemical composition and mechanical properties to ensure they align with your project requirements.

Step 5: Assess Pricing and Payment Terms

Collect quotes from multiple suppliers and compare pricing structures. While cost is a critical factor, consider the overall value, including quality, delivery times, and customer service. Discuss payment terms to ensure they align with your budgeting and cash flow needs, keeping an eye out for any hidden fees or minimum order quantities.

Step 6: Conduct Supplier Audits

If possible, perform audits or site visits to potential suppliers. This step helps you gain insight into their production processes, quality control measures, and overall operational practices. An on-site evaluation can reveal the supplier’s commitment to quality and reliability, which is crucial for long-term partnerships.

Step 7: Finalize the Contract

Once you have selected a supplier, finalize the contract detailing all terms, including delivery schedules, pricing, and quality assurances. Ensure that the contract protects your interests and includes clauses for dispute resolution and warranty claims. A well-structured contract is essential to minimize risks and facilitate a smooth procurement process.

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing 12L14 carbon steel, ensuring they partner with reliable suppliers who meet their technical and business needs.

Comprehensive Cost and Pricing Analysis for 12l14 carbon steel Sourcing

What Are the Key Cost Components in Sourcing 12L14 Carbon Steel?

When sourcing 12L14 carbon steel, several cost components must be considered to understand the overall pricing structure. These include:

-

Materials: The cost of raw materials, including the specific alloying elements like sulfur and lead, directly impacts pricing. Fluctuations in global steel markets can lead to variations in material costs, which should be monitored closely.

-

Labor: Labor costs encompass the wages of workers involved in the manufacturing process, including machining and finishing. The level of automation in the production facility also influences labor costs, with more automated processes typically resulting in lower labor expenses.

-

Manufacturing Overhead: This includes costs related to the facility, utilities, equipment maintenance, and administrative expenses. Efficient production processes can help minimize overhead, thus reducing the overall cost of the steel.

-

Tooling: The cost of tooling, particularly for machining operations, is significant due to the need for specialized equipment to handle the unique properties of 12L14. Suppliers with advanced machining capabilities may offer better pricing due to lower tooling costs.

-

Quality Control (QC): Ensuring the material meets industry specifications (like ASTM A108) requires investment in quality control processes. This includes testing for tensile strength, yield strength, and hardness, which adds to the overall cost.

-

Logistics: Transportation and handling costs are critical, especially for international shipments. The choice of Incoterms can significantly influence logistics costs, including duties, tariffs, and insurance.

-

Margin: Supplier margins vary based on market conditions, competition, and the supplier’s reputation. Understanding the typical margins in your region can aid in negotiating better pricing.

What Factors Influence Pricing for 12L14 Carbon Steel?

Several factors can influence the pricing of 12L14 carbon steel, particularly for international B2B buyers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically result in lower per-unit costs due to economies of scale. Suppliers often have a MOQ, which can affect pricing for smaller buyers.

-

Specifications and Customization: Customized products or specific tolerances may incur additional costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Material Quality and Certifications: Higher quality materials with certifications (e.g., ISO, ASTM) may come at a premium. Buyers should assess whether these certifications are necessary for their applications.

-

Supplier Factors: The supplier’s location, reliability, and production capabilities can impact pricing. Established suppliers with a good track record may charge more but offer better service and quality assurance.

-

Incoterms: The chosen Incoterms (e.g., FOB, CIF) affect the total landed cost. Buyers should select terms that align with their logistics capabilities and risk tolerance.

How Can Buyers Negotiate Effectively for 12L14 Carbon Steel?

To maximize cost-efficiency when sourcing 12L14 carbon steel, consider the following tips:

-

Understanding Total Cost of Ownership (TCO): Beyond the initial purchase price, assess additional costs such as shipping, customs, and handling. A lower upfront cost may not always translate to overall savings.

-

Negotiation Strategies: Be prepared to negotiate based on volume, payment terms, and delivery timelines. Suppliers may be willing to offer discounts for larger orders or prompt payment.

-

Local Market Insights: For buyers in regions like Africa, South America, the Middle East, and Europe, understanding local market dynamics can lead to better pricing. Engaging with local suppliers may reduce logistics costs and tariffs.

-

Timing and Market Trends: Keep an eye on market trends and seasonal pricing fluctuations. Timing your purchase during off-peak seasons can lead to significant savings.

-

Alternatives and Substitutes: Inquire about alternative materials or grades, such as 1144SP, which may offer similar machinability at a different price point. Exploring substitutes can provide leverage in negotiations.

Conclusion: What Should Buyers Keep in Mind?

While sourcing 12L14 carbon steel, it’s crucial to maintain a comprehensive understanding of the cost structure and pricing influencers. This approach enables buyers to negotiate effectively and make informed decisions that enhance their operational efficiency and profitability. Keep in mind that prices are subject to fluctuation based on various factors, and it is advisable to seek multiple quotations for comparative analysis.

Alternatives Analysis: Comparing 12l14 carbon steel With Other Solutions

Understanding Alternatives to 12L14 Carbon Steel

When evaluating materials for precision machining and manufacturing, it is essential to consider alternatives to 12L14 carbon steel. While 12L14 is favored for its excellent machinability and ease of use, various alternatives may offer specific benefits depending on the application. This analysis will compare 12L14 carbon steel with two viable alternatives: 1144 Stressproof steel and 1018 carbon steel.

Comparison Table

| Comparison Aspect | 12L14 Carbon Steel | 1144 Stressproof Steel | 1018 Carbon Steel |

|---|---|---|---|

| Performance | High machinability; lower strength | Superior strength; good machinability | Moderate strength; decent machinability |

| Cost | Generally cost-effective | Higher cost due to superior properties | Economical and widely available |

| Ease of Implementation | Easy to machine; requires careful handling | Slightly more complex machining process | Simple machining and fabrication |

| Maintenance | Low maintenance but prone to rust | Low maintenance; excellent durability | Moderate maintenance; susceptible to corrosion |

| Best Use Case | Precision components, fittings, pins | Heavy-duty applications, shafts | General-purpose applications |

Detailed Breakdown of Alternatives

1144 Stressproof Steel

1144 Stressproof steel is a high-strength alloy that provides excellent fatigue resistance. Its unique manufacturing process results in a steel that can be easily machined while maintaining superior strength properties. The main advantage of 1144 is its ability to withstand heavy loads and stresses, making it ideal for applications such as shafts, gears, and other components that require enhanced durability. However, its higher cost may deter some buyers looking for a more budget-friendly solution.

1018 Carbon Steel

1018 carbon steel is a low-carbon steel known for its good weldability and machinability. It is a versatile material suitable for a wide range of applications, including automotive and construction industries. The primary advantage of 1018 is its affordability and availability, making it an attractive option for general-purpose use. However, it lacks the high machinability and precision capabilities of 12L14, which may limit its application in specialized manufacturing processes.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the right material is crucial for achieving optimal performance in machining and manufacturing. B2B buyers should consider factors such as performance requirements, cost constraints, and specific application needs when evaluating alternatives to 12L14 carbon steel. While 12L14 offers excellent machinability for precision parts, alternatives like 1144 Stressproof steel and 1018 carbon steel can provide advantages in strength and cost-effectiveness. By thoroughly assessing the unique properties of each option, businesses can make informed decisions that align with their operational goals and market demands.

Essential Technical Properties and Trade Terminology for 12l14 carbon steel

What Are the Key Technical Properties of 12L14 Carbon Steel?

When considering 12L14 carbon steel for your manufacturing needs, understanding its technical properties is crucial for making informed decisions. Here are some key specifications:

1. Material Grade

12L14 is categorized as a free-machining carbon steel, primarily due to its enhanced machinability from the addition of sulfur and lead. This grade is particularly advantageous in applications requiring intricate machining, allowing for higher production rates and reduced tool wear.

2. Tensile Strength

The tensile strength of 12L14 ranges between 70,000 and 80,000 psi. This property indicates the maximum stress the material can withstand while being stretched or pulled before failing. For B2B buyers, understanding tensile strength is essential when evaluating the material’s suitability for high-stress applications, such as automotive and aerospace components.

3. Yield Strength

Yield strength for 12L14 falls between 65,000 and 75,000 psi, representing the maximum stress that can be applied before the material begins to deform permanently. This is a critical property for manufacturers designing components that must maintain their shape under load, such as fittings and couplings.

4. Elongation

Elongation in 12L14 is about 15-20%, indicating how much the material can stretch before breaking. This property is vital for applications where flexibility and ductility are necessary, allowing the finished components to absorb stress without fracturing.

5. Brinell Hardness

The Brinell hardness rating of 12L14 is between 150 and 170 BHN. Hardness is a key factor influencing wear resistance and surface finish quality, which are important considerations for parts subjected to friction or abrasive environments.

6. Machinability Index

With a machinability index of 170%, 12L14 is considered one of the easiest steels to machine. This high rating is significant for manufacturers as it translates to lower production costs and improved efficiency in machining operations.

What Are Common Trade Terms Associated with 12L14 Carbon Steel?

Understanding the terminology used in the steel industry is essential for effective communication and negotiation. Here are several important terms relevant to B2B buyers:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of 12L14, an OEM may require specific material grades to meet performance standards in their products.

2. MOQ (Minimum Order Quantity)

MOQ represents the smallest quantity of a product that a supplier is willing to sell. For 12L14 carbon steel, suppliers may set MOQs based on production efficiency, which is crucial for buyers to consider when placing orders to avoid excess inventory.

3. RFQ (Request for Quote)

An RFQ is a document issued by a buyer to potential suppliers requesting pricing and terms for specific products. Submitting an RFQ for 12L14 carbon steel allows buyers to compare costs and terms from different suppliers, ensuring they get the best deal.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. Understanding these terms is essential for B2B buyers to clarify shipping, insurance, and delivery responsibilities when procuring 12L14 from international suppliers.

5. Lead Time

Lead time refers to the period from placing an order to receiving the product. Knowing the lead time for 12L14 carbon steel is crucial for B2B buyers to plan their production schedules effectively and avoid delays.

6. Certification

Certification denotes that a material meets specific industry standards and regulations. For 12L14 carbon steel, certifications like ASTM A108 or ASTM A576 provide assurance regarding the material’s quality and performance, which is vital for industries such as aerospace and automotive.

By understanding these essential technical properties and trade terminology, B2B buyers can make better-informed decisions when sourcing 12L14 carbon steel, ensuring that their procurement aligns with their manufacturing needs and industry standards.

Navigating Market Dynamics and Sourcing Trends in the 12l14 carbon steel Sector

What Are the Key Trends Influencing the 12L14 Carbon Steel Market?

The global market for 12L14 carbon steel is shaped by several key drivers, including the rising demand for high machinability materials across various industries such as automotive, aerospace, and oil and gas. Notably, the ongoing trend towards automation and precision manufacturing is propelling the demand for free machining steels like 12L14. This steel grade is favored for its excellent machinability, which reduces tooling costs and enhances production efficiency.

Furthermore, international B2B buyers are increasingly leveraging digital platforms for sourcing materials. The integration of technologies such as AI and big data analytics in supply chain management allows buyers to make informed decisions, optimize inventory levels, and forecast demand more accurately. In regions like Africa, South America, the Middle East, and Europe, the shift towards e-commerce in B2B transactions is facilitating quicker procurement processes, enabling buyers to access a wider array of suppliers and products efficiently.

Emerging markets are also playing a significant role in the dynamics of the 12L14 steel sector. Countries like Brazil and Vietnam are witnessing rapid industrialization, which is driving the need for reliable and high-quality steel products. This trend is further supported by government initiatives aimed at boosting local manufacturing capabilities, thereby increasing the demand for locally sourced materials.

How Is Sustainability and Ethical Sourcing Impacting the 12L14 Carbon Steel Sector?

Sustainability has become a critical focus for international B2B buyers, especially concerning materials like 12L14 carbon steel. The environmental impact of steel production, including carbon emissions and resource depletion, is prompting buyers to prioritize suppliers who implement sustainable practices. This includes adopting cleaner manufacturing processes and utilizing recycled materials whenever possible.

Ethical sourcing is equally important, as buyers are increasingly aware of the need for transparency in supply chains. Certifications such as ISO 14001 for environmental management and adherence to responsible sourcing initiatives are becoming prerequisites for suppliers. Buyers are encouraged to verify that their suppliers comply with these standards to ensure that their procurement practices align with their corporate social responsibility goals.

Moreover, as more companies commit to reducing their carbon footprints, the demand for ‘green’ materials is on the rise. This includes exploring alternatives to leaded materials, as concerns about health and environmental risks associated with lead are growing. Buyers can benefit from engaging with suppliers who are innovating in this area, potentially leading to the development of new steel grades that maintain machinability while being more environmentally friendly.

What Is the Historical Context of 12L14 Carbon Steel in B2B Markets?

The development of 12L14 carbon steel dates back to the mid-20th century when advancements in metallurgy led to the creation of free machining steels that significantly enhanced productivity in machining operations. The addition of sulfur and lead to the steel composition was a breakthrough, resulting in a material that offered exceptional machinability and reduced tool wear.

Over the years, 12L14 has established itself as a staple in various industries, particularly in the production of fittings and components that require intricate machining. Its popularity has persisted, despite emerging concerns about lead content, which has prompted ongoing discussions around alternatives that can deliver similar performance without the associated environmental and health risks.

As the global market evolves, the historical significance of 12L14 carbon steel continues to inform current practices, driving innovation and adaptation in sourcing strategies among international B2B buyers. Understanding its evolution provides valuable insights into the material’s future trajectory and potential shifts in market demand.

Frequently Asked Questions (FAQs) for B2B Buyers of 12l14 carbon steel

-

How do I ensure the quality of 12L14 carbon steel from suppliers?

To ensure the quality of 12L14 carbon steel, request detailed specifications and certifications from suppliers, such as ASTM A108 and ASTM A576 compliance. Conduct audits of their manufacturing processes, and ask for material test reports that confirm chemical composition and mechanical properties. Additionally, consider requesting samples for initial evaluation and performing your own quality assurance tests before placing large orders. Establishing a long-term partnership with reputable suppliers can also enhance consistency in quality. -

What are the typical applications of 12L14 carbon steel?

12L14 carbon steel is widely used in applications requiring excellent machinability. Common uses include manufacturing fittings, couplings, valves, bushings, hydraulic fittings, studs, and pins. Its ability to produce high-precision components with minimal tool wear makes it ideal for industries such as automotive, aerospace, oil and gas, and construction. When selecting 12L14, consider the specific requirements of your application to ensure optimal performance. -

What are the minimum order quantities (MOQ) for 12L14 carbon steel?

The minimum order quantity for 12L14 carbon steel typically starts at around 10,000 lbs (approximately 4,500 kg), but this can vary between suppliers. When sourcing internationally, confirm the MOQ with your supplier, as it may impact your procurement strategy, especially if you’re operating on a limited budget or have specific project timelines. Some suppliers may offer flexibility on MOQs for first-time buyers or larger contracts. -

What payment terms should I expect when sourcing 12L14 carbon steel?

Payment terms for 12L14 carbon steel can vary significantly by supplier and region. Common terms include payment upfront, net 30 or 60 days after delivery, or letter of credit arrangements for larger orders. When negotiating, consider your cash flow needs and the supplier’s payment policies. Establishing a solid relationship with your supplier may open up more favorable terms, especially for repeat purchases. -

How can I customize my order for 12L14 carbon steel?

Customization options for 12L14 carbon steel may include specific dimensions, surface finishes, and machining requirements. When discussing your order with suppliers, clearly outline your specifications and any unique needs related to your project. Suppliers with in-house machining capabilities can often provide tailored solutions, but be prepared for potential adjustments in pricing and lead times based on your customization requests. -

What logistics considerations should I keep in mind when importing 12L14 carbon steel?

When importing 12L14 carbon steel, consider factors such as shipping methods, delivery times, customs regulations, and local tariffs. Ensure that your supplier is familiar with international shipping logistics and can provide necessary documentation for customs clearance. Additionally, discuss packaging options that protect the steel during transit, and factor in transportation costs to your overall budget to avoid unexpected expenses. -

Are there alternatives to 12L14 carbon steel?

Yes, alternatives to 12L14 carbon steel include grades like 1144SP and other free-machining steels. While these alternatives may offer similar machinability, they could differ in strength, cost, and availability. When considering alternatives, evaluate the specific requirements of your application, such as strength, corrosion resistance, and weldability, to determine if a different grade might be more suitable for your needs. -

What should I know about the machinability of 12L14 carbon steel?

12L14 carbon steel is renowned for its excellent machinability, attributed to the presence of sulfur and lead, which reduce friction and enhance chip formation. It achieves a machinability index of 170%, making it a preferred choice for complex machining operations. However, it’s important to note that while it machines well, welding can be challenging due to lead segregation, so ensure that your application aligns with its machining capabilities and limitations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 12L14 Carbon Steel Manufacturers & Suppliers List

1. Eaton Steel – 12L14 Cold Drawn Steel Bar

Domain: eatonsteel.com

Registered: 1996 (29 years)

Introduction: {‘product_name’: ’12L14 Cold Drawn Steel Bar’, ‘product_types’: [‘Round’, ‘Square’, ‘Hex’], ‘material_type’: ‘Resulfurized and rephosphorized carbon steel’, ‘machinability’: ‘Excellent’, ‘carbon_content_max’: ‘0.15’, ‘manganese_content’: ‘0.85-1.15’, ‘phosphorus_content’: ‘0.04-0.09’, ‘sulfur_content’: ‘0.26-0.35’, ‘lead_content’: ‘0.15-0.35’, ‘tensile_strength_range’: ‘70,000 – 80,000 psi’, ‘yiel…

2. AISI 12L14 Carbon Steel – Fastest Machining Bar Product

Domain: azom.com

Registered: 1999 (26 years)

Introduction: AISI 12L14 Carbon Steel (UNS G12144) is known as the fastest machining bar product.

**Chemical Composition:**

– Iron (Fe): 97.91 – 98.7%

– Manganese (Mn): 0.85 – 1.15%

– Sulfur (S): 0.260 – 0.35%

– Lead (Pb): 0.15 – 0.35%

– Carbon (C): 0.15%

– Phosphorous (P): 0.040 – 0.090%

**Physical Properties:**

– Density: 7.87 g/cm³ (0.284 lb/in³)

**Mechanical Properties:**

– Tensile S…

3. Alro – 12L14 Cold-Finished Steel Bar

Domain: alro.com

Registered: 1996 (29 years)

Introduction: 12L14 Cold-Finished Steel Bar

Chemical Composition:

– Carbon (C) Max: 0.15

– Manganese (Mn): 0.85-1.15

– Lead (Pb): 0.15-0.35

– Phosphorus (P): 0.04-0.09

– Sulfur (S): 0.26-0.35

Features:

– Good strength

– Excellent machinability

– Precision grade

– Various shape options (round, hex, square)

– Increased part life

Properties:

– Tensile Strength: 78 ksi

– Yield Strength: 60 ksi

– Elongation in 2″…

4. McMaster – Grade 12L14 Steel

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Grade 12L14 Steel, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Castle Metals – 12L14 Carbon Round Bar

Domain: castlemetals.com

Registered: 1996 (29 years)

Introduction: {“item_number”: “741”, “grade”: “12L14”, “material_type”: “Carbon”, “shape”: “Round”, “diameter”: “.3125 IN”, “length_range”: “120.0000-144.0000 IN”, “specifications”: {“ASTM”: “A108”, “UNS”: “G12144”}, “weight_per_foot”: “.261 LBS/FT”, “availability”: “In Stock”, “machinability”: {“relative”: “180 (based on AISI 1212 as 100%)”, “high”: “200 for ProCut® 12L14”, “with_Te_or_Se”: “250”}, “tensile_st…

6. MatWeb – Material Property Data

Domain: matweb.com

Registered: 1997 (28 years)

Introduction: This company, MatWeb – Material Property Data, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Practical Machinist – 12L14 Leaded Steel

Domain: practicalmachinist.com

Registered: 2000 (25 years)

Introduction: 12L14 is a leaded steel known for its free machining properties, which are enhanced by the addition of sulfur and lead. It is generally not recommended for welding due to potential issues with weld quality, such as porosity. When welding 12L14, low hydrogen electrodes are advised for stick welding, while MIG welding is acceptable as it is inherently low hydrogen. The sulfur content in free-machini…

Strategic Sourcing Conclusion and Outlook for 12l14 carbon steel

As the demand for precision-engineered components continues to rise across various industries, 12L14 carbon steel stands out due to its exceptional machinability and versatility. This resulfurized and rephosphorized carbon steel is particularly advantageous for applications in sectors such as automotive, aerospace, and oil & gas. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, strategic sourcing of 12L14 steel can significantly enhance production efficiency and reduce manufacturing costs.

Investing in 12L14 carbon steel not only streamlines the machining process but also ensures high-quality output with reduced tool wear. Buyers should consider sourcing from suppliers that maintain robust inventories and adhere to ASTM standards, ensuring quick delivery and compliance with global quality benchmarks.

Looking ahead, as environmental regulations evolve and alternatives to leaded materials gain traction, buyers must stay informed about market shifts and potential substitutes. By fostering strong supplier relationships and keeping abreast of industry developments, businesses can navigate these changes effectively. Now is the time to leverage the advantages of 12L14 carbon steel in your operations—prioritize strategic sourcing to enhance your competitive edge in the global marketplace.