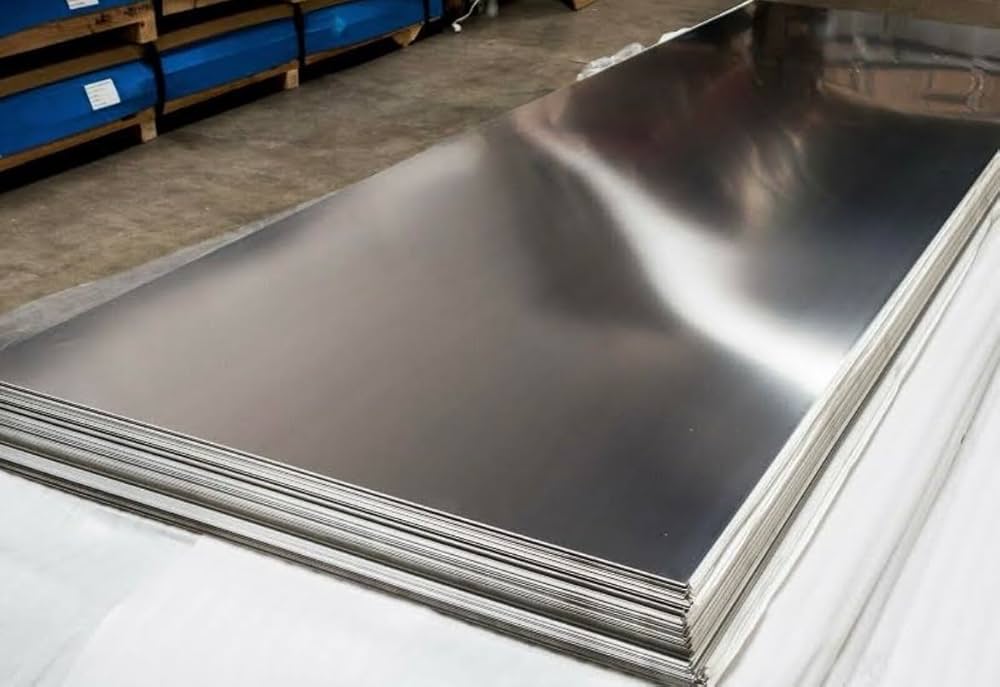

Introduction: Navigating the Global Market for 032 aluminum sheet metal

In today’s competitive landscape, sourcing 0.032 aluminum sheet metal can be a daunting task for B2B buyers, particularly those operating in diverse markets across Africa, South America, the Middle East, and Europe, including countries like Nigeria and Brazil. The challenge lies not only in finding high-quality materials but also in navigating the complexities of pricing, supplier reliability, and regional regulations. This guide aims to equip international buyers with the essential knowledge needed to make informed purchasing decisions regarding 0.032 aluminum sheet metal.

Throughout this comprehensive resource, we delve into various aspects of aluminum sheet metal, covering the different types, such as 5052-H32, 3003-H14, and 6061-T6, along with their specific applications across industries like aerospace, automotive, construction, and packaging. Additionally, we provide insights on how to effectively vet suppliers, ensuring that your procurement process aligns with quality standards and delivery expectations.

Moreover, the guide addresses cost considerations, helping buyers understand pricing structures and potential savings on bulk orders. By leveraging the information presented here, B2B buyers can navigate the global market confidently, optimize their supply chain, and ultimately enhance their operational efficiency. This resource serves as your gateway to mastering the procurement of 0.032 aluminum sheet metal, empowering your business to thrive in an increasingly interconnected world.

Understanding 032 aluminum sheet metal Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 5052-H32 | Excellent corrosion resistance, good weldability | Marine applications, automotive, construction | Pros: Corrosion-resistant, versatile. Cons: Moderate strength compared to other alloys. |

| 3003-H14 | Good workability, moderate strength | Food processing, chemical equipment | Pros: Excellent formability, lightweight. Cons: Lower strength than 5052. |

| 6061-T6 | High strength, good machinability | Structural components, automotive frames | Pros: Strong and durable, good for fabrication. Cons: More challenging to work with due to strength. |

| 5005 | Good anodizing response, aesthetic appeal | Architectural applications, signage | Pros: Attractive finish, good corrosion resistance. Cons: Lower mechanical properties compared to 6061. |

| 7075 | High strength, used in aerospace applications | Aircraft components, military applications | Pros: Exceptional strength-to-weight ratio. Cons: More expensive and less corrosion resistant. |

What Are the Characteristics of 5052-H32 Aluminum Sheet Metal?

5052-H32 aluminum sheet metal is renowned for its exceptional corrosion resistance and good weldability, making it an ideal choice for marine applications, automotive parts, and construction. This alloy features a moderate strength level, which is suitable for various applications where durability is essential. B2B buyers should consider its versatility and resistance to saltwater corrosion, particularly for projects in coastal regions or industries requiring reliable performance in harsh environments.

How Does 3003-H14 Aluminum Sheet Metal Stand Out?

The 3003-H14 aluminum sheet metal offers good workability and moderate strength, making it a popular choice for food processing and chemical equipment. Its excellent formability allows for easy shaping and installation, which is advantageous for manufacturers looking to create customized solutions. Buyers should weigh its lower strength compared to other alloys against its lightweight nature and suitability for applications where corrosion resistance is a priority.

Why Choose 6061-T6 Aluminum Sheet Metal for Structural Applications?

6061-T6 aluminum sheet metal is characterized by its high strength and good machinability, making it an excellent option for structural components and automotive frames. This alloy’s durability and ability to withstand stress are critical for heavy-duty applications. However, B2B buyers should note that while it offers superior strength, the challenges in fabrication due to its toughness may require specialized equipment or techniques.

What Makes 5005 Aluminum Sheet Metal Ideal for Aesthetics?

5005 aluminum sheet metal is particularly valued for its good anodizing response and aesthetic appeal, making it a preferred choice in architectural applications and signage. This alloy provides an attractive finish while maintaining good corrosion resistance. Buyers looking for materials that enhance visual appeal should consider 5005, keeping in mind that its mechanical properties may not be as robust as those of 6061 or 7075.

When Should You Consider 7075 Aluminum Sheet Metal?

7075 aluminum sheet metal is known for its exceptional strength, making it a go-to choice for aerospace and military applications. While it boasts a high strength-to-weight ratio, B2B buyers should be aware of its higher cost and lower corrosion resistance compared to other aluminum alloys. This makes it suitable for applications where strength is paramount, but buyers must also consider the environmental conditions the material will face.

Key Industrial Applications of 032 aluminum sheet metal

| Industry/Sector | Specific Application of 032 Aluminum Sheet Metal | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Aircraft components like fuselages and wings | Lightweight yet strong, improving fuel efficiency | Compliance with aviation standards, weight specifications |

| Automotive | Body panels for vehicles | Enhances fuel efficiency and reduces overall weight | Custom sizes, corrosion resistance, and aesthetic finish |

| Construction | Roofing, siding, and architectural details | Durable and resistant to corrosion | Local climate considerations, insulation properties |

| Marine | Boat hulls and structural components | Corrosion resistance in harsh marine environments | Compliance with maritime regulations, weight limits |

| Electrical & Electronics | Enclosures for electrical components and heat sinks | Protects sensitive electronics and aids in cooling | Thermal conductivity, electrical shielding requirements |

How is 032 Aluminum Sheet Metal Used in Aerospace Applications?

In the aerospace sector, 0.032 aluminum sheet metal is crucial for manufacturing aircraft components such as fuselages and wings. The lightweight nature of aluminum enhances fuel efficiency while maintaining structural integrity. Buyers from regions like Africa and South America should ensure compliance with stringent aviation standards and specifications to meet safety regulations. Furthermore, sourcing from certified suppliers can provide assurance of quality and performance.

What Role Does 032 Aluminum Sheet Metal Play in Automotive Manufacturing?

In automotive manufacturing, 0.032 aluminum sheet metal is primarily used for body panels, including hoods, trunks, and doors. Its lightweight properties contribute to improved fuel efficiency, which is increasingly important in a market focused on sustainability. Buyers, especially in Europe and the Middle East, should consider custom sizes and finishes to meet specific design and performance criteria, along with corrosion resistance to ensure longevity in diverse environments.

How is 032 Aluminum Sheet Metal Utilized in the Construction Sector?

In the construction industry, 0.032 aluminum sheet metal is employed for roofing, siding, and architectural details. Its durability and resistance to corrosion make it ideal for both residential and commercial applications. International buyers must consider local climate conditions when selecting materials, as aluminum can provide insulation benefits in extreme temperatures. Sourcing from local suppliers may also reduce shipping costs and lead times.

Why is 032 Aluminum Sheet Metal Important for Marine Applications?

Marine applications leverage the corrosion resistance of 0.032 aluminum sheet metal for components like boat hulls and structural frames. The material’s ability to withstand harsh saltwater environments makes it a preferred choice in the boating industry. Buyers from coastal regions should prioritize suppliers with expertise in marine-grade aluminum to ensure compliance with relevant maritime regulations and performance standards.

How Does 032 Aluminum Sheet Metal Benefit Electrical and Electronics Industries?

In the electrical and electronics sectors, 0.032 aluminum sheet metal is used for manufacturing enclosures and heat sinks. Its excellent thermal conductivity aids in cooling sensitive electronic components, while its lightweight nature facilitates easy installation. B2B buyers must consider thermal management properties and electrical shielding requirements when sourcing, ensuring that the material meets industry-specific standards for safety and performance.

3 Common User Pain Points for ‘032 aluminum sheet metal’ & Their Solutions

Scenario 1: Inconsistent Supply of 0.032 Aluminum Sheets

The Problem: B2B buyers often face the challenge of inconsistent supply chains, which can lead to delays in production. For instance, a manufacturing company in Nigeria might rely on 0.032 aluminum sheets for building components. If their supplier experiences stock shortages or delivery delays, it can halt production, affecting timelines and customer satisfaction. This problem is exacerbated when suppliers do not communicate effectively about stock levels or lead times, leading to unexpected interruptions.

The Solution: To mitigate supply chain inconsistencies, buyers should establish relationships with multiple suppliers to diversify their sources of 0.032 aluminum sheets. This strategy reduces dependence on a single supplier and increases the chances of maintaining inventory levels. Additionally, buyers should utilize inventory management systems that track stock levels and forecast demand accurately. Regular communication with suppliers about their inventory status and lead times can help anticipate shortages. Setting up a just-in-time (JIT) inventory approach can also minimize excess stock while ensuring that materials are available when needed.

Scenario 2: Difficulty in Sourcing Custom Sizes of 0.032 Aluminum Sheets

The Problem: Many projects require custom sizes of 0.032 aluminum sheets, which can be difficult to source. For example, an architectural firm in Brazil may need specific dimensions for a building project but finds that most suppliers only offer standard sizes. This limitation can lead to wasted materials and increased costs, as the company may need to purchase larger sheets and cut them down to size, leading to inefficiencies.

The Solution: To effectively source custom sizes, buyers should partner with suppliers that offer cutting and fabrication services. When requesting quotes, clearly specify the dimensions needed and any additional requirements such as tolerances or surface finishes. Utilizing suppliers that have the capability to provide custom cuts can save time and reduce waste. Additionally, buyers can explore online platforms that allow for custom orders, ensuring they find the right sizes without compromising on quality. Creating a strong relationship with these suppliers can also facilitate faster turnaround times for future projects.

Scenario 3: Understanding Material Specifications and Applications of 0.032 Aluminum Sheets

The Problem: B2B buyers often struggle to understand the various grades and specifications of 0.032 aluminum sheets, which can lead to incorrect material selection for their applications. For instance, a company in the Middle East might not realize that the alloy type significantly affects properties like corrosion resistance, strength, and workability, potentially resulting in product failures or increased costs.

The Solution: To make informed purchasing decisions, buyers should invest time in understanding the specifications and properties of different aluminum alloys. This includes familiarizing themselves with the differences between 5052, 3003, and 6061 grades, as well as their respective applications. Engaging with suppliers who can provide detailed material data sheets and technical support can also enhance understanding. Furthermore, attending industry workshops or webinars focused on material science can provide valuable insights into selecting the right aluminum sheets for specific projects. This knowledge will empower buyers to specify the right materials confidently, ultimately leading to better project outcomes and cost efficiencies.

Strategic Material Selection Guide for 032 aluminum sheet metal

What Are the Key Properties of 032 Aluminum Sheet Metal?

When selecting 032 aluminum sheet metal, the alloy type significantly influences its properties and suitability for various applications. Common alloys include 5052, 3003, and 6061, each with unique characteristics that cater to specific industrial needs.

What Are the Properties and Applications of 5052 Aluminum Sheet Metal?

5052 aluminum sheet metal is renowned for its excellent corrosion resistance, particularly in marine environments. It boasts a high strength-to-weight ratio, making it ideal for applications requiring durability without adding excessive weight. The alloy’s temperature rating is suitable for moderate heat applications, and it is easily weldable, which is advantageous for manufacturing processes.

Pros: The primary advantages of 5052 include its superior corrosion resistance and formability, making it suitable for complex shapes. It is commonly used in marine applications, automotive fuel tanks, and architectural components.

Cons: However, 5052 can be more expensive than other alloys, and its workability decreases at higher temperatures, which may limit its use in specific high-heat applications.

How Does 3003 Aluminum Sheet Metal Compare in Performance?

3003 aluminum sheet metal is another popular choice, particularly valued for its excellent workability and moderate strength. It is often used in applications that require good corrosion resistance and is particularly effective in chemical environments.

Pros: The key advantages of 3003 are its affordability and ease of fabrication. It is commonly found in cooking utensils, chemical equipment, and storage tanks.

Cons: On the downside, 3003 has a lower strength compared to 5052 and 6061, which may limit its use in high-stress applications.

What Are the Benefits of Using 6061 Aluminum Sheet Metal?

6061 aluminum sheet metal is a versatile alloy known for its high strength and excellent mechanical properties. It is often used in structural applications, including truck bodies and frames, where strength and corrosion resistance are critical.

Pros: The major benefits of 6061 include its high tensile strength and good weldability. It is suitable for a wide range of applications, including aerospace and automotive components.

Cons: However, the T6 temper of 6061 can make it less malleable, complicating manufacturing processes that require extensive forming.

What Should International B2B Buyers Consider When Selecting Aluminum Sheet Metal?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, must consider compliance with local standards and regulations. Common standards like ASTM B209, DIN, and JIS are critical for ensuring product quality and compatibility. Additionally, factors such as shipping logistics, customs regulations, and material availability can significantly impact procurement decisions. Understanding regional preferences for specific alloys can also guide buyers in making informed choices that align with local industry practices.

| Material | Typical Use Case for 032 aluminum sheet metal | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| 5052 | Marine applications, automotive fuel tanks | Excellent corrosion resistance | Higher cost and reduced workability at high temperatures | Medium |

| 3003 | Cooking utensils, chemical equipment | Good workability and affordability | Lower strength compared to other alloys | Low |

| 6061 | Structural components in automotive and aerospace | High tensile strength and weldability | Less malleable in T6 temper, complicating fabrication | High |

In-depth Look: Manufacturing Processes and Quality Assurance for 032 aluminum sheet metal

What Are the Key Stages in the Manufacturing Process of 0.032 Aluminum Sheet Metal?

The manufacturing of 0.032 aluminum sheet metal involves several critical stages that ensure the final product meets the required specifications and quality standards. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation

The process begins with material preparation, which involves sourcing high-quality aluminum ingots. For 0.032 aluminum sheets, alloys such as 5052-H32 or 6061-T6 are commonly used due to their favorable properties, including strength and corrosion resistance. Before manufacturing, the raw aluminum is inspected for impurities and must meet international standards like ASTM B209.

During this phase, the aluminum is cut into manageable sizes and pre-treated to remove any surface contaminants that could affect the subsequent processes.

Forming Techniques

The forming stage is where the aluminum sheets are shaped. This can involve techniques such as rolling, where large coils of aluminum are passed through rollers to achieve the desired thickness. For 0.032 sheets, precision is paramount; thus, the rolling process must be closely monitored to ensure uniform thickness across the sheet.

In addition to rolling, other forming methods like stamping and cutting may be employed, depending on the end-use requirements. For instance, stamping is often used for creating intricate designs or shapes needed in various applications, from automotive parts to decorative features.

Assembly and Fabrication

Once the sheets are formed, they may undergo assembly processes if they are part of larger components. This could involve welding, riveting, or fastening, depending on the specific application. For instance, in the aerospace sector, where lightweight and strong materials are critical, advanced welding techniques might be employed to ensure structural integrity.

Finishing Processes

The finishing stage is essential for enhancing the durability and aesthetic appeal of the aluminum sheets. Common finishing processes include anodizing, which improves corrosion resistance and surface hardness, and painting, which provides additional protection and allows for customization in color and design.

How Is Quality Assurance Implemented in the Manufacturing of 0.032 Aluminum Sheet Metal?

Quality assurance is a critical component of the manufacturing process, ensuring that the products meet both industry standards and customer specifications. The key aspects of quality assurance in this context involve adherence to international standards, systematic quality control checkpoints, and rigorous testing methods.

What International Standards Should B2B Buyers Be Aware Of?

B2B buyers should be familiar with several international quality standards, such as ISO 9001, which outlines the requirements for a quality management system. Compliance with ISO standards ensures that manufacturers consistently produce products that meet customer and regulatory requirements.

In addition to ISO 9001, industry-specific standards such as CE marking for European markets, and API (American Petroleum Institute) standards for oil and gas applications may also apply. Manufacturers must ensure their products are compliant with these standards to facilitate international trade, particularly for buyers from Africa, South America, the Middle East, and Europe.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are integral to maintaining high standards throughout the manufacturing process. The typical QC checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified standards before production begins.

-

In-Process Quality Control (IPQC): During manufacturing, processes are monitored to catch any deviations in real-time. This includes checking thickness, surface finish, and mechanical properties at various stages of production.

-

Final Quality Control (FQC): Once manufacturing is complete, the finished products undergo a final inspection to ensure they meet all specifications and standards before shipping.

What Common Testing Methods Are Used for Quality Assurance?

Testing methods are crucial for verifying the quality of aluminum sheets. Common methods include:

-

Tensile Testing: Measures the strength and ductility of the aluminum, ensuring it meets the required mechanical properties.

-

Hardness Testing: Determines the material’s hardness, which is important for applications requiring durability.

-

Chemical Composition Analysis: Confirms that the aluminum alloy contains the correct proportions of elements as per the specified standards.

-

Surface Inspection: Involves visual and instrumental checks for surface defects such as scratches, dents, or improper finishes.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers can ensure that their suppliers adhere to stringent quality control processes through various methods:

-

Supplier Audits: Conducting regular audits allows buyers to assess the supplier’s quality management systems and manufacturing processes in person.

-

Requesting Quality Control Reports: Suppliers should provide documentation of their quality control processes, including IQC, IPQC, and FQC reports, as well as any certifications they hold.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s manufacturing practices and product quality.

What Are the Quality Control Considerations for International B2B Buyers?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, there are unique quality control considerations:

-

Regulatory Compliance: Ensure that the supplier’s products comply with local regulations and international standards to avoid issues during customs clearance.

-

Cultural and Communication Barriers: Engage suppliers who can effectively communicate quality standards and practices in a language that is mutually understood.

-

Understanding Certifications: Familiarize yourself with the certifications and quality marks relevant to your region, as these can influence purchasing decisions and market acceptance.

In conclusion, the manufacturing processes and quality assurance measures for 0.032 aluminum sheet metal are vital for ensuring that the final products meet the necessary standards for various applications. B2B buyers should leverage their understanding of these processes to make informed purchasing decisions, ensuring quality and compliance in their supply chain.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘032 aluminum sheet metal’

When sourcing 0.032″ aluminum sheet metal, a systematic approach can help ensure you find the right materials for your needs. This checklist provides actionable steps to guide international B2B buyers through the procurement process, ensuring quality, cost-effectiveness, and supplier reliability.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s essential to clarify your requirements. Consider factors such as the alloy type (e.g., 5052, 6061), temper (e.g., H32, T6), dimensions, and any specific mechanical properties needed for your applications. Clear specifications help suppliers understand your needs and provide accurate quotes.

- Common Applications: Identify the intended use, such as automotive parts, marine applications, or construction materials.

- Standards Compliance: Ensure your specifications meet industry standards, like ASTM B209.

Step 2: Research Potential Suppliers

Identifying reputable suppliers is crucial for quality assurance. Look for manufacturers with a proven track record in producing aluminum sheet metal.

- Supplier Credentials: Verify certifications (e.g., ISO 9001) to ensure adherence to quality management standards.

- Industry Experience: Suppliers with experience in your specific industry will better understand your requirements.

Step 3: Request Samples for Evaluation

Once you have shortlisted potential suppliers, request samples of the aluminum sheet metal.

- Quality Assessment: Examine the samples for thickness, finish, and overall quality. This step is vital for ensuring the product meets your expectations before placing a large order.

- Testing: Consider conducting mechanical tests on samples to verify their strength and durability.

Step 4: Compare Pricing and Terms

Gather quotes from multiple suppliers to evaluate pricing structures.

- Cost Transparency: Ensure quotes include all costs such as shipping, customs duties, and any additional fees to avoid unexpected expenses.

- Bulk Discounts: Inquire about pricing for larger orders, as many suppliers offer discounts for bulk purchases.

Step 5: Verify Supplier Certifications

It’s essential to confirm that your chosen supplier adheres to relevant quality and safety standards.

- Regulatory Compliance: Check for compliance with local and international regulations, especially if you are importing materials.

- Sustainability Practices: Increasingly, buyers prefer suppliers that follow sustainable practices, so inquire about their environmental policies.

Step 6: Establish Clear Communication Channels

Effective communication is key to a successful procurement process.

- Point of Contact: Designate a primary contact person for all inquiries and updates to streamline communication.

- Response Times: Assess how quickly suppliers respond to inquiries, which can be indicative of their customer service quality.

Step 7: Finalize the Purchase Agreement

After selecting a supplier, ensure that all terms are clearly outlined in a purchase agreement.

- Contract Details: Include delivery timelines, payment terms, and return policies to protect your interests.

- Contingency Plans: Discuss potential issues that may arise during the process, such as delays or product defects, and establish a plan for resolution.

Following this checklist will facilitate a smoother sourcing process for 0.032″ aluminum sheet metal, helping you secure quality materials that meet your business needs efficiently and effectively.

Comprehensive Cost and Pricing Analysis for 032 aluminum sheet metal Sourcing

What Are the Key Cost Components in Sourcing 0.032 Aluminum Sheet Metal?

When sourcing 0.032 aluminum sheet metal, understanding the cost structure is crucial for international B2B buyers. The primary components include:

-

Materials: The cost of raw aluminum significantly influences the final price. The alloy type (e.g., 5052-H32 vs. 6061-T6) can affect pricing due to differences in strength, corrosion resistance, and weight. Prices can fluctuate based on global aluminum market trends, making it essential to stay informed about commodity pricing.

-

Labor: Labor costs vary by region and are impacted by the local economy, labor laws, and skill availability. In countries with a skilled workforce, labor costs might be higher, but the quality of manufacturing can also improve, potentially leading to lower rework or defect rates.

-

Manufacturing Overhead: This encompasses expenses such as utilities, rent, and equipment maintenance. Efficient operations can reduce overhead, allowing suppliers to offer competitive pricing.

-

Tooling: The cost of specialized tools for cutting and shaping aluminum can be significant, particularly for custom orders. Buyers should consider whether the supplier has the necessary tooling or if additional costs will apply.

-

Quality Control (QC): Ensuring that the aluminum sheets meet specific standards (e.g., ASTM B209) involves quality assurance processes. This adds to the cost but is vital for maintaining product integrity.

-

Logistics: Transportation and shipping costs can vary widely based on destination, order size, and selected shipping method. International buyers should factor in customs duties and potential tariffs, especially when importing materials.

-

Margin: Suppliers typically add a profit margin to cover their costs and risk. Understanding the average markup in your region can help in negotiations.

What Influences Pricing for 0.032 Aluminum Sheet Metal?

Several factors can influence the pricing of aluminum sheets:

-

Volume/MOQ: Bulk purchases often lead to lower per-unit costs. Suppliers may have minimum order quantities (MOQs) that can impact pricing structures.

-

Specifications and Customization: Custom sizes or specifications can lead to increased costs. Standard sizes usually have better pricing due to existing inventory and reduced setup times.

-

Material Quality and Certifications: Higher quality materials or specific certifications (e.g., RoHS compliance) can increase costs. Buyers should assess whether the additional expense aligns with their project requirements.

-

Supplier Factors: Relationships with suppliers can affect pricing. Long-term partnerships may yield better rates and terms.

-

Incoterms: The chosen Incoterms can significantly impact total costs, as they define the responsibilities of buyers and sellers in terms of shipping, insurance, and tariffs.

How Can Buyers Optimize Costs When Sourcing Aluminum Sheet Metal?

To ensure cost-effectiveness when sourcing aluminum sheet metal, consider the following tips:

-

Negotiate Pricing: Engage in open discussions with suppliers about pricing structures. Leverage volume purchases or long-term commitments to negotiate better terms.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider factors such as shipping costs, potential rework, and the lifespan of the material to assess overall value.

-

Understand Pricing Nuances for International Trade: When sourcing from different continents, be aware of regional pricing variances, currency fluctuations, and import duties. This knowledge can help in making informed purchasing decisions.

-

Request Multiple Quotes: Gathering quotes from various suppliers provides a broader perspective on market rates and helps in identifying the best deal.

-

Stay Informed: Keep abreast of market trends and aluminum price fluctuations to make timely purchasing decisions that can save costs.

Disclaimer

The prices mentioned in this analysis are indicative and can vary based on market conditions, regional differences, and supplier negotiations. Always confirm current pricing directly with suppliers to ensure accuracy.

Alternatives Analysis: Comparing 032 aluminum sheet metal With Other Solutions

Understanding Alternatives for 032 Aluminum Sheet Metal

In the realm of industrial applications, selecting the right material is crucial for performance and cost-effectiveness. While 032 aluminum sheet metal is a popular choice due to its lightweight and corrosion-resistant properties, various alternatives exist that may better suit specific project requirements. This analysis compares 032 aluminum sheet metal with two viable alternatives: galvanized steel and stainless steel, focusing on performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | 032 Aluminum Sheet Metal | Galvanized Steel | Stainless Steel |

|---|---|---|---|

| Performance | High strength-to-weight ratio; excellent corrosion resistance | Moderate strength; good corrosion resistance due to zinc coating | Superior strength; excellent corrosion resistance and durability |

| Cost | Moderate cost | Generally lower cost | Higher cost |

| Ease of Implementation | Easy to cut and shape; requires minimal tools | Moderate; requires cutting tools and welding | More challenging due to hardness; requires specialized tools |

| Maintenance | Low; does not require coatings | Moderate; zinc can wear off, requiring re-coating | Very low; resistant to rust and staining |

| Best Use Case | Aerospace, automotive, and decorative applications | Construction, roofing, and outdoor structures | High-end appliances, medical equipment, and architectural applications |

Detailed Breakdown of Alternatives

Galvanized Steel

Galvanized steel is a carbon steel that has been coated with zinc to prevent rusting. Its cost-effectiveness makes it an attractive option for many construction projects. While it offers moderate strength and good corrosion resistance, it may not perform as well as aluminum in lightweight applications. The zinc coating can wear off over time, necessitating periodic maintenance to prevent rust. However, for projects where budget constraints are significant and weight is less of a concern, galvanized steel is a viable alternative.

Stainless Steel

Stainless steel is renowned for its exceptional strength and corrosion resistance. It is particularly beneficial in environments that require durability and hygiene, such as in the food and medical industries. However, the cost of stainless steel is generally higher than that of both aluminum and galvanized steel, which can impact budget considerations for large-scale projects. Moreover, its hardness makes it more difficult to work with, requiring specialized tools for cutting and shaping. Stainless steel is best suited for applications that demand long-lasting performance and aesthetic appeal.

Conclusion: How to Choose the Right Solution for Your Needs

When deciding between 032 aluminum sheet metal and its alternatives, B2B buyers should consider various factors including application requirements, budget constraints, and long-term maintenance needs. If lightweight performance and corrosion resistance are priorities, 032 aluminum remains a strong choice. Conversely, if cost is a primary concern and the application allows for heavier materials, galvanized steel could be a suitable option. For applications demanding durability and low maintenance, stainless steel may justify its higher cost. Ultimately, the right material will depend on the specific needs of the project, balancing performance, cost, and ease of implementation.

Essential Technical Properties and Trade Terminology for 032 aluminum sheet metal

What Are the Key Technical Properties of 0.032 Aluminum Sheet Metal?

When evaluating 0.032 aluminum sheet metal, several critical specifications are essential for B2B buyers to understand. These properties not only impact the material’s performance but also influence the selection process for various applications.

-

Material Grade: Common grades for 0.032 aluminum sheets include 5052 and 6061. The 5052 alloy offers excellent corrosion resistance and is often used in marine applications, while 6061 is known for its strength and versatility, making it suitable for structural components. Understanding the right alloy for your application is crucial for achieving desired performance outcomes.

-

Temper: The temper refers to the heat treatment process applied to aluminum, which affects its mechanical properties. For instance, the H32 temper of 5052 aluminum indicates it has been strain-hardened and stabilized, making it more robust while retaining some flexibility. This specification is vital for applications that require specific strength and formability.

-

Thickness Tolerance: Tolerances for aluminum sheets typically vary, with standard tolerances being ±0.125 inches for thickness. This detail is important for ensuring compatibility with other components in manufacturing processes. Understanding tolerances helps buyers prevent issues related to fitting and assembly.

-

Mechanical Properties: Key mechanical properties include yield strength, tensile strength, and elongation percentage. For example, 5052 aluminum exhibits a yield strength of approximately 28 KSI and an ultimate tensile strength of 33 KSI, which indicates its capacity to withstand stress without permanent deformation. These values are crucial for applications where structural integrity is paramount.

-

Corrosion Resistance: Aluminum inherently possesses excellent resistance to corrosion, particularly in environments exposed to moisture and chemicals. This property is essential for applications in industries such as marine, automotive, and construction, where durability and longevity are critical.

-

Electrical Conductivity: Although aluminum is not as conductive as copper, it still provides reasonable electrical conductivity, around 35% IACS (International Annealed Copper Standard). This characteristic makes it suitable for applications in electrical enclosures and heat sinks.

Which Trade Terms Are Commonly Used in the Aluminum Sheet Metal Industry?

Familiarity with industry terminology enhances communication and negotiation in B2B transactions. Here are several key terms relevant to 0.032 aluminum sheet metal:

-

OEM (Original Equipment Manufacturer): This term refers to companies that manufacture products that are sold under another company’s brand. Understanding OEM relationships can help buyers identify reliable suppliers for custom aluminum sheet metal components.

-

MOQ (Minimum Order Quantity): MOQ represents the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for buyers to manage inventory effectively and understand pricing structures, especially when sourcing materials from international suppliers.

-

RFQ (Request for Quotation): An RFQ is a formal process where buyers request pricing and terms from suppliers. This process is vital for obtaining competitive quotes and ensuring that all suppliers meet the required specifications.

-

Incoterms (International Commercial Terms): Incoterms define the responsibilities of buyers and sellers in international trade, including shipping, insurance, and tariffs. Understanding these terms is essential for B2B buyers to ensure smooth transactions and manage risks associated with international logistics.

-

Lead Time: Lead time refers to the amount of time it takes from placing an order to receiving the goods. Buyers must be aware of lead times to effectively plan production schedules and inventory levels.

-

Certification Standards: Certifications, such as ASTM B209, specify the standards that aluminum products must meet. These certifications provide assurance of quality and compliance, which is particularly important for industries like aerospace and automotive.

Understanding these technical properties and trade terms equips B2B buyers with the knowledge necessary for informed decision-making, ultimately enhancing procurement processes and supplier negotiations.

Navigating Market Dynamics and Sourcing Trends in the 032 aluminum sheet metal Sector

What Are the Current Market Dynamics and Key Trends in the 032 Aluminum Sheet Metal Sector?

The global aluminum sheet metal market, particularly for 0.032″ thickness, is witnessing robust growth driven by increasing demand across various sectors such as automotive, aerospace, construction, and packaging. The lightweight nature of aluminum makes it a preferred choice for manufacturers aiming to enhance fuel efficiency and reduce emissions. In regions like Africa, South America, the Middle East, and Europe, infrastructure development and the push towards sustainable practices are significant contributors to the market’s expansion. For instance, countries like Nigeria and Brazil are investing heavily in infrastructure, which bolsters the demand for aluminum in construction and transportation.

Emerging B2B technology trends such as digital sourcing platforms and supply chain automation are reshaping how international buyers engage with suppliers. These platforms facilitate real-time communication, competitive pricing, and streamlined procurement processes. Additionally, the adoption of advanced analytics allows companies to better understand market trends and optimize inventory management. As manufacturers seek to enhance operational efficiency, sourcing strategies are increasingly focused on establishing long-term partnerships with reliable suppliers who can provide consistent quality and timely deliveries.

How Are Sustainability and Ethical Sourcing Influencing B2B Purchases of 032 Aluminum Sheet Metal?

Sustainability has become a central theme in the aluminum sheet metal sector, with B2B buyers increasingly prioritizing environmentally responsible sourcing practices. The production of aluminum is energy-intensive, and its environmental impact is a significant concern. Buyers are now looking for suppliers who demonstrate a commitment to sustainable practices, such as using recycled aluminum and minimizing waste during production.

Ethical supply chains are also gaining importance as companies aim to enhance their corporate social responsibility (CSR) profiles. Certifications such as ISO 14001 (Environmental Management) and the Aluminium Stewardship Initiative (ASI) certification are becoming essential for suppliers seeking to prove their commitment to sustainability. These certifications not only enhance a supplier’s credibility but also help buyers ensure that their sourcing decisions align with ethical and environmental standards. By choosing suppliers who prioritize sustainability, B2B buyers can contribute to reducing the carbon footprint associated with their operations while meeting the growing consumer demand for green products.

What Is the Evolution of the 032 Aluminum Sheet Metal Market?

The 032 aluminum sheet metal market has evolved significantly over the past few decades. Initially, aluminum was primarily used in the aerospace sector due to its lightweight and high-strength properties. However, as technology advanced, industries such as automotive and construction began to adopt aluminum for its versatility and cost-effectiveness. The introduction of various alloys, such as 5052 and 6061, has further expanded its applications, making it a staple in products ranging from automotive panels to packaging materials.

As the global focus shifts towards sustainability, the aluminum industry has adapted by improving recycling techniques and promoting the use of recycled materials. This evolution reflects a broader trend within the manufacturing sector, where the emphasis on reducing environmental impact is reshaping sourcing decisions and product development strategies. Today, the 032 aluminum sheet metal is not only a functional material but also a key player in the push for a more sustainable industrial future.

Frequently Asked Questions (FAQs) for B2B Buyers of 032 aluminum sheet metal

1. What are the key specifications to look for when sourcing 0.032 aluminum sheet metal?

When sourcing 0.032 aluminum sheet metal, key specifications include the alloy type (commonly 5052 or 6061), temper (like H32 or T6), thickness, dimensions, and compliance with industry standards such as ASTM B209. Consider the mechanical properties such as tensile strength and yield strength, which are critical for determining suitability for specific applications. Additionally, assess the corrosion resistance and weight characteristics, especially if the sheets will be used in demanding environments like marine or aerospace applications.

2. How can I ensure quality when purchasing aluminum sheet metal internationally?

To ensure quality when purchasing aluminum sheet metal internationally, partner with suppliers who provide Material Test Reports (MTRs) and comply with international quality standards. Request samples prior to placing bulk orders to assess the material’s properties and finish. It’s also beneficial to check for certifications such as ISO or ASTM compliance. Establish clear communication regarding specifications and quality assurance processes, and consider third-party inspection services if required, especially for large orders.

3. What are the common applications for 0.032 aluminum sheet metal?

0.032 aluminum sheet metal is versatile, used in various applications including automotive panels, aerospace components, and construction materials. Its lightweight and corrosion-resistant properties make it ideal for marine applications, HVAC ductwork, and electrical enclosures. Additionally, it serves in packaging, signage, and decorative applications due to its durability and ease of fabrication. Understanding the specific needs of your industry can help tailor your sourcing strategy.

4. What are the typical lead times for international orders of aluminum sheet metal?

Lead times for international orders of aluminum sheet metal can vary significantly based on factors such as order size, supplier location, and shipping method. Typically, standard orders may take 2-4 weeks for processing and shipping. However, custom orders or large quantities may require additional time for production and logistics. It’s advisable to discuss lead times upfront with suppliers and factor in potential customs delays when planning your project timelines.

5. What minimum order quantities (MOQs) should I expect when sourcing aluminum sheets?

Minimum order quantities (MOQs) for aluminum sheets can vary by supplier and depend on the size and specifications of the product. Generally, MOQs can range from 100 to 500 kilograms for standard products. Custom sizes or specialized alloys may require higher MOQs. It’s important to clarify MOQs with potential suppliers early in discussions to ensure they align with your project needs and budget.

6. How do I handle payment terms when sourcing from international suppliers?

When sourcing from international suppliers, it’s crucial to negotiate clear payment terms that protect both parties. Common methods include letters of credit, advance payments, or payment upon delivery. Ensure that payment terms are documented in the contract, specifying conditions such as partial payments for large orders. Also, consider using escrow services for added security, especially for first-time transactions, to mitigate risks associated with international trade.

7. What customs considerations should I keep in mind when importing aluminum sheet metal?

When importing aluminum sheet metal, be aware of customs duties, tariffs, and import regulations specific to your country. Research the Harmonized System (HS) codes for aluminum products to understand applicable tariffs. Ensure that all documentation, including invoices and certificates of origin, is accurate and complete to avoid delays. It may also be beneficial to work with a customs broker to navigate complex regulations and ensure compliance with local laws.

8. How can I customize my order of aluminum sheet metal to meet specific project needs?

To customize your order of aluminum sheet metal, communicate your specific requirements to the supplier, including dimensions, alloy type, and temper. Many suppliers offer custom cutting services, allowing you to order sheets tailored to your project specifications. Additionally, inquire about surface treatments, such as anodizing or painting, that may enhance durability and aesthetics. Providing detailed drawings or specifications will help suppliers understand your needs and deliver the desired product efficiently.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 032 Aluminum Sheet Metal Manufacturers & Suppliers List

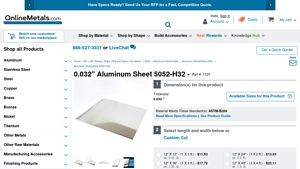

1. Online Metals – Aluminum Sheet/Plate 5052 H32

Domain: onlinemetals.com

Registered: 1997 (28 years)

Introduction: {‘thickness’: ‘0.032″‘, ‘max_width’: ’48″‘, ‘max_length’: ‘120″‘, ‘alloy’: ‘5052’, ‘temper’: ‘H32’, ‘covering’: ‘PVC 1 Side’, ‘material’: ‘Aluminum’, ‘shape’: ‘Sheet/Plate’, ‘MTR_availability’: ‘Yes’, ‘RoHS’: ‘Yes’, ‘6C_REACH’: ‘No’, ‘weight_per_lineal_foot’: ‘0.45 pounds’, ‘density’: ‘3 g/cm^3’, ‘brinell_hardness’: ’60’, ‘ultimate_tensile_strength’: ’33 KSI’, ‘yield_tensile_strength’: ’28 KSI’, ‘…

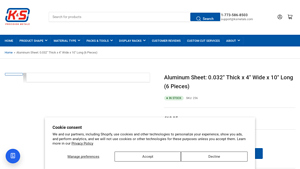

2. KSMetals – Aluminum Sheet .032 Thick x 4 W x 10 L

Domain: ksmetals.com

Registered: 1999 (26 years)

Introduction: Aluminum Sheet .032″ Thick x 4″ W x 10″ L (6 Pieces) | SKU: 256 | Regular price: $18.99 | Material Type: Aluminum | Product Shape: Sheet | Thickness: .032″ | Width x Length: 4″ x 10″ | Alloy: 3003-H14 | Pieces Per Pack: 6 | Applications: Aircraft components, automotive panels, building and construction, packaging, electrical enclosures, heat exchangers, marine applications, signage and billboards,…

3. Fast Metals – 032 Sheet 6061-T6 ASTM B209

4. Metals Depot – Aluminum Sheets

Domain: metalsdepot.com

Registered: 1999 (26 years)

Introduction: Aluminum Sheet Types: 3003-H14, 5052-H32, 6061-T6; Specifications: ASTM B209, QQ-A-250/2, QQ-A-250/8, QQ-A-250/11; 3003-H14: Excellent weldability, formability, good corrosion resistance, applications include fuel tanks, food & chemical handling, trailer siding & roofing; Mill Finish – Not Polished, Non-magnetic, Brinell = 40, Tensile = 22,000, Yield = 21,000 (+/-); 5052-H32: Superior corrosion re…

5. Speedy Metals – .032 6061-T6 Aluminum Sheet

Domain: speedymetals.com

Registered: 2001 (24 years)

Introduction: {“Product Name”: “.032″ 6061-T6 Aluminum Sheet”, “Material”: “Aluminum”, “Grade”: “6061”, “Shape”: “Sheet”, “Available Sizes”: [{“Dimensions”: “12\”x12\””, “Weight”: “0.4464 lbs”, “Price”: “$8.94”}, {“Dimensions”: “12\”x18\””, “Weight”: “0.6696 lbs”, “Price”: “$11.74”}, {“Dimensions”: “12\”x24\””, “Weight”: “0.8928 lbs”, “Price”: “$14.31”}], “Cutting Tolerance”: “+/- 1/4″”}

6. Manufacturer – #PETA3CA10

Domain: becn.com

Registered: 2002 (23 years)

Introduction: {“Item”:”#348188″,”Product”:”#PETA3CA10″,”Manufacturer”:”#32″,”Color”:”Clear”,”Specifications”:{“Thickness”:”.032″,”Dimensions”:”4′ x 10′”},”Applicable Standards”:[“CRRC Certified”,”AIA Certified”,”Energy Star”,”LEED”]}

7. Industrial Metal Supply – Aluminum 3003 H14 Sheet & Plate

Domain: industrialmetalsupply.com

Registered: 1999 (26 years)

Introduction: {“Type”:”Sheet & Plate”,”Metal”:”Aluminum”,”Alloy”:”3003″,”Length(L)”:”120 inches”,”Thickness(T)”:”0.032 inches”,”Weight Each(#)”:”18.40 lbs”,”Width(W)”:”48 inches”,”Temper”:”H14″,”Sale Pricing”:{“0-999 lbs”:{“Sell Price”:”$4.13″,”Discount Price”:”$2.34″},”1000-2999 lbs”:{“Sell Price”:”$3.71″,”Discount Price”:”$2.13″},”3000+ lbs”:{“Sell Price”:”$3.38″,”Discount Price”:”$1.99″}},”Material test repo…

Strategic Sourcing Conclusion and Outlook for 032 aluminum sheet metal

What Are the Key Takeaways for Sourcing 0.032 Aluminum Sheet Metal?

In summary, the strategic sourcing of 0.032 aluminum sheet metal presents a myriad of opportunities for international B2B buyers. The versatility of this material, especially in industries such as aerospace, automotive, and construction, underscores its importance in modern manufacturing. By leveraging the strengths of various aluminum alloys like 5052 and 6061, companies can meet specific performance requirements while benefiting from attributes such as corrosion resistance and lightweight properties.

How Can Strategic Sourcing Enhance Your Supply Chain?

Effective sourcing strategies can lead to significant cost savings and improved operational efficiencies. Buyers should prioritize suppliers that offer competitive pricing, fast turnaround times, and customizable options to meet unique project specifications. Engaging in direct communication with suppliers can facilitate better negotiation outcomes and foster long-term partnerships.

What Is the Future Outlook for Aluminum Sheet Metal Sourcing?

Looking ahead, the demand for 0.032 aluminum sheet metal is expected to grow, driven by increasing applications across diverse sectors. As global markets expand, particularly in Africa, South America, the Middle East, and Europe, buyers should position themselves to capitalize on these emerging opportunities. Now is the time to evaluate your sourcing strategies and engage with reliable suppliers to ensure you are well-equipped to meet future demands. Take action today to secure your supply chain and leverage the potential of aluminum sheet metal for your business growth.