Contents

Manufacturing Insight: 1215 Steel Properties

Optimizing Prototyping with 1215 Steel: Precision Machining Expertise at Honyo Prototype

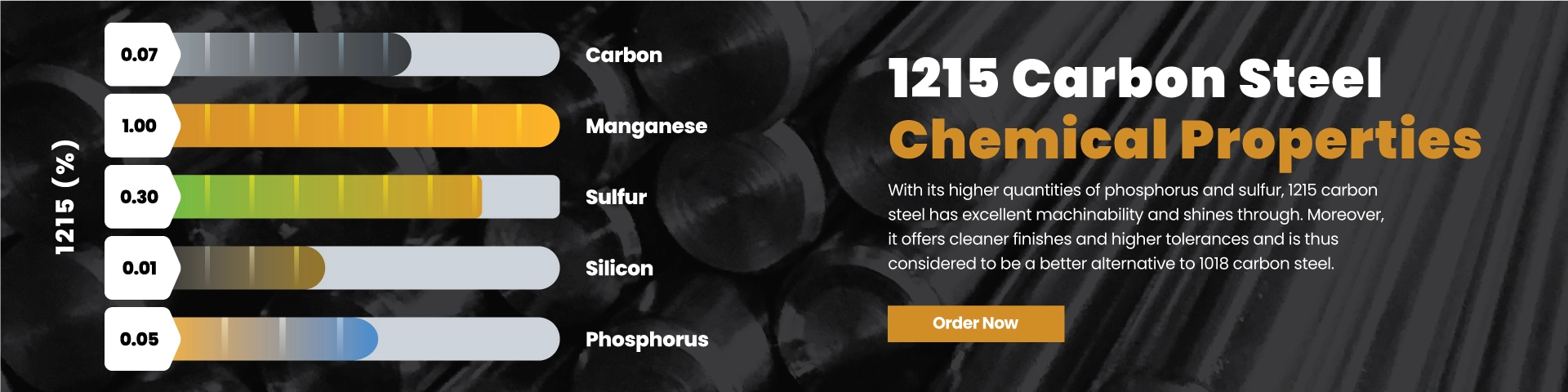

AISI 1215 steel remains a cornerstone material in rapid prototyping and low-volume production due to its exceptional free-machining characteristics. This resulfurized and rephosphorized low-carbon steel incorporates controlled levels of sulfur and phosphorus, significantly enhancing machinability compared to standard 1018 or 12L14 grades. The resulting improved chip breakability, reduced tool wear, and superior surface finish make 1215 ideal for high-precision CNC machining of complex geometries, pins, bushings, fittings, and other components demanding tight tolerances and smooth finishes. Its favorable balance of strength, weldability, and cost-effectiveness positions it as a preferred choice for engineers seeking efficient prototyping cycles without compromising part integrity.

At Honyo Prototype, our Senior Manufacturing Engineering team leverages deep material science understanding to maximize the inherent advantages of 1215 steel within our advanced CNC machining processes. We implement optimized toolpath strategies, specialized cutting parameters, and rigorous coolant management specifically calibrated for 1215’s unique composition. This ensures consistent dimensional accuracy, exceptional surface quality, and minimized production lead times for your critical prototypes and bridge production runs. Our ISO 9001-certified facility utilizes state-of-the-art multi-axis CNC mills and lathes, coupled with stringent in-process inspection, guaranteeing that every 1215 steel component meets exacting engineering specifications.

Transitioning from design to physical part with 1215 steel is streamlined through Honyo Prototype’s commitment to operational efficiency. We understand the urgency of prototyping timelines, which is why our Online Instant Quote system provides rapid, transparent pricing and lead time estimates for 1215 steel machining projects within minutes. Upload your CAD file, specify material requirements, and receive actionable manufacturing feedback immediately—accelerating your development process from concept to functional prototype without delay. Partner with Honyo to transform the advantageous properties of 1215 steel into precision-engineered reality.

Technical Capabilities

1215 Steel Properties and Machining Characteristics for Precision Manufacturing

1215 steel is a rephosphorized and resulfurized low-carbon steel known for its excellent machinability, making it ideal for high-speed automated machining operations such as 3-, 4-, and 5-axis milling and turning. It is commonly used in applications requiring tight tolerances and fine surface finishes, particularly in the production of shafts, pins, and fasteners. Below is a detailed comparison of 1215 steel with other commonly machined materials in precision manufacturing environments.

| Property / Material | 1215 Steel | Aluminum (6061-T6) | Steel (1018) | ABS (Acrylonitrile Butadiene Styrene) | Nylon (PA66) |

|---|---|---|---|---|---|

| Tensile Strength (psi) | 69,000 | 45,000 | 63,800 | 7,000 | 11,000 |

| Yield Strength (psi) | 58,000 | 40,000 | 53,700 | 5,500 | 8,500 |

| Hardness (Brinell) | 140 HB | 95 HB | 126 HB | 80–100 MPa (Shore D) | 80–85 MPa (Shore D) |

| Machinability Rating (%) | 75–85% | 90–100% | 70% | 100% | 80% |

| Density (lb/in³) | 0.283 | 0.098 | 0.284 | 0.039 | 0.041 |

| Thermal Conductivity (BTU/hr·ft·°F) | 29.8 | 101 | 26.0 | 0.11 | 0.14 |

| Typical Tolerance Capability (±) | ±0.0005″ – ±0.001″ | ±0.0005″ – ±0.001″ | ±0.0005″ – ±0.001″ | ±0.002″ – ±0.005″ | ±0.002″ – ±0.005″ |

| Surface Finish (Ra, µin) | 32–64 (typical), down to 16 with fine tooling | 16–32 (easily achievable) | 32–64 | 64–125 | 64–125 |

| Primary Machining Process | 3/4/5-axis milling, turning | 3/4/5-axis milling, turning | 3/4/5-axis milling, turning | 3/4-axis milling, turning | 3/4-axis milling, turning |

| Tool Wear Characteristics | Moderate (free-machining additives reduce tool wear) | Low (soft material) | Moderate to high | Very low | Low to moderate |

| Key Advantages | High machinability, good dimensional stability, tight tolerance capability | Lightweight, excellent strength-to-weight, good thermal conductivity | Good weldability, uniform properties | Easy to machine, low cost, good impact strength | High toughness, wear resistance, low friction |

| Limitations | Lower strength vs. alloy steels, not for high-stress applications | Lower hardness, prone to chatter in deep cavities | Higher tool wear vs. 1215 | Poor heat resistance, prone to warping | Hygroscopic, dimensional instability if not conditioned |

Notes on 1215 Steel for Tight Tolerance Applications:

1215 steel is particularly well-suited for CNC turning and multi-axis milling due to its sulfur and phosphorus content, which improves chip breaking and reduces tool wear. This results in consistent dimensional accuracy, essential for ±0.0005″ tolerances. Its dimensional stability under machining stress allows for high repeatability in automated production environments.

When compared to aluminum, 1215 steel offers higher strength and better wear resistance but requires more robust tooling and higher cutting forces. Relative to 1018 steel, 1215 provides superior machinability, though slightly lower ductility.

For non-metallic materials like ABS and nylon, machining tolerances are generally looser due to material flexibility and thermal expansion. These materials are easier to cut but not suitable for high-precision mechanical components requiring long-term stability.

In summary, 1215 steel is a preferred choice for tight-tolerance, high-volume precision parts where machinability and consistency are critical, especially in 3-, 4-, and 5-axis CNC environments.

From CAD to Part: The Process

Honyo Prototype applies rigorous material science principles throughout our manufacturing workflow, with 1215 steel properties systematically evaluated at each stage. Our process ensures optimal machining outcomes while maintaining strict compliance with material specifications. Below is the integrated workflow for components requiring 1215 steel:

Upload CAD

Upon receiving CAD files, our system immediately identifies material callouts including 1215 steel (AISI 1215, UNS G12150). We verify critical properties against ASTM A29/A29M standards: machinability rating of 170% (relative to 1018 steel), typical Brinell hardness of 110 HB, tensile strength range of 50-65 ksi, and sulfur content of 0.08-0.13% for chip control. Any ambiguity in material specification triggers an automated clarification request.

AI-Powered Quoting Engine

The AI quotation system cross-references 1215 steel characteristics with real-time production parameters. Key considerations include:

Machining time reduction (15-20% faster than 1018 due to sulfur inclusion)

Coolant selection optimized for sulfur-bearing alloys

Scrap rate adjustment accounting for 1215’s lower ductility versus 1045 steel

Regulatory flags for lead-free alternatives (e.g., 12L14) when shipping to EU/California

Pricing algorithms incorporate material surcharges based on current ferrous scrap indices and lead content compliance requirements.

DFM Analysis

Our engineering team conducts material-specific manufacturability review:

Verifying minimum wall thickness against 1215’s reduced strength (yield strength 27.5 ksi)

Adjusting feed rates and spindle speeds to prevent built-up edge from sulfur inclusions

Evaluating thread rolling feasibility given the steel’s lower ductility

Recommending alternative alloys (e.g., 12L14 for lead-free compliance) with comparative cost analysis

Flagging potential stress corrosion issues in thin-walled features due to manganese sulfide stringers

Production Execution

Machining parameters are dynamically optimized:

Carbide tooling selected with 15-20° rake angles to handle free-machining chips

Coolant concentration maintained at 8-10% to manage heat from high-speed cutting

In-process hardness testing at critical features to confirm 110-130 HB range

Dimensional checks focused on features prone to distortion in low-carbon steels

All 1215 steel batches include mill test reports verifying chemical composition and mechanical properties.

Delivery Assurance

Final inspection includes material validation:

Spectrographic analysis confirming sulfur (0.08-0.13%) and phosphorus (0.08-0.13%) content

Hardness verification at three locations per part

Dimensional certification with Cpk ≥1.33 for critical features

RoHS/REACH compliance documentation for export shipments

Certified material test reports and process validation data accompany all 1215 steel components.

This integrated approach ensures 1215 steel components meet stringent performance requirements while leveraging the alloy’s machinability advantages. We maintain AS9100-certified traceability from raw material to finished part, with all process parameters documented in our digital twin system for full production transparency. For applications requiring enhanced corrosion resistance or strength, our engineers proactively suggest validated alternatives during DFM review.

Start Your Project

For detailed technical specifications on 1215 steel properties, including machinability, strength, and dimensional stability, contact Susan Leo at [email protected]. As a trusted manufacturing partner based in Shenzhen, Honyo Prototype offers precision machining and material expertise tailored to your prototyping and production needs. Reach out today to discuss your project requirements and leverage our in-house capabilities for faster turnaround and consistent quality.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.