Introduction: Navigating the Global Market for 1 8 inch gauge steel

In today’s competitive landscape, sourcing 1/8 inch gauge steel presents a significant challenge for international B2B buyers, particularly those operating in regions like Africa, South America, the Middle East, and Europe. The complexity of the global market demands not only an understanding of gauge specifications but also insights into the diverse applications and potential suppliers. This guide aims to demystify the intricacies of 1/8 inch gauge steel, providing a comprehensive overview that includes various types, applications, and critical supplier vetting processes.

With the fluctuations in pricing and the varying standards across different regions, making informed purchasing decisions can be daunting. This guide empowers buyers by offering actionable insights into cost considerations, quality assessments, and the importance of understanding material specifications. By exploring the different applications of 1/8 inch gauge steel, from construction to manufacturing, we illuminate how this versatile material can meet specific project requirements.

Additionally, we emphasize the importance of selecting reputable suppliers who can deliver consistent quality and reliable service. Whether you are based in Vietnam or Germany, this guide serves as a vital resource for navigating the global market, ensuring that your sourcing decisions are strategic, informed, and aligned with your business objectives. By leveraging the insights provided, you can confidently procure 1/8 inch gauge steel that meets your operational needs.

Understanding 1 8 inch gauge steel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cold Rolled Steel | Smooth surface finish, high strength, and precision | Automotive, appliances, and furniture | Pros: Excellent surface finish; Cons: Prone to rust without coating. |

| Hot Rolled Steel | Less precise dimensions, lower cost, and versatile | Construction, manufacturing, and pipelines | Pros: Cost-effective; Cons: Rough surface; lower tensile strength than cold rolled. |

| Galvanized Steel | Coated with zinc for corrosion resistance | Outdoor structures, HVAC systems, roofing | Pros: Rust-resistant; Cons: Can be more expensive than non-coated steel. |

| Stainless Steel | High corrosion resistance and aesthetic appeal | Food processing, medical equipment, automotive | Pros: Durable and hygienic; Cons: Higher cost than carbon steel. |

| Aluminum Steel | Lightweight, corrosion-resistant, and malleable | Aerospace, automotive, and packaging | Pros: Lightweight; Cons: Generally less strong than steel. |

What are the Key Characteristics of Cold Rolled Steel?

Cold rolled steel is produced by rolling steel at room temperature, resulting in a smooth surface finish and enhanced strength. This type is ideal for applications requiring tight tolerances and high-quality aesthetics, such as automotive parts and furniture. Buyers should consider the necessity of protective coatings, as cold rolled steel can be prone to rust if left unprotected.

How Does Hot Rolled Steel Compare to Other Types?

Hot rolled steel is manufactured at high temperatures, allowing for easier shaping and forming. Although it has a rougher surface finish and less precise dimensions, its cost-effectiveness makes it a popular choice in construction and manufacturing. B2B buyers should weigh the benefits of lower costs against the potential need for additional finishing processes.

Why Choose Galvanized Steel for Outdoor Applications?

Galvanized steel is coated with zinc to enhance its corrosion resistance, making it suitable for outdoor environments and applications like HVAC systems and roofing. While it provides excellent protection against rust, it typically comes at a higher price point. Buyers should evaluate their budget against the long-term benefits of reduced maintenance costs due to corrosion resistance.

What Makes Stainless Steel a Preferred Choice in Certain Industries?

Stainless steel is renowned for its high corrosion resistance and aesthetic appeal, making it a preferred material in industries such as food processing and medical equipment. Its durability and hygiene properties add value, although it generally comes with a higher price tag compared to carbon steels. B2B buyers must consider the balance between initial costs and the longevity of the material.

How Does Aluminum Steel Serve Specific Market Needs?

Aluminum steel is lightweight and highly malleable, making it an ideal choice for applications in the aerospace and automotive sectors. Its corrosion resistance adds to its appeal, but it is generally less strong than traditional steel. Buyers should assess the specific strength requirements of their projects when considering aluminum as an alternative material.

Key Industrial Applications of 1 8 inch gauge steel

| Industry/Sector | Specific Application of 1 8 inch gauge steel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Structural components for vehicle frames and body panels | High strength-to-weight ratio improves vehicle efficiency and safety | Ensure compliance with international safety standards and quality certifications. |

| Construction | Roofing and siding materials for commercial buildings | Durable and weather-resistant, reducing maintenance costs | Consider local climate conditions and corrosion resistance requirements. |

| HVAC Systems | Ductwork and enclosures for heating and cooling systems | Efficient thermal performance and energy savings for end-users | Verify material compatibility with insulation and sealing materials. |

| Agricultural Equipment | Chassis and frames for farming machinery | Enhanced durability under heavy loads and harsh conditions | Assess the need for custom sizes and potential for local sourcing. |

| Fabrication and Metalworking | Custom parts and assemblies for various industrial applications | Versatile material allows for a wide range of applications and designs | Focus on precision cutting and fabrication capabilities of suppliers. |

How is 1 8 Inch Gauge Steel Used in Automotive Manufacturing?

In the automotive sector, 1 8 inch gauge steel is commonly employed to manufacture structural components such as vehicle frames and body panels. This gauge offers an optimal balance between strength and weight, contributing to enhanced vehicle efficiency and safety. For international buyers, particularly in regions like Europe and the Middle East, compliance with stringent safety regulations is paramount. Buyers should prioritize sourcing from manufacturers who adhere to recognized automotive standards and provide certifications.

What Role Does 1 8 Inch Gauge Steel Play in Construction?

Within the construction industry, 1 8 inch gauge steel is often utilized for roofing and siding materials in commercial buildings. Its durability and weather resistance make it an ideal choice for structures exposed to harsh environmental conditions, significantly reducing long-term maintenance costs. Buyers in Africa and South America should consider local climate factors and ensure that the steel is treated for corrosion resistance, particularly in coastal areas where salt exposure is a concern.

How is 1 8 Inch Gauge Steel Essential for HVAC Systems?

In HVAC applications, 1 8 inch gauge steel is utilized for ductwork and enclosures, ensuring efficient thermal performance and energy savings for end-users. This gauge provides the necessary strength to withstand the pressures of air movement while maintaining a lightweight profile. International buyers, especially in regions with varying climate conditions, should verify the compatibility of the steel with insulation and sealing materials to optimize system performance.

What is the Significance of 1 8 Inch Gauge Steel in Agricultural Equipment?

1 8 inch gauge steel finds significant application in the agricultural sector, particularly in the chassis and frames of farming machinery. This material’s high strength allows it to endure heavy loads and operate effectively in rugged conditions, which is crucial for agricultural productivity. Buyers should assess the potential need for custom sizes and consider the advantages of sourcing locally to reduce lead times and shipping costs.

Why is 1 8 Inch Gauge Steel Valuable in Fabrication and Metalworking?

In the fabrication and metalworking industries, 1 8 inch gauge steel is favored for custom parts and assemblies due to its versatility and ease of fabrication. This gauge allows for a wide range of applications, from industrial machinery to decorative elements. When sourcing, businesses should focus on suppliers that offer precision cutting and fabrication capabilities to ensure high-quality outputs that meet specific design requirements.

3 Common User Pain Points for ‘1 8 inch gauge steel’ & Their Solutions

Scenario 1: Difficulty in Sourcing Consistent Quality of 18 Gauge Steel

The Problem: B2B buyers often struggle to find suppliers who can deliver consistent quality when ordering 1/8 inch gauge steel. Variability in thickness, composition, and finish can lead to significant issues in production lines, affecting the integrity and performance of the final products. Buyers may face delays in production due to having to return subpar materials or rework components that do not meet specifications. This inconsistency can particularly impact industries such as construction and manufacturing, where precision is critical.

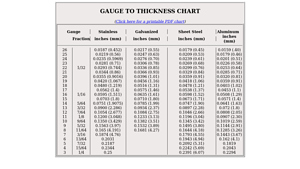

The Solution: To ensure the consistent quality of 1/8 inch gauge steel, buyers should establish long-term relationships with reputable suppliers known for their stringent quality control processes. Requesting material certifications and conducting regular audits can help verify that suppliers adhere to industry standards. Additionally, employing a standardized gauge conversion chart when ordering can mitigate misunderstandings regarding thickness. Leveraging technology, such as digital tracking systems, can also provide real-time data on material quality and delivery timelines, allowing for proactive management of supply chain issues.

Scenario 2: Misunderstanding the Gauge System and Specifications

The Problem: Many B2B buyers are not fully versed in the gauge system, leading to confusion when specifying 1/8 inch gauge steel. This lack of understanding can result in ordering the wrong material type, which can cause delays and increased costs. For instance, buyers might confuse 18 gauge steel with other materials like aluminum or stainless steel, leading to compatibility issues in their applications. This misunderstanding can be particularly prevalent in regions where international suppliers use different gauge standards.

The Solution: To overcome this challenge, buyers should invest time in educating themselves and their teams about the gauge systems and their implications. Utilizing detailed gauge conversion charts specific to their material needs can provide clarity and prevent costly mistakes. Furthermore, including clear specifications in purchase orders—such as intended use, required tolerances, and environmental conditions—can help suppliers deliver the appropriate material. Engaging with knowledgeable sales representatives who can explain the nuances of different gauge materials will also aid in making informed purchasing decisions.

Scenario 3: Challenges with Fabrication and Processing of 18 Gauge Steel

The Problem: Buyers in the manufacturing and construction sectors frequently encounter difficulties when fabricating or processing 1/8 inch gauge steel. Issues such as warping during cutting, difficulty in bending, and challenges in welding can arise if the steel is not properly suited for their specific applications. These complications not only slow down production but can also lead to wastage of materials and increased labor costs.

The Solution: To mitigate fabrication challenges, buyers should select 1/8 inch gauge steel specifically designed for their intended processing methods. For instance, if welding is a primary concern, sourcing steel with optimal carbon content for weldability is crucial. Implementing proper handling techniques, such as using temperature controls during cutting and bending processes, can help maintain material integrity. Collaborating with skilled fabricators who understand the characteristics of 1/8 inch gauge steel can further ensure that the processing methods used are appropriate for the material, thereby reducing the likelihood of complications and enhancing overall productivity.

Strategic Material Selection Guide for 1 8 inch gauge steel

What are the Key Properties of 18 Gauge Steel?

18 gauge steel, which measures approximately 0.0478 inches (1.214 mm) in thickness, is commonly utilized in various industrial applications due to its balance of strength and weight. This steel exhibits excellent tensile strength, making it suitable for applications requiring structural integrity under load. Additionally, it offers moderate corrosion resistance, especially when treated or coated, which is crucial for environments exposed to moisture or chemicals. Its ability to withstand moderate temperatures and pressures also makes it versatile across different sectors.

What are the Pros and Cons of Using 18 Gauge Steel?

When considering 18 gauge steel, several advantages stand out. It is relatively lightweight compared to thicker gauges, which can reduce shipping costs and ease handling during fabrication. The material is also cost-effective, making it an attractive option for large-scale projects. However, the thinner profile means it may not be suitable for high-stress applications or environments where heavy impact resistance is required. Additionally, the manufacturing process can be more complex due to the need for precision cutting and forming, which may increase production times.

How Does 18 Gauge Steel Impact Specific Applications?

The application of 18 gauge steel varies significantly based on its environment. In construction, it is often used for roofing, siding, and interior partitions, where its strength-to-weight ratio is beneficial. In the automotive industry, it can be found in body panels and frames, where durability is essential but excessive weight must be avoided. However, in industries dealing with highly corrosive materials, such as chemical processing, additional protective coatings may be necessary to prevent degradation over time.

What Should International B2B Buyers Consider When Sourcing 18 Gauge Steel?

International buyers, especially those from Africa, South America, the Middle East, and Europe, should be aware of compliance with local standards such as ASTM in the U.S., DIN in Germany, and JIS in Japan. These standards dictate the quality and performance characteristics of the steel, ensuring it meets specific safety and functionality requirements. Additionally, buyers should consider the availability of suppliers who can provide certifications for their products, as this can impact procurement decisions. Cultural preferences for certain materials or treatments may also influence purchasing choices, so understanding regional market trends is essential.

| Material | Typical Use Case for 1 8 inch gauge steel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Mild Steel | Automotive body panels and structural components | Cost-effective and widely available | Limited corrosion resistance | Low |

| Galvanized Steel | Roofing and siding applications | Excellent corrosion resistance | Higher cost due to galvanization process | Medium |

| Stainless Steel | Food processing equipment and chemical tanks | Superior corrosion resistance | Higher initial cost | High |

| Aluminum | Lightweight automotive and aerospace components | Lightweight and easy to fabricate | Lower strength compared to steel | Medium |

This table summarizes the essential aspects of various materials suitable for 18 gauge steel applications, providing B2B buyers with a quick reference for decision-making. Each material has unique properties that cater to specific use cases, ensuring that buyers can select the most appropriate option for their needs.

In-depth Look: Manufacturing Processes and Quality Assurance for 1 8 inch gauge steel

What Are the Main Stages in the Manufacturing Process of 18 Gauge Steel?

The manufacturing process for 18 gauge steel involves several critical stages, each essential for producing high-quality steel sheets that meet international standards. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with selecting high-quality raw materials, typically cold-rolled or hot-rolled steel coils. The steel is inspected for impurities and defects before being cut to specific dimensions. This initial quality check is crucial as it sets the foundation for subsequent processing stages.

-

Forming: The prepared steel sheets undergo forming processes, which can include techniques such as shearing, bending, and stamping. Shearing is often used to cut sheets to the desired sizes, while bending shapes the steel into specific angles as needed for various applications. Precision in this stage is vital to ensure that the final product meets specified tolerances.

-

Assembly: In cases where steel sheets are part of larger assemblies, components may be welded or fastened together. This stage requires a high level of skill to ensure that joints are strong and meet structural integrity standards. The assembly process may also involve the application of additional materials or components to enhance the functionality of the final product.

-

Finishing: The final stage includes surface treatments such as painting, galvanizing, or applying protective coatings. These treatments not only improve the aesthetic appeal of the steel but also enhance its corrosion resistance and durability. Quality checks at this stage ensure that the surface finish meets the required specifications.

What Key Techniques Are Used in Manufacturing 18 Gauge Steel?

Several techniques are employed throughout the manufacturing process of 18 gauge steel, ensuring that it meets the specific requirements of various industries.

-

Cold Rolling: This technique enhances the mechanical properties of steel by reducing thickness and improving surface finish without the need for heating. Cold rolling is particularly advantageous for producing thinner gauges like 18 gauge steel, as it allows for tighter tolerances.

-

Hot Rolling: While less common for 18 gauge steel, hot rolling can be used to produce thicker sheets. This method involves rolling the steel at high temperatures, which allows for easier shaping and forming.

-

Laser Cutting: For precision cutting, laser technology is increasingly being utilized. Laser cutting ensures clean edges and minimizes material waste, making it an attractive option for high-volume production.

-

Welding and Joining: Various welding techniques, such as MIG and TIG welding, are employed during the assembly stage. These methods provide strong joints and can be automated for increased efficiency.

How Is Quality Assurance Implemented in the Manufacturing of 18 Gauge Steel?

Quality assurance is paramount in the production of 18 gauge steel, ensuring that products meet both international standards and customer specifications. Several key practices are involved in this process.

-

International Standards Compliance: Manufacturers often adhere to ISO 9001, which outlines criteria for a quality management system. This certification demonstrates a commitment to consistent quality and customer satisfaction. Additionally, industry-specific standards such as CE marking for the European market and API for the oil and gas sector are crucial for ensuring that products meet regulatory requirements.

-

Quality Control Checkpoints: The quality control process typically includes several checkpoints:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards before production begins.

– In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify defects early, allowing for immediate corrective actions.

– Final Quality Control (FQC): After finishing, products undergo rigorous testing and inspection to verify that they meet all specifications before shipping. -

Common Testing Methods: Various testing methods are employed to assess the quality of 18 gauge steel, including:

– Mechanical Testing: Tensile tests, yield strength, and elongation tests evaluate the material’s mechanical properties.

– Dimensional Inspection: Calipers and micrometers are used to ensure that dimensions meet specified tolerances.

– Surface Inspection: Visual inspections and non-destructive testing methods such as ultrasonic testing can be employed to detect surface and subsurface defects.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential to ensure that products meet necessary standards.

-

Supplier Audits: Conducting audits of potential suppliers can provide insight into their manufacturing processes and quality control systems. These audits should assess compliance with international standards, production capabilities, and adherence to quality assurance practices.

-

Quality Assurance Reports: Requesting quality assurance reports from suppliers can provide detailed insights into their quality control processes and testing results. These documents should outline the methods used for quality assurance and any relevant certifications obtained.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s quality control processes. These inspectors can assess compliance with industry standards and verify that products meet the required specifications before shipment.

What Are the QC and Certification Nuances for International B2B Buyers?

Understanding the nuances of quality control and certification is crucial for international B2B buyers, especially when sourcing 18 gauge steel from different regions.

-

Regional Standards: Different regions may have varying standards for quality and safety. Buyers should familiarize themselves with local regulations and standards applicable to their industry to ensure compliance.

-

Certification Validity: It is essential to verify that suppliers’ certifications are current and relevant to the specific products being purchased. Regular updates and renewals of certifications are indicators of a supplier’s commitment to quality.

-

Cultural Considerations: Communication styles and business practices can vary significantly across regions. B2B buyers should be aware of these differences when establishing relationships with suppliers and negotiating terms.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance protocols for 18 gauge steel is vital for international B2B buyers. By focusing on these aspects, buyers can make informed decisions, ensuring they source high-quality materials that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘1 8 inch gauge steel’

Introduction

Sourcing 18 gauge steel can be a critical component in various manufacturing and construction projects. This guide provides a practical checklist to help B2B buyers navigate the procurement process effectively. By following these steps, you can ensure that you select the right suppliers, verify product quality, and make informed purchasing decisions.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline the technical specifications of the 18 gauge steel you require. This includes details such as dimensions, tolerances, and any specific standards that must be met (e.g., ASTM, ISO). Having a well-defined specification helps streamline communication with suppliers and ensures that the products meet your operational needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers of 18 gauge steel. Look for suppliers with a solid reputation in the industry, positive customer reviews, and a history of reliable service. Utilize online platforms, industry directories, and trade shows to gather a list of candidates, focusing on those with experience in your target markets, such as Africa, South America, or Europe.

Step 3: Evaluate Supplier Certifications

It’s crucial to verify that potential suppliers hold the necessary certifications and comply with relevant quality standards. Certifications such as ISO 9001 or specific industry-related certifications demonstrate a supplier’s commitment to quality management. Inquire about their quality control processes and whether they conduct regular inspections of their materials.

Step 4: Request Samples for Evaluation

Before placing a bulk order, request samples of the 18 gauge steel to assess quality and suitability for your application. This step allows you to evaluate the steel’s physical properties, such as thickness, finish, and overall integrity. Ensure that the samples are representative of the supplier’s typical output to make an informed decision.

Step 5: Compare Pricing and Payment Terms

Once you have gathered quotes from various suppliers, compare pricing while considering the total cost of ownership. Look beyond the initial price to include factors such as shipping costs, import duties, and potential tariffs, particularly for international purchases. Additionally, negotiate payment terms that align with your cash flow needs and assess the flexibility of each supplier in this regard.

Step 6: Assess Delivery Capabilities

Delivery timelines can significantly impact your project schedule, so it’s essential to evaluate the delivery capabilities of your chosen suppliers. Confirm lead times and inquire about their logistics processes, including shipping methods and tracking capabilities. Ensure that they can meet your timeline requirements without compromising quality.

Step 7: Establish Clear Communication Channels

Effective communication is vital throughout the sourcing process. Establish clear channels of communication with your suppliers to facilitate updates, inquiries, and issue resolution. Regular check-ins can help preempt potential delays and keep your project on track. Be sure to document all agreements and specifications in writing to avoid misunderstandings.

By following this checklist, B2B buyers can approach the procurement of 18 gauge steel with confidence, ensuring that they select the best suppliers and materials for their specific needs.

Comprehensive Cost and Pricing Analysis for 1 8 inch gauge steel Sourcing

What Are the Key Cost Components for 1/8 Inch Gauge Steel Sourcing?

When sourcing 1/8 inch gauge steel, several cost components must be considered to arrive at a comprehensive pricing structure. The primary elements include:

-

Materials: The base cost of steel fluctuates based on market conditions. Global demand, availability of raw materials, and geopolitical factors can significantly impact pricing. Buyers should stay informed on current market trends to negotiate effectively.

-

Labor: Labor costs encompass the wages for skilled workers involved in the manufacturing process. This varies by region; for example, labor costs in Europe may differ significantly from those in South America or Africa.

-

Manufacturing Overhead: This includes costs associated with running production facilities, such as utilities, equipment maintenance, and administrative expenses. Companies with higher operational efficiency often have lower overhead, which can translate into competitive pricing.

-

Tooling: Custom tooling or molds may be necessary for specific applications. The initial investment in tooling can be substantial, but it often leads to cost savings in large-scale production runs.

-

Quality Control (QC): Ensuring that the steel meets required specifications involves rigorous testing and quality assurance processes. These costs are essential to mitigate risks related to defects and compliance with industry standards.

-

Logistics: Transportation costs, including shipping and handling, play a crucial role in the total cost structure. Factors like distance, mode of transport, and Incoterms can significantly affect logistics expenses.

-

Margin: Suppliers typically add a profit margin to cover their risks and ensure sustainability. This margin can vary widely based on market competition and supplier reputation.

How Do Price Influencers Affect the Cost of 1/8 Inch Gauge Steel?

Several key factors influence the pricing of 1/8 inch gauge steel, making it imperative for buyers to understand these nuances:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in bulk often leads to discounts. However, some suppliers may have stringent MOQs, impacting smaller buyers’ ability to negotiate favorable terms.

-

Specifications and Customization: Custom orders can lead to higher prices due to the additional processing required. Clearly defining specifications upfront can help minimize unexpected costs.

-

Materials and Quality Certifications: The type of steel and its certifications (e.g., ASTM, ISO) significantly influence pricing. Higher-quality materials or those meeting specific industry standards typically come at a premium.

-

Supplier Factors: Supplier reliability, reputation, and location can all affect pricing. Engaging with established suppliers may yield better service and product quality, albeit at a potentially higher price.

-

Incoterms: Understanding shipping terms is crucial for cost management. Incoterms dictate the responsibilities of buyers and sellers regarding shipping costs, insurance, and liability, which can affect the total landed cost.

What Are the Best Negotiation Tips for B2B Buyers of 1/8 Inch Gauge Steel?

B2B buyers can adopt various strategies to enhance cost-efficiency when sourcing 1/8 inch gauge steel:

-

Leverage Total Cost of Ownership (TCO): Focus on the long-term value rather than just the upfront costs. This includes considering durability, maintenance, and potential waste reduction.

-

Negotiate Terms: Don’t hesitate to negotiate payment terms, delivery schedules, and service agreements. Flexibility on both sides can lead to better overall pricing.

-

Research Market Prices: Stay updated on market trends and pricing benchmarks. This knowledge empowers buyers during negotiations and helps identify fair pricing.

-

Build Relationships: Establishing long-term relationships with suppliers can lead to better deals and priority service. Trust and reliability can often yield more favorable terms.

-

Consider Local Suppliers: For international buyers, engaging with local suppliers can reduce logistics costs and complexities related to customs and tariffs.

Disclaimer on Pricing

Prices for 1/8 inch gauge steel can vary widely based on market conditions and specific buyer requirements. It is advisable to conduct thorough research and obtain multiple quotes to ensure competitive pricing. Always clarify terms with suppliers to avoid unexpected costs.

Alternatives Analysis: Comparing 1 8 inch gauge steel With Other Solutions

Understanding Alternatives to 1 8 Inch Gauge Steel

In the competitive landscape of industrial materials, 1 8 inch gauge steel is often favored for its strength and versatility. However, international B2B buyers may find themselves considering alternative materials that offer specific advantages tailored to their unique operational needs. This analysis will compare 1 8 inch gauge steel with two viable alternatives: aluminum sheets and fiberglass reinforced plastic (FRP).

Comparison of 1 8 Inch Gauge Steel and Alternatives

| Comparison Aspect | 1 8 Inch Gauge Steel | Aluminum Sheets | Fiberglass Reinforced Plastic (FRP) |

|---|---|---|---|

| Performance | High tensile strength; durable and impact-resistant. | Lightweight; good strength-to-weight ratio; corrosion-resistant. | Excellent chemical resistance; lightweight; good tensile strength. |

| Cost | Generally cost-effective; fluctuates with market steel prices. | Higher initial costs; price stability but may require thicker sheets for similar strength. | Moderate to high; often cost-effective in long-term use due to durability. |

| Ease of Implementation | Easy to work with; widely available; compatible with standard tools. | Requires specialized tools for cutting and shaping; more difficult to weld. | Easy to mold and shape; requires special adhesives for assembly. |

| Maintenance | Low maintenance; can be painted to prevent rust; susceptible to corrosion without treatment. | Low maintenance; resistant to rust and corrosion; may require surface treatment for aesthetics. | Very low maintenance; highly resistant to moisture and chemicals. |

| Best Use Case | Structural applications, automotive parts, and construction materials. | Aerospace, automotive, and marine applications where weight is critical. | Chemical processing, water treatment facilities, and environments prone to corrosion. |

In-Depth Look at Alternatives

Aluminum Sheets

Aluminum sheets provide a lightweight alternative to 1 8 inch gauge steel, making them particularly valuable in applications where weight reduction is critical, such as in aerospace and automotive industries. Their corrosion resistance makes them suitable for outdoor applications or environments with high moisture. However, while aluminum can be cost-effective over time, the initial investment is generally higher than that of steel. Additionally, working with aluminum requires specialized tools and techniques, which could complicate implementation.

Fiberglass Reinforced Plastic (FRP)

FRP is an increasingly popular alternative, especially in environments where chemical resistance is essential. Its lightweight nature and high tensile strength make it suitable for a variety of applications, including water treatment and chemical storage. One of the significant advantages of FRP is its resistance to corrosion, which leads to reduced maintenance costs over time. However, the initial costs can be moderate to high, and the requirement for special adhesives during assembly might complicate the installation process compared to more traditional materials like steel.

Choosing the Right Solution for Your Needs

When selecting between 1 8 inch gauge steel and its alternatives, B2B buyers should assess their specific requirements, including the environment in which the material will be used, weight considerations, and budget constraints. If strength and affordability are paramount, 1 8 inch gauge steel may be the best choice. Conversely, if corrosion resistance and weight are critical factors, aluminum or FRP might offer better long-term value. Understanding these alternatives empowers buyers to make informed decisions tailored to their operational demands, ensuring optimal material performance and cost efficiency.

Essential Technical Properties and Trade Terminology for 1 8 inch gauge steel

What Are the Key Technical Properties of 1/8 Inch Gauge Steel?

-

Material Grade

The material grade of steel significantly impacts its strength, durability, and application. Common grades for 1/8 inch gauge steel include ASTM A36, which is a standard carbon steel offering good weldability and machinability. Understanding the grade is crucial for buyers to ensure the material meets the required specifications for structural integrity in their projects. -

Thickness and Tolerance

For 1/8 inch gauge steel, the actual thickness is approximately 0.120 inches (3.048 mm). Tolerance levels indicate how much the actual thickness may vary from the specified measurement. High tolerances are essential in applications where precision is critical, such as in aerospace or automotive manufacturing. Buyers should verify tolerances to prevent issues during assembly or fabrication. -

Weight per Unit Area

The weight of 1/8 inch gauge steel is approximately 3.0 pounds per square foot (14.6 kg/m²). This specification is vital for logistical planning, as it affects shipping costs and the structural capacity of the materials being used. Buyers need to consider weight when determining handling and transportation methods. -

Yield Strength

Yield strength refers to the maximum stress that the steel can withstand without permanent deformation. For A36 steel, the yield strength is typically around 36,000 psi (250 MPa). This property is critical for applications involving heavy loads or dynamic forces, as it ensures the material can perform safely under stress. -

Corrosion Resistance

Depending on the application, corrosion resistance may be a crucial factor. While standard 1/8 inch gauge steel is susceptible to rust, galvanized options or stainless steel variants offer enhanced protection. Buyers in industries such as construction or manufacturing must assess environmental factors that may affect the longevity of the steel.

What Are Common Trade Terms Related to 1/8 Inch Gauge Steel?

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is vital for buyers seeking quality assurance and compatibility in their projects, particularly in industries such as automotive and electronics. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For 1/8 inch gauge steel, MOQs can vary significantly based on the supplier and the specific product. Knowing the MOQ helps buyers manage inventory costs and negotiate better terms. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to request pricing and terms for a specific quantity of goods. This process is essential for buyers to compare offers and ensure they are receiving competitive pricing for 1/8 inch gauge steel. -

Incoterms (International Commercial Terms)

These are standardized terms that define the responsibilities of buyers and sellers in international trade, including shipping, insurance, and tariffs. Familiarity with Incoterms is crucial for B2B buyers, especially those involved in cross-border transactions, to mitigate risks and clarify obligations. -

Lead Time

Lead time refers to the time taken from placing an order to delivery. For 1/8 inch gauge steel, lead times can vary based on availability, production schedules, and shipping logistics. Buyers must understand lead times to plan their projects effectively and avoid delays.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing 1/8 inch gauge steel, ensuring that their projects are executed efficiently and effectively.

Navigating Market Dynamics and Sourcing Trends in the 1 8 inch gauge steel Sector

What Are the Current Market Dynamics Influencing 1 8 Inch Gauge Steel Sourcing?

The market for 1 8 inch gauge steel is increasingly shaped by a confluence of global drivers that international B2B buyers must navigate. A primary factor is the rising demand for durable, lightweight materials in construction, automotive, and manufacturing sectors. Countries in Africa and South America are experiencing rapid urbanization, leading to increased construction activities, which in turn drives demand for steel products. In Europe, particularly in Germany, the push for high-quality engineering and manufacturing practices further fuels the need for reliable steel sources.

Emerging technologies such as digital sourcing platforms and supply chain management software are transforming how buyers procure materials. These platforms enable real-time price comparisons, streamline order processes, and enhance transparency in supply chains. Moreover, the integration of AI and data analytics in forecasting demand and managing inventories is gaining traction, allowing companies to make informed purchasing decisions.

Another noteworthy trend is the shift towards localization of supply chains, especially post-COVID-19. International buyers are increasingly looking for local suppliers to reduce lead times and shipping costs. This trend is particularly evident in regions like the Middle East, where infrastructure projects require timely delivery of materials. Understanding these dynamics is crucial for international buyers to make strategic sourcing decisions in the 1 8 inch gauge steel sector.

How Is Sustainability Impacting the Sourcing of 1 8 Inch Gauge Steel?

Sustainability has become a key consideration in the sourcing of 1 8 inch gauge steel. The environmental impact of steel production, including significant carbon emissions and resource depletion, has prompted buyers to seek out more sustainable options. Ethical sourcing practices are now not just a preference but a requirement for many companies aiming to enhance their corporate social responsibility profiles.

Buyers are increasingly looking for suppliers that can provide transparency in their supply chains, demonstrating adherence to environmental regulations and sustainability standards. Certifications such as ISO 14001 (Environmental Management) and initiatives like the ResponsibleSteel certification are gaining importance. These certifications signal a commitment to sustainable practices, which can be a deciding factor for B2B buyers.

Moreover, the demand for “green” steel—produced using renewable energy sources or through innovative methods like hydrogen reduction—is on the rise. This trend is particularly relevant in Europe, where strict regulations on carbon emissions are driving innovation in the steel industry. For buyers in regions like Africa and South America, aligning with suppliers that prioritize sustainability can also open doors to new markets and customer bases that value eco-friendly products.

What Is the Historical Context of 1 8 Inch Gauge Steel in B2B Markets?

The history of the gauge system used for steel, including 1 8 inch gauge steel, traces back to the British wire industry, where it originally described the diameter of drawn wire. Over time, this system evolved to standardize the thickness of sheet metal and has since become integral to metal fabrication. The gauge number is inversely related to thickness; thus, a higher gauge indicates a thinner sheet.

The significance of 1 8 inch gauge steel has grown as industries have sought materials that offer a balance of strength and weight, particularly in applications like automotive manufacturing and construction. As global markets have expanded, the historical context of gauge standards has provided a framework for international trade, allowing B2B buyers to make informed decisions based on standardized measurements. This understanding of historical developments enhances buyers’ ability to navigate current market dynamics effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of 1 8 inch gauge steel

-

How do I determine the right specifications for 1/8 inch gauge steel?

To select the appropriate specifications for 1/8 inch gauge steel, start by understanding the intended application. Consider factors such as load-bearing capacity, environmental conditions, and corrosion resistance. For instance, if the steel will be used in a marine environment, opting for galvanized or stainless steel may be prudent. Consult with suppliers for detailed product specifications and ensure they align with your project requirements. Utilizing a gauge conversion chart can also help clarify the thickness and weight of the steel, aiding in accurate calculations. -

What is the best application for 1/8 inch gauge steel?

1/8 inch gauge steel is commonly used in various applications, including construction, automotive parts, and manufacturing equipment. Its strength and durability make it suitable for structural components, brackets, and frames. Additionally, it is often utilized in the production of appliances and machinery due to its resistance to deformation under stress. When selecting 1/8 inch gauge steel, consider the specific demands of your project to ensure optimal performance. -

What are the typical lead times for sourcing 1/8 inch gauge steel internationally?

Lead times for sourcing 1/8 inch gauge steel can vary significantly based on the supplier’s location, production capacity, and shipping logistics. Typically, international orders may take anywhere from 4 to 12 weeks, depending on the complexity of the order and the distance from the supplier. It is advisable to communicate directly with suppliers to establish a clear timeline and to factor in any potential delays due to customs clearance or local regulations. -

What should I look for when vetting suppliers of 1/8 inch gauge steel?

When vetting suppliers, prioritize their industry reputation, certifications, and quality control processes. Look for suppliers who have ISO certification or similar credentials, as this indicates adherence to international quality standards. Additionally, request references or case studies from previous clients to gauge their reliability. Ensure they can provide detailed product specifications and are willing to accommodate your customization needs. Visiting the supplier’s facility, if feasible, can also provide valuable insights into their operations. -

Can I customize my order for 1/8 inch gauge steel?

Yes, many suppliers offer customization options for 1/8 inch gauge steel orders. You can request specific dimensions, shapes, and finishes based on your project requirements. Customization may also include pre-drilling holes or cutting the steel to size. However, keep in mind that custom orders may have different lead times and minimum order quantities (MOQs), so it’s essential to discuss these details upfront with your supplier. -

What are the minimum order quantities (MOQs) for 1/8 inch gauge steel?

Minimum order quantities for 1/8 inch gauge steel can vary widely depending on the supplier and the nature of your order. Some suppliers may have an MOQ as low as 500 pounds, while others may require orders of several tons. When sourcing internationally, consider how MOQs can affect your overall costs and inventory management. It’s wise to negotiate MOQs with suppliers to ensure they align with your purchasing capabilities and project needs. -

What payment terms are typically offered for international steel purchases?

Payment terms for international steel purchases usually vary by supplier and can include options like advance payment, letters of credit, or net payment terms (e.g., net 30 or net 60 days). Discussing payment options upfront can help establish trust and transparency in the transaction. Additionally, consider currency exchange rates and potential fees associated with international transactions, as these factors can influence the final cost of your purchase. -

How can I ensure quality assurance for my 1/8 inch gauge steel order?

To ensure quality assurance, request detailed documentation from your supplier, including material certifications and test reports. Establish quality control protocols, such as random inspections upon receipt of goods, to verify compliance with your specifications. It may also be beneficial to include quality assurance clauses in your purchase agreements, outlining the expectations and remedies if the steel does not meet the required standards. Engaging a third-party inspection service can further enhance your quality assurance process, especially for large orders.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 1 8 Inch Gauge Steel Manufacturers & Suppliers List

1. Stainless Supply – Gauge to Thickness Chart

Domain: stainlesssupply.com

Registered: 2000 (25 years)

Introduction: Gauge to Thickness Chart for Stainless, Galvanized Sheet Steel, and Aluminum. The chart lists gauges from 26 to 3, with corresponding thickness in inches and millimeters for each material. For example, gauge 26 stainless steel is 0.0187 inches (0.452 mm), while gauge 10 stainless steel is 0.1350 inches (3.429 mm). The chart includes various gauges and their respective thicknesses for each type of …

2. Metals Depot – Hot Rolled Steel Sheet

Domain: metalsdepot.com

Registered: 1999 (26 years)

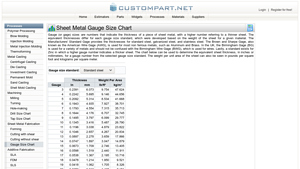

Introduction: {“products”:[{“type”:”Hot Rolled Steel Sheet”,”specification”:”ASTM A1011 CS Type B”,”description”:”Economical steel sheets with a slightly grainy surface, ideal for painting.”,”popular_uses”:[“general fabrication”,”equipment panels”,”tool boxes”,”hoppers”,”drip pans”],”thickness_options”:[{“gauge”:”16 GA”,”thickness”:”.060″,”weight_per_sqft”:”2.50 lb/sqft”},{“gauge”:”14 GA”,”thickness”:”.075″,”we…

3. Custom Part Net – Sheet Metal Gauge Size Chart

Domain: custompartnet.com

Registered: 2006 (19 years)

Introduction: Sheet Metal Gauge Size Chart: Gauge sizes indicate the thickness of sheet metal, with higher numbers signifying thinner sheets. Different standards exist for various materials: Manufacturers’ Standard Gage for steel, galvanized steel, and stainless steel; Brown and Sharpe Gage (AWG) for non-ferrous metals like aluminum and brass; Birmingham Gage (BG) in the UK for various metals; and a standard fo…

4. Riverside Sheet Metal – Gauge Thickness and Weight Chart

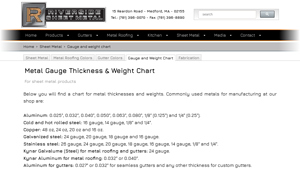

Domain: riversidesheetmetal.net

Registered: 2007 (18 years)

Introduction: Gauge Thickness and Weight Chart for Sheet Metal Products: Commonly used metals for manufacturing include: Aluminum (0.025″, 0.032″, 0.040″, 0.050″, 0.063″, 0.080″, 1/8″ (0.125″), 1/4″ (0.25″)), Cold and hot rolled steel (16 gauge, 14 gauge, 1/8″, 1/4″), Copper (48 oz, 24 oz, 20 oz, 16 oz), Galvanized steel (24 gauge, 20 gauge, 18 gauge, 16 gauge), Stainless steel (26 gauge, 24 gauge, 20 gauge, 18…

5. Reddit – Steel Gauge Comparison

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 11 gauge (11 Ga.) steel is approximately 0.1196 inches thick, while 1/8 inch steel is 0.125 inches thick, resulting in about a 4% difference in thickness. The thickness can vary depending on the material type, with 11 gauge galvanized steel measuring 0.1233 inches, stainless steel at 0.120 inches, and aluminum at 0.090 inches.

6. eBay – Steel Industrial Metal Sheets & Flat Stock

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: 1/8 Inch Steel Industrial Metal Sheets & Flat Stock for sale on eBay. Key products include: 1) Rectangular Steel Blank Stock – 1/8″ x 1-1/4″ x 6ft for $1.50; 2) K & S Engineering Copper Tube 1/8 OD X 12in for $6.07; 3) K S Round Stainless Steel Rod 1 8 87135 for $15.93; 4) Aluminum Sheet 4x10x016 KS Precision Metals 255 Pkg of 6 for $2.89; 5) STARRETT Oil Hardening Flat Stock-Width 3/4″ Length 18″…

7. Metal Supermarkets – Sheet Metal Gauge Chart

Domain: metalsupermarkets.com

Registered: 1996 (29 years)

Introduction: Sheet Metal Gauge Chart – Metal Supermarkets offers a variety of metals including Mild Steel, Aluminum, Stainless Steel, Alloy Steel, Brass, Bronze, and Copper. The gauge system is used to specify the thickness of sheet metal, with different thicknesses for different metals. The chart includes gauge numbers and their corresponding thickness in inches and millimeters for Mild Steel, Aluminum, Stain…

Strategic Sourcing Conclusion and Outlook for 1 8 inch gauge steel

As the demand for 18 gauge steel continues to rise across various industries, strategic sourcing emerges as a pivotal element for international B2B buyers. Understanding the specific applications and benefits of 18 gauge steel—such as its balance between strength and weight—enables companies to make informed purchasing decisions that can enhance operational efficiency and product quality.

In markets spanning Africa, South America, the Middle East, and Europe, leveraging a comprehensive sourcing strategy can lead to significant cost savings and improved supply chain resilience. Buyers should focus on building relationships with reputable suppliers who can guarantee consistent quality and timely delivery, as these factors are crucial in maintaining competitiveness in today’s dynamic market landscape.

Looking ahead, the global steel market is expected to evolve, influenced by technological advancements and shifting economic conditions. To stay ahead, B2B buyers must remain agile and proactive in their sourcing strategies. Engaging with suppliers who understand the nuances of local and international regulations will be key. Embrace the opportunity to refine your sourcing approach and secure a reliable supply of 18 gauge steel to meet your business needs.