Contents

Manufacturing Insight: 1045 Steel Yield Strength

Material Context for 1045 Steel Yield Strength in Precision Manufacturing

Understanding the mechanical properties of 1045 steel is critical for component integrity in demanding applications. As a medium-carbon steel, 1045 exhibits a typical yield strength of 530 MPa (77 ksi) in the cold-drawn condition per ASTM A108, though this value varies significantly with heat treatment and processing. Its balance of strength, machinability, and cost-effectiveness makes it a frequent choice for shafts, pins, and structural elements where moderate hardness and wear resistance are required. However, leveraging its full potential demands precise control over machining parameters to mitigate work hardening tendencies and maintain dimensional accuracy during CNC operations.

Honyo Prototype’s CNC Machining Expertise for 1045 Steel Components

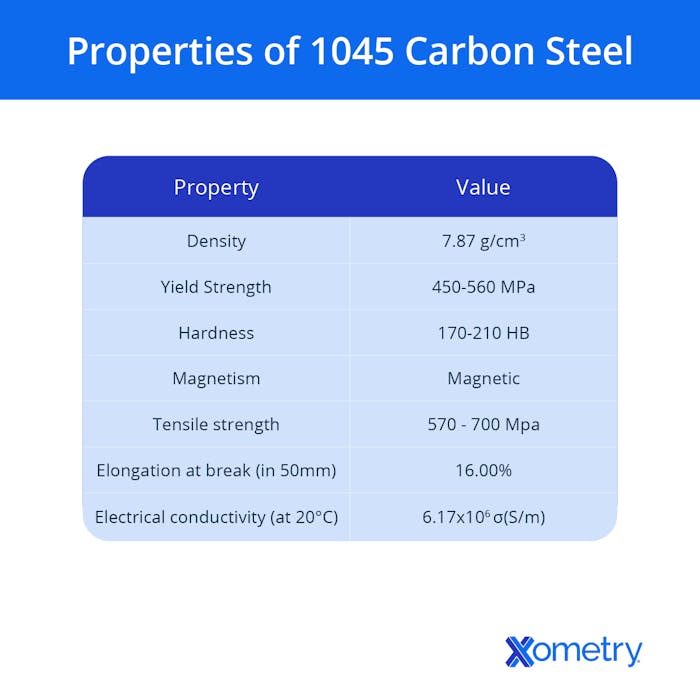

At Honyo Prototype, we specialize in transforming 1045 steel billets into high-tolerance components through advanced CNC milling, turning, and grinding processes. Our engineering team optimizes toolpaths and cutting strategies specifically for 1045’s characteristics, ensuring consistent yield strength retention and surface finish while minimizing residual stress. This precision is validated through in-house material testing and adherence to ISO 2768-mK geometric tolerancing standards. Below are key mechanical properties of 1045 steel relevant to machined part performance:

| Condition | Yield Strength (MPa) | Tensile Strength (MPa) | Hardness (HB) |

|---|---|---|---|

| Annealed | 310 | 565 | 170 |

| Cold-Drawn | 530 | 625 | 197 |

| Normalized | 360 | 600 | 187 |

Accelerate Your 1045 Steel Prototyping with Instant Quoting

For engineering teams prioritizing speed without compromising quality, Honyo Prototype offers an industry-leading Online Instant Quote system. Upload your 1045 steel part CAD file, specify material condition and tolerances, and receive a detailed manufacturability analysis with pricing in under 60 seconds. This eliminates traditional quoting delays, enabling rapid iteration for prototypes and low-volume production runs. Our CNC facility maintains tight control over the entire process—from raw material certification to final inspection—ensuring your 1045 steel components meet exact yield strength and performance requirements.

Leverage Honyo’s technical mastery of 1045 steel machining to reduce time-to-test while guaranteeing material integrity. Start your project with a precise quote today.

Technical Capabilities

Technical Specifications for 1045 Steel Yield Strength and Machining Considerations

AISI 1045 steel is a medium carbon steel commonly used in precision machining applications due to its good balance of strength, hardness, and machinability. Its yield strength and mechanical properties significantly influence performance during 3-axis, 4-axis, and 5-axis milling and turning operations, especially when tight tolerances (±0.0005″ to ±0.005″) are required.

The following table outlines key technical specifications for AISI 1045 steel and comparative data for other commonly machined materials including Aluminum (6061-T6), Steel (1018), ABS, and Nylon (6/6). This provides context for material selection in high-precision CNC environments.

| Material | Tensile Strength (Ultimate) | Yield Strength (Typical) | Hardness (Brinell) | Machinability Rating | Thermal Conductivity (W/m·K) | Common Use in 3/4/5-Axis Machining |

|---|---|---|---|---|---|---|

| AISI 1045 Steel | 565–695 MPa (82–101 ksi) | 310–450 MPa (45–65 ksi) | 170–210 HB | 60% | 51.9 | High-strength components, shafts, tooling fixtures requiring tight tolerances and post-machining heat treatment |

| AISI 1018 Steel | 440 MPa (64 ksi) | 370 MPa (54 ksi) | 125–135 HB | 70% | 51.9 | General-purpose machining, pins, spindles; easier to machine than 1045 but lower strength |

| Aluminum 6061-T6 | 310 MPa (45 ksi) | 275 MPa (40 ksi) | 95 HB | 90% | 167 | Aerospace, enclosures, prototypes; excellent for high-speed 5-axis milling with tight tolerance requirements |

| ABS (Thermoplastic) | 41 MPa (6 ksi) | N/A (Ductile failure) | 100–110 Shore D | 100%+ | 0.19 | Low-wear prototypes, jigs, and fixtures; suitable for high-speed turning and milling without tool wear concerns |

| Nylon 6/6 | 80 MPa (11.6 ksi) | N/A (Non-yielding) | 85–90 Shore D | 85% | 0.25 | Insulating components, bushings; requires sharp tools and stable setups due to material flex and thermal expansion |

Notes on Machining 1045 Steel for Tight Tolerance Applications:

Yield Strength Impact on Tooling: The relatively high yield strength of 1045 steel (compared to aluminum and plastics) necessitates the use of rigid tooling, high-torque spindles, and carbide end mills during 3/4/5-axis milling. Tool deflection must be minimized to maintain dimensional accuracy.

Turning Considerations: In CNC turning, 1045 steel responds well to controlled feed rates and positive rake inserts. Pre- and post-heat treatment (annealed vs. normalized/heat-treated) significantly affects machinability and final dimensional stability.

Tight Tolerance Stability: 1045 steel exhibits good dimensional stability after stress relief, making it suitable for parts requiring tolerances down to ±0.001″. However, residual stresses from prior processing must be managed to avoid post-machining distortion.

Material Comparison: While aluminum and plastics like ABS and nylon offer easier and faster machining, they lack the structural integrity required for high-load applications. 1045 steel is selected when strength and wear resistance are critical, even at the cost of increased tool wear and machining time.

For optimal results in multi-axis CNC environments, proper fixturing, coolant application, and toolpath strategies (e.g., climb milling, adaptive clearing) are essential when machining 1045 steel to tight tolerances.

From CAD to Part: The Process

Honyo Prototype’s workflow for ensuring 1045 steel yield strength compliance follows a rigorously defined sequence integrating material science with precision manufacturing. This process guarantees the final component meets the critical mechanical property requirement of minimum 530 MPa yield strength per ASTM A29 standards.

CAD Upload and Material Specification

Upon receiving the client’s CAD file, our engineering team immediately verifies the explicit material designation “1045 steel” within the model properties or drawing notes. We cross-reference this against ASTM A29 specifications to confirm baseline requirements, including the mandatory yield strength threshold. Any ambiguity in material callout triggers an automated client query before proceeding, preventing downstream non-conformance.

AI-Powered Quoting with Material Intelligence

Our proprietary quoting AI analyzes the CAD geometry while embedding 1045 steel’s physical properties into cost and lead time calculations. The system factors in yield strength implications: thicker sections requiring specific heat treatment parameters to achieve uniform 530+ MPa yield strength increase machining complexity and thermal processing time. Real-time material cost data from certified mills is integrated, reflecting current 1045 steel pricing volatility.

DFM Analysis Focused on Yield Strength Integrity

During Design for Manufacturability review, our engineers specifically assess features that could compromise yield strength. This includes evaluating:

Section thickness transitions that may cause uneven cooling during quenching

Tight tolerance zones near heat-affected areas from welding or cutting

Surface finish requirements that could introduce stress risers below 1.6 μm Ra

We provide actionable feedback if design elements risk localized yield strength reduction below 530 MPa, such as recommending fillet radii adjustments or heat treatment zone modifications.

Production Execution with Material Certification

Production initiates only after receiving the certified mill test report (MTR) for the specific 1045 steel batch. Key steps include:

1. Material verification: Incoming stock undergoes chemical composition spot-checking via OES spectrometry

2. Heat treatment: Strictly controlled quenching (water or polymer) followed by tempering at 540°C minimum to achieve target yield strength

3. In-process validation: Hardness testing at multiple points correlates directly to yield strength using ASTM E140 conversion

The following table details critical process controls for 1045 steel yield strength:

| Process Stage | Parameter | Control Limit | Verification Method |

|---|---|---|---|

| Material Receipt | Carbon Content | 0.43-0.50% | OES Spectrometry |

| Heat Treatment | Tempering Temperature | ≥540°C | Dual thermocouples + data logger |

| Post-Treatment | Surface Hardness | 197-217 HB | Rockwell B scale (5 locations) |

| Final Inspection | Yield Strength | ≥530 MPa | ASTM E8 tensile test (witness coupon) |

Delivery with Traceable Certification

Every shipment includes the full MTR from the steel mill plus Honyo’s supplementary test documentation. This contains:

Witness coupon tensile test results showing actual yield strength values

Heat treatment furnace calibration records

Hardness mapping of critical component zones

Traceability to the specific steel ingot number

This documentation package provides auditable proof that the delivered part maintains 1045 steel’s required mechanical properties throughout its structure, mitigating the client’s liability risk in end-use applications.

Start Your Project

For detailed technical specifications on 1045 steel yield strength and material certifications, contact Susan Leo at [email protected]. As a trusted manufacturing partner with an ISO-certified factory in Shenzhen, Honyo Prototype delivers precision-engineered components using high-quality 1045 steel, ideal for applications requiring balanced strength and machinability. Reach out today to request material data sheets or discuss your project requirements.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.