Contents

Manufacturing Insight: 1018 Steel Ultimate Tensile Strength

Understanding 1018 Steel Ultimate Tensile Strength for Precision CNC Applications

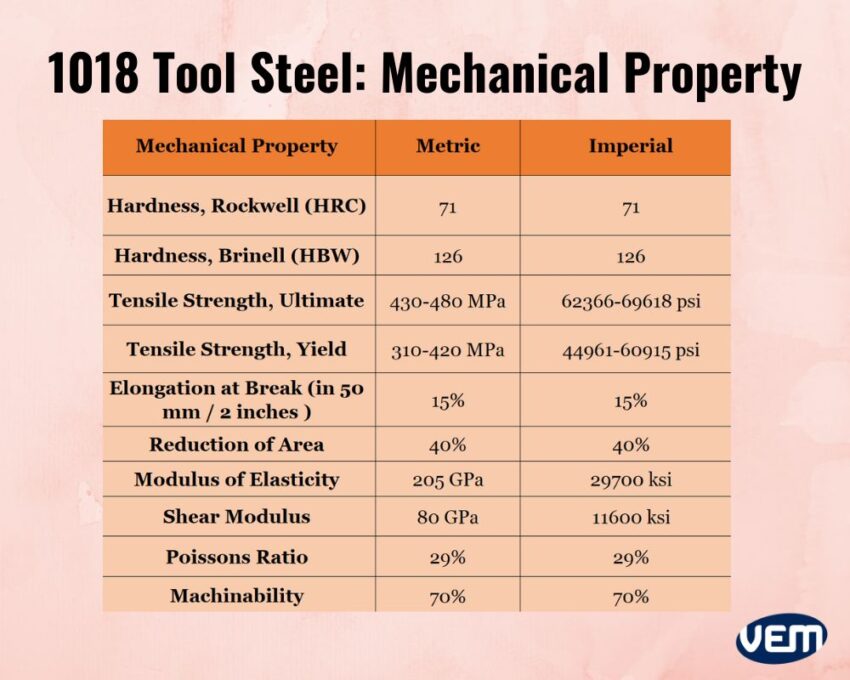

As a widely specified low-carbon steel in prototyping and production, AISI 1018 steel offers a balanced combination of machinability, weldability, and moderate strength. Its typical ultimate tensile strength (UTS) ranges from 440 MPa (63.8 ksi) to 470 MPa (68.2 ksi) under standard annealed conditions per ASTM A276. This predictable mechanical profile makes 1018 a pragmatic choice for non-critical structural components, shafts, pins, and jigs where moderate load resistance is sufficient. However, achieving consistent part performance requires precise control over machining parameters to avoid compromising material integrity through heat generation or residual stress.

Honyo Prototype excels in CNC machining 1018 steel with engineered precision, leveraging optimized toolpaths, coolant strategies, and in-process metrology to maintain dimensional accuracy while preserving the material’s inherent strength characteristics. Our ISO 9001-certified processes ensure that every machined component meets stringent tolerances without inducing unintended work hardening or surface defects that could affect fatigue life.

Material selection is only the first step; execution determines reliability. Below is a comparative overview of 1018 steel against common alternatives:

| Material | Typical UTS (MPa) | Typical UTS (ksi) | Primary Machining Advantage |

|---|---|---|---|

| AISI 1018 | 440–470 | 63.8–68.2 | Excellent machinability, cost-effective |

| AISI 1045 | 570–630 | 82.7–91.4 | Higher strength, moderate machinability |

| 304 Stainless | 515–620 | 74.7–89.9 | Corrosion resistance, tougher to machine |

For projects requiring 1018 steel’s specific balance of performance and economy, Honyo Prototype delivers rapid, high-fidelity components without sacrificing repeatability. Our technical team collaborates early in the design phase to advise on feature optimization for machinability and structural integrity, ensuring your part performs as intended under operational loads.

Accelerate your development timeline with Honyo’s Online Instant Quote platform. Input your 1018 steel part geometry, tolerances, and quantity to receive a detailed, no-obligation manufacturing assessment within hours—not days. This integrated system factors in material-specific machining complexities to provide transparent, accurate pricing from the outset. Visit Honyo Prototype’s website to leverage our instant quoting capability and experience CNC machining precision engineered for real-world application demands.

Technical Capabilities

Technical Specifications for 1018 Steel – Ultimate Tensile Strength and Machinability in Precision Machining Applications

1018 steel is a low-carbon steel known for its excellent weldability, good machinability, and uniformity in mechanical properties. It is commonly used in precision machining operations such as 3-axis, 4-axis, and 5-axis milling, as well as CNC turning, especially when tight tolerances (±0.0005″ to ±0.005″) are required. Its moderate strength and ductility make it suitable for parts requiring case hardening or moderate structural performance.

Below is a comparison of 1018 steel with other commonly machined materials—aluminum (6061-T6), steel (1018), ABS, and nylon—highlighting key mechanical properties and machinability characteristics relevant to high-precision CNC operations.

| Material | Ultimate Tensile Strength (UTS) | Yield Strength | Elongation at Break | Hardness (Brinell) | Machinability Rating (%) | Typical Tolerance Range (inches) | Notes for 3/4/5-Axis Milling & Turning |

|---|---|---|---|---|---|---|---|

| 1018 Steel | 63,800 psi (440 MPa) | 53,700 psi | 15% | 126 HB | 70% | ±0.001″ to ±0.0005″ | Excellent dimensional stability; produces clean cuts with sharp HSS or carbide tools; minimal work hardening; ideal for tight-tolerance features and threaded components |

| Aluminum 6061-T6 | 45,000 psi (310 MPa) | 40,000 psi | 8–12% | 95 HB | 90% | ±0.001″ to ±0.0005″ | High material removal rate; requires proper chip evacuation; low cutting forces allow high-speed 5-axis milling; prone to thermal expansion |

| ABS (Plastic) | 6,000 psi (41 MPa) | 4,500 psi | 3.5% | 80–100 HB | 80% | ±0.005″ to ±0.002″ | Low melting point; requires sharp tools and light cuts; minimal clamping force; suitable for prototypes and non-structural components |

| Nylon 6/6 | 10,000 psi (69 MPa) | 8,000 psi | 60–120% | 85 HB | 60% | ±0.005″ to ±0.002″ | High moisture absorption; prone to dimensional shift; requires pre-drying; flexible; best for low-friction wear parts |

Key Considerations for Machining 1018 Steel in High-Precision Applications:

Tooling: Use coated carbide end mills and inserts for extended tool life. Recommended spindle speeds: 600–1,200 SFM for turning; 400–800 SFM for milling.

Coolant: Soluble oil or synthetic coolant is recommended to minimize built-up edge and maintain dimensional accuracy.

Fixturing: Due to higher rigidity and cutting forces compared to aluminum and plastics, ensure robust fixturing—especially in 5-axis operations where tool reach may affect stability.

Tolerance Control: 1018 steel responds well to tight tolerance machining due to consistent microstructure and low internal stress. Final passes should use minimal depth of cut (<0.005″) for surface finish and accuracy.

Post-Processing: Often case hardened or plated for wear resistance. Passivation or painting may be applied for corrosion protection.

In summary, 1018 steel offers a balanced combination of strength, machinability, and dimensional consistency, making it a preferred material for precision-machined components in automation, fixtures, and mechanical assemblies—particularly when compared to softer materials like ABS and nylon, or higher-strength alloys requiring more aggressive tooling strategies.

From CAD to Part: The Process

Honyo Prototype ensures 1018 steel components meet ultimate tensile strength (UTS) requirements through a rigorously controlled end-to-end process. As a low-carbon steel, 1018’s UTS is primarily governed by material specification and processing rather than direct manufacturing manipulation. Our workflow guarantees compliance with ASTM A29/A29M standards where UTS for cold-drawn 1018 is typically 440 MPa (63,800 psi) minimum, with typical values ranging 490–530 MPa (71,000–77,000 psi).

CAD Upload

Customers submit CAD files specifying material grade (1018 steel) and critical features. Our system automatically checks for material callouts against ASTM standards. If 1018 is not explicitly designated or if UTS-sensitive features exist (e.g., thin sections, high-stress geometries), we initiate an engineering review before proceeding. Material certification requirements are flagged here to ensure downstream traceability.

AI Quote Generation

Our AI engine cross-references the CAD geometry with 1018 steel’s mechanical properties, including UTS ranges. Material costs are calculated based on certified mill-test-report (MTR) compliance. The quote explicitly states that UTS adherence depends on certified material sourcing and standard processing—no artificial UTS enhancement is performed unless special heat treatment is requested (not standard for 1018). Non-compliant designs triggering UTS risks (e.g., sharp notches) are flagged for DFM intervention.

DFM Analysis

This phase is critical for ensuring the part achieves required strength, even if the material UTS is certified. Our engineers:

Verify that design features won’t inadvertently reduce effective strength below UTS requirements (e.g., stress concentrators in load paths).

Confirm that wall thicknesses and section geometries maintain structural integrity per applied loads.

Recommend adjustments if machining processes (e.g., aggressive corner radii) could compromise strength margins.

Document all strength-related assumptions for production validation. Note that 1018 UTS is not altered during standard machining; cold working may slightly increase surface hardness but does not significantly elevate bulk UTS.

Production

Material procurement mandates certified 1018 steel with full MTRs validating UTS against ASTM A29. All stock is quarantined until MTRs are verified in our QMS. Machining uses optimized parameters to prevent thermal stress or work hardening that could affect localized properties. For critical applications, we conduct in-process hardness spot checks (correlating to tensile strength via ASTM E140) but do not retest UTS unless specified.

Delivery

Every shipment includes:

The original mill-certified MTR confirming 1018 UTS compliance.

A Honyo-produced certificate of conformance (CoC) linking part serial numbers to MTR lot numbers.

DFM documentation detailing how strength-critical features were validated.

No additional UTS testing occurs unless contracted upfront; our process relies on certified material and geometric integrity to ensure the component meets design strength requirements.

Key UTS Compliance Data for 1018 Steel

| Parameter | ASTM A29 Requirement | Typical Honyo-Supplied Range | Verification Method |

|——————–|———————-|—————————-|—————————|

| Ultimate Tensile Strength | ≥ 440 MPa (63,800 psi) | 490–530 MPa (71,000–77,000 psi) | Mill Test Report (MTR) |

| Condition | Cold Drawn | Cold Drawn | MTR + CoC |

| Traceability | Lot-controlled | Full lot traceability | MTR/CoC cross-reference |

This process ensures 1018 components inherently meet UTS specifications through material certification and geometric fidelity—not post-production strength modification. Design-driven strength validation during DFM remains essential, as UTS is a bulk material property unaffected by standard machining. For applications requiring elevated strength, we recommend alternative alloys (e.g., 1045, 4140) with appropriate heat treatment.

Start Your Project

For detailed specifications on 1018 steel ultimate tensile strength and material certifications, contact Susan Leo at [email protected]. Honyo Prototype operates a precision manufacturing facility in Shenzhen, providing high-quality metal fabrication and prototyping services with strict adherence to material performance standards. Reach out for technical data sheets, lead times, and project consultation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.