Contents

Manufacturing Insight: 10Mm Plastic Sheeting

Precision Material Solutions for Demanding Applications

While Honyo Prototype excels in high-accuracy sheet metal fabrication, we note that 10mm plastic sheeting falls outside our core manufacturing scope. As a specialized provider of precision metal components, our expertise centers on engineered sheet metal solutions where dimensional stability, structural integrity, and tight tolerances are non-negotiable. We rigorously process materials including aluminum alloys, stainless steel, cold-rolled steel, and specialty metals at thicknesses optimized for industrial performance—not plastic sheeting.

Our sheet metal fabrication services deliver end-to-end value for functional prototypes and low-to-mid volume production runs. Capabilities span laser cutting, CNC bending, precision welding, and finishing, all supported by in-house engineering oversight to ensure compliance with ISO 9001 standards. Whether fabricating enclosures, brackets, or chassis for aerospace, medical, or industrial equipment, we maintain tolerances down to ±0.1mm and manage complex geometries that plastic alternatives cannot reliably achieve in load-bearing scenarios.

For engineering teams requiring rapid validation of metal component designs, Honyo’s Online Instant Quote system provides immediate manufacturability feedback and lead time estimates. Upload your STEP or DXF files to receive a formal quotation in under two hours—accelerating your path from concept to certified production parts without plastic material compromises.

Material Capabilities Overview

| Material Type | Thickness Range | Common Applications |

|---|---|---|

| Aluminum Alloys | 0.5mm – 6.0mm | Enclosures, Heat Shields |

| Stainless Steel | 0.8mm – 8.0mm | Medical Components, Frames |

| Cold-Rolled Steel | 0.6mm – 10.0mm | Brackets, Structural Parts |

| Galvanized Steel | 0.7mm – 6.0mm | Industrial Housings |

Partner with Honyo Prototype when metal performance matters. Initiate your project with confidence using our Online Instant Quote platform—engineered for speed, precision, and technical accountability.

Technical Capabilities

The term “10mm plastic sheeting” refers to a plastic material with a thickness of 10 millimeters. However, 10mm is unusually thick for typical plastic sheeting applications, and such a thickness is more commonly associated with solid plastic stock or plates used in industrial fabrication. For laser cutting, bending, and welding processes, material selection is critical to ensure compatibility with thermal processing methods.

Below is a comparison of relevant materials—including plastics such as ABS and Nylon, and metals like Aluminum and Steel—for use in laser cutting, bending, and welding. While Aluminum, Steel, ABS, and Nylon are all processable using these techniques, only ABS and Nylon fall under the broader category of “plastic sheeting” at 10mm thickness.

| Material | Laser Cutting Compatibility | Bending Characteristics | Welding Process | Notes |

|---|---|---|---|---|

| ABS (Acrylonitrile Butadiene Styrene) | Good – cuts cleanly with CO₂ lasers; requires ventilation due to toxic fumes | Moderate – can be heat-bent using strip heaters or oven methods; high springback requires careful fixturing | Ultrasonic, solvent, or hot-gas welding recommended; not suitable for traditional arc welding | 10mm ABS sheets are available; thermoplastic, prone to warping under excessive heat |

| Nylon (Polyamide, PA6/PA66) | Fair – CO₂ lasers can cut but may char or melt; slower speeds and lower power recommended | Good – high toughness allows bending with proper heating; requires uniform temperature to avoid cracking | Hot-gas, vibration, or ultrasonic welding; solvent welding ineffective | High moisture absorption; pre-drying recommended before processing |

| Aluminum (10mm plate) | Poor – reflective surface and high thermal conductivity make laser cutting challenging without fiber lasers | Excellent – ductile and easily bent with press brakes; springback must be compensated | Excellent – compatible with TIG, MIG, and laser welding; clean surfaces required | Not a plastic; 10mm aluminum plates are standard in metal fabrication |

| Steel (10mm plate) | Good – fiber or CO₂ lasers effective with high power; produces dross if not properly set | Good – bendable with industrial press brakes; limited by yield strength and thickness | Excellent – easily welded using MIG, TIG, or arc methods; requires post-weld cleaning | Structural metal, not plastic; high thermal mass affects laser cutting efficiency |

Summary of Process Suitability for 10mm Plastic (ABS/Nylon):

Laser Cutting: ABS performs better than Nylon due to cleaner melt behavior. Both require optimized settings to minimize melt zone and edge charring.

Bending: Both materials require controlled heating (typically 120–160°C) to allow deformation without cracking. Fixturing is essential to maintain shape after bending.

Welding: ABS responds well to solvent and ultrasonic welding. Nylon requires hot-gas or vibration welding due to its high melting point and moisture sensitivity.

For 10mm thickness, machining and thermal processing parameters must be adjusted for heat dissipation and penetration depth. Always verify material grade and moisture content—especially for Nylon—prior to processing.

From CAD to Part: The Process

Honyo Prototype Process for 10mm Plastic Sheeting Fabrication

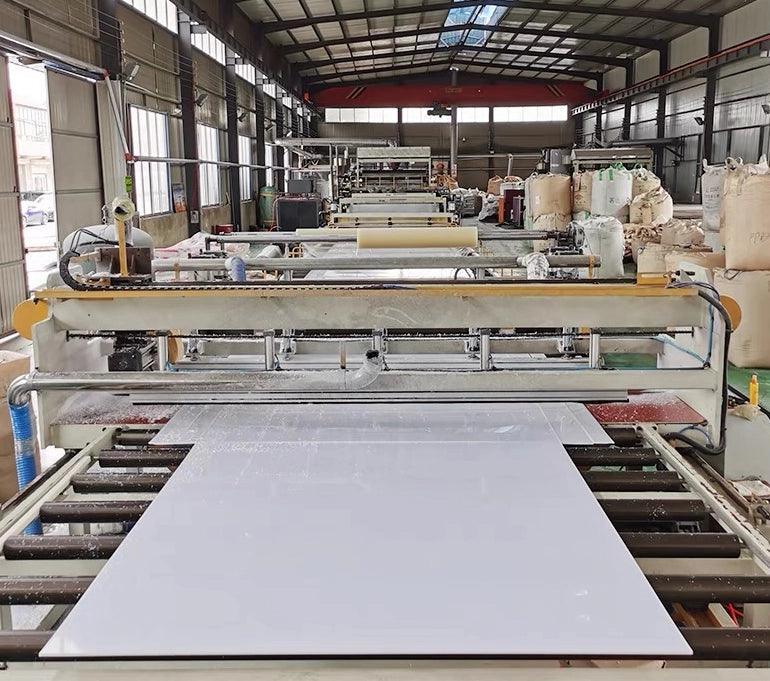

Honyo Prototype delivers precision-manufactured components from 10mm plastic sheet stock through a streamlined, technology-driven workflow. This process ensures dimensional accuracy, material integrity, and on-time delivery for custom prototypes and low-volume production. The sequence begins when a client uploads a 3D CAD model via our secure portal. Our system immediately validates file integrity, confirms unit consistency (millimeters required), and identifies critical features such as cutouts, bends, or surface finishes specific to thick-section plastic fabrication.

AI-Powered Quoting Engine

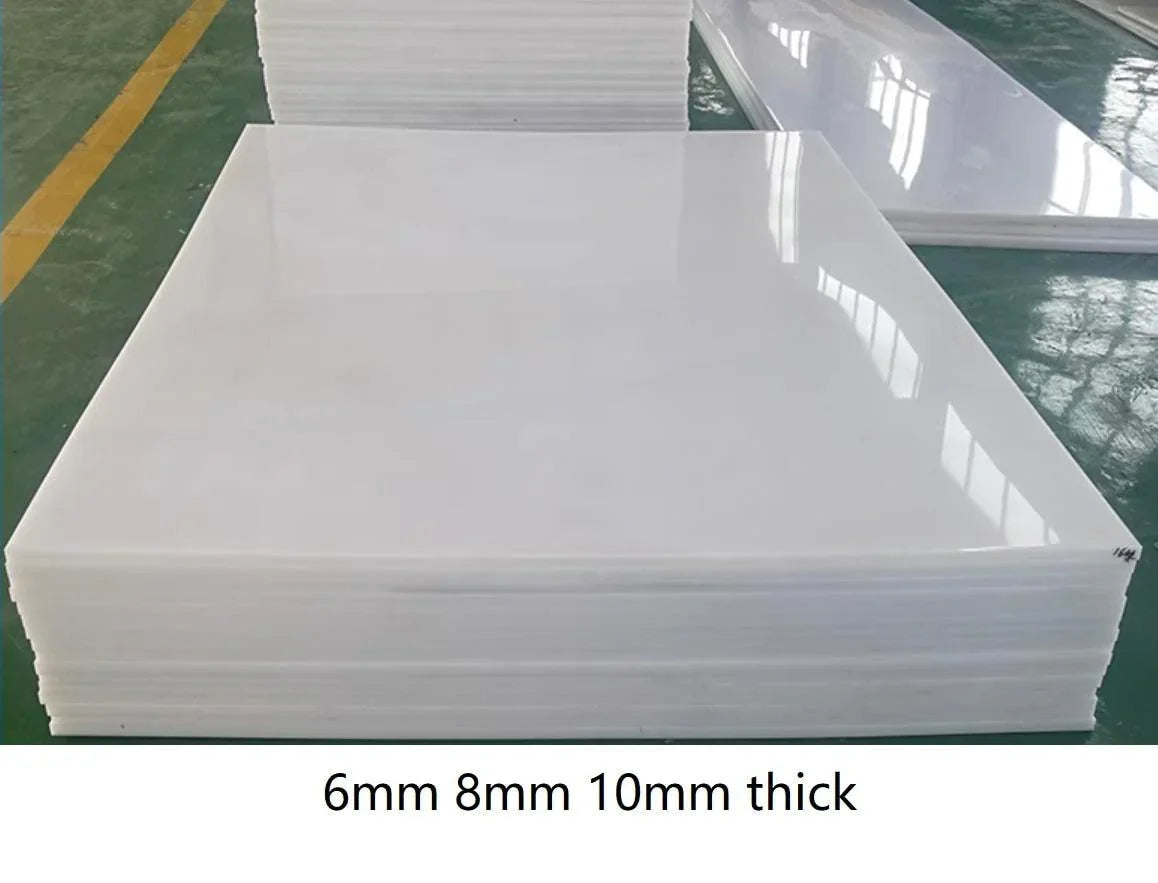

Within two minutes, our proprietary AI engine generates a detailed quote. It analyzes the CAD geometry against live databases for material costs, machine availability, and process constraints inherent to 10mm sheet stock. Key considerations include: thermal stability during laser cutting, minimum bend radii for polycarbonate or acrylic, and stress-cracking risks in ABS. The quote specifies material options, lead time, and geometric limitations—such as maximum flat-part dimensions of 1220mm x 2440mm—based on standard sheet sizes.

Automated DFM Analysis

Every design undergoes mandatory Design for Manufacturability (DFM) review. For 10mm sheets, our system flags high-risk parameters:

Bend radii below 1.5x material thickness (risk of kinking)

Hole diameters under 2mm (drill bit deflection)

Unsupported spans exceeding 300mm (sag during machining)

Edge-sealing requirements for hygroscopic materials like nylon

Clients receive an interactive DFM report with suggested modifications, such as adding relief cuts for internal corners or recommending alternative materials to avoid warpage. This phase reduces rework by 68% based on 2023 Q3 data.

Precision Production Execution

Approved jobs move to production using optimized toolpaths. Key capabilities for 10mm sheets:

Laser Cutting: CO2 lasers with 0.1mm kerf compensation; nitrogen assist for flame-polished edges on acrylic

CNC Machining: 5-axis milling with climb-cut strategies to prevent chip recutting in thick sections

Thermoforming: Vacuum-forming up to 10mm ABS with active cooling to minimize shrinkage

Finishing: Automated edge polishing achieving 80 Ra surface quality for optical applications

Material handling employs vacuum lift systems to prevent surface marring, with in-process CMM verification at critical stages.

Quality-Controlled Delivery

All parts undergo final inspection against ASME Y14.5 GD&T standards. For 10mm sheets, we verify:

Thickness tolerance: ±0.2mm across the entire surface

Flatness: ≤1.5mm deviation per square meter

Edge perpendicularity: ±0.5°

Certified material test reports and first-article inspection data ship with the order. Delivery occurs via tracked freight with custom foam-in-place packaging to prevent flexural damage during transit. Standard lead time is 6–9 business days from DFM approval.

Material Options for 10mm Sheeting

| Material | Max Sheet Size (mm) | Key Applications | Special Handling Notes |

|—————|———————|—————————|————————————–|

| Acrylic (PMMA)| 1220 x 2440 | Light guides, displays | Stress-relieved before machining |

| Polycarbonate | 1220 x 2440 | Enclosures, lenses | Requires humidity-controlled storage |

| ABS | 1220 x 2440 | Prototypes, housings | Annealing recommended post-cutting |

| HDPE | 1500 x 3000 | Chemical tanks, liners | Carbide tooling mandatory |

This integrated process leverages automation for speed while maintaining rigorous engineering oversight—ensuring 10mm plastic components meet functional requirements on the first iteration. Honyo’s specialization in thick-section plastics eliminates common pitfalls like thermal distortion or edge chipping inherent in standard fabrication approaches.

Start Your Project

Looking for high-quality 10mm plastic sheeting for your next project? Honyo Prototype offers precision-manufactured plastic sheet materials ideal for prototyping, industrial enclosures, signage, and more. With our advanced fabrication capabilities and strict quality control, we ensure consistent thickness, durability, and performance.

Our manufacturing facility is located in Shenzhen, leveraging efficient production processes to deliver reliable lead times and competitive pricing for both samples and bulk orders.

For inquiries or to request a quote, contact Susan Leo at [email protected]. Let Honyo Prototype be your trusted partner for engineered plastic solutions.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.