Introduction: Navigating the Global Market for 1045 cold rolled steel

In today’s competitive landscape, sourcing high-quality 1045 cold rolled steel can be a daunting challenge for international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe. With various suppliers and fluctuating market conditions, ensuring the right material for critical applications—such as manufacturing gears, shafts, and machine parts—requires a strategic approach. This guide aims to demystify the complexities of the global market for 1045 cold rolled steel, providing insights into types, specifications, applications, and essential supplier vetting processes.

The scope of this guide extends beyond mere product descriptions; it delves into the technical specifications that set 1045 cold rolled steel apart, including its mechanical properties and processing advantages. Additionally, we explore cost considerations, procurement strategies, and best practices for establishing reliable supplier relationships. By equipping buyers with actionable knowledge and clear evaluation criteria, this guide empowers them to make informed purchasing decisions that align with their operational needs.

Whether you are a seasoned procurement specialist or new to the industry, understanding the nuances of 1045 cold rolled steel will enhance your ability to navigate the global market effectively. The insights provided herein are designed to support your strategic sourcing efforts, ensuring that you secure the right materials to drive your business forward.

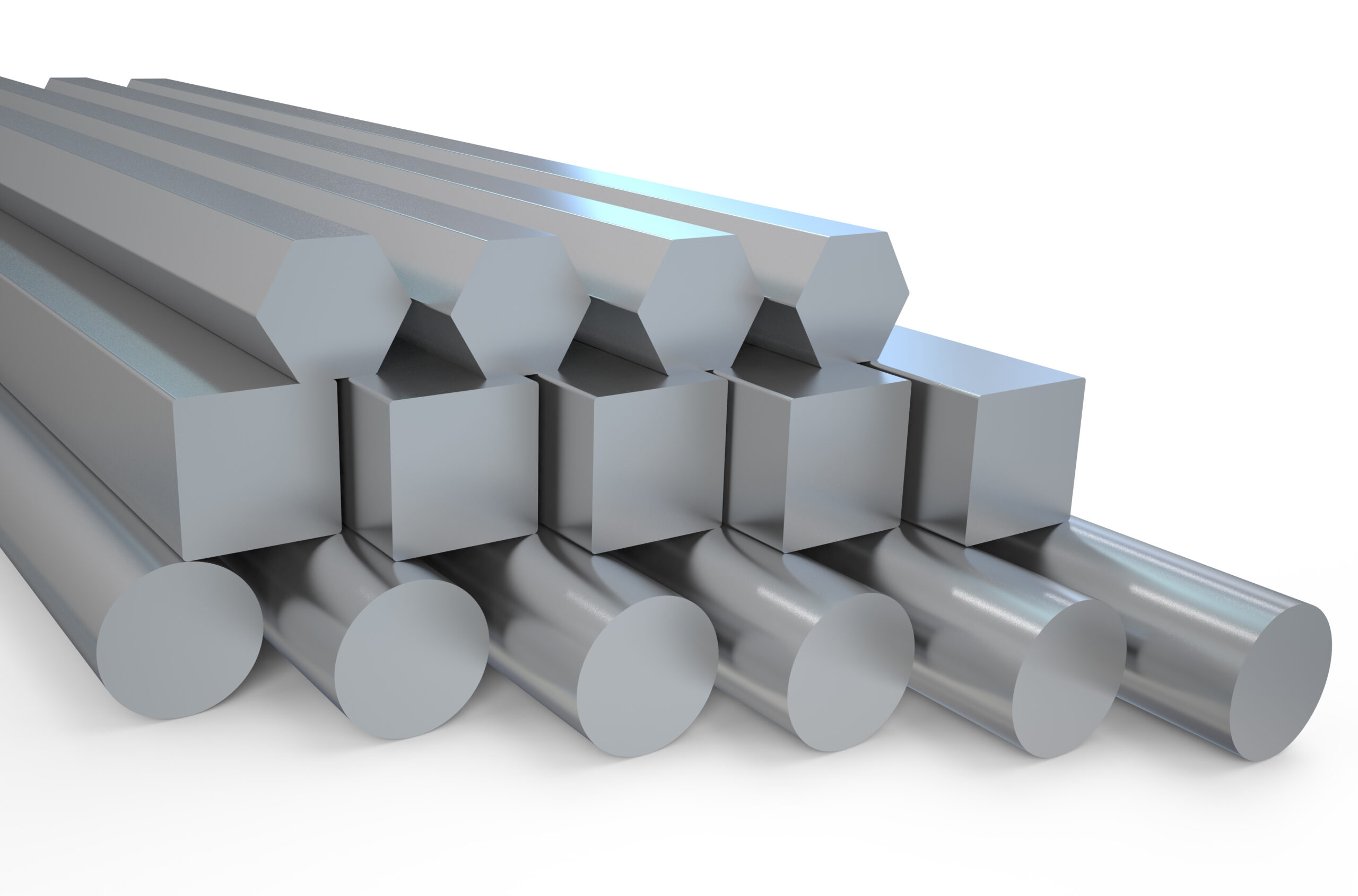

Understanding 1045 cold rolled steel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 1045 Cold Rolled Round Bar | High strength, smooth finish, precise dimensions | Gears, shafts, axles, machine parts | Pros: Excellent strength and precision. Cons: Poor corrosion resistance. |

| 1045 Cold Rolled Flat Bar | Flat profile, enhanced surface finish | Structural applications, brackets, supports | Pros: Good for welding and machining. Cons: Limited in applications requiring bending. |

| 1045 Cold Rolled Hex Bar | Hexagonal shape, enhanced grip for fastening | Fasteners, bolts, custom parts | Pros: Better torque and grip. Cons: More expensive than round bars. |

| 1045 Cold Rolled Ground Bar | Ground finish, tighter tolerances | Precision machining, high-performance parts | Pros: Superior dimensional accuracy. Cons: Higher cost due to processing. |

| 1045 Cold Rolled Square Bar | Square profile, versatile application | Construction, fabrication, tooling | Pros: Easy to handle and machine. Cons: May require additional machining for specific uses. |

What Are the Characteristics of 1045 Cold Rolled Round Bars?

1045 Cold Rolled Round Bars are characterized by their high strength and smooth surface finish, achieved through the cold rolling process. This type of steel is commonly utilized in applications where precision and durability are paramount, such as in the manufacturing of gears, shafts, and various machine parts. B2B buyers should consider the high tensile strength and dimensional accuracy, which minimizes wear in high-speed applications. However, it’s important to note that this type of steel has poor corrosion resistance, making it less suitable for outdoor or humid environments.

How Do 1045 Cold Rolled Flat Bars Differ in Use?

1045 Cold Rolled Flat Bars feature a flat profile that enhances their usability in structural applications. These bars are often used for brackets, supports, and other structural components where welding and machining are required. The flat shape allows for easy handling and installation, making it a preferred choice for many fabricators. Buyers should weigh the benefits of good weldability and machining ease against the limitations in applications that require bending or forming.

What Are the Benefits of 1045 Cold Rolled Hex Bars?

1045 Cold Rolled Hex Bars offer a unique hexagonal shape that enhances grip for fastening applications. This type is ideal for creating bolts and custom parts that need to be securely fastened. The hex shape allows for better torque application compared to round bars, making them suitable for high-stress environments. However, buyers should consider the cost implications, as hex bars can be more expensive than their round counterparts.

Why Choose 1045 Cold Rolled Ground Bars for Precision Machining?

1045 Cold Rolled Ground Bars are known for their superior finish and tighter tolerances, making them ideal for precision machining applications. These bars undergo additional grinding processes, resulting in enhanced dimensional accuracy. They are particularly suitable for high-performance parts where precision is critical. However, the additional processing leads to a higher cost, which buyers must account for when budgeting for their projects.

What Versatility Do 1045 Cold Rolled Square Bars Offer?

1045 Cold Rolled Square Bars provide versatility in various applications, from construction to tooling. Their square profile makes them easy to handle and machine, allowing for a wide range of uses in fabrication and manufacturing. While they are advantageous for projects requiring precise dimensions, buyers should be aware that specific applications may necessitate further machining to meet exact specifications. This could lead to additional costs and time considerations.

Key Industrial Applications of 1045 cold rolled steel

| Industry/Sector | Specific Application of 1045 cold rolled steel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Manufacturing of axles and shafts | High strength and durability in critical components | Consistent material quality and precise dimensions |

| Industrial Machinery | Production of gears and machine parts | Enhanced performance and reduced wear | Availability in various sizes and custom machining |

| Construction | Use in structural components and fasteners | Increased load-bearing capacity | Compliance with international standards and certifications |

| Oil & Gas | Components for drilling equipment and pipelines | Reliability in high-stress environments | Sourcing from reputable suppliers with traceability |

| Aerospace | Parts for aircraft and satellite structures | Lightweight with high tensile strength | Certification for aerospace-grade materials |

How is 1045 Cold Rolled Steel Used in the Automotive Industry?

In the automotive sector, 1045 cold rolled steel is primarily utilized for manufacturing axles and shafts. These components require high strength and durability to withstand the stresses of operation. By using 1045 steel, manufacturers can ensure longevity and reliability, critical for maintaining vehicle performance. International buyers should focus on suppliers that can guarantee consistent material quality and precise dimensions to meet stringent automotive standards.

What Role Does 1045 Cold Rolled Steel Play in Industrial Machinery?

1045 cold rolled steel is commonly used in the production of gears and machine parts, where enhanced performance and reduced wear are paramount. The cold rolling process improves surface finish and mechanical properties, making it ideal for precision fabrication. Buyers in this sector should prioritize sourcing from suppliers who offer a range of sizes and custom machining options to meet specific operational requirements.

How is 1045 Cold Rolled Steel Applied in Construction?

In construction, 1045 cold rolled steel is favored for structural components and fasteners due to its increased load-bearing capacity. This medium carbon steel provides the necessary strength while being adaptable for various applications. For international buyers, it is crucial to ensure that the sourced materials comply with local and international standards, ensuring safety and structural integrity.

Why is 1045 Cold Rolled Steel Essential in the Oil & Gas Industry?

The oil and gas industry relies on 1045 cold rolled steel for components in drilling equipment and pipelines. The material’s reliability in high-stress environments is vital for operational safety and efficiency. When sourcing, companies should seek reputable suppliers who provide materials with traceability and compliance with industry-specific certifications, ensuring that the products can withstand the demanding conditions of the field.

How is 1045 Cold Rolled Steel Beneficial in Aerospace Applications?

In the aerospace sector, 1045 cold rolled steel is used for parts in aircraft and satellite structures, where lightweight yet high tensile strength is crucial. This steel allows for the fabrication of components that meet the rigorous demands of flight. Buyers in this industry should ensure that their suppliers can provide certification for aerospace-grade materials to meet regulatory requirements and maintain safety standards.

3 Common User Pain Points for ‘1045 cold rolled steel’ & Their Solutions

Scenario 1: Difficulty in Obtaining Accurate Specifications

The Problem:

B2B buyers often face challenges when sourcing 1045 cold rolled steel due to the lack of standardized specifications across different suppliers. This inconsistency can lead to issues such as incorrect dimensions, variations in mechanical properties, and even non-compliance with industry standards. For instance, a buyer in the automotive sector may require specific tensile strength characteristics for components, and if the supplier fails to meet these requirements, it can cause significant production delays and safety risks.

The Solution:

To overcome this challenge, buyers should develop a detailed specification sheet that outlines all necessary parameters, including chemical composition, mechanical properties, and dimensional tolerances. When contacting suppliers, request Material Test Reports (MTRs) to verify compliance with ASTM A108 standards. Additionally, engaging in a pre-purchase dialogue can clarify these specifications. Consider establishing relationships with trusted suppliers who can provide consistent quality and transparency in their offerings. This proactive approach not only mitigates the risk of receiving subpar materials but also enhances the overall supply chain efficiency.

Scenario 2: Challenges with Machinability and Processing

The Problem:

Another common pain point is the machinability of 1045 cold rolled steel. While it offers good strength and surface finish, it is known for poor machinability compared to other materials. B2B buyers, particularly those in manufacturing sectors, might encounter difficulties when machining parts, leading to increased tooling costs and extended production times. For example, if a company is producing precision gears, the difficulty in achieving tight tolerances can compromise the quality of the final product.

The Solution:

To address machinability issues, buyers should consider the following strategies: first, select the appropriate cutting tools designed for medium carbon steels, such as high-speed steel (HSS) or carbide tools, which can withstand the material’s hardness. Additionally, using proper machining parameters—like optimized cutting speeds and feeds—can significantly enhance performance. Implementing cooling methods, such as flood coolant or mist lubrication, can also help reduce heat buildup during machining. Furthermore, conducting a thorough assessment of the required tolerances before starting production will guide the selection of appropriate machining processes, ensuring that parts meet quality standards without excessive rework.

Scenario 3: Limited Corrosion Resistance Concerns

The Problem:

1045 cold rolled steel is known for its strength but falls short in terms of corrosion resistance. This limitation can be a significant concern for buyers in industries like construction or marine applications, where components are often exposed to harsh environments. For instance, a company manufacturing machinery for coastal applications may find that untreated 1045 steel components corrode quickly, leading to premature failure and costly repairs.

The Solution:

To combat corrosion issues, buyers should consider applying protective coatings to 1045 cold rolled steel components. Options include galvanization, powder coating, or applying rust-inhibiting paints. Additionally, selecting stainless steel or alloys with better corrosion resistance for critical applications can be a more viable long-term solution. It is also advisable to evaluate the environmental conditions where the steel will be used and to develop a maintenance plan that includes regular inspections and touch-ups of protective coatings. By proactively addressing corrosion concerns, companies can significantly extend the lifespan of their steel components and reduce total lifecycle costs.

Strategic Material Selection Guide for 1045 cold rolled steel

What Are the Key Properties of 1045 Cold Rolled Steel?

1045 cold rolled steel is a medium carbon steel known for its strength and hardness. Its chemical composition typically includes around 0.45% carbon, 0.8% manganese, and minimal amounts of sulfur and phosphorus. This composition allows for a tensile strength of approximately 90,600 psi and a yield strength of 76,900 psi, making it suitable for applications requiring high strength and durability. However, its corrosion resistance is limited, which necessitates protective coatings or treatments in certain environments.

What Are the Pros and Cons of Using 1045 Cold Rolled Steel?

When considering 1045 cold rolled steel for various applications, it is essential to weigh its advantages against potential drawbacks.

Pros:

– Durability: The medium carbon content provides enhanced strength and wear resistance, making it ideal for high-stress applications like gears, shafts, and machine parts.

– Machinability: While it has fair machining characteristics, it is generally easier to work with than higher carbon steels, allowing for precision fabrication.

– Cost-Effectiveness: Compared to higher alloy steels, 1045 offers a balance of performance and cost, making it a popular choice in various industries.

Cons:

– Corrosion Resistance: 1045 cold rolled steel has poor resistance to corrosion, which can limit its use in harsh environments without additional protective measures.

– Welding Challenges: While it can be welded, the process may require preheating and post-weld heat treatment to avoid cracking, complicating manufacturing processes.

– Limited Formability: The material does not lend itself well to forming operations, which may necessitate additional processing steps for certain applications.

How Does 1045 Cold Rolled Steel Impact Specific Applications?

The application of 1045 cold rolled steel is primarily influenced by its mechanical properties and limitations. For example, its high strength makes it suitable for manufacturing components like axles and bolts that are subjected to significant loads. However, its poor corrosion resistance means that in applications exposed to moisture or corrosive substances, additional protective measures such as coatings or plating are necessary.

International B2B buyers should also consider the compatibility of 1045 with specific media; for instance, it performs well in mechanical applications but may not be suitable for environments involving aggressive chemicals.

What Should International B2B Buyers Consider When Sourcing 1045 Cold Rolled Steel?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several factors come into play when sourcing 1045 cold rolled steel. Compliance with local standards is crucial; for example, ASTM A108 is the relevant standard in the U.S., while European buyers may refer to EN standards. Understanding these standards ensures that the material meets the necessary quality and safety requirements.

Additionally, buyers should consider logistical aspects such as shipping costs, lead times, and supplier reliability. In regions with limited access to certain grades of steel, establishing relationships with reliable suppliers can significantly impact project timelines and costs.

Summary Table of 1045 Cold Rolled Steel Material Selection

| Material | Typical Use Case for 1045 Cold Rolled Steel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| 1045 Cold Rolled Steel Bar | Gears, shafts, machine parts | High strength and durability | Poor corrosion resistance | Medium |

| 1045 Cold Rolled Round Bar | Axles, bolts, studs | Excellent machinability | Requires careful welding techniques | Medium |

| 1045 Cold Rolled Steel Plate | Structural components | Cost-effective for high-performance | Limited formability | Medium |

| 1045 Cold Rolled Steel Rod | Precision engineering applications | Enhanced surface finish and strength | Needs protective coatings in corrosive environments | Medium |

This table summarizes the key aspects of 1045 cold rolled steel, helping international B2B buyers make informed decisions based on their specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for 1045 cold rolled steel

What Are the Key Manufacturing Processes for 1045 Cold Rolled Steel?

The production of 1045 cold rolled steel involves several critical stages that ensure the material meets specific performance standards suitable for various applications. Understanding these processes can help B2B buyers make informed decisions when sourcing this steel type.

What Are the Main Stages of Manufacturing 1045 Cold Rolled Steel?

-

Material Preparation:

The process begins with the selection of high-quality raw materials, typically in the form of hot-rolled steel. The 1045 steel is characterized by its medium carbon content, which provides a balance between strength and ductility. The raw material undergoes a series of inspections to ensure compliance with chemical composition specifications, including carbon (C), manganese (Mn), sulfur (S), and phosphorus (P) levels. -

Forming:

After preparation, the steel is subjected to cold rolling. This technique involves passing the hot-rolled steel through a series of rollers at room temperature to reduce its cross-section while increasing its length. Cold rolling enhances the material’s surface finish, strength, and dimensional accuracy. The resulting round bars exhibit a smooth dark grey finish and precise dimensions, making them suitable for applications like gears, shafts, and machine parts. -

Heat Treatment (if applicable):

Depending on the end-use requirements, the cold-rolled steel may undergo heat treatment processes such as quenching and tempering. These processes alter the mechanical properties, enhancing hardness and strength, which can be crucial for high-stress applications. -

Finishing:

The final stage involves surface treatments, which may include grinding, polishing, or coating. This step is essential for improving corrosion resistance and ensuring that the steel meets specific aesthetic and functional requirements. The finishing process also helps eliminate any surface defects that may have occurred during rolling.

How Is Quality Assurance Implemented in 1045 Cold Rolled Steel Production?

Quality assurance (QA) is integral to the manufacturing process of 1045 cold rolled steel, ensuring that the final product meets both international standards and customer specifications.

What International Standards Are Relevant for Quality Assurance?

B2B buyers should be aware of various international quality standards that manufacturers of 1045 cold rolled steel may adhere to, including:

- ISO 9001: This standard outlines criteria for a quality management system, emphasizing consistent quality in products and services.

- ASTM A108: This specification covers cold-finished carbon steel bars, defining the chemical composition and mechanical properties of 1045 steel.

- CE Marking: For buyers in Europe, CE marking indicates compliance with EU safety and environmental requirements.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is typically divided into several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC):

Upon receiving raw materials, manufacturers conduct inspections to verify that they meet specified chemical and physical properties. This step ensures that only suitable materials proceed to the manufacturing stage. -

In-Process Quality Control (IPQC):

During the cold rolling and finishing processes, continuous monitoring takes place. Operators check dimensions, surface finish, and mechanical properties at various stages to identify and rectify any deviations from specifications promptly. -

Final Quality Control (FQC):

Once the manufacturing process is complete, a comprehensive final inspection is conducted. This includes non-destructive testing methods such as ultrasonic testing and magnetic particle inspection to detect internal and surface defects.

What Testing Methods Are Commonly Used for 1045 Cold Rolled Steel?

Several testing methods are employed to ensure the quality and reliability of 1045 cold rolled steel:

- Tensile Testing: Measures the ultimate tensile strength and yield strength to ensure the steel meets the required mechanical properties.

- Hardness Testing: Commonly performed using Brinell or Rockwell hardness tests to confirm that the material has the desired hardness levels.

- Impact Testing: Assesses the material’s toughness and ability to withstand sudden loads.

How Can B2B Buyers Verify Supplier Quality Assurance?

When sourcing 1045 cold rolled steel, B2B buyers should take proactive steps to verify the quality assurance processes of their suppliers:

-

Supplier Audits:

Conducting audits of potential suppliers can provide insight into their manufacturing processes and quality control measures. Buyers should assess the supplier’s adherence to international standards and their commitment to quality. -

Quality Reports and Certificates:

Requesting material test reports (MTRs) and certifications from suppliers can provide documentation of compliance with relevant standards. This information is crucial for verifying the quality of the steel being purchased. -

Third-Party Inspections:

Utilizing third-party inspection services can further ensure that the steel meets the required specifications. Independent inspectors can provide unbiased evaluations of the manufacturing process and final products.

What Are the Quality Control and Certification Nuances for International Buyers?

International buyers, particularly those from Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control and certification:

- Regional Standards Compliance: Buyers must ensure that the steel meets not only international standards but also any regional requirements specific to their market.

- Documentation and Traceability: It is essential to maintain detailed documentation of all quality control processes, as this can facilitate smoother customs clearance and compliance with local regulations.

- Cultural and Language Considerations: Effective communication with suppliers is vital. Understanding local practices and languages can help mitigate misunderstandings related to quality expectations.

By thoroughly understanding the manufacturing processes and quality assurance measures for 1045 cold rolled steel, B2B buyers can make informed decisions, ensuring that they source materials that meet their specific needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘1045 cold rolled steel’

In this guide, we aim to equip B2B buyers with a comprehensive checklist for sourcing 1045 cold rolled steel. This medium carbon steel is widely used for its strength and versatility, making it essential for various applications. By following these steps, you can ensure a smooth procurement process and secure high-quality materials for your projects.

Step 1: Define Your Technical Specifications

Understanding your project requirements is the first step in sourcing 1045 cold rolled steel. Define the exact dimensions, tolerances, and mechanical properties you need, such as yield strength and hardness. This clarity will help you communicate effectively with suppliers and ensure that the material meets your engineering standards.

- Key properties to consider:

- Ultimate tensile strength: 90,600 psi

- Yield tensile strength: 76,900 psi

- Hardness: Brinell 180

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers with a strong reputation in the industry. Look for companies that specialize in cold rolled steel and have experience supplying to your specific sector. Reviews, ratings, and case studies can provide valuable insights into their reliability and service quality.

- Where to look:

- Industry directories and trade associations

- Online marketplaces with supplier ratings

Step 3: Evaluate Supplier Certifications

Before making a commitment, verify that your selected suppliers hold relevant certifications, such as ISO 9001 or ASTM compliance. These certifications indicate that the supplier adheres to quality management principles and industry standards, ensuring the reliability of their products.

- What to ask for:

- Copies of certifications

- Quality control processes they employ

Step 4: Request Material Samples

Always request samples of the 1045 cold rolled steel before placing a bulk order. This allows you to assess the material’s quality, surface finish, and dimensions. Ensure that the samples align with your specified technical requirements.

- What to inspect:

- Surface finish and any signs of defects

- Compliance with your requested specifications

Step 5: Assess Pricing and Payment Terms

Once you have identified potential suppliers, compare their pricing structures and payment terms. It’s essential to consider both the cost of the material and any additional charges such as shipping, taxes, or import duties. Favor suppliers who offer transparent pricing and flexible payment options.

- Key considerations:

- Bulk order discounts

- Payment terms: upfront, net 30, or other arrangements

Step 6: Understand Lead Times and Delivery Options

Inquire about lead times for production and delivery, as these can significantly impact your project timelines. Ensure that the supplier can meet your deadlines and discuss logistics options to minimize delays.

- Questions to ask:

- What is the typical lead time for your orders?

- Do you offer expedited shipping services?

Step 7: Establish a Communication Plan

Effective communication is vital throughout the procurement process. Establish a clear point of contact at the supplier’s organization and set expectations for regular updates on order status and any potential issues that may arise.

- What to include in your plan:

- Frequency of updates (weekly, bi-weekly)

- Preferred communication channels (email, phone, messaging apps)

By following this structured checklist, B2B buyers can enhance their sourcing strategy for 1045 cold rolled steel, ensuring that they select the right suppliers and materials for their needs.

Comprehensive Cost and Pricing Analysis for 1045 cold rolled steel Sourcing

What Are the Key Cost Components in Sourcing 1045 Cold Rolled Steel?

When sourcing 1045 cold rolled steel, understanding the cost structure is crucial for effective budgeting and negotiation. The primary cost components include:

-

Materials: The base cost of 1045 cold rolled steel is influenced by the market price of raw materials, primarily iron and carbon. Price fluctuations can occur due to global supply chain dynamics, geopolitical factors, and demand from various industries.

-

Labor: Labor costs encompass the wages of workers involved in the manufacturing and processing of the steel. Skilled labor is often required for precise machining and quality assurance, which can elevate costs.

-

Manufacturing Overhead: This includes expenses related to utilities, equipment maintenance, and facilities. Efficient production processes can help reduce overhead costs, making it essential to choose suppliers with optimized operations.

-

Tooling: The cost of tools and dies used in the cold rolling process is significant. Custom tooling can drive costs up, particularly for specialized specifications.

-

Quality Control (QC): Ensuring the steel meets required standards involves testing and inspection, contributing to overall costs. Suppliers with robust QC processes may charge higher prices but offer better reliability.

-

Logistics: Transportation costs can vary widely based on the supplier’s location, delivery method, and the buyer’s destination. International logistics can introduce additional complexities, such as tariffs and customs duties.

-

Margin: Suppliers will add a margin to cover their costs and profit. Understanding typical margins in your region can aid in negotiations.

How Do Price Influencers Impact the Cost of 1045 Cold Rolled Steel?

Several factors can influence the pricing of 1045 cold rolled steel, making it essential for buyers to consider these in their procurement strategies:

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly impact unit prices. Larger orders typically reduce the per-unit cost, making it economically beneficial to consolidate purchases.

-

Specifications/Customization: Custom specifications may lead to higher costs due to additional processing or tooling requirements. Standard sizes and grades generally incur lower costs.

-

Materials Quality/Certifications: Higher quality materials and certifications (e.g., ASTM standards) can affect pricing. Buyers should assess whether the additional costs align with their project requirements.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more but offer better quality assurance and service.

-

Incoterms: The terms of shipping (Incoterms) can affect overall costs. For instance, choosing Ex Works (EXW) may result in lower initial costs but higher logistics expenses later.

What Are Effective Buyer Tips for Negotiating 1045 Cold Rolled Steel Prices?

To optimize procurement costs for 1045 cold rolled steel, international buyers should consider the following strategies:

-

Negotiate Volume Discounts: Leverage larger orders to negotiate better prices. Establishing a long-term relationship with a supplier can also lead to favorable pricing terms.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, assess long-term costs, including maintenance, logistics, and potential downtime. This holistic view can guide better purchasing decisions.

-

Understand Pricing Nuances for International Sourcing: Familiarize yourself with local market conditions, currency fluctuations, and import tariffs that may impact pricing. Building relationships with local suppliers can mitigate risks associated with international sourcing.

-

Request Detailed Quotations: Always ask for comprehensive quotes that break down costs. This transparency allows for better comparisons and identifies areas where negotiations may be possible.

-

Stay Informed on Market Trends: Keeping abreast of industry trends and material costs can help in timing purchases effectively, potentially securing better deals during price dips.

Disclaimer on Pricing

Prices for 1045 cold rolled steel are indicative and can fluctuate based on market conditions, supplier pricing strategies, and global economic factors. It is advisable for buyers to obtain multiple quotes and conduct thorough research to ensure competitive pricing.

Alternatives Analysis: Comparing 1045 cold rolled steel With Other Solutions

Introduction to Alternatives in Steel Solutions

When selecting materials for industrial applications, understanding the range of available options is crucial for making informed decisions. 1045 cold rolled steel is a popular choice due to its strength and versatility. However, several alternatives exist that may offer distinct advantages depending on specific project requirements. This analysis compares 1045 cold rolled steel with alternatives such as 1018 cold rolled steel and 4140 alloy steel, each presenting unique characteristics that can impact performance, cost, and application suitability.

Comparison Table

| Comparison Aspect | 1045 Cold Rolled Steel | 1018 Cold Rolled Steel | 4140 Alloy Steel |

|---|---|---|---|

| Performance | High strength, medium carbon | Lower strength, good for machining | Superior strength, excellent toughness |

| Cost | Moderate | Lower | Higher |

| Ease of Implementation | Straightforward | Easy to work with | More complex (requires specific heat treatment) |

| Maintenance | Moderate | Low | Moderate |

| Best Use Case | Gears, shafts, machine parts | Structural components, general fabrication | High-stress applications, tooling |

Detailed Breakdown of Alternatives

1018 Cold Rolled Steel

1018 cold rolled steel is often regarded as a more economical option, especially for applications where high strength is not a primary concern. It offers excellent machinability and is easier to weld compared to 1045. However, its lower carbon content results in reduced strength and hardness, making it less suitable for heavy-duty applications. It excels in structural components and general fabrication tasks, making it a go-to for cost-sensitive projects.

4140 Alloy Steel

4140 alloy steel is a robust alternative that provides superior strength and toughness, making it ideal for high-stress applications such as tooling, gears, and heavy machinery parts. While it comes at a higher cost, its performance benefits often justify the investment, particularly in demanding environments. However, the complexity of its heat treatment process can complicate implementation, requiring skilled labor and precise control during fabrication. Its maintenance level is moderate, as it can withstand significant wear and tear.

Conclusion: How to Choose the Right Steel Solution for Your Needs

For B2B buyers evaluating material options, the choice between 1045 cold rolled steel and its alternatives hinges on specific application requirements. If high strength and performance are paramount, 4140 alloy steel may be the most suitable choice despite its higher cost and complexity. Conversely, for projects prioritizing cost-efficiency with adequate performance, 1018 cold rolled steel could be the better fit. Ultimately, understanding the trade-offs in performance, cost, and ease of implementation will empower buyers to select the most appropriate material for their unique needs.

Essential Technical Properties and Trade Terminology for 1045 cold rolled steel

What Are the Key Technical Properties of 1045 Cold Rolled Steel?

Understanding the essential technical properties of 1045 cold rolled steel is crucial for B2B buyers, especially those sourcing materials for manufacturing and industrial applications. Here are the critical specifications you should be aware of:

1. Material Grade

1045 cold rolled steel is classified as medium carbon steel. This grade offers a balance of strength and ductility, making it suitable for a variety of applications, including machinery and automotive components. For B2B buyers, selecting the appropriate material grade ensures that the end product meets performance requirements and operational standards.

2. Chemical Composition

The chemical composition of 1045 steel typically includes approximately 0.45% carbon, 0.8% manganese, and negligible amounts of sulfur and phosphorus. Understanding these elements is essential for predicting the material’s behavior during processing and its performance in applications. For instance, the higher carbon content contributes to increased hardness and strength, which are vital in high-stress environments.

3. Mechanical Properties

Key mechanical properties of 1045 cold rolled steel include:

– Ultimate Tensile Strength: Approximately 90,600 psi (625 MPa), indicating its capability to withstand heavy loads before failing.

– Yield Strength: About 76,900 psi (530 MPa), which is crucial for understanding how much stress the material can endure before deforming permanently.

– Hardness: Brinell hardness of 180 and Rockwell B89, reflecting the material’s resistance to deformation and wear. These properties are fundamental for B2B buyers looking for durable and reliable materials.

4. Tolerance and Dimensions

Cold rolled steel bars are known for their exceptional dimensional accuracy and surface finish. The tolerances on these bars are typically tighter than those of hot rolled steel, which minimizes waste and improves machining efficiency. For B2B operations, maintaining strict tolerances is essential for ensuring that components fit correctly in assemblies and perform as expected.

5. Surface Finish

The cold rolling process results in a smooth, dark grey surface that is often oiled to prevent corrosion. This surface quality not only enhances aesthetics but also improves the performance of the steel in machining operations. Buyers should consider this property when evaluating the suitability of 1045 steel for specific applications, as it can reduce the need for additional finishing processes.

What Are Common Trade Terms Related to 1045 Cold Rolled Steel?

Familiarity with trade terminology is vital for effective communication and negotiation in the B2B landscape. Here are some common terms related to 1045 cold rolled steel:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. Understanding the OEM landscape is crucial for buyers looking to source components that will fit seamlessly into existing systems.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is important for buyers to manage inventory and cash flow effectively, especially when considering bulk purchases of 1045 steel.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. For B2B buyers, crafting a clear RFQ for 1045 cold rolled steel can facilitate better negotiations and ensure that all specifications are met.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce, defining the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for B2B buyers engaged in cross-border trade, as they influence shipping costs, risk management, and delivery timelines.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. For B2B buyers, especially in regions with longer supply chains, understanding lead times for 1045 cold rolled steel can impact project timelines and inventory management.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, ensuring that they select the right materials and engage effectively with suppliers.

Navigating Market Dynamics and Sourcing Trends in the 1045 cold rolled steel Sector

What Are the Current Market Trends Impacting 1045 Cold Rolled Steel?

The 1045 cold rolled steel sector is experiencing notable growth driven by increased demand for high-strength materials in various industries, including automotive, machinery, and construction. Global market dynamics are influenced by factors such as technological advancements in manufacturing processes, rising infrastructure projects, and the ongoing shift towards automation. In regions like Africa and South America, where industrialization is accelerating, the demand for durable and precise materials like 1045 cold rolled steel is expected to rise significantly.

Emerging B2B technologies, such as advanced inventory management systems and digital supply chain platforms, are reshaping sourcing strategies. International buyers are increasingly leveraging these tools to enhance efficiency, reduce costs, and improve transparency in their supply chains. Furthermore, the integration of predictive analytics in sourcing decisions helps businesses anticipate market fluctuations, ensuring timely procurement of materials.

Another key trend is the growing emphasis on customization and just-in-time delivery. Suppliers that can offer tailored solutions and flexible ordering systems are gaining a competitive edge. In Europe, for instance, manufacturers are focusing on shorter lead times and enhanced customer service, which aligns with the lean manufacturing practices prevalent in the region.

How Are Sustainability and Ethical Sourcing Shaping the 1045 Cold Rolled Steel Market?

Sustainability is becoming a cornerstone of sourcing strategies in the 1045 cold rolled steel sector. The environmental impact of steel production is significant, leading to increased scrutiny from consumers and regulatory bodies alike. B2B buyers are now prioritizing suppliers who adopt sustainable practices, such as reducing carbon emissions and optimizing energy use during production.

Ethical sourcing is also gaining traction, with businesses looking to ensure that their supply chains are free from unethical labor practices and environmentally harmful processes. Certifications such as ISO 14001 (Environmental Management) and responsible sourcing initiatives are becoming critical factors in supplier selection. Buyers are increasingly asking for documentation that verifies sustainable practices, emphasizing the importance of transparency in supply chains.

Moreover, the demand for ‘green’ materials is on the rise. Suppliers that can demonstrate the use of recycled content in their 1045 cold rolled steel products or those that engage in circular economy practices are likely to attract more business. This trend not only aligns with corporate social responsibility goals but also appeals to a growing segment of environmentally conscious consumers and businesses.

How Has the 1045 Cold Rolled Steel Sector Evolved Over Time?

The evolution of the 1045 cold rolled steel sector can be traced back to advancements in steel manufacturing processes that have significantly improved the quality and performance of steel products. Initially, 1045 steel was primarily used in applications requiring moderate strength and hardness. However, with the introduction of cold rolling techniques, the material’s mechanical properties have been enhanced, making it suitable for more demanding applications, such as precision machined components.

Over the years, the global market for 1045 cold rolled steel has expanded, driven by industrial growth in emerging economies and advancements in engineering applications. This evolution reflects a broader trend in materials science, where the focus has shifted towards producing higher-performance materials that meet the stringent requirements of modern manufacturing. As industries continue to innovate, the demand for 1045 cold rolled steel is expected to remain robust, highlighting its pivotal role in contemporary engineering solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of 1045 cold rolled steel

-

1. How do I choose the right supplier for 1045 cold rolled steel?

When selecting a supplier for 1045 cold rolled steel, evaluate their reputation, reliability, and industry experience. Request references and check online reviews. Ensure they can provide certifications for quality standards, such as ASTM A108, and inquire about their production capabilities. Communication is key; choose a supplier who is responsive and can meet your specific requirements, including lead times and customization options. -

2. What are the common applications of 1045 cold rolled steel?

1045 cold rolled steel is widely used in manufacturing components that require higher strength and hardness. Common applications include gears, shafts, axles, bolts, and machine parts. Its excellent machinability and enhanced mechanical properties make it suitable for precision fabrication in various industries, including automotive, aerospace, and machinery manufacturing. -

3. What are the typical payment terms for international orders of 1045 cold rolled steel?

Payment terms can vary by supplier but typically include options such as upfront payment, letters of credit, or payment upon delivery. For international transactions, it’s advisable to discuss payment methods that offer protection, such as escrow services or bank guarantees. Always clarify the currency used and any potential additional costs related to customs and taxes. -

4. How can I ensure the quality of 1045 cold rolled steel before purchase?

To ensure quality, request material test reports that verify the chemical composition and mechanical properties of the steel. Suppliers should provide certifications that comply with international standards. Conducting an independent inspection can also be beneficial, especially for large orders. Establishing a clear quality assurance process with the supplier upfront will help prevent issues down the line. -

5. What is the minimum order quantity (MOQ) for 1045 cold rolled steel?

MOQs for 1045 cold rolled steel can vary significantly between suppliers, often depending on their production capabilities and inventory levels. Generally, MOQs can range from a few hundred kilograms to several tons. It is advisable to discuss your specific needs with the supplier to negotiate terms that suit your order size. -

6. How does the cold rolling process affect the properties of 1045 steel?

The cold rolling process enhances the surface finish and mechanical properties of 1045 steel, resulting in improved strength, dimensional accuracy, and surface smoothness. This process also contributes to better wear resistance compared to hot-rolled steel, making cold rolled 1045 an ideal choice for applications requiring tight tolerances and high-performance characteristics. -

7. What logistical considerations should I be aware of when importing 1045 cold rolled steel?

When importing 1045 cold rolled steel, consider factors such as shipping costs, delivery times, and customs regulations in your country. Ensure your supplier can provide the necessary documentation for customs clearance, including invoices, packing lists, and certificates of origin. It is wise to work with logistics experts who understand the intricacies of international shipping to avoid delays and additional fees. -

8. Can I customize my order of 1045 cold rolled steel?

Yes, many suppliers offer customization options for 1045 cold rolled steel, including specific dimensions, lengths, and surface treatments. Discuss your requirements with the supplier to determine what modifications can be accommodated. Be clear about your specifications and desired outcomes to ensure the final product meets your operational needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 1045 Cold Rolled Steel Manufacturers & Suppliers List

1. Core Mark Metals – 1045 Cold Rolled Round Bar

Domain: coremarkmetals.com

Registered: 2018 (7 years)

Introduction: 1045 Cold Rolled Round Bar

– Description: 1045 cold rolled round bars are suitable for various processing techniques, featuring a smooth dark grey oiled surface with accurate dimensions. It is a medium carbon steel used for applications requiring greater strength and hardness than the ‘as rolled’ condition. Common applications include gears, shafts, axles, bolts, studs, and machine parts.

– Featur…

2. Alro – 1045 Cold Finished Steel Bar

Domain: alro.com

Registered: 1996 (29 years)

Introduction: {“product_name”: “1045 Cold Finished Steel Bar”, “alternative_names”: [“1045 CF Bar”, “1045 CF Medium Steel Bar”], “chemical_composition”: {“Carbon”: “0.42%-0.50%”, “Manganese”: “0.60%-0.90%”, “Phosphorous”: “0.04% (Max)”, “Sulfur”: “0.05% (Max)”}, “properties”: {“Tensile_Strength”: “91,000 PSI”, “Yield_Strength”: “75,000 PSI”, “Elongation”: “16%”}, “typical_uses”: [“Gears”, “Hydraulic Shafts”, “P…

3. Online Metals – 1 Carbon Steel Round Bar 1045 Cold Finish

Domain: onlinemetals.com

Registered: 1997 (28 years)

Introduction: {‘name’: ‘1″ Carbon Steel Round Bar 1045 Cold Finish’, ‘part_number’: ‘21682’, ‘diameter’: ‘1 inch’, ‘max_length’: ‘144 inches’, ‘alloy’: ‘1045’, ‘production_method’: ‘Cold Finished’, ‘material’: ‘Carbon Steel’, ‘shape’: ‘Bar-Round’, ‘weight_per_lineal_foot’: ‘2.67 pounds’, ‘material_specifications’: [‘ASTM-A108’, ‘ASTM-A29’], ‘mechanical_properties’: {‘density’: ‘8 g/cm^3’, ‘yield_tensile_strengt…

4. Metal Supermarkets – Mild Steel Round Bar Cold Rolled 1045

Domain: metalsupermarkets.com

Registered: 1996 (29 years)

Introduction: {“product_name”: “Mild Steel Round Bar Cold Rolled 1045”, “material”: “1045 medium-carbon steel”, “process”: “cold-rolled”, “specifications”: {“ASTM”: “A108”, “machining_grinding”: “Excellent”, “welding”: “Fair”, “bending_forming”: “Fair”, “wear_resistance”: “Fair”, “corrosion_resistance”: “Poor”}, “characteristics”: “Precision-engineered steel bar with enhanced surface finish and strength, suitab…

5. Eaton Steel – 1045 Cold Drawn Steel Bar

Domain: eatonsteel.com

Registered: 1996 (29 years)

Introduction: {“product_name”: “1045 Cold Drawn Steel Bar”, “description”: “Medium carbon steel grade with higher mechanical properties, fair weldability, and limited formability. Widely available and commonly stocked due to excellent properties and cost.”, “standards”: [“ASTM A108”, “ASTM A576”, “JDM QL-2 certified”], “sizes_available”: “1/4″-8″”, “shapes_available”: [“Rounds”, “Hexagon”, “Square”], “minimum_o…

6. Stock Car Steel – 1045 Cold Rolled Steel Round Bar

Domain: stockcarsteel.com

Registered: 2002 (23 years)

Introduction: 1045 Cold Rolled Steel Round Bar, Diameter: Various sizes available, Material: 1045 steel, Finish: Cold rolled, Applications: Suitable for machining, manufacturing, and construction, Properties: High strength, good machinability, and weldability.

7. MatWeb – Material Data Solutions

Domain: matweb.com

Registered: 1997 (28 years)

Introduction: This company, MatWeb – Material Data Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

8. All Metals Inc – Steel Cold Rolled Ground & Polished Round Bar 3/4

Domain: allmetalsinc.com

Registered: 1999 (26 years)

Introduction: {‘product_name’: ‘Steel Cold Rolled Ground & Polished Round Bar 3/4″‘, ‘grade’: ‘1045’, ‘diameter’: ‘0.750 Inches’, ‘length’: ‘Customer Input’, ‘weight_per_foot’: ‘1.5 Pounds’, ‘price’: ‘$6.81 USD’, ‘saw_cut_tolerance’: ‘-0″ to +1/8″‘, ‘finish’: ‘ground, mirror-like’}

9. Speedy Metals – 1045 Cold Roll Steel

Domain: speedymetals.com

Registered: 2001 (24 years)

Introduction: {“material”:”1045 Cold Roll”,”type”:”silicon killed medium carbon steel”,”standards”:”ASTM A29, A108″,”applications”:[“machinery parts”,”die forging”,”hot upsetting”,”gears”,”crankshafts”,”shafts”,”axles”,”bolts”,”studs”,”pinions”,”casters”,”support plates”],”machinability”:”64% of B1112″,”average_cutting_speed”:”95-120 ft/min”,”weldability”:”not readily welded; preheating necessary for thicker se…

Strategic Sourcing Conclusion and Outlook for 1045 cold rolled steel

In navigating the complexities of sourcing 1045 cold rolled steel, B2B buyers must prioritize strategic partnerships and supplier reliability. The unique properties of 1045 steel, such as its medium carbon content and enhanced mechanical strength, make it an ideal choice for a range of applications including gears, axles, and machine parts. By leveraging competitive pricing, precise specifications, and the ability to source custom sizes, businesses can optimize their production processes and reduce operational costs.

Furthermore, understanding regional market dynamics is crucial. For buyers in Africa, South America, the Middle East, and Europe, forming alliances with reputable suppliers can lead to better procurement strategies and access to high-quality materials. As the demand for durable and high-performance materials continues to rise, the ability to source effectively will play a pivotal role in maintaining a competitive edge.

Looking ahead, now is the time to refine your sourcing strategies for 1045 cold rolled steel. Engage with suppliers who can provide not only quality products but also insights into market trends and innovations. Take proactive steps today to ensure your business is positioned for success in an increasingly competitive landscape.