Contents

Manufacturing Insight: 1 16 Sheet Metal Gauge

Precision Fabrication for 16 Gauge Sheet Metal: Engineered for Your Production Demands

At Honyo Prototype, we specialize in transforming 16 gauge sheet metal—a versatile thickness of 0.0625 inches (1.5875 mm)—into high-integrity components for demanding industrial applications. This gauge strikes an optimal balance between structural rigidity and formability, making it indispensable for enclosures, brackets, chassis, and machinery guards where dimensional accuracy and material integrity are non-negotiable. Our advanced sheet metal fabrication ecosystem leverages state-of-the-art CO2 and fiber laser cutting, precision CNC punching, and automated bending cells to consistently achieve tolerances down to ±0.005 inches, ensuring seamless integration into your final assemblies.

Beyond raw processing, Honyo delivers end-to-end value through integrated secondary operations including welding, tapping, hardware insertion, and finishing services such as powder coating or anodizing. Every 16 gauge part undergoes rigorous in-process inspection using CMM and optical comparators, adhering to ISO 9001:2015 standards to eliminate rework and accelerate time-to-market. Whether prototyping or scaling to high-volume production, our engineering team collaborates early to optimize designs for manufacturability, minimizing material waste and cost without compromising performance.

Accelerate your project timeline with Honyo’s Online Instant Quote platform—engineer-validated estimates delivered in under 60 seconds. Simply upload your STEP or DXF file, specify 16 gauge material (steel, aluminum, stainless), and receive a transparent cost breakdown with lead time projections, all while maintaining full IP security. This digital workflow eliminates traditional quotation bottlenecks, empowering procurement and engineering teams to iterate faster and deploy capital with confidence.

| Key Specification | Value |

|---|---|

| 16 Gauge Thickness | 0.0625 in (1.5875 mm) |

| Tolerance Capability | ±0.005 in (0.127 mm) |

| Material Options | Mild Steel, 5052/6061 Aluminum, 304/316 Stainless |

| Max Laser Cutting Area | 60 in × 120 in (1524 mm × 3048 mm) |

Partner with Honyo to convert 16 gauge sheet metal specifications into field-proven solutions, backed by engineering rigor and digital supply chain efficiency. Start your next project with a validated quote today.

Technical Capabilities

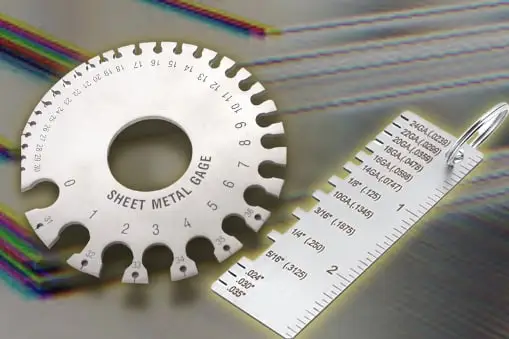

The term “1 16 sheet metal gauge” is commonly interpreted as a 1/16 inch (0.0625 inch or approximately 1.59 mm) thickness of sheet material. It’s important to clarify that 1/16 inch is not a standard gauge number for steel or aluminum—gauge systems are non-linear and material-specific. For example, 16-gauge steel is approximately 0.0625 inch, aligning with 1/16 inch, while 16-gauge aluminum is thinner (~0.0508 inch). Therefore, this specification is best referenced by actual thickness (1/16″) rather than gauge to ensure accuracy across materials.

Below are the technical considerations for processing 1/16″ thick sheet material in laser cutting, bending, and welding operations, for common materials used in prototyping and low-volume manufacturing.

| Material | Thickness (in/mm) | Laser Cutting Suitability | Bending Notes | Welding Compatibility | Notes |

|---|---|---|---|---|---|

| Cold Rolled Steel (CRS) | 0.0625″ / 1.59 mm | Excellent – cleanly cut with CO₂ or fiber lasers; minimal dross with proper parameters | Good – bend radius ≥ 1x material thickness recommended (0.0625″) to avoid cracking; springback ~2–3° | Excellent – compatible with MIG, TIG, and spot welding; pre-cleaning required for best results | Most common material for 1/16″ gauge applications; high strength and weldability |

| Aluminum (5052, 6061) | 0.0625″ / 1.59 mm | Good – requires higher energy and assist gas (N₂ or O₂); reflective nature demands protective measures for laser optics | Fair – ductile but prone to overbending; use bottoming or coining for accuracy; minimum bend radius = 1t | Good – TIG or MIG welding possible; 6061 requires pre/post-heat treatment to avoid cracking | 5052 preferred for bending; 6061 stronger but less formable |

| ABS (Acrylonitrile Butadiene Styrene) | 0.0625″ / 1.59 mm | Limited – can be laser cut with CO₂ lasers; edges melt and re-solidify; emits toxic fumes; not recommended for production | Poor – thermoplastic behavior leads to creep and deformation; not suitable for sharp bends | Not applicable – joined via adhesives or mechanical fasteners | Not a metal; not suitable for traditional sheet metal processes; used in non-structural enclosures |

| Nylon (PA6, PA66) | 0.0625″ / 1.59 mm | Poor – laser cutting causes severe melting and charring; not recommended | Not suitable – highly thermoplastic; lacks springback control | Not weldable via arc methods; limited to ultrasonic or hot plate welding | Used for wear-resistant non-metallic parts; incompatible with standard metal fabrication |

Summary Notes:

Laser cutting performs best with metals such as steel and aluminum; plastics like ABS and nylon are processable but with significant limitations and safety concerns.

Bending 1/16″ steel and aluminum is feasible with standard press brake tooling, but minimum bend radius and tool selection are critical to avoid fracture.

Welding is viable only for conductive metals—steel and aluminum—with appropriate techniques and surface preparation.

ABS and nylon are not structural sheet metals and should not be treated as such in fabrication planning. They are typically machined or thermoformed rather than laser-cut or bent like metal.

From CAD to Part: The Process

Honyo Prototype executes 16-gauge sheet metal fabrication through a tightly integrated digital workflow designed for speed, accuracy, and manufacturability. 16-gauge steel corresponds to a nominal thickness of 1.519 mm (0.060 inches), a common specification requiring precise process control to avoid deformation or tooling issues. Our end-to-end process eliminates traditional handoffs and communication gaps.

CAD Upload & Validation

Clients upload native CAD files (STEP, IGES, DWG, or native SOLIDWORKS) directly to our secure portal. Our system immediately performs automated geometry validation, checking for non-manifold edges, missing radii, and unit inconsistencies. Crucially, it verifies that all features comply with 16-gauge constraints, such as minimum bend radii (typically ≥ 0.8 mm for mild steel) and hole-to-edge distances. Invalid files trigger instant feedback with specific error locations, preventing downstream quoting delays.

AI-Powered Quoting Engine

Validated CAD data feeds directly into our proprietary AI quoting algorithm. This system analyzes over 200 manufacturability parameters specific to 16-gauge material, including flat pattern area, bend count, secondary operations (tapping, welding), and material yield optimization. Unlike basic volume-based quoting, it calculates true production cost drivers: laser cutting path length, press brake setup complexity, and finishing requirements. Quotes include granular cost breakdowns and are typically generated within 2 business hours, with expedited options available.

Automated DFM Analysis & Collaboration

Every quote includes an actionable DFM report generated by our rules-based engine calibrated for 16-gauge production. The system flags high-risk features like narrow tabs prone to warping, insufficient bend relief cuts, or tolerances tighter than ±0.1 mm achievable with standard tooling. Critical issues are prioritized with visual annotations on the 3D model. Clients access a collaborative portal to approve, discuss, or modify designs with our engineering team in real-time, reducing revision cycles by up to 70% compared to email-based workflows.

Seamless Production Handoff

Approved designs trigger automatic release to production. CAM programming occurs within minutes using pre-verified toolpaths optimized for 1.5 mm material thickness. Our nested scheduling system dynamically allocates jobs to laser cutters (with kerf compensation for 16ga steel) and CNC press brakes based on real-time machine availability. Material traceability is maintained via barcode scanning from coil inventory through all stages.

Delivery & Quality Assurance

All 16-gauge parts undergo first-article inspection against GD&T callouts, with CMM reports available upon request. Standard lead time from approved DFM to shipment is 5-7 business days. Clients receive proactive logistics updates via our portal, including shipment tracking and digital quality documentation. Expedited 72-hour turnaround is available for qualified prototypes.

The following table summarizes key process metrics for 16-gauge sheet metal projects:

| Process Phase | Standard Lead Time | Key Differentiator | Quality Control Point |

|---|---|---|---|

| CAD to Quote | < 2 business hours | AI-driven true cost modeling, not estimation | Automated geometry validation |

| DFM Resolution | 24-48 hours | Collaborative cloud portal with 3D markup | Risk-prioritized manufacturability |

| Production | 3-5 business days | Direct CAM integration, no manual rework | In-process bend angle verification |

| Delivery | 5-7 business days | Real-time logistics portal | FAI report with dimensional data |

This integrated approach ensures 16-gauge parts meet dimensional and functional requirements on the first iteration, minimizing costly redesigns and accelerating time-to-test for our clients’ prototypes. All processes are certified to ISO 9001:2015 standards with material certs provided for critical applications.

Start Your Project

Interested in high-precision fabrication for 16-gauge sheet metal? Honyo Prototype delivers reliable, cost-effective solutions with fast turnaround times.

Our Shenzhen-based manufacturing facility is equipped to handle low-volume prototypes and high-volume production with strict quality control and material traceability.

For project inquiries or quotes, contact Susan Leo at [email protected]. Let’s discuss your next sheet metal fabrication requirement.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.